Académique Documents

Professionnel Documents

Culture Documents

Control Plan Tiga Raksa

Transféré par

HardjonoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Control Plan Tiga Raksa

Transféré par

HardjonoDroits d'auteur :

Formats disponibles

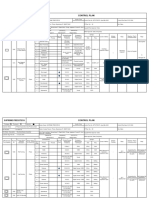

CONTROL PLAN

PT. PRESTASI INTI RUBBER Doc No : PIR: 01 - 01 Original Date Valid Date

Factory : Blok P2 No:3. Kawasan Industri Millenium -Tigaraksa Part Name General Tube Process 14 Oktober 2019 14 Oktober 2019

Tangerang - Banten. Part No 1 Rev.Nomer Rev.Date Zaenur Rachman Ferry

Classification : Supplier Code 0 0 Prepared Approval

Portotype Pre-Launch X Production Others Approval Team Member :

- Zaenur Rachman - Adiguna NP

Customer Engineering Approval / Date ( If Req'd ) Customer Quality Approval / Date ( If - Agus S. - Karsiman

Req'd )

- Eka

Methods

Characteristics

Part / Process Process Name / Operation Machine, Device, Jig,Tools For Special

Evaluation / Sample Reaction Plan

Number Description Mfg Char / Class Product / Process

Specification /Tolerance Measurement Control Method

NO Product Process Techniue Size Freq

1 Material preparation Material WIP 1 Material Identity Tag Identity Visual 1 Early Work Check Sheet Separated

Claim to Supplier

2 Weight of Material Standard Process Weighing Scale 1 Every Weighing Check Sheet Separated

No:SP-K-01 Scrap

2 Mixing Kneider 1 Compound Standard Process Visual 1 Set Up Check Sheet Separated

Appearance No: SP-K-02 Scrap

Out put of Kneider

Limit Sample Visual 1 Set Up Check sheet Referring to Limit Sample

No:LS-K-01

3 Exrtuding Warm up mill 1 Feed Strip thickness Standard Process Thickness Gauge 1 Set Up Check Sheet Return

No:SP-E-01

2 Feed Strip Width Stell Rule 1 Set Up Check Sheet Return

3 Compound Limit Sample Visual 1 Set Up Check Sheet Referring to Limit Sample

Appearance No:LS-S-03

out put of Warm Up mill

Strainer 1 Mesh Strainer Net Standard Process Visual 1 Set Up Check Sheet Separated

No;SP-S-01 Change a new Net

2 Amper Standard Process Amper meter 1 Set Up Check Sheet Reort to Leader

No;SP-S-01 To Re - Set Up

3 Compound Limit Sample Visual 1 Set Up Check Sheet Referring to Limit Sample

Appearance No:LS-S-01

out put of Strainer

Feed mill 1 Feed Strip Supply Standard Process Visual 1 Set Up Check Sheet Return

No:SP-E-01

2 Feed Strip thickness Standard Process Thickness Gauge 1 Set Up Check Sheet Return

No:SP-E-01

3 Feed Strip Width Standard Process Stell Rule 1 Set Up Check Sheet Return

No:SP-E-01

4 Compound Limit Sample Visual 1 Set Up Check Sheet Quarantine

Appearance No:LS-F-02

out put of Feeder Mill

Exruder 1 RPM Standard Process RPM Meter 1 Set Up Check Sheet Report to Leader

No:SP-E-02 To Re-Set up

2 Thickness Base Standard Process Thickness Gauge 1 Size / Set Up Check Sheet Return

No:SP-E-02

3 Thickness Crown Standard Process Thickness Gauge 1 Size / Set Up Check Sheet Retrurn

No:SP-E-02

4 Width Green Stick Standard Process Still Rule 1 Size / Set Up Check Sheet Return

No:SP-E-02

5 Length Green Stick Standard Process Roll Meter 1 Size / Set Up Check Sheet Return

No:SP-E-02

6 Creen Stick Limit Sample Visual 1 Size Check Sheet Referring to Limit Sample

Appearance N0:LS-E-01

3 Valve Assembling Pounching 1 Green Stick Cutting Standard Process Scissors Cut 1 Size Check Sheet Return

Valve Hole No:SP-E-03

2 Hole Standard Process Visual 100% Size Check Sheet Return

No:SP-E-03

Valve 3 Valve Position Standard Process Visual 100% Size Check Sheet Return

Assy No:SP-E-03

4 Press Valve Standard Process Visual 100% all Check Sheet Return

No:SP-E-03

5 Appearance Valve Limit Sample Visual 100% Size Check Sheet Referring to Limit Sample

After Press No:LS-SP-01

4 Splicing Splicer 1 Amper Standard Process Amper Meter 1 Set Up Check Sheet Report to Leader

No:SP-SP-01 To Re-Set Up

2 Butting Pressure Standard Process Pressure Gauge 1 Size Report to Leader

No:SP-SP-01 To Re-Set Up

3 Air Pressure Standard Process Pressure Gauge 1 Set Up Check Sheet Report to Leader

No:SP-SP-01 To Re-Set Up

4 Appearance Joint Limit Sample Visual 1 Size Referring to Limit Sample

No:LS-SP-02

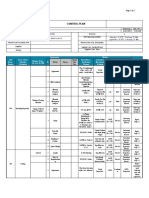

5 Curing Curing Press 1 Steam Pressure Standard Process Pressure Gauge 1 Set Up Check Sheet Stop Process dan Report to Leader

No:SP-C-01 To Re-Set Up

2 Oil Pressure Standard Process Pressure Gauge 1 Set Up Check Sheet Stop Process dan Report to Leader

No:SP-C-01 To Re-Set Up

3 Air Pressure Standard Process Pressure Gauge 1 Set Up Check Sheet Stop Process dan Report to Leader

No:SP-C-01 To Re-Set Up

4 Time Cure Standard Process PLC 1 Set Up Check Sheet Stop Process dan Report to Leader

No:SP-C-01 To Re-Set Up

6 Checking Tube Inspection 1 Inflate Inflate Gauge By Hand 100% All Check Sheet RE-Inflate

No:SP-K-01 ( One By One )

( One By One )

2 Tube Appearance Limit Sample Visual 100% All Check Sheet Referring to Limit Sample

No:LS-F-01 ( One By One )

Washer & Nut Assy Standard Process By Air Tool 100% All Check Sheet Re-Assy

No:SP-K-01 ( One By One )

Inside Core Assy Standard Process By Hand 100% All Check Sheet Re-Assy

No:SP-K-01 ( One By One )

Deflate /Vacuum Standard Process By Hand 100% All Check Sheet Re- Vacuum

No:SP-K-01 ( One By One )

Cup Assy Standard Process By Hand 100% All Check Sheet Re- Assy

No:SP-K-01 ( One By One )

3 Tube Folding & Quantity Standard Process By Hand 100% All Check Sheet Re -Packing

Packing No:SP-K-01 ( One By One )

Storage Standard Process Visual 100% Per Size Check Sheet Re -Packing

No:SP-K-01

7 Surveillance Tube Test 1 Tube Properties SNI Lab.Uji 1 / Merk Every 6 Month Test Results

8 Storage Ware House 1 Booking Quantity

Vous aimerez peut-être aussi

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanPas encore d'évaluation

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaPas encore d'évaluation

- CP Gear Spindle MkeDocument2 pagesCP Gear Spindle Mkeamol vadnerePas encore d'évaluation

- Control Plan For Zinc Flake CoatingDocument3 pagesControl Plan For Zinc Flake Coatingx y100% (1)

- Control PlanDocument4 pagesControl PlanRakesh PandeyPas encore d'évaluation

- Plan ControlDocument14 pagesPlan ControlJesus J Paniagua SegoviaPas encore d'évaluation

- Control PlanDocument4 pagesControl PlanJosué PérezPas encore d'évaluation

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatPas encore d'évaluation

- 07 Control PlanDocument5 pages07 Control PlanManoharar RPas encore d'évaluation

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiPas encore d'évaluation

- Quality Control PlanDocument1 pageQuality Control PlanJoki PenangPas encore d'évaluation

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaurePas encore d'évaluation

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- CP YwdDocument5 pagesCP YwdRaj BistPas encore d'évaluation

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KPas encore d'évaluation

- Plating Process Control Plan Template (2738)Document10 pagesPlating Process Control Plan Template (2738)George Hardy100% (1)

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktPas encore d'évaluation

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraPas encore d'évaluation

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaPas encore d'évaluation

- 2.5 PCPDocument6 pages2.5 PCPAndrea InfantePas encore d'évaluation

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanPas encore d'évaluation

- CP ProductionDocument7 pagesCP Productionsandeep.pantPas encore d'évaluation

- 195 CasingDocument14 pages195 Casingsasi10000Pas encore d'évaluation

- WoodwardDocument104 pagesWoodwardwachuwachuPas encore d'évaluation

- CP St. Assy Upp 12.04.24Document92 pagesCP St. Assy Upp 12.04.24Hemant GuptaPas encore d'évaluation

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200Pas encore d'évaluation

- 137.process Map +flow Chart ASSY S.drawER DC97-23881Document6 pages137.process Map +flow Chart ASSY S.drawER DC97-23881Shinichi SuzukiPas encore d'évaluation

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanQuality VenusPas encore d'évaluation

- Machining Control PlanDocument1 pageMachining Control PlanGARIMA CASTINGS, JAIPURPas encore d'évaluation

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 pagesUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanPas encore d'évaluation

- Maharashtra Polymer Products: Control PlanDocument3 pagesMaharashtra Polymer Products: Control PlanHitarth_dhamsaniaPas encore d'évaluation

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SPas encore d'évaluation

- Plan de Surveillance ExempleDocument2 pagesPlan de Surveillance ExempleAudrey GavaletPas encore d'évaluation

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj RawatPas encore d'évaluation

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALPas encore d'évaluation

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkPas encore d'évaluation

- Spot Welding Control PlanDocument1 pageSpot Welding Control Planshiv jangale100% (1)

- Casting CPDocument2 pagesCasting CPSuraj RawatPas encore d'évaluation

- Quality Plan CharcoalDocument2 pagesQuality Plan CharcoalPT. Estupedo Agri MakmurPas encore d'évaluation

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDPas encore d'évaluation

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarPas encore d'évaluation

- CP For Assembly PartsDocument1 pageCP For Assembly Partssantosh kumarPas encore d'évaluation

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranPas encore d'évaluation

- 9.PFD - 001733000520Document1 page9.PFD - 001733000520BHUSHANPas encore d'évaluation

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatPas encore d'évaluation

- Control PlanDocument1 pageControl Planilaya rajaPas encore d'évaluation

- Control Plan: Prototype Pre-Launch XDocument1 pageControl Plan: Prototype Pre-Launch XkishortilekarPas encore d'évaluation

- Quality Control Process Chart: Prototype Pre-Launch ProductionDocument2 pagesQuality Control Process Chart: Prototype Pre-Launch Productionmaria katherine pantojaPas encore d'évaluation

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabathePas encore d'évaluation

- Control PlanDocument9 pagesControl Planjose antonioPas encore d'évaluation

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiPas encore d'évaluation

- CP Brought Out PartsDocument1 pageCP Brought Out Partssantosh kumarPas encore d'évaluation

- Control Plan ExampleDocument1 pageControl Plan Examplelingkungan.agathaPas encore d'évaluation

- Camptech Manufacturing Control PlanDocument5 pagesCamptech Manufacturing Control PlanR.BALASUBRAMANIPas encore d'évaluation

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- Pro-Quality Associates Control PlanDocument1 pagePro-Quality Associates Control PlanDeepak kumarPas encore d'évaluation

