Académique Documents

Professionnel Documents

Culture Documents

Nadar, 2012

Transféré par

Silvio JúniorTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nadar, 2012

Transféré par

Silvio JúniorDroits d'auteur :

Formats disponibles

Proceedings of International Conference on Advances in Architecture and Civil Engineering (AARCV 2012), 21st – 23rd June 2012 169

Paper ID SAM200, Vol. 1

Inplane Shear Strength of Normal, High Strength

and Self Compacting Concrete Using Push-Off

Specimen

Nadar Nissar Shaikh, Mohammed Zeeshan, Mohammed Muzaffar Saba, S.B. Nirmala and R.

Prabhakara

Abstract--- The fundamental knowledge of the shear properties of concrete are very important before it is put into

failure of concrete is essential for the introduction of ductility practice. Lot of investigations is available on flexure, shear,

or toughness parameters in relevant structural design. If such torsion etc. However it has found from literature on in plane

parameters can be obtained from simple tests, they could be shear strength investigation is less. Change in different grade

probably used in designs including shear keys, web-flange of concrete changes the mechanical and fracture properties.

stress transfer, and punching resistance. Additionally, the Therefore fundamental knowledge is essential for the ductility

validation of a simple test method will facilitate the or toughness parameters in structural design. The codal

comparison of the behavior of different types of concrete provisions for NSC, can it be applied to SCC and HSC is the

within materials engineering processes aimed at enhancing question to be answer. The push off test on a prism used to

shear transfer in applications such as slabs and tunnel linings. quantify the shear stress-displacement behavior. In plane shear

strength is required in the designs of shear keys, web flange

The experimental investigation carried out in this project

stress transfer, and punching resistance. In this investigation

is to study the in plane shear behavior of Normal Strength

push off specimen adopted to see the variation of shear stress

Concrete (NSC), High Strength Concrete (HSC) and Self

Compacting Concrete (SCC) by conducting push-off test. The for different grades of concrete.

grades of concrete used are M20NSC, M30SCC, M70HSC. A A. High Strength Concrete

procedure of trials was adopted to find a suitable mix design. Although HSC is often considered a relatively new

The specimens are of 150 x 150 x 260mm. Based on the material, its development has been gradual over many years.

literature specimen length was chosen to be 260 mm and two The ACI committee has defined HSC as concrete of normal

notches of 75 mm length were cut 60 mm apart, perpendicular weight aggregates having compressive strength for design of

to the axis of the specimen. The load was applied through steel 41MPa or greater and shall not include the concrete made

bars of 25 mm width are placed between the fixed loading using exotic material or techniques. More recently,

crosshead of the machine. The test was performed in a stable compressive strengths approaching 138MPa have been used in

manner permitting the determination of the pre- and post-peak cast-in-place buildings. However, in recent years, the

responses and, consequently, characterizing the shear stress applications of HSC have increased, and HSC has now been

that can be transferred across an open crack. The shear used in many parts of the world. The growth has been possible

stress-slip response is analyzed and toughness based as a result of recent developments in material technology and

parameters, for possible use in design, are calculated. a demand for HSC. The construction of Chicago water tower

and 311 south wicker driver concrete building, long span

cable-stayed bridges such as East Huntington, W.V. and

Keywords--- Concrete, In Plane, Shear, Toughness, Push-

bridge over the Ohio River would not have taken place

off

without the availability of HSC [1].

HSC are known to have more durable properties and better

corrosion resisting properties than the conventional concrete.

I. INTRODUCTION Higher compressive strength of concrete results in higher

C ONCRETE is made out of chemically active material like

cement and rigid inclusions like aggregates. Mechanical

modulus of elasticity and thus improves the serviceability [2].

HSC provides better solutions to reduce sizes and weight of

concrete structural elements [3]. The tendency of concrete

building structures to become taller and simpler made

Nadar Nissar Shaikh, UG Student Department of Civil Engineering,

MSRIT, Bangalore India.

necessary of using HSC to obtain columns of reduced section

Mohammed Zeeshan, UG Student Department of Civil Engineering, and floor system without internal beams. In the case of

MSRIT, Bangalore India. columns, the increase of concrete strength often results in

Mohammed Muzaffar Saba, UG Student Department of Civil more economical sections, while allowing increased usable

Engineering, MSRIT, Bangalore India.

S.B. Nirmala, UG Student Department of Civil Engineering, MSRIT,

floor space. For flat slabs, the main reason to use higher

Bangalore India. strength is to obtain minimum slab height with sufficient

R. Prabhakara, Professor, Department of Civil Engineering, MSRIT, punching shear resistance [4]. HSC mixes tend to be very

Bangalore India. E-mail: r.prabhakara@gmail.com

ISBN 978-93-82338-01-7 | © 2012 Bonfring

Proceedings of International Conference on Advances in Architecture and Civil Engineering (AARCV 2012), 21st – 23rd June 2012 170

Paper ID SAM200, Vol. 1

cohesive and a concrete with measured of slump may be 50 J. Sagaseