Académique Documents

Professionnel Documents

Culture Documents

OU500563236 - R1 - IOMS Master Manual PDF

Transféré par

Julver Goyzueta ArceTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

OU500563236 - R1 - IOMS Master Manual PDF

Transféré par

Julver Goyzueta ArceDroits d'auteur :

Formats disponibles

TankCell®

Flotation Machine

Bolt Connections

Doc. No. [000000], English 2015

Appendix A: Bolt

TankCell® Flotation Machine

Connections

This document is proprietary to Outotec Oyj and its affiliated companies (“Outotec”). This document is intended for the use of Outotec's customers only for the purposes of

the agreement under which the document is submitted and no ownership rights are hereby transferred. No part of the document shall be used, reproduced, translated,

converted, adapted, stored in a retrieval system, communicated or transmitted by any means, for any commercial purpose, including without limitation, sale, resale,

licence, rental or lease, without the prior express written consent of Outotec.

Customer understands and accepts that the information in this document is subject to any change without notice. It is the customer's responsibility to determine whether

there have been any such updates or amendments.

The document has been prepared to be used by professional and properly trained personnel, and the customer assumes full responsibility when using it. Despite the fact

that every effort has been made to ensure that the information in this document is accurate Outotec does not make any representations, warranties or guarantees, express

or implied, as to the accuracy or completeness of the document. In case of any discrepancies between different language versions English version shall prevail. Outotec

shall not be liable in contract, tort or in any other manner whatsoever to any person for any loss, damage, injury, liability, cost or expense of any nature, including without

limitation incidental, special, direct or consequential damages arising out of or in connection with the use of the document. Outotec's liability for any errors in the document

is limited to the documentary correction of errors.

Outotec logo is a registered trademark of Outotec Oyj.

Other product names mentioned in this document may be trademarks of their respective companies, and they are mentioned for identification purposes only.

Copyright © Outotec Oyj 2015. All rights reserved.

Outotec Oyj

Address: Rauhalanpuisto 9, PO Box 1000

FI-02231 Espoo, Finland

Telephone: +358 (0) 20 529 211

Fax: +358 20 529 2200

Internet: www.outotec.com

04

03

02

01

00 [name] [date] [name] [date] [name] [date]

Rev Name Date Name Date Name Date Revision Text

Prepared Checked Released

Status: Original Size:

Customer: Project Phase: Site No.:

Project Name: Customer Document ID:

Replaced by: Replaces:

Document Title:

[DOCUMENT TITLE]

[PRODUCT NAME]

Equipment No: Item No:

[MANUAL NAME]

Language: EN

© Outotec Oyj 2015. All rights reserved. 2 (6)

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Outotec Document ID:

Appendix A: Bolt

TankCell® Flotation Machine

Connections

Contents

Contents

1 Implementation and tightening torques for bolted joints ................ 4

© Outotec Oyj 2015. All rights reserved. 3 (6)

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Outotec Document ID:

Appendix A: Bolt

TankCell® Flotation Machine

Connections

1 Implementation and tightening torques for bolted joints

Table 1. Tightening torques for screws and nuts

TIGHTENING INSTRUCTIONS FOR BOLTED JOINTS

IN FLOTATION MACHINES

THREADS SHALL BE CLEAN AND LUBRICATED.

RECOMMENDED LUBRICANT: MoS 2 GREASE

MULTIPLE SCREW JOINT

TIGHTEN BOLTS CROSSWISE USING STAR PATTERN IN FOLLOWING STAGES:

STAGE 1 TORQUE ALL BOLTS TO TORQUE 0.3*T (30%) (if rubber sealing)

SEE TABLE 1.1 (metric)

STAGE 2 TORQUE ALL BOLTS TO TORQUE 0.7*T (70%)

OR 1.2 (imperial) FOR

STAGE 3 TORQUE ALL BOLTS TO TORQUE T (100%) VALUE T

STAGE 4 TORQUE ALL BOLTS AGAIN TO TORQUE T (100%)

