Académique Documents

Professionnel Documents

Culture Documents

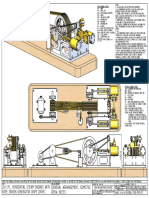

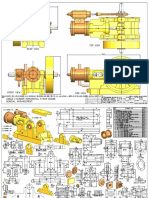

General Arrangement, Bom, Parts & Assemblies A Simple 1 Cylinder Vertical Steam Engine 12Mm Bore X 12Mm Stroke

Transféré par

EstefannyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

General Arrangement, Bom, Parts & Assemblies A Simple 1 Cylinder Vertical Steam Engine 12Mm Bore X 12Mm Stroke

Transféré par

EstefannyDroits d'auteur :

Formats disponibles

70 TIMBER 30°

1-01 30° 12RM

6 6 6RM

A

30

°

30

°

6

4.5 3PL

12

8

° 6 0

2.5

60 ° B B

30PCD

12

52

120

4 8

8.5x16DP 4xM3x10DP

°

A

74

TAPPED

2.5

C'BORE 11 DP HOLES SECTION B-B

STEAM OUT

38

6 45° 45°

STEAM IN BRS

6.5

14.5

20

SECTION A-A

M8

6

52

37

R3 1-06 5

1

5

5

8

16

R4

13

13

16

6.5

7 16 8 7

24

1.5 1-03

1

4 3.5 BRS

11

8

M4x10DP

BRS 7

38 3.5

S/S

30PCD S 5.5

8.5

5X3DP

M4x10DP 3PL 4xM3x10DP

6

3 4PL TAPPED

HOLES

6

8.5

1-07 CU

4

M4x10DP

C'BORE

SYN

1.5

12

°

120

1-09 15.25 15.25

1-08

8

3.4

HIDDEN LINES REMOVED FOR CLARITY

5

110

D 60° D M8

60°

12

25 BRS 4.5 4.5

1-04 6.8

1.5

5 4.5 SPS 6

3

M4

3.5

DRILL

8

1-12

3.5

THRU

4

6 6

6

5

9

4

R19

6

10

0.8

5

13 13

3

14

1-10 1.5

3

1-02 12 12

9

14

BRS

5

10

15 COILS 10

REAM

24

4 5 PLUG AFTER

1.5

13

15.5

3 PRESS FIT 6RM ASSEM

13

6 1-11

1

SECTION D-D TIGHT FIT

3.5

BRZ R2.5 R2.5

7

DRILL

70 TAKE 2 AFTER 39

R1

1

OVER ASSEM

.5

FROM AND 8

QTY. PART NUMBER REFER TO BRS

1 DVBYDT-2-01-VALVE PUSH ROD 1-03

QTY. PART NUMBER 1 DVBYDT-2-02-CRANK SHAFT

R5

1 DVBYDT-1-01-BASE 1 DVBYDT-2-03-CAM

1 DVBYDT-1-02-STAND OFF 1 DVBYDT-2-04-PISTON 8

30.5

1 DVBYDT-1-03-MAIN CYLINDER BODY 1 DVBYDT-2-05-GUDGEON PIN

1 DVBYDT-1-04-CYLINDER HEAD 2 DVBYDT-2-06-GUDGEON PINEND PAD

2 DVBYDT-1-05-BEARING CAP 1 DVBYDT-2-07-CON ROD

14

1 DVBYDT-1-06-SPRING HOUSING 1 DVBYDT-2-08-FLYWHEEL

1 DVBYDT-1-07-BALL VALVE 1 DVBYDT-2-09-FLYWHEEL HOLDING SCREW

1 DVBYDT-1-08-O-RING 2 DVBYDT-M2x10 A-K CYL HEAD SCREW

2 DVBYDT-1-09-IN-OUTLET PIPE 1 DVBYDT-M3x3 GRUB SREW HIDDEN LINES REMOVED FOR CLARITY 10

1 DVBYDT-1-10-VALVE SPRING 4 DVBYDT-M3x18 A-K CYL HEAD SCREW

2 DVBYDT-1-11-MAIN BEARING BUSH 4 DVBYDT-M3x30 A-K CYL HEAD SCREW 38 LIGHT PUSH FIT

3 DVBYDT-1-12-M4 CAP NUT 2 DVBYDT-M4x25 A-K CYL HEAD SCREW

1 DVBYDT-1-13-PROTECTOR CAP 3 DVBYDT-M4x32 STUD

NOTES: THE ORIGINAL DRAWINGS WERE MADE BY "DVBYDT" AND DOWNLOADED FROM THE MEM WEBSITE

TITLE DRAWING CONTENTS PROJECT No 09E-16-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

A SIMPLE 1 CYLINDER VERTICAL STEAM GENERAL ARRANGEMENT, BOM, JDW DRAUGHTING SERVICES DATE

SEPTEMBER-2015

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ENGINE 12mm BORE x 12mm STROKE PARTS & ASSEMBLIES

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 02 A3 No: DVBYDT-01

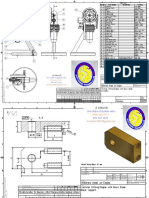

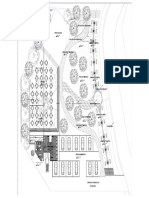

6 S/S 26 22 26 BRS

4 6 4 26 4RM 2-08

R8 B

R8 1 4 1 3.5 5 3.7 6.3 R2 R2 1 1

12 5PF 5PF

10

9 2-09

2.2

R3.5

10

1.5

M2

2-02

8.5

R2

6.5

6

6

6

R8

60°

R8

M4

5

2-07

2.52.5

1

16

16

4

4

6

10 5PF 5PF

23

R2

13

6.5

5

2-03

8.5

M/S

2.2

6 S/S 9 5

S/S 30

M/S SCALE 1.5:1 B

4

7 323

SECTION B-B

10RM SCALE 1.5 : 1

2-01 S/S

6

2.5

12

1-13

2-06 2-04 SA-2-202

10 SA-2-202

4 4 6

2-05

4PF

2-06

4 4

M3

R4 NOTES:

2-05 0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

2-03 11 MS PTFE 1. ALL ENGINEERING PRACTICES SHALL BE APPLIED

WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

MS 6

9.5 4PF 2. WHERE SCREWS OR BOLTS ARE USED THE

CLEARANCE HOLES SHALL BE APPROXIMATELY 5% 1-05 1-05

2-07

2-01

SA-2-201

3 2-06 TO 8% LARGER THAN THE MATCHING TAPPED HOLE.

4PF

A 0.75mm 3. PREFERABLY ALL TAPPED HOLES AND MATCHING

THICK SA-2-201

12SDF

SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

10

A 0.2 4. MATERIALS SPECIFIED ON THE DRAWINGS ARE

INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER 1-02

OWN MATERIAL CHOICE. 1-07

4 6.5

R2

60° 5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM

2.5 PRESSURE APPLIED TO IT SHALL BE SILVER/HARD 1-11 1-11 1-10

2-04 DETAIL G SOLDERED.

SECTION A-A SCALE 4 : 1 7. COMPRESSION SPRINGS ARE DRAWN IN

COMPRESSED STATE (CP), UNCOMPRESSED STATE IS

PEEK 13 BRS APPROX 40% TO 60% LONGER THEN COMPRESSED

STATE. 1-03

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM

1 AND/OR WATER SHOULD BE CONSTRUCTED USING

NON-FERROUS OR NON CORROSIVE MATERIAL SUCH

AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL,

COPPER OR MONEL. SA-1-101

38

30

14

9. THE ORDER IN WHICH THE PARTS/COMPONENTS

6

ARE MANUFACTURED AND THE MODEL IS ASSEMBLED

IS ENTIRELY LEFT TO THE BUILDER/MODELMAKER.

1-04

SA-2-205

11. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE

DRAWINGS, DO NOT HESITATE TO CONTACT ME SO

2-08 THAT THE ERRORS/OMISSSIONS CAN BE RECTIFIED.

MS 1-09

8.3 1.5 6 MATERIAL ABBREVIATIONS:

ALU = ALUMINIUM

3HEX

BRS = BRASS

60°

M4

2-09 BRZ = BRONZE OR GUNMETAL (BRZ/GM) 1-09

CI = CAST IRON

CU = COPPER

OTHER ABBREVIATIONS GRA = GRAPHITE 1-08

DP = DEEP MS = MILD STEEL/BRIGHT MILD STEEL

PF = PRESS FIT S/S = SILVER STEEL OR STAINLESS STEEL 1-06

PCD = PITCH CIRCLE DIAMETER SPS = SPRING STEEL

RM = REAM SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR 1-01

HEX = HEXACON, 6SIDED RUBBER

CP = COMPRESSED IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO

KNL = KNURLED WITHSTAND THE HEAT AND PRESSURE(S) APPLIED TO THEM.

SDF = SLIDING FIT PEEK = POLYETHER ETHER KETONE.

SA-n-xxx = SUB ASSEMBL-n-xxx PTFE = POLYTETRAFLUOROETHYLENE

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED.

1-12 1-12

1-12

SA-1-101

NOTES: THE ORIGINAL DRAWINGS WERE MADE BY "DVBYDT" AND DOWNLOADED FROM THE MEM WEBSITE

TITLE DRAWING CONTENTS PROJECT No 09E-16-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

A SIMPLE 1 CYLINDER VERTICAL STEAM PARTS & ASSEMBLIES JDW DRAUGHTING SERVICES DATE

SEPTEMBER-2015

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ENGINE 12mm BORE x 12mm STROKE

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 02 OF 02 A3 No: DVBYDT-02

Vous aimerez peut-être aussi

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroPas encore d'évaluation

- Sa-3-303 Sa-3-304 Sa-3-305 Sa-3-311 Sa-3-312 Sa-3-313Document1 pageSa-3-303 Sa-3-304 Sa-3-305 Sa-3-311 Sa-3-312 Sa-3-313सचिन पटेलPas encore d'évaluation

- Bản Vẽ Lắp Động Cơ DọcDocument32 pagesBản Vẽ Lắp Động Cơ DọcCủa Tôi Thần TuợngPas encore d'évaluation

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesStojan Pece CmarPas encore d'évaluation

- Lanz A3 Sheet 05 PDFDocument1 pageLanz A3 Sheet 05 PDFsrihariPas encore d'évaluation

- A Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesDocument1 pageA Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesStojan Pece CmarPas encore d'évaluation

- Top View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionDocument4 pagesTop View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionLe TruongPas encore d'évaluation

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesmiriPas encore d'évaluation

- Hoccokhi - VN Bai Tap Tu Hoc Catia P1editDocument10 pagesHoccokhi - VN Bai Tap Tu Hoc Catia P1editKiệt LêPas encore d'évaluation

- Wren Minibike PlansDocument1 pageWren Minibike PlansANDRES MARCELO GORDON GARCESPas encore d'évaluation

- Single Cylinder Oscillating Steam EngineDocument1 pageSingle Cylinder Oscillating Steam EngineNiruban Santiagu Fernando100% (1)

- Tandem Scotch Yoke Steam EngineDocument4 pagesTandem Scotch Yoke Steam EngineAmar HairlahovicPas encore d'évaluation

- BGRHHDocument3 pagesBGRHHShubham KalbhutPas encore d'évaluation

- GyroscopeDocument6 pagesGyroscopeapi-358072612Pas encore d'évaluation

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocument2 pages4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoPas encore d'évaluation

- Exp Vert See Saw 09 04 09Document5 pagesExp Vert See Saw 09 04 09radi adityaPas encore d'évaluation

- Muncaster 11 A3 Sheet 04Document1 pageMuncaster 11 A3 Sheet 04Juan PastorPas encore d'évaluation

- Ose 1 Vertical Ose Beginner 1 Ok PDFDocument1 pageOse 1 Vertical Ose Beginner 1 Ok PDFAnonymous MMLzZjbyPas encore d'évaluation

- (Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangDocument4 pages(Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangChien Dang VanPas encore d'évaluation

- Vertical and Horizontal Steam Engine Plans and DiagramsDocument2 pagesVertical and Horizontal Steam Engine Plans and Diagramsserrano75Pas encore d'évaluation

- rs11 OpDocument32 pagesrs11 OpDavid ÁlvarezPas encore d'évaluation

- 1chseaw JDW CompletDocument4 pages1chseaw JDW CompletJesús Los ArcosPas encore d'évaluation

- Single Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Document3 pagesSingle Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Jhon Fredy MartinPas encore d'évaluation

- Kertas A3 - Freight-Lorry-Jdw 2Document3 pagesKertas A3 - Freight-Lorry-Jdw 2Pemesinan SMK Migas CepuPas encore d'évaluation

- Trevithick Steam Locomotive 1805Document6 pagesTrevithick Steam Locomotive 1805АленаPas encore d'évaluation

- Bicylindre en V PDFDocument5 pagesBicylindre en V PDFOrlando Rojas PintoPas encore d'évaluation

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioPas encore d'évaluation

- General Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEDocument4 pagesGeneral Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEAracely Cárdenas100% (1)

