Académique Documents

Professionnel Documents

Culture Documents

Cusn6: Copper Tin Alloy General Description Features

Transféré par

Jesus CanelonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cusn6: Copper Tin Alloy General Description Features

Transféré par

Jesus CanelonDroits d'auteur :

Formats disponibles

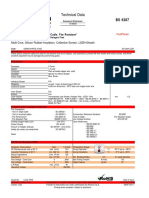

CuSn6 Copper Tin Alloy

CuSn6

Copper Tin Alloy

General Description Features

ELEKTRISOLA bronze wire CuSn6 has very good Very good mechanical properties

mechanical and chemical properties. This binary Excellent bending proof performance

alloy is made of copper alloyed with 6% Very high corrosion resistance

tin. Advantages of this product include a very high

corrosion resistance and good solderabilty. The

bronze wire CuSn6 can be used for a wide range Applications

of electro technical applications, such as heating

elements. Heating applications

Bronze wire CuSn6 is available as litz wire Resistance wires

or single wire with all insulation and self-bonding Other applications with high mechanical and

enamels. Bare wire is available upon request. corrosion resistance requirements

Electrical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

Conductivity 7.5 S*m/mm²

Resistivity 0.1333 Ω*mm²/m

Thermal coefficient of resistance 600 650 700 10E-6/K

Resistance (IACS) 13 %

Mechanical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

T Tensile strength 470 500 530 N/mm²

Y 1% Yield strength at 1% 380 420 460 N/mm²

Elongation 20 35 45 %

Bending proof performance (Note 4) 2900 %

Physical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

Density 8.8 kg/dm³

February 2010 1 www.elektrisola.com

CuSn6 Copper Tin Alloy

Note 1: Unless otherwise specified, all limits are guaranteed for annealed and enameled wire at T A = 20°C and measured

according international standard IEC 851 as far as applicable.

Note 2: Typical Values represent the most likely parametric norm.

Note 3: All limits are evaluated by testing or statistical analysis but are not guaranteed.

Note 4: The bending fatigue strength tests are conducted with a 0.08mm annealed and enameled wire according

ELEKTRISOLA internal specification. The value specifies the Time To Fracture (TTF) compared to copper (100%) under

these test conditions.

Typical Performance Characteristics

Tensile strength vs. elongation

(Diameter: 0.050mm)

550

500

Tensile strength [N /mm²]

450

400

350

300

250

200

150

100

50

0

0 5 10 15 20 25 30 35 40 45

Elongation [%]

BANNED SUBSTANCES COMPLIANCE

ELEKTRISOLA FEINDRAHT AG certifies that the products and packing materials meet the provision from the European

Union for the Restriction of certain Hazardous Substances (RoHS) and the directive for Waste from Electrical and

Electronic Equipment (WEEE).

ELEKTRISOLA FEINDRAHT AG Telephone +41 (0)41 487 77 00 Sister Companies: ELEKTRISOLA Dr. Gerd Schildbach, Germany

Hauptstrasse 35, PO Box 177 Fax +41 (0)41 487 78 00 ELEKTRISOLA GmbH, Italy

CH - 6182 Escholzmatt E-Mail info@elektrisola.ch ELEKTRISOLA Inc., USA

Switzerland Internet www.elektrisola.ch ELEKTRISOLA Sdn. Bhd., Malaysia

ELEKTRISOLA SA, México

ELEKTRISOLA Hangzhou, China

February 2010 2 www.elektrisola.com

CuSn6 Copper Tin Alloy

Annex A

Electrical Resistance

The limits of electrical resistance are derived from the calculations made in IEC standard 317-0-1 Annex C.1

“Method for the calculation of linear resistance” for copper wire and are restricted by a factor of 2.

Nom. AWG Min Nominal Max Nom. AWG Min Nominal Max

Diameter Diameter

[mm] [Ω/m] [Ω/m] [Ω/m] [mm] [Ω/m] [Ω/m] [Ω/m]

0.0098 58 1591 1768 1944 0.0410 45.5 91.19 101.0 110.8

0.0101 1498 1664 1831 0.0420 86.90 96.24 105.6

0.0109 57 1286 1429 1572 0.0430 82.91 91.81 100.7

0.0113 1197 1330 1462 0.0437 80.27 88.90 97.52

0.0120 1061 1179 1297 0.0440 45 79.18 87.69 96.19

0.0125 56 977.8 1086 1195 0.0450 75.70 83.83 91.97

0.0130 55.5 904.1 1005 1105 0.0460 72.45 80.23 88.01

0.0135 55 838.3 931.5 1025 0.0470 44.5 69.93 76.85 83.77

0.0140 779.5 866.1 952.8 0.0480 67.05 73.68 80.31

0.0145 54.5 726.7 807.4 888.2 0.0490 64.34 70.71 77.07

0.0155 54 636.0 706.6 777.3 0.0500 44 61.79 67.91 74.02

0.0160 596.8 663.1 729.5 0.0520 43.5 57.13 62.78 68.43

0.0165 53.5 561.2 623.6 685.9 0.0530 55.00 60.44 65.88

0.0170 528.7 587.4 646.2 0.0550 43 51.07 56.12 61.17

0.0175 53 498.9 554.3 609.8 0.0560 49.26 54.13 59.01

0.0180 471.6 524.0 576.4 0.0580 45.92 50.47 55.01

0.0185 52.5 446.4 496.0 545.6 0.0600 42.5 43.38 47.16 50.93

0.0190 423.2 470.3 517.3 0.0620 40.63 44.16 47.70

0.0195 52 401.8 446.5 491.1 0.0630 42 39.35 42.77 46.19

0.0200 382.0 424.4 466.9 0.0650 41.5 36.40 40.18 44.54

0.0210 51.5 346.5 385.0 423.5 0.0670 34.35 37.82 41.80

0.0215 330.5 367.3 404.0 0.0680 33.39 36.71 40.52

0.0220 51 315.7 350.8 385.8 0.0700 41 31.58 34.65 38.14

0.0230 50.5 288.8 320.9 353.0 0.0710 30.74 33.68 37.03

0.0240 265.3 294.7 324.2 0.0740 28.39 31.00 33.96

0.0245 50 254.5 282.8 311.1 0.0750 40.5 27.67 30.18 33.03

0.0250 244.5 271.6 298.8 0.0780 40 25.65 27.90 30.44

0.0260 49.5 226.0 251.1 276.2 0.0800 24.43 26.53 28.88

0.0270 209.6 232.9 256.2 0.0830 39.5 22.76 24.64 26.75

0.0275 49 202.0 224.5 246.9 0.0850 21.73 23.50 25.46

0.0280 194.9 216.5 238.2 0.0880 39 20.33 21.92 23.70

0.0290 48.5 181.7 201.9 222.0 0.0900 19.46 20.96 22.62

0.0300 169.8 188.6 207.5 0.0930 38.5 18.26 19.63 21.14

0.0310 48 159.0 176.7 194.3 0.0950 17.53 18.81 20.23

0.0320 149.2 165.8 182.4 0.1000 15.87 16.98 18.20

0.0330 47.5 140.8 155.9 171.0 0.101 38.0 15.56 16.64 17.83

0.0340 132.6 146.9 161.1 0.106 37.5 14.17 15.11 16.14

0.0350 47 125.1 138.6 152.0 0.110 13.18 14.03 14.95

0.0360 118.3 131.0 143.7 0.112 12.73 13.53 14.41

0.0370 46.5 112.0 124.0 136.0 0.113 37 12.51 13.30 14.15

0.0380 106.2 117.6 129.0 0.115 12.09 12.84 13.65

0.0381 46.1 105.6 116.9 128.3 0.118 36.5 11.50 12.19 12.95

0.0390 46.0 100.8 111.6 122.4 0.120 11.13 11.79 12.51

0.0400 95.81 106.1 116.4 0.125 10.27 10.86 11.50

February 2010 3 www.elektrisola.com

CuSn6 Copper Tin Alloy

Annex A

Electrical Resistance (Continued)

Nom. AWG Min Nominal Max Nom. AWG Min Nominal Max

Diameter Diameter

[mm] [Ω/m] [Ω/m] [Ω/m] [mm] [Ω/m] [Ω/m] [Ω/m]

0.126 36 10.11 10.69 11.32 0.265 2.326 2.417 2.513

0.130 9.515 10.05 10.62 0.268 29.5 2.275 2.364 2.457

0.132 9.235 9.743 10.29 0.270 2.242 2.329 2.420

0.134 35.5 8.968 9.455 9.977 0.280 2.087 2.165 2.248

0.138 8.466 8.914 9.395 0.286 29 2.001 2.075 2.153

0.140 8.231 8.661 9.122 0.290 1.947 2.019 2.093

0.141 35 8.117 8.539 8.991 0.295 1.883 1.951 2.022

0.149 34.5 7.285 7.647 8.032 0.300 1.821 1.886 1.954

0.150 7.190 7.545 7.923 0.301 28.5 1.809 1.874 1.941

0.159 34.0 6.413 6.715 7.036 0.315 1.654 1.711 1.770

0.160 6.335 6.631 6.946 0.319 28 1.613 1.668 1.726

0.169 33.5 5.689 5.944 6.213 0.335 1.465 1.513 1.563

0.170 5.624 5.874 6.139 0.339 27.5 1.431 1.477 1.526

0.179 33 5.081 5.298 5.527 0.345 1.382 1.426 1.472

0.180 5.026 5.240 5.465 0.350 1.343 1.386 1.430

0.189 4.566 4.753 4.949 0.355 1.306 1.347 1.390

0.190 32.5 4.519 4.703 4.896 0.360 27 1.263 1.310 1.359

0.200 4.084 4.244 4.412 0.375 1.166 1.207 1.251

0.202 32 4.005 4.161 4.324 0.380 26.5 1.136 1.176 1.218

0.210 3.710 3.850 3.996 0.383 1.118 1.157 1.198

0.212 31.5 3.641 3.777 3.920 0.390 1.079 1.116 1.155

0.220 3.385 3.508 3.636 0.400 1.026 1.061 1.097

0.222 3.325 3.445 3.570 0.402 26 1.016 1.051 1.086

0.224 3.266 3.383 3.506 0.420 0.9318 0.9624 0.9941

0.225 31 3.210 3.353 3.506 0.425 0.9103 0.9399 0.9706

0.230 3.074 3.209 3.352 0.427 25.5 0.9019 0.9311 0.9614

0.236 2.922 3.048 3.181 0.450 0.8130 0.8383 0.8646

0.239 2.850 2.972 3.100 0.453 25 0.8024 0.8273 0.8531

0.240 30.5 2.827 2.947 3.074 0.475 0.7305 0.7524 0.7751

0.250 2.609 2.716 2.829 0.481 24.5 0.7126 0.7338 0.7557

0.253 30 2.548 2.652 2.762 0.500 0.6600 0.6791 0.6988

0.260 2.415 2.511 2.613 0.508 24 0.6371 0.6578 0.6794

February 2010 4 www.elektrisola.com

Vous aimerez peut-être aussi

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionD'EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Elektrisola Datasheet AlDocument4 pagesElektrisola Datasheet AlCarlos CaraballoPas encore d'évaluation

- 3-Low Voltage Aerial Bundle Cables (6001000V)Document11 pages3-Low Voltage Aerial Bundle Cables (6001000V)apranaguptaPas encore d'évaluation

- SDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 BeaconDocument1 pageSDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 Beaconchandrahai hrangkhawlPas encore d'évaluation

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- NFC AAAC 117MM2 EES Cable SPECIFICATIONDocument5 pagesNFC AAAC 117MM2 EES Cable SPECIFICATIONmedazzPas encore d'évaluation

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedPas encore d'évaluation

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- Specs ZTT TACSR AW 410 PDFDocument5 pagesSpecs ZTT TACSR AW 410 PDFVictor DoyoganPas encore d'évaluation

- Annex A - Abc Cable SpecificationsDocument4 pagesAnnex A - Abc Cable SpecificationschimiwangmoPas encore d'évaluation

- ZTT ACS Strand 7x3.21-1Document4 pagesZTT ACS Strand 7x3.21-1tees220510Pas encore d'évaluation

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanPas encore d'évaluation

- 1-V23834 L6 E1etc6 011001Document9 pages1-V23834 L6 E1etc6 011001brunobrambilla90Pas encore d'évaluation

- Spec - AAAC CAIRO DARIEN OPGWDocument4 pagesSpec - AAAC CAIRO DARIEN OPGWErnesto Antonio Astorga FloresPas encore d'évaluation

- Networking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHDocument3 pagesNetworking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHZeinab Ashraf ElgammalPas encore d'évaluation

- Online Catalogue PDFDocument4 pagesOnline Catalogue PDFmnmPas encore d'évaluation

- Instrumentation Cable Gen. To EN 50288-7Document4 pagesInstrumentation Cable Gen. To EN 50288-7Shashank SaxenaPas encore d'évaluation

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuPas encore d'évaluation

- Mi MihDocument1 pageMi MihclickfirmPas encore d'évaluation

- FREETOX NH-80 450/750 V Up To and Including 10 mm2 in Double LayerDocument3 pagesFREETOX NH-80 450/750 V Up To and Including 10 mm2 in Double LayerAlexander ColqePas encore d'évaluation

- T.C. Forensic - JAPANESE REPORTS ON ELECTRICAL FIRE CAUSES - Abstract 15Document3 pagesT.C. Forensic - JAPANESE REPORTS ON ELECTRICAL FIRE CAUSES - Abstract 15ecordova1Pas encore d'évaluation

- Phoenix Contact 3260056 enDocument5 pagesPhoenix Contact 3260056 enDGPas encore d'évaluation

- IEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONDocument7 pagesIEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONmedazzPas encore d'évaluation

- Automation Technology - Sensors and Actuators: Product Data SheetDocument3 pagesAutomation Technology - Sensors and Actuators: Product Data SheetMichael MitchellPas encore d'évaluation

- ZTT Et Expressway AAAC Conductor 21-Xj00486Document4 pagesZTT Et Expressway AAAC Conductor 21-Xj00486HarisPas encore d'évaluation

- Phoenix Contact 3044076 enDocument6 pagesPhoenix Contact 3044076 enDGPas encore d'évaluation

- Machine DesignDocument82 pagesMachine Designlearning never endsPas encore d'évaluation

- Datasheet BTL1E22 284293 enDocument2 pagesDatasheet BTL1E22 284293 enajahiseng58Pas encore d'évaluation

- Phoenix Contact 3031186 enDocument6 pagesPhoenix Contact 3031186 enDGPas encore d'évaluation

- Sc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Document1 pageSc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Nader AhmedPas encore d'évaluation

- Specification: 0.6/1kV XLPE CableDocument4 pagesSpecification: 0.6/1kV XLPE CableChrysthyan HitachiPas encore d'évaluation

- Abc Cable Specification: 1. DesignDocument13 pagesAbc Cable Specification: 1. Designabdulkawi alasharyPas encore d'évaluation

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoPas encore d'évaluation

- Ksalahuddin T02 16518915 201905191502Document2 pagesKsalahuddin T02 16518915 201905191502Mohammed SalahPas encore d'évaluation

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalPas encore d'évaluation

- Doha Cables Technical Data SheetDocument74 pagesDoha Cables Technical Data Sheetabdowais0% (1)

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraPas encore d'évaluation

- Cable RS232-RJ45 Hoja de DatosDocument1 pageCable RS232-RJ45 Hoja de DatosssecaesPas encore d'évaluation

- L02002A0094 L02002A0095 U/UTP Cat.6 LSZH: Solid Cable 100 Data CableDocument2 pagesL02002A0094 L02002A0095 U/UTP Cat.6 LSZH: Solid Cable 100 Data CableDani BejoPas encore d'évaluation

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasPas encore d'évaluation

- Printed-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Document15 pagesPrinted-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Evandro PavesiPas encore d'évaluation

- Datasheet BTL04N9 246828 enDocument2 pagesDatasheet BTL04N9 246828 enHamed RajabiPas encore d'évaluation

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianPas encore d'évaluation

- Unit 1Document19 pagesUnit 1SafjrocnPas encore d'évaluation

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaPas encore d'évaluation

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaPas encore d'évaluation

- Phoenix Contact 3001514 enDocument6 pagesPhoenix Contact 3001514 enDGPas encore d'évaluation

- EMD - EMEA - Temflex Vinyl Electrical Tape 1500 - TDS - BME32051422 - EN05Document2 pagesEMD - EMEA - Temflex Vinyl Electrical Tape 1500 - TDS - BME32051422 - EN05sarathkumaarsamuraiPas encore d'évaluation

- BCC 12164210Document1 pageBCC 12164210abdulkawi alasharyPas encore d'évaluation

- Safety Relay SR4 D/M: General Purpose RelaysDocument3 pagesSafety Relay SR4 D/M: General Purpose RelaysMUHAMMAD SISWANTOROPas encore d'évaluation

- Phoenix Contact 3044102 enDocument6 pagesPhoenix Contact 3044102 enDGPas encore d'évaluation

- Datasheet 6 Utp 23 Awg 4 Pair CableDocument2 pagesDatasheet 6 Utp 23 Awg 4 Pair Cablelou janePas encore d'évaluation

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalPas encore d'évaluation

- Specification: Easy Electric Supply LimitedDocument7 pagesSpecification: Easy Electric Supply LimitedDavid Mamani HuacaniPas encore d'évaluation

- Module 1 EMD: Electrical Machine Design Fundamental Aspects of Electrical Machine DesignDocument9 pagesModule 1 EMD: Electrical Machine Design Fundamental Aspects of Electrical Machine Designkubra SultanaPas encore d'évaluation

- 5-LV Service Drop CablesDocument10 pages5-LV Service Drop CablesapranaguptaPas encore d'évaluation

