Académique Documents

Professionnel Documents

Culture Documents

3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation Controls

Transféré par

Electroventica ElectroventicaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation Controls

Transféré par

Electroventica ElectroventicaDroits d'auteur :

Formats disponibles

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

(cont’d)

8 NOTE: The vehicle OEM has responsibility for all

external wiring harnesses and vehicle

input/output switch repair. Harness and

switch repairs performed by Allison

Transmission distributors and dealers are

not covered by Allison Transmission

warranty.

Coordinate with the vehicle OEM to repair or

replace the vehicle wiring or switch.

Is the repair complete?

9 1. Turn ignition OFF.

2. Connect the 80-way connector, if removed in

Step 6.

3. Install Allison DOC™ For PC–Service Tool.

4. Turn ignition ON.

5. Using Allison DOC™ For PC–Service Tool Data

Bus Viewer, observe status of service brake

switch. Refer to Allison DOC™ For PC–Service

Tool User’s Guide (GN3433EN) for instructions

on using Data Bus Viewer.

On Data Bus Viewer, does brake switch show ON

when brake pedal is pressed and OFF when brake

pedal is released?

10 NOTE: Allison Transmission is not responsible for

data link messages that originate in other

transmission controllers. Repairs not

associated with the transmission controller

are not covered by Allison Transmission

warranty.

Coordinate with the vehicle or engine OEM to

correct the cause of the inconsistent service brake

switch status message.

Is the repair complete?

11 To verify the repair:

1. Clear the DTC.

2. Use Allison DOC™ For PC–Service Tool to

monitor service brake status.

3. Drive the vehicle under conditions noted in

failure records.

4. Confirm with the service tool in the test passed

section that the diagnostic test was run.

Did the DTC return?

6–80 Copyright © 2008 Allison Transmission, Inc.

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

END VIEW OF END VIEW OF

20-WAY CONNECTOR 80-WAY CONNECTOR

D N R

1 2 3 D N R

TCM

STRIP SHIFT

SELECTOR

Circuit Description

The 3000 and 4000 Product Family transmission control module (TCM) can receive input from a strip-type shift

selector. This type of shift selector communicates with the TCM via 4-bit parallel data wires. The strip shift

selector button position determines the switch state (low or high voltage) of each parallel data wire. The TCM

interprets each particular combination of switch states into a specific range selection, i.e. Reverse, Neutral, and

DRIVE. The TCM sets a DTC P0708 if the switch state of the four parallel data wires does not agree with a valid

switch combination.

Conditions for Running the DTC

• The components are powered and ignition voltage is greater than 9V and less than 18V (12V TCM) or greater

than 9V and less than 32V (24V TCM).

• The components are powered and engine speed is greater than 200 rpm and less than 7500 rpm.

Conditions for Setting the DTC

DTC P0708 sets when the TCM detects an invalid parallel data message from a strip-type shift selector.

Copyright © 2008 Allison Transmission, Inc. 6–81

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

Actions Taken When the DTC Sets

When DTC P0708 is active, the following conditions occur:

• The CHECK TRANS light illuminates.

• DTC is stored in TCM history.

• The TCM ignores invalid strip shift selector inputs.

Conditions for Clearing the DTC/CHECK TRANS Light

Use the Allison DOC™ For PC–Service Tool to clear the DTC from the TCM history. The TCM automatically

clears the DTC from the TCM history if the vehicle completes 40 warm-up cycle without failure.

Diagnostic Aids

• You may have to drive the vehicle in order to experience a fault. Use the data obtained from failure records to

determine transmission range and/or certain vehicle operating variables such as temperature, run time, etc. This

data can be useful in reproducing the failure mode when DTC was set.

• Inspect the wiring for poor electrical connections at the TCM and transmission connector. Look for the

following conditions:

A bent terminal

A backed-out terminal

A damaged terminal

Poor terminal tension

A chafed wire

A broken wire inside the insulation

• Inspect OEM wiring harness routing, look for possible contact points where chafing could occur leading to an

open or short circuit condition. Moving parts on the vehicle could be contacting the harness; this includes

parking brake drum, suspension components, etc.

• When diagnosing for an intermittent short or open, massage the wiring harness while watching the test

equipment for a change.

Test Description

This DTC requires the use of the J 47275 TCM Breakout. The numbers below refer to step numbers on the

diagnostic table.

2. Tests for the proper function of the strip shift selector.

3. This step measures the switch states (low or high voltage) for each button position.

4. Tests for wiring defects in the OEM wiring harness.

6–82 Copyright © 2008 Allison Transmission, Inc.

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

1 Was Section 3–5, Beginning The Troubleshooting

Process, performed?

2 1. Install the Allison DOC™ For PC–Service Tool.

2. Turn ignition ON. Leave the engine OFF.

3. Record the failure records.

4. Using Allison DOC™ For PC–Service Tool,

monitor STRIP SELECTOR OUTPUT

PATTERN for the affected strip shift selector.

5. Toggle through each button position while

observing the Allison DOC™ For PC–Service

Tool display.

Does STRIP SELECTOR OUTPUT PATTERN

status match the actual shift selector button

position?

3 1. Turn ignition OFF. Refer to Strip Shift

2. Install J 47275 TCM Breakout between the OEM Selector Parallel

and TCM 80-way connectors. Data Table 6–1

3. Turn ON ignition. Leave engine OFF.

4. Using a DVOM at J 47275-1 TCM Overlay,

determine the state (High or Low) of each parallel

data wire by measuring the following voltages.

Record voltages <1V as Low and voltages >3V as

High.

Between pin 73 (SS-1) and isolated ground

Between pin 53 (SS-2) and isolated ground

Between pin 14 (SS-4) and isolated ground

Between pin 38 (SS-P) and isolated ground

5. Toggle through each strip selector button position

that displays a faulty output pattern and measure

voltages at pins listed in sub-step 4 above.

6. Compare the switch states (low or high voltage)

obtained in sub-steps 4 and 5 with the Strip Shift

Selector Parallel data in Table 6–9.

7. Note if any wire is not in the proper switch state.

Do the switch states (low or high voltage) match the

valid switch states shown in Table 6–9 for all button

positions?

Copyright © 2008 Allison Transmission, Inc. 6–83

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

(cont’d)

4 NOTE: Review Section 4, Wire Test Procedures,

before performing the following steps.

1. Turn ignition OFF.

2. Disconnect the TCM from the J 47275 TCM

Breakout. Leave the OEM-side connected.

3. Disconnect the strip shift selector.

4. Physically inspect the wiring between the strip-

type shift selector and the TCM.

5. Using a DVOM at magnetic overlay, test for

opens, wire-to-wire shorts, and shorts-to-ground

for any wire found to be in the incorrect switch

state (low or high voltage) in Step 3 above.

Were any wiring defects found?

5 NOTE: The vehicle OEM has responsibility for all

external harness repair. Harness repairs

performed by Allison Transmission

distributors and dealers are not covered by

Allison Transmission warranty.

Coordinate with the vehicle OEM to repair or

replace the vehicle wiring.

Is the repair complete?

6 Replace the shift selector.

Is the replacement complete?

7 To verify the repair:

1. Clear the DTC.

2. Drive the vehicle under conditions noted in

failure records.

Did the DTC return?

R REVERSE Low** Low** Low** High***

N NEUTRAL Low** High*** High*** High***

D DRIVE-A Low** Low** High*** Low**

3* DRIVE-B High*** Low** High*** High***

2* DRIVE-C High*** Low** Low** Low**

1* DRIVE-D High*** High*** Low** High***

*Six-button shift selectors only

**Low is <1V

***High is >3V

6–84 Copyright © 2008 Allison Transmission, Inc.

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

END VIEW OF END VIEW OF

20-WAY CONNECTOR 80-WAY CONNECTOR

TO RETARDER

CONTROL DEVICES

RETARDER

REQUEST SENSOR

(RESISTANCE

MODULE)

PWM

THROTTLE

SOURCE

TCM

THROTTLE

POSITION

SENSOR (TPS)

OR

ELECTRONIC

BRAKING (EBS)

RTDR PRESSURE

SENSOR

TRANSMISSION

Copyright © 2008 Allison Transmission, Inc. 6–85

Vous aimerez peut-être aussi

- Rtlo 20918B AsDocument36 pagesRtlo 20918B AsVolcambus SacPas encore d'évaluation

- 2011 Ford F650 6.7 Turning Stop and Hazard Wiring DiagramDocument1 page2011 Ford F650 6.7 Turning Stop and Hazard Wiring DiagramDenton RohrerPas encore d'évaluation

- Ssam sSAM Pinning List: Next Generation CascadiaDocument1 pageSsam sSAM Pinning List: Next Generation CascadiaManuel SolarPas encore d'évaluation

- Peterbilt Smart Nav Manual BasicoDocument149 pagesPeterbilt Smart Nav Manual BasicoDIONYBLINKPas encore d'évaluation

- Wa0006 PDFDocument47 pagesWa0006 PDFEduardo ColinPas encore d'évaluation

- Diagram - System, Sleeper HVAC P94-1478 A 01Document8 pagesDiagram - System, Sleeper HVAC P94-1478 A 01Gonzalo GalvezPas encore d'évaluation

- Gen Datalink CommDocument323 pagesGen Datalink CommJohn SantosPas encore d'évaluation

- Allison WTECIII ECU Wiring DiagramDocument13 pagesAllison WTECIII ECU Wiring DiagramElliot67% (3)

- @detroit.: Service Information BulletinDocument53 pages@detroit.: Service Information BulletinhaviettuanPas encore d'évaluation

- Conf Wgy178Document44 pagesConf Wgy178ivan oliverosPas encore d'évaluation

- 06873E - Manual, T700 PDFDocument366 pages06873E - Manual, T700 PDFCharles LeiftonPas encore d'évaluation

- J1939 Datalink Layout Overview: AllisonDocument1 pageJ1939 Datalink Layout Overview: Allisonamin chaabenPas encore d'évaluation

- Fault Code 3597: Aftertreatment Diesel Exhaust Fluid Controller - Abnormal Update RateDocument3 pagesFault Code 3597: Aftertreatment Diesel Exhaust Fluid Controller - Abnormal Update RateCarlosPas encore d'évaluation

- P94-2044 AbsDocument5 pagesP94-2044 AbsGonzalo GalvezPas encore d'évaluation

- BendixBw1974UsersManual651005 2025189577Document1 pageBendixBw1974UsersManual651005 2025189577h0% (1)

- Control Unit Outer Lighting (LCM), Load at PinoutsDocument5 pagesControl Unit Outer Lighting (LCM), Load at Pinoutsfrank mutale100% (1)

- CPC Fault Code ListDocument6 pagesCPC Fault Code ListEbied Yousif AlyPas encore d'évaluation

- DDEC III AND IV Cable DiagramsDocument5 pagesDDEC III AND IV Cable DiagramsScribdTranslationsPas encore d'évaluation

- Faultcode 687Document3 pagesFaultcode 687Abel OrtegaPas encore d'évaluation

- EPA07 Aftertreatment System Technician's Guide (DDC-SVC-MAN-0036)Document6 pagesEPA07 Aftertreatment System Technician's Guide (DDC-SVC-MAN-0036)Jose Amador GuardadoPas encore d'évaluation

- PV776 89094385Document45 pagesPV776 89094385lepg64Pas encore d'évaluation

- 423-8756-23 - Cab Wiring Diagram (50-Series)Document5 pages423-8756-23 - Cab Wiring Diagram (50-Series)jPas encore d'évaluation

- C13 Service Manual - 1Document180 pagesC13 Service Manual - 1mes100% (1)

- EPA98 Y 04 MBE 900.4000 Troubleshooting Manual DDC-SVC-MAN-0027Document248 pagesEPA98 Y 04 MBE 900.4000 Troubleshooting Manual DDC-SVC-MAN-0027Omar HernándezPas encore d'évaluation

- Engine Config SettingsDocument28 pagesEngine Config Settingsgustavoqr27Pas encore d'évaluation

- Bulkhead Module: Contents of Subject 300Document17 pagesBulkhead Module: Contents of Subject 300Pablo CervantesPas encore d'évaluation

- Gliderlink ManualDocument8 pagesGliderlink ManualMagdiel Eliu Hernandez FloresPas encore d'évaluation

- Catálogo de Partes Electrónicas - Detalle de La OpciónDocument4 pagesCatálogo de Partes Electrónicas - Detalle de La OpciónVictor Hugo Benitez PaezPas encore d'évaluation

- Codigos Celec PlusDocument3 pagesCodigos Celec PlusChester PalermoPas encore d'évaluation

- Sistema Electrico 785dDocument15 pagesSistema Electrico 785dFrank Agurto LucianoPas encore d'évaluation

- Cat - c15 (Prefix MBN, 6nz, 9nz, or Egh) .Prefix Egh, 6nz, or 9nzDocument6 pagesCat - c15 (Prefix MBN, 6nz, 9nz, or Egh) .Prefix Egh, 6nz, or 9nzRickey MatthewsPas encore d'évaluation

- Vecu5 pc28 23970505011wDocument145 pagesVecu5 pc28 23970505011wramon hidalgoPas encore d'évaluation

- Diag - Instrumentation P94-1585 A 01: Prod Serv XDocument8 pagesDiag - Instrumentation P94-1585 A 01: Prod Serv XElmer Tintaya MamaniPas encore d'évaluation

- TS2973ENDocument408 pagesTS2973ENAnonymous l93V4AD0yJPas encore d'évaluation

- 18SP655 PDFDocument19 pages18SP655 PDFJoseGarzaPas encore d'évaluation

- Master 2 Schema BordDocument3 pagesMaster 2 Schema BordElectroventica Electroventica0% (1)

- Harness - Tail Lamp K068-6997 A 01Document1 pageHarness - Tail Lamp K068-6997 A 01Daniel RobichaudPas encore d'évaluation

- EPA07 10 GHG14 DDEC VI 10 Electronics and Troubleshooting Manual (DDC-SVC-MAN-0084)Document36 pagesEPA07 10 GHG14 DDEC VI 10 Electronics and Troubleshooting Manual (DDC-SVC-MAN-0084)E. CastilloPas encore d'évaluation

- Zafira ADocument3 pagesZafira AElectroventica ElectroventicaPas encore d'évaluation

- The I2C Bus SpecificationsDocument46 pagesThe I2C Bus Specificationsshrivastav.ajay100% (14)

- Fault Code: 2771 - SPN: 3226 - FMI: 9: ISX15 CM2250Document16 pagesFault Code: 2771 - SPN: 3226 - FMI: 9: ISX15 CM2250EnriquePas encore d'évaluation

- Schema Master Meu OkDocument3 pagesSchema Master Meu OkElectroventica ElectroventicaPas encore d'évaluation

- 001 Gas Turbine Generator Commissioning ProcedureDocument62 pages001 Gas Turbine Generator Commissioning Proceduremghogha88% (8)

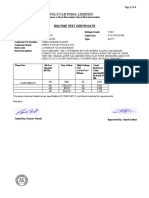

- Polycab India Limited: Routine Test CertificateDocument1 pagePolycab India Limited: Routine Test CertificateDinesh Kumar50% (2)

- Additions, Revisions, or Updates: Subject DateDocument7 pagesAdditions, Revisions, or Updates: Subject DateGeoff AndrewPas encore d'évaluation

- Oil Pump Service and RepairDocument9 pagesOil Pump Service and RepairToriTo Levy100% (1)

- Cummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Document4 pagesCummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Enrrique LaraPas encore d'évaluation

- Usage:: TolerancesDocument39 pagesUsage:: TolerancesMANUEL VICTORPas encore d'évaluation

- Idle ShutdownDocument5 pagesIdle ShutdownMarco MelchorPas encore d'évaluation

- Kenworth t2000 Service Manual - ZipDocument3 pagesKenworth t2000 Service Manual - ZipMark meltonPas encore d'évaluation

- FC2191 TroubleshootingDocument7 pagesFC2191 TroubleshootingM Arshad Iqbal Harral100% (1)

- Sa3360en PDFDocument18 pagesSa3360en PDFkengo2xPas encore d'évaluation

- Replacement: Engine Rating Tier Rating Interlock Code Interlock Code Camshaft Injector Group Piston Body Assembly TurboDocument3 pagesReplacement: Engine Rating Tier Rating Interlock Code Interlock Code Camshaft Injector Group Piston Body Assembly TurboSergio Ramos RiveraPas encore d'évaluation

- 06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFDocument4 pages06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFSuryadiPas encore d'évaluation

- S08337b PDFDocument121 pagesS08337b PDFJhony KizePas encore d'évaluation

- ISB02 Engine Wiring Diagrams 11 X 17Document9 pagesISB02 Engine Wiring Diagrams 11 X 17Juan ReyesPas encore d'évaluation

- Manual MeritorDocument2 pagesManual MeritorJully Paola Gaitan NeisaPas encore d'évaluation

- 019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitDocument9 pages019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitIan WoodsPas encore d'évaluation

- Service Manual Trucks Group 87 Air Heater Espar D1LC CompactDocument58 pagesService Manual Trucks Group 87 Air Heater Espar D1LC CompactNeojai jaiyuPas encore d'évaluation

- Ledwell Chain and Auger Bottom Parts Manual PDFDocument37 pagesLedwell Chain and Auger Bottom Parts Manual PDFconcogua1988Pas encore d'évaluation

- Fuel Injection Pump - Install - With Electronic GovernorDocument5 pagesFuel Injection Pump - Install - With Electronic Governoreshopmanual limaPas encore d'évaluation

- Suggested Installation Connection PointsDocument12 pagesSuggested Installation Connection Pointsgustavoqr27Pas encore d'évaluation

- Wires, Connectors, and Wiring Harnesses 3Document1 pageWires, Connectors, and Wiring Harnesses 3luisPas encore d'évaluation

- tp99124 PDFDocument20 pagestp99124 PDFDieselkPas encore d'évaluation

- New NGP Presentations - Sleeper OptionsDocument19 pagesNew NGP Presentations - Sleeper OptionsEduardo ColinPas encore d'évaluation

- 2011 Dodge Avenger Express 2011 Dodge Avenger Express: Theory of OperationDocument171 pages2011 Dodge Avenger Express 2011 Dodge Avenger Express: Theory of Operationjosecuellar69Pas encore d'évaluation

- Atv312 Quick Start en S1a10942 01Document4 pagesAtv312 Quick Start en S1a10942 01Auliya UrrochmanPas encore d'évaluation

- CF-LX3 Series, CF-AX3Series F-53 (2/3/4/5/7), CF-C2C, FZ-G1F, FZ-M1C, FZ-Q1C (Windows 7)Document4 pagesCF-LX3 Series, CF-AX3Series F-53 (2/3/4/5/7), CF-C2C, FZ-G1F, FZ-M1C, FZ-Q1C (Windows 7)Electroventica ElectroventicaPas encore d'évaluation

- EVE FA Standalone Install ProcedureDocument3 pagesEVE FA Standalone Install ProcedureElectroventica ElectroventicaPas encore d'évaluation

- Update Instructions For TPM 1.2 FirmwareDocument12 pagesUpdate Instructions For TPM 1.2 FirmwareElectroventica ElectroventicaPas encore d'évaluation

- SC Electrovntica SRL STR Prelungirea Taberei nr7 299388 TulceaDocument3 pagesSC Electrovntica SRL STR Prelungirea Taberei nr7 299388 TulceaElectroventica ElectroventicaPas encore d'évaluation

- Digital Coachscrewing Machine Bolt Hornet - TDH2 - GeismarDocument3 pagesDigital Coachscrewing Machine Bolt Hornet - TDH2 - GeismarElectroventica ElectroventicaPas encore d'évaluation

- CF-53 (2/3/4/5/7), FZ-G1F, CF-C2C, FZ-M1 (C/A), FZ-Q1 (C/A), FZ-R1 (A/F) (Windows 8.1)Document3 pagesCF-53 (2/3/4/5/7), FZ-G1F, CF-C2C, FZ-M1 (C/A), FZ-Q1 (C/A), FZ-R1 (A/F) (Windows 8.1)Electroventica ElectroventicaPas encore d'évaluation

- Update Instructions For Wireless WAN Driver (For EM7355 (US) /MC7355 (US) Model Only)Document2 pagesUpdate Instructions For Wireless WAN Driver (For EM7355 (US) /MC7355 (US) Model Only)Electroventica ElectroventicaPas encore d'évaluation

- Zs Online Uk LTD Invoice 10514 PDFDocument1 pageZs Online Uk LTD Invoice 10514 PDFElectroventica ElectroventicaPas encore d'évaluation

- WLAN BT Update 19 40 0 FM W10engDocument4 pagesWLAN BT Update 19 40 0 FM W10engElectroventica ElectroventicaPas encore d'évaluation

- Carberry Brochure ENG 2 WebDocument25 pagesCarberry Brochure ENG 2 WebElectroventica ElectroventicaPas encore d'évaluation

- IMMOs ECUs DUMPs EEPROMs ALL CARS - TXDocument1 pageIMMOs ECUs DUMPs EEPROMs ALL CARS - TXElectroventica ElectroventicaPas encore d'évaluation

- SC Electrovntica SRL STR Prelungirea Taberei nr7 299388 TulceaDocument3 pagesSC Electrovntica SRL STR Prelungirea Taberei nr7 299388 TulceaElectroventica ElectroventicaPas encore d'évaluation

- Wow 2Document4 pagesWow 2Electroventica ElectroventicaPas encore d'évaluation

- Ölflex® Heat 205 MC: Product InformationDocument4 pagesÖlflex® Heat 205 MC: Product InformationElectroventica ElectroventicaPas encore d'évaluation

- Alex FordDocument4 pagesAlex FordElectroventica ElectroventicaPas encore d'évaluation

- Volvo s80 t8gDocument4 pagesVolvo s80 t8gElectroventica ElectroventicaPas encore d'évaluation

- Fault Code Summary: Report Creation DateDocument12 pagesFault Code Summary: Report Creation DateElectroventica ElectroventicaPas encore d'évaluation

- Component Value: $01 - EOBD System StatusDocument1 pageComponent Value: $01 - EOBD System StatusElectroventica ElectroventicaPas encore d'évaluation

- Pin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEADocument7 pagesPin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEAElectroventica ElectroventicaPas encore d'évaluation

- Wow q5 Audi La SanduDocument2 pagesWow q5 Audi La SanduElectroventica ElectroventicaPas encore d'évaluation

- Ford Alex3Document3 pagesFord Alex3Electroventica ElectroventicaPas encore d'évaluation

- Ford Alex6Document4 pagesFord Alex6Electroventica ElectroventicaPas encore d'évaluation

- Pin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEADocument7 pagesPin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEAElectroventica ElectroventicaPas encore d'évaluation

- Pin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEADocument5 pagesPin Assignment: SC Electroventica SRL Romania TULCEA Prelungirea Taberei NR 7 821065 TULCEAElectroventica ElectroventicaPas encore d'évaluation

- Alex Ford FocusDocument4 pagesAlex Ford FocusElectroventica ElectroventicaPas encore d'évaluation

- ImmoDocument1 pageImmoElectroventica ElectroventicaPas encore d'évaluation

- .Ec Machinery Directive 89/392/eec Electrical Manual: Machine Name: ModelDocument52 pages.Ec Machinery Directive 89/392/eec Electrical Manual: Machine Name: ModelArkady ZabrovßkyPas encore d'évaluation

- SLIMDIP L MitsubishiDocument12 pagesSLIMDIP L MitsubishiHanh TranPas encore d'évaluation

- C0582 Junction Box-CentralDocument2 pagesC0582 Junction Box-CentralfadholiPas encore d'évaluation

- Lec.02 - Medium Voltage SwitchgearDocument22 pagesLec.02 - Medium Voltage SwitchgearAchafi Moussa MahamatPas encore d'évaluation

- Alternating Current 24Document31 pagesAlternating Current 24sri kanthPas encore d'évaluation

- Simplex TrueAlert Non-Addressable Free-Run Horn StrobesDocument4 pagesSimplex TrueAlert Non-Addressable Free-Run Horn StrobesSpencer MaloufPas encore d'évaluation

- HPL Meter PDFDocument4 pagesHPL Meter PDFgunabalan2008100% (1)

- DCode v50 220711.01Document184 pagesDCode v50 220711.01Chris ParkinsonPas encore d'évaluation

- Digital Multifunction Instrument: ApplicationDocument7 pagesDigital Multifunction Instrument: ApplicationNihar RoyPas encore d'évaluation

- EE-354 Analog Communication SystemsDocument8 pagesEE-354 Analog Communication Systemsishac kayaPas encore d'évaluation

- CablesDocument29 pagesCablesbimaPas encore d'évaluation

- Gis Busbar Contact Resistance TestDocument2 pagesGis Busbar Contact Resistance Testsikander843562Pas encore d'évaluation

- Standalone Access Control: Packing List WiringDocument1 pageStandalone Access Control: Packing List WiringAmine AminouPas encore d'évaluation

- Valhalla Schematic PDFDocument1 pageValhalla Schematic PDFelekoss100% (1)

- Unit 2 - Introduction To Iots - Improving Quality of Life: Week1 AssessmentDocument30 pagesUnit 2 - Introduction To Iots - Improving Quality of Life: Week1 AssessmentPraghashrajaPas encore d'évaluation

- DC-DC Conversion Without Inductors: Charge Pumps-A General DescriptionDocument8 pagesDC-DC Conversion Without Inductors: Charge Pumps-A General Descriptionaustinlee0502Pas encore d'évaluation

- 2SD745 2sd745a 2SD745BDocument3 pages2SD745 2sd745a 2SD745Bjsalinas78Pas encore d'évaluation

- Thermo Trex Thermocouple Extension WireDocument2 pagesThermo Trex Thermocouple Extension WireKhin Aung ShwePas encore d'évaluation

- Effect of Tray (1, 4, 8) in Silicon Dioxide Semiconductors From Rise HuskDocument6 pagesEffect of Tray (1, 4, 8) in Silicon Dioxide Semiconductors From Rise HuskCasnan ConanPas encore d'évaluation

- Morgan, Matthew A - Reflectionless Filters-Artech House (2017)Document277 pagesMorgan, Matthew A - Reflectionless Filters-Artech House (2017)frankmhowellPas encore d'évaluation

- Bs 6004 BasecDocument2 pagesBs 6004 BasecMOHAMMED. HAKAMIPas encore d'évaluation

- Manual Avr Leroy Somer Mod. R 181 - enDocument8 pagesManual Avr Leroy Somer Mod. R 181 - enMiguel Angel Pavon CarbonellPas encore d'évaluation

- MV Panel DiemensionsDocument32 pagesMV Panel DiemensionsM Umar ChatthaPas encore d'évaluation

- To Study Various Factors On Which The Internal Resistance Emf of A Cell DependsDocument12 pagesTo Study Various Factors On Which The Internal Resistance Emf of A Cell Dependslovelyboyrocky456Pas encore d'évaluation

- Commscope CCVVPX308.11R - 2016Document3 pagesCommscope CCVVPX308.11R - 2016klamar5Pas encore d'évaluation

- Safety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersDocument158 pagesSafety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersFemko CorporationPas encore d'évaluation