- Single cylinder steam engine general arrangementDocument4 pagesSingle cylinder steam engine general arrangementJorge Luis Villegas ValdiviaPas encore d'évaluation

- LBSC Steam CraneDocument7 pagesLBSC Steam CraneSantiago Londoño LopezPas encore d'évaluation

- Care and Use of Boyar Schultz Model 6-12 Surface GrinderDocument11 pagesCare and Use of Boyar Schultz Model 6-12 Surface GrinderRandyWilsonPas encore d'évaluation

- Shaper Used As Surface GrinderDocument1 pageShaper Used As Surface Grinderradio-chaserPas encore d'évaluation

- D&H World's Fair CarsDocument4 pagesD&H World's Fair Carsstaustell92Pas encore d'évaluation

- Inch To MM ChartDocument3 pagesInch To MM Chartthemoon69Pas encore d'évaluation

- 09C-40-00-A3-SHEET-01 - Sheet1Document1 page09C-40-00-A3-SHEET-01 - Sheet1Nam HoangPas encore d'évaluation

- Single cylinder steam engine slide valveDocument6 pagesSingle cylinder steam engine slide valveDanilo AlvarezPas encore d'évaluation

- Cilindro Horizontal PequeñoDocument1 pageCilindro Horizontal PequeñoNMM100% (1)

- SteelWheelsMagazine Issue1Document58 pagesSteelWheelsMagazine Issue1David ParfittPas encore d'évaluation

- A3 Little Huskey Steam EngineDocument4 pagesA3 Little Huskey Steam Engineradi adityaPas encore d'évaluation

- Lionel 6-12885 40watt Speed Control SchematicDocument1 pageLionel 6-12885 40watt Speed Control SchematicEnrique FemeniaPas encore d'évaluation

- Dokumen - Tips 1801 457 2019-04-14 2 Compound 1 42 Slide Valve Guide Bracket 1 Compound 2 01 CrankshaftDocument9 pagesDokumen - Tips 1801 457 2019-04-14 2 Compound 1 42 Slide Valve Guide Bracket 1 Compound 2 01 Crankshaftpercy obandoPas encore d'évaluation

- Cartoon Car PDFDocument3 pagesCartoon Car PDFShridhar ZambarePas encore d'évaluation

- Msy Parts PricelistDocument5 pagesMsy Parts PricelistBillClintonRepPas encore d'évaluation

- Denah Tampak - Detail Pintu JendelaDocument8 pagesDenah Tampak - Detail Pintu Jendelahansen 97Pas encore d'évaluation

- Nano Ic EngineDocument12 pagesNano Ic EngineVinod JadavPas encore d'évaluation

- Small Horizontal Steam Engine DrawingDocument6 pagesSmall Horizontal Steam Engine Drawingnferreira_245024Pas encore d'évaluation

- Sven Ha-385 SCHDocument2 pagesSven Ha-385 SCHАндрюха КорнPas encore d'évaluation

- M1 Garand US1892141Document15 pagesM1 Garand US1892141apoorva singh100% (1)

- This Area Must Be Confirmed With Landscape Package: D.F.01.03 D.F.01.02 D.F.01.05 D.F.01.01Document1 pageThis Area Must Be Confirmed With Landscape Package: D.F.01.03 D.F.01.02 D.F.01.05 D.F.01.01janPas encore d'évaluation

- 2500 160 VE 7100 22000 - 002 2500 160 VE 7100 22000 - 002 - CompressedDocument1 page2500 160 VE 7100 22000 - 002 2500 160 VE 7100 22000 - 002 - Compressedshafiq3221821Pas encore d'évaluation

- Road From Palugaswewa To HabaranaDocument2 pagesRoad From Palugaswewa To HabaranaRenga Ramanujan CPas encore d'évaluation

- 2 Cylinder Steam Engine To The Bernay DesignDocument4 pages2 Cylinder Steam Engine To The Bernay DesignAxel Dominique100% (1)

- Experimental twin cylinder steam engineDocument6 pagesExperimental twin cylinder steam engineGiuliana Acosta acostaPas encore d'évaluation

- MSY Technology 17 Year Computer Sale LocationsDocument5 pagesMSY Technology 17 Year Computer Sale LocationskanetreblePas encore d'évaluation

- (09.10.30) Dsme H-4453-4 Magnetic Compass (Final)Document18 pages(09.10.30) Dsme H-4453-4 Magnetic Compass (Final)Kevin Earl BoralPas encore d'évaluation

- Grinding Machinery GuideDocument472 pagesGrinding Machinery Guidetm100% (1)

- Proyeccion de Cubierta: Oficio BARDocument1 pageProyeccion de Cubierta: Oficio BARBruce JimenezPas encore d'évaluation

- Southern Maunsell 4-4-0 Classes: (L, D1, E1, L1 and V)D'EverandSouthern Maunsell 4-4-0 Classes: (L, D1, E1, L1 and V)Pas encore d'évaluation

- ROC800-Series IEC 62591 Interface: ScalabilityDocument10 pagesROC800-Series IEC 62591 Interface: ScalabilityBMPas encore d'évaluation

- Part 07 Digital Modulations - EEE309Document13 pagesPart 07 Digital Modulations - EEE309elon muskPas encore d'évaluation

- Structural Analysis With The Finite Element Method. Linear StaticsDocument1 pageStructural Analysis With The Finite Element Method. Linear StaticsluchogilmourPas encore d'évaluation

- Khatib Dissertation FinalDocument193 pagesKhatib Dissertation FinalMonalisa MohantyPas encore d'évaluation

- Gas SpringsDocument122 pagesGas SpringsslavcecaciPas encore d'évaluation

- DRC800 Remote Control UserGuideDocument2 pagesDRC800 Remote Control UserGuideLuis MurilloPas encore d'évaluation

- Re 29037Document12 pagesRe 29037BorisPas encore d'évaluation

- Canon Ir3245 Series-PcDocument154 pagesCanon Ir3245 Series-PcPetrescu CezarPas encore d'évaluation

- Determine Floating Body StabilityDocument11 pagesDetermine Floating Body StabilityDember Paul100% (1)

- Crompton ProjectDocument110 pagesCrompton Projectarunkcmt0% (2)

- Attribute Achievement FormDocument14 pagesAttribute Achievement FormPablo Guzmán López0% (2)

- THS Structural Plans (Combine)Document12 pagesTHS Structural Plans (Combine)genciPas encore d'évaluation

- FC100 ServiceManual MG90L102Document209 pagesFC100 ServiceManual MG90L102Said BoubkerPas encore d'évaluation

- Important Alloy CompositionDocument2 pagesImportant Alloy CompositionRSLPas encore d'évaluation

- Prestige Bella VistaDocument27 pagesPrestige Bella VistaArun RajagopalPas encore d'évaluation

- Instruction Manual - Digital Drybath - ENDocument19 pagesInstruction Manual - Digital Drybath - ENAlain ManceraPas encore d'évaluation

- Otis Relay Coils SpecificationsDocument1 pageOtis Relay Coils SpecificationsDamian Alberto EspositoPas encore d'évaluation

- Technical Readout (TRO) 2750 (Fan Made)Document106 pagesTechnical Readout (TRO) 2750 (Fan Made)Mescalero100% (4)

- N248J ManualDocument13 pagesN248J ManualChit KhunPas encore d'évaluation

- FintechDocument8 pagesFintechArnab Das50% (4)

- Purwoko Arie Sujadi: ExperienceDocument4 pagesPurwoko Arie Sujadi: Experienceeriant014Pas encore d'évaluation

- Friction in OrthodonticsDocument9 pagesFriction in Orthodonticsaa bbPas encore d'évaluation

- Architecture Technology CurriculumDocument129 pagesArchitecture Technology CurriculumShakib Shoumik57% (21)

- Marking Fixture PresentationDocument31 pagesMarking Fixture PresentationAvinash JejurkarPas encore d'évaluation

- Central Changing of Triggers in WinCC V6.2 Images (PDL)Document10 pagesCentral Changing of Triggers in WinCC V6.2 Images (PDL)www.otomasyonegitimi.comPas encore d'évaluation

- Sa2009-001608 en Rel670 CT Calculation ExampleDocument7 pagesSa2009-001608 en Rel670 CT Calculation ExampleinsanazizPas encore d'évaluation

- Experiment Central 2010Document1 481 pagesExperiment Central 2010D BASU100% (1)

- Voltage Divider Bias Stabilizes BJT Transistor OutputDocument5 pagesVoltage Divider Bias Stabilizes BJT Transistor OutputMalikAlrahabiPas encore d'évaluation

- Journallistofscopus PDFDocument630 pagesJournallistofscopus PDFSatyanarayana RentalaPas encore d'évaluation

- Tufail MaboodDocument3 pagesTufail MaboodMickey DalbeheraPas encore d'évaluation