SINGLE SCREW JOINT

TORQUE BOLT TO TORQUE T SEE TABLE 1.1 (OR 1.2)

TABLE 1.1 TORQUE T IN NEWTON METRES [Nm]. FRICTION COEFFICIENT 0.14

STRENGTH CLASS M8 M10 M12 M14 M16 M20 M24 M30 M36

CARBON

STEELS

8.8 26 51 86 140 210 420 725 1445 2510

10.9 29 57 97 155 240 460 790 1575 2740

AUSTENITIC

50 9 19 32 51 77 155 260 520 900

STEELS

70 20 40 68 110 170 325 555 1110 1925

80 27 54 91 145 225 430 740 1475 2570

TABLE 1.2 TORQUE T IN POUND FORCE INCHES [lbf-in]. FRICTION COEFFICIENT 0.14

STRENGTH CLASS M8 M10 M12 M14 M16 M20 M24 M30 M36

CARBON

STEELS

8.8 227 451 765 1239 1859 3717 6417 12790 22216

10.9 255 507 861 1372 2124 4072 6992 13941 24252

AUSTENITIC

50 84 166 282 449 684 1372 2301 4603 7966

STEELS

70 179 357 605 974 1505 2877 4912 9825 17038

80 239 475 807 1283 1992 3806 6550 13055 22747

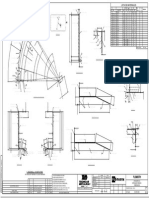

STAR PATTERN EXAMPLES FOR CROSSWISE BOLT TIGHTENING

2 1

7 5 3 6

4 8

5 4

1 3

7 2

6

EVEN NUMBER OF BOLTS ODD NUMBER OF BOLTS

© Outotec Oyj 2015. All rights reserved. 4 (6)

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Outotec Document ID:

Appendix A: Bolt

TankCell® Flotation Machine

Connections

Tightening values in Table 1.1 and Table 1.2 are for 8.8, 10.9, A-50, A-70 and A-

80 screws, and for friction coefficient 0.14. If friction is lower, use 80% of table

values. If friction is higher, use 120% of table values.

Tightening should be done with torque wrench, not with impact wrench.

Friction coefficient 0.14

Black annealed or phosphatized dry bolts

Zinc electroplating coated lightly oiled bolts

Lightly oiled steel bolts without coating.

Friction coefficient 0.10

With MoS2 lubricated thread and bolt head when using black annealed or

phosphatized bolts.

Friction coefficient 0.20

Dry bolts without coating

Dry bolts with hot zinc coating

Acid proof and stainless steel bolts with oil lubrication.

Thread sealing and locking

Use the recommended glue for thread locking (see section 4.3.3 Agents in the

Installation manual). Let the locking dry minimum of two (2) hours before applying

mechanical forces. Thread locking can be opened without heating. To lock loose

thread joints, for example loose tube fitting threads pointing to particular direction,

use Loctite 577.

All parts must be clean and oil-free. Only metal surfaces are accepted (no

painting or coating). Use Loctite 7063 to clean surfaces before applying locking

glue.

© Outotec Oyj 2015. All rights reserved. 5 (6)

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Outotec Document ID:

Outotec

P.O. Box 1000, FI-02231 Espoo

Tel +358 (0) 20 529 211

www.outotec.com

E-mail info@outotec.com

© 2015 Outotec Oyj. All rights reserved.

Vous aimerez peut-être aussi

- G.R. No. 196020, April 18, 2018 Meralco, Et - Al V. Nordec Philippines And/Or Marvex Industrial G.R. No. 196116, April 18, 2018 Nordec Philippines And/Or Marvex Industrial V. Meralco, Et - Al. FactsDocument2 pagesG.R. No. 196020, April 18, 2018 Meralco, Et - Al V. Nordec Philippines And/Or Marvex Industrial G.R. No. 196116, April 18, 2018 Nordec Philippines And/Or Marvex Industrial V. Meralco, Et - Al. FactsLara CacalPas encore d'évaluation

- 1.3 Materiales de Caucho para PF Serie 60Document33 pages1.3 Materiales de Caucho para PF Serie 60ronald palomino100% (1)

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Document12 pagesFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPPas encore d'évaluation

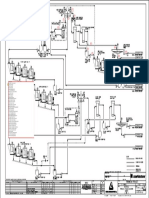

- Toromocho Project: Overall 0 Process Flow DiagramDocument1 pageToromocho Project: Overall 0 Process Flow DiagramFranklins T MedinaPas encore d'évaluation

- Corp & Buss. Law Class 5 & 6 (15062019 - 22062019)Document37 pagesCorp & Buss. Law Class 5 & 6 (15062019 - 22062019)Anesh KumarPas encore d'évaluation

- Probebrochure Rev8Document7 pagesProbebrochure Rev8Matheus TorresPas encore d'évaluation

- 015-80T3-FW8 - Rev 1Document1 page015-80T3-FW8 - Rev 1José Luis TolaPas encore d'évaluation

- Unidad Hidráulica PF1019Document2 pagesUnidad Hidráulica PF1019Juan Carlos Lopez TorresPas encore d'évaluation

- 1.2.1 PF Filter PlatesDocument52 pages1.2.1 PF Filter PlatesCristian Pulgar Fabres100% (1)

- Complex Tailings Handling ChallengesDocument25 pagesComplex Tailings Handling ChallengescyberminePas encore d'évaluation

- Planos SAG Shell PDFDocument1 pagePlanos SAG Shell PDFA̶l̶x̶a̶n̶d̶e̶r̶ PaniPas encore d'évaluation

- Cerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21Document5 pagesCerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21jhonPas encore d'évaluation

- Power Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001Document1 pagePower Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001jhonPas encore d'évaluation

- Outotec Oktop Agitator Unit UpgradeDocument2 pagesOutotec Oktop Agitator Unit UpgradegicntPas encore d'évaluation

- RME Data Sheet - RUSSELL Mill Relining MachineDocument1 pageRME Data Sheet - RUSSELL Mill Relining MachineСергейPas encore d'évaluation

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoPas encore d'évaluation

- 600-EQ-014 Operation Manual Stripping Machine PDFDocument90 pages600-EQ-014 Operation Manual Stripping Machine PDFcorasaulPas encore d'évaluation

- Diemme FiltrationDocument8 pagesDiemme FiltrationAbu Fathi Mifth Huda100% (1)

- Filtro Marco y PlatosDocument5 pagesFiltro Marco y PlatosCesar LapaPas encore d'évaluation

- Cerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09Document4 pagesCerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09jhonPas encore d'évaluation

- Lightnin Compact Series MixersDocument21 pagesLightnin Compact Series Mixersmiguel_vera6592Pas encore d'évaluation

- World Non US Gasification DatabaseDocument9 pagesWorld Non US Gasification DatabaseKhairi Maulida AzhariPas encore d'évaluation

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Document66 pages15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroPas encore d'évaluation

- Y JEENDocument1 pageY JEENYousef AlipourPas encore d'évaluation

- 34-27-13 AutoBall Charger 301W Operations MaintenanceDocument28 pages34-27-13 AutoBall Charger 301W Operations Maintenanceerik masongPas encore d'évaluation

- Celdas de FlotacionDocument4 pagesCeldas de FlotacionRodrigo Zura0% (1)

- Tac4598 - 3350KW - Instruction ManualDocument48 pagesTac4598 - 3350KW - Instruction ManualMiguel Angel RodriguezPas encore d'évaluation

- Slon Magnetic Separators Applied in TheDocument8 pagesSlon Magnetic Separators Applied in TheMulti DELLPas encore d'évaluation

- Liner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750Document1 pageLiner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750jhonPas encore d'évaluation

- CMP2015 - Assessing Vertimill Ultrafine Grinding PerformanceDocument7 pagesCMP2015 - Assessing Vertimill Ultrafine Grinding PerformancerodrigoPas encore d'évaluation

- Vedanta Green Anode Plant Liquid Pitch Stirring ManualDocument47 pagesVedanta Green Anode Plant Liquid Pitch Stirring ManualSubhransu MohapatraPas encore d'évaluation

- Outotec en MMH PDFDocument24 pagesOutotec en MMH PDFjaja_543Pas encore d'évaluation

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarPas encore d'évaluation

- 015-80T4-FW6 - Rev 1Document1 page015-80T4-FW6 - Rev 1José Luis TolaPas encore d'évaluation

- Flotation Advances PDFDocument7 pagesFlotation Advances PDFvictrburgosPas encore d'évaluation

- Ws Tyler Uml Class PartsDocument4 pagesWs Tyler Uml Class Partsyolimar escorciaPas encore d'évaluation

- EMC 3273 E-Cat MechDocument4 pagesEMC 3273 E-Cat Mechrichard gutierrezPas encore d'évaluation

- Operating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnDocument41 pagesOperating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnDiego Carhuaz VasquezPas encore d'évaluation

- CIP CIL Interstage Screening SolutionsDocument4 pagesCIP CIL Interstage Screening SolutionsevalenciaPas encore d'évaluation

- OTE Outotec Flotation Technologies Eng WebDocument12 pagesOTE Outotec Flotation Technologies Eng Webpmanquera89Pas encore d'évaluation

- Csp703-Sluicepipe 1: Detail ADocument1 pageCsp703-Sluicepipe 1: Detail AKarlyCharlisPas encore d'évaluation

- Curso F Prensa 1Document52 pagesCurso F Prensa 1Rafael QuilichePas encore d'évaluation

- Plano de ChancadoraDocument3 pagesPlano de ChancadoraNilson Cieza Zamora100% (1)

- S-Class Ty-Speed Body PartsDocument6 pagesS-Class Ty-Speed Body Partsyolimar escorciaPas encore d'évaluation

- Outotec OK-R and OK-U Flotation Cells: Optional Cells For Smaller Tank VolumesDocument4 pagesOutotec OK-R and OK-U Flotation Cells: Optional Cells For Smaller Tank VolumesAndrew HoylePas encore d'évaluation

- Dm-dcld-f-cm-0017 Rev 4 Ems Test ChargesDocument112 pagesDm-dcld-f-cm-0017 Rev 4 Ems Test ChargesPervaiz BaigPas encore d'évaluation

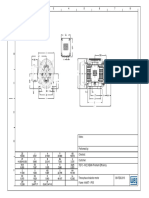

- Induction Motor Data: Siemens Industry, Inc. Norwood, OhioDocument3 pagesInduction Motor Data: Siemens Industry, Inc. Norwood, OhioelvisPas encore d'évaluation

- Manual Instructuni - SITA ROTATIVA - T.R. 40-75 PDFDocument141 pagesManual Instructuni - SITA ROTATIVA - T.R. 40-75 PDFRoxana AnteaPas encore d'évaluation

- Toromocho Project Slurry Sampling Systems SpecificationDocument93 pagesToromocho Project Slurry Sampling Systems SpecificationLuis Valdez espinozaPas encore d'évaluation

- Sihi lph75000Document10 pagesSihi lph75000Hernando SalamancaPas encore d'évaluation

- Cerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12Document3 pagesCerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12jhonPas encore d'évaluation

- Maelgwyn Imhoflot (Chile)Document0 pageMaelgwyn Imhoflot (Chile)crazymax90Pas encore d'évaluation

- AFG Alpine Fluidised Bed Opposed Jet Mills (En)Document10 pagesAFG Alpine Fluidised Bed Opposed Jet Mills (En)alevandrorPas encore d'évaluation

- 3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Document10 pages3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Cristian CanazaPas encore d'évaluation

- SIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Document7 pagesSIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Jorge PalacioPas encore d'évaluation

- Intarder 386 - e - 3626-011200 - en - Rev.5Document108 pagesIntarder 386 - e - 3626-011200 - en - Rev.5Herdre Van NiekerkPas encore d'évaluation

- Recommended Spare Parts: SE, SL 9-30 KW: LenntechDocument1 pageRecommended Spare Parts: SE, SL 9-30 KW: LenntechAish MohammedPas encore d'évaluation

- Installation and Operating Manual: Tri TR Turbo Coupling With Constant Fill and PulleyDocument128 pagesInstallation and Operating Manual: Tri TR Turbo Coupling With Constant Fill and PulleyChintan GorasiaPas encore d'évaluation

- OBPF Technical BulletinDocument10 pagesOBPF Technical BulletinLance Cydrick Paggao GuaricoPas encore d'évaluation

- Technical Spec EVC Pump - R0Document18 pagesTechnical Spec EVC Pump - R0AyahKenziePas encore d'évaluation

- CT1 CSTB Eta-11 0354Document19 pagesCT1 CSTB Eta-11 0354Alden CayagaPas encore d'évaluation

- Hand Tool Appearance SpecificationsDocument22 pagesHand Tool Appearance SpecificationsTHI MEN PHAMPas encore d'évaluation

- Tankcell® Flotation Machine: Bolt ConnectionsDocument6 pagesTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta ArcePas encore d'évaluation

- Manufacturing BOM / Multi LevelDocument4 pagesManufacturing BOM / Multi LevelJulver Goyzueta ArcePas encore d'évaluation

- Manual de Variador DeltaDocument129 pagesManual de Variador DeltaJulver Goyzueta ArcePas encore d'évaluation

- Motor WegDocument56 pagesMotor WegJulver Goyzueta ArcePas encore d'évaluation

- Manufacturing BOM / Multi LevelDocument4 pagesManufacturing BOM / Multi LevelJulver Goyzueta ArcePas encore d'évaluation

- Siemens Ultrasonic Transmitter 7ML1201Document3 pagesSiemens Ultrasonic Transmitter 7ML1201Julver Goyzueta ArcePas encore d'évaluation

- Ou600550552Document2 pagesOu600550552Julver Goyzueta ArcePas encore d'évaluation

- Siemens Ultrasonic Transmitter 7ML1201Document3 pagesSiemens Ultrasonic Transmitter 7ML1201Julver Goyzueta ArcePas encore d'évaluation

- Ds-En 104551 64372705Document1 pageDs-En 104551 64372705Julver Goyzueta ArcePas encore d'évaluation

- Certified: Project ImplementationDocument1 pageCertified: Project ImplementationJulver Goyzueta ArcePas encore d'évaluation

- DQ150433 Otpbuen DT 0004Document1 pageDQ150433 Otpbuen DT 0004Julver Goyzueta ArcePas encore d'évaluation

- OU600732294 - R1 - GENERAL ARRANGEMENT - Certified PDFDocument1 pageOU600732294 - R1 - GENERAL ARRANGEMENT - Certified PDFJulver Goyzueta ArcePas encore d'évaluation

- Petitioner Vs Vs Respondents Alvin B. Cunada Ronald O. LayawenDocument9 pagesPetitioner Vs Vs Respondents Alvin B. Cunada Ronald O. LayawenAggy AlbotraPas encore d'évaluation

- Vantage Introducer Agreement - VGL STP ECN (.R)Document16 pagesVantage Introducer Agreement - VGL STP ECN (.R)forexwilson66Pas encore d'évaluation

- CH 03Document19 pagesCH 03Ashraf ZabidiPas encore d'évaluation

- IFRS 17 Insurance Contracts - SummaryDocument8 pagesIFRS 17 Insurance Contracts - SummaryEltonPas encore d'évaluation

- Long Term Construction Contracts - QuizDocument10 pagesLong Term Construction Contracts - QuizEliza BethPas encore d'évaluation

- Persuasive marketing proposal for client growthDocument9 pagesPersuasive marketing proposal for client growthISAAC MUSEKA LUPUPAPas encore d'évaluation

- Purpose of This Agreement Is For Atty. Kirstie Dawn F. Barrion To Provide ClientDocument8 pagesPurpose of This Agreement Is For Atty. Kirstie Dawn F. Barrion To Provide ClientJenny ButacanPas encore d'évaluation

- Eminent Domain Association of Small Landowners Vs Secretary of Agrarian ReformDocument7 pagesEminent Domain Association of Small Landowners Vs Secretary of Agrarian ReformYen055100% (1)

- SERVICE OF PROCESS AND NEGLIGENCEDocument5 pagesSERVICE OF PROCESS AND NEGLIGENCEPaolo Vittorio Perdigueros GonzalesPas encore d'évaluation

- Garden of Memories Employee Wins Illegal Dismissal CaseDocument1 pageGarden of Memories Employee Wins Illegal Dismissal CaseVenus Jane FinuliarPas encore d'évaluation

- Kes MahkamahDocument16 pagesKes Mahkamahfirdaus azinunPas encore d'évaluation

- Pice Life MembersDocument275 pagesPice Life MembersAlvin ClaridadesPas encore d'évaluation

- Consignation and Judicial DepositDocument5 pagesConsignation and Judicial DepositkdescallarPas encore d'évaluation

- B-BLAW222 BSA23 2nd Sem (2021-2022) ENABLING ASSESSMENT 3: Comprehensive Examination On The Law On PartnershipDocument4 pagesB-BLAW222 BSA23 2nd Sem (2021-2022) ENABLING ASSESSMENT 3: Comprehensive Examination On The Law On PartnershipGleiza HoPas encore d'évaluation

- Conciliation Proceedings Under The Arbitration Conciliation ActDocument5 pagesConciliation Proceedings Under The Arbitration Conciliation ActGarima AgrawalPas encore d'évaluation

- Definition:: Nature of GrievanceDocument8 pagesDefinition:: Nature of GrievanceSruthiDeetiPas encore d'évaluation

- Legprof Cases 2Document8 pagesLegprof Cases 2Mark Hiro NakagawaPas encore d'évaluation

- Pre Reviewed Employment Contract SampleDocument4 pagesPre Reviewed Employment Contract SampleGene AbotPas encore d'évaluation

- Alitalia v. IACDocument2 pagesAlitalia v. IACTippy Dos SantosPas encore d'évaluation

- Doas-Garden GroveDocument4 pagesDoas-Garden Groveshrine obenietaPas encore d'évaluation

- LEGAL ETHICS Midterm ReviewerDocument14 pagesLEGAL ETHICS Midterm Reviewerjake31Pas encore d'évaluation

- Give, To Do or Not To Do.: Art. 1156 - An Obligation Is A Juridical Necessity ToDocument12 pagesGive, To Do or Not To Do.: Art. 1156 - An Obligation Is A Juridical Necessity ToR100% (1)

- Kenneth Gumbs and Yvonne Gumbs v. International Harvester, Inc., 718 F.2d 88, 3rd Cir. (1983)Document15 pagesKenneth Gumbs and Yvonne Gumbs v. International Harvester, Inc., 718 F.2d 88, 3rd Cir. (1983)Scribd Government DocsPas encore d'évaluation

- Dental TEST-BANKDocument11 pagesDental TEST-BANKMC EllisPas encore d'évaluation

- 5 G.R. No. 194560Document6 pages5 G.R. No. 194560Julia Rebuyas-EdañoPas encore d'évaluation

- ILO Principles and Collective Bargaining AssignmentDocument14 pagesILO Principles and Collective Bargaining AssignmentNasif MustahidPas encore d'évaluation

- Code of Conduct and Disciplinary Guidance for Health and Safety ProfessionalsDocument16 pagesCode of Conduct and Disciplinary Guidance for Health and Safety ProfessionalsShabin ShabiPas encore d'évaluation

- Slfrs4 Insurance ContractsDocument24 pagesSlfrs4 Insurance ContractssamaanPas encore d'évaluation