- Phoenix Contact 3209510 enDocument7 pagesPhoenix Contact 3209510 enDGPas encore d'évaluation

- Thermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationDocument2 pagesThermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationMikePas encore d'évaluation

- Datasheet - BTL156W - 254084 - Item 10Document2 pagesDatasheet - BTL156W - 254084 - Item 10Nahid RahmaniPas encore d'évaluation

- FAMOUS PP Past TenseDocument21 pagesFAMOUS PP Past Tenseme me kyawPas encore d'évaluation

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuPas encore d'évaluation

- Sam Media Recruitment QuestionnaireDocument17 pagesSam Media Recruitment Questionnairechek taiPas encore d'évaluation

- Homework 1 W13 SolutionDocument5 pagesHomework 1 W13 SolutionSuzuhara EmiriPas encore d'évaluation

- 2SB817 - 2SD1047 PDFDocument4 pages2SB817 - 2SD1047 PDFisaiasvaPas encore d'évaluation

- Methods of Recording Retruded Contact Position in Dentate PatientsDocument15 pagesMethods of Recording Retruded Contact Position in Dentate PatientsYossr MokhtarPas encore d'évaluation

- Lecturenotes Data MiningDocument23 pagesLecturenotes Data Miningtanyah LloydPas encore d'évaluation

- Plaza 66 Tower 2 Structural Design ChallengesDocument13 pagesPlaza 66 Tower 2 Structural Design ChallengessrvshPas encore d'évaluation

- 5c3f1a8b262ec7a Ek PDFDocument5 pages5c3f1a8b262ec7a Ek PDFIsmet HizyoluPas encore d'évaluation

- PM CH 14Document24 pagesPM CH 14phani chowdaryPas encore d'évaluation

- German Atv-Dvwk Rules and StandardsDocument25 pagesGerman Atv-Dvwk Rules and StandardsMehmet Emre Bastopcu100% (1)

- Excon2019 ShowPreview02122019 PDFDocument492 pagesExcon2019 ShowPreview02122019 PDFSanjay KherPas encore d'évaluation

- DC 7 BrochureDocument4 pagesDC 7 Brochures_a_r_r_yPas encore d'évaluation

- E MudhraDownload HardDocument17 pagesE MudhraDownload HardVivek RajanPas encore d'évaluation

- Problem Set-02Document2 pagesProblem Set-02linn.pa.pa.khaing.2020.2021.fbPas encore d'évaluation

- HirePro Video Proctored Online-Instruction Sheet - Bain IndiaDocument1 pageHirePro Video Proctored Online-Instruction Sheet - Bain Indiaapoorv sharmaPas encore d'évaluation

- Service Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return PositionDocument5 pagesService Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return Positionmahdi elmay100% (3)

- Corrosion Fatigue Phenomena Learned From Failure AnalysisDocument10 pagesCorrosion Fatigue Phenomena Learned From Failure AnalysisDavid Jose Velandia MunozPas encore d'évaluation

- Computing of Test Statistic On Population MeanDocument36 pagesComputing of Test Statistic On Population MeanKristoffer RañolaPas encore d'évaluation

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDocument19 pagesHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraPas encore d'évaluation

- Monkey Says, Monkey Does Security andDocument11 pagesMonkey Says, Monkey Does Security andNudePas encore d'évaluation

- B.SC BOTANY Semester 5-6 Syllabus June 2013Document33 pagesB.SC BOTANY Semester 5-6 Syllabus June 2013Barnali DuttaPas encore d'évaluation

- The Person Environment Occupation (PEO) Model of Occupational TherapyDocument15 pagesThe Person Environment Occupation (PEO) Model of Occupational TherapyAlice GiffordPas encore d'évaluation

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowDocument2 pagesLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- Hole CapacityDocument2 pagesHole CapacityAbdul Hameed OmarPas encore d'évaluation

- PED003Document1 pagePED003ely mae dag-umanPas encore d'évaluation

- Report On GDP of Top 6 Countries.: Submitted To: Prof. Sunil MadanDocument5 pagesReport On GDP of Top 6 Countries.: Submitted To: Prof. Sunil MadanAbdullah JamalPas encore d'évaluation

- AnticyclonesDocument5 pagesAnticyclonescicileanaPas encore d'évaluation

- 18 June 2020 12:03: New Section 1 Page 1Document4 pages18 June 2020 12:03: New Section 1 Page 1KarthikNayakaPas encore d'évaluation

- C C C C: "P P P P PDocument25 pagesC C C C: "P P P P PShalu Dua KatyalPas encore d'évaluation