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroPas encore d'évaluation

- Lir - Cv.truba Jaya EngDocument7 pagesLir - Cv.truba Jaya EngbegateamPas encore d'évaluation

- Scaling of MosfetDocument40 pagesScaling of MosfetSaumitra TripathiPas encore d'évaluation

- Respirable Dust Sampler Envirotech Apm460BlDocument19 pagesRespirable Dust Sampler Envirotech Apm460BlECRDPas encore d'évaluation

- Thermal Physics Assignment 2013Document10 pagesThermal Physics Assignment 2013asdsadPas encore d'évaluation

- Aci 351.1r StandardDocument18 pagesAci 351.1r StandardAjay Ranganathan100% (1)

- The Electronic Spectra of Coordination CompoundsDocument52 pagesThe Electronic Spectra of Coordination CompoundsAyuditPas encore d'évaluation

- ABO & Acid CleaningDocument38 pagesABO & Acid Cleaningsrigirisetty208100% (1)

- Paints Coatings Novel Teta Free Polyamides 2k Epoxy SystemsDocument10 pagesPaints Coatings Novel Teta Free Polyamides 2k Epoxy SystemsHugo WizenbergPas encore d'évaluation

- Hesss LawDocument15 pagesHesss LawAriAnggoroPas encore d'évaluation

- Computational Evaluate Self-Reactivity HazardsDocument8 pagesComputational Evaluate Self-Reactivity Hazardspolaris44100% (1)

- Maya Gate QuestionDocument9 pagesMaya Gate QuestionGarv KumarPas encore d'évaluation

- Pulp and PaperDocument18 pagesPulp and PaperAbhishek AwasthiPas encore d'évaluation

- Yi Jian ElementBuilderSEDocument6 pagesYi Jian ElementBuilderSEYi Jian80% (5)

- A. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)Document240 pagesA. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)EdilberPas encore d'évaluation

- Electronics - 1 Lecture 13Document37 pagesElectronics - 1 Lecture 13rizwanspirit11Pas encore d'évaluation

- Chapter II: Reciprocal Lattice: Read Chapter 2 of KittelDocument39 pagesChapter II: Reciprocal Lattice: Read Chapter 2 of KittelEdson Jansen MirandaPas encore d'évaluation

- TPXData SheetDocument4 pagesTPXData Sheetrameshkarthik810Pas encore d'évaluation

- (Courseware) ICSE: Mendeleev's Periodic TableDocument39 pages(Courseware) ICSE: Mendeleev's Periodic Tableorigami ninjaPas encore d'évaluation

- Sierra Megonnell and Kyle Lovisone ExpDocument1 pageSierra Megonnell and Kyle Lovisone Expapi-528179516Pas encore d'évaluation

- Hexweb CR Iii: Corrosion Resistant Specification Grade Aluminum HoneycombDocument6 pagesHexweb CR Iii: Corrosion Resistant Specification Grade Aluminum Honeycombsahiljain_146Pas encore d'évaluation

- AMP16602P032Document6 pagesAMP16602P032Ravi TejaPas encore d'évaluation

- Lecture 10a OptoelctronicsDocument33 pagesLecture 10a OptoelctronicsMegaHertz_92Pas encore d'évaluation

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDocument32 pagesAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanPas encore d'évaluation

- OGP Report No. 413 Rev 1.1Document54 pagesOGP Report No. 413 Rev 1.1febriekowPas encore d'évaluation

- HoneywellDocument2 pagesHoneywellzenerdiodePas encore d'évaluation

- 3123 PDFDocument4 pages3123 PDFTrefina PranaPas encore d'évaluation

- Thermochemistry BookletDocument29 pagesThermochemistry Bookletdurmic_suadaPas encore d'évaluation

- Activity 3 Carbon Compound M3Document2 pagesActivity 3 Carbon Compound M3Rosario Antoniete R. CabilinPas encore d'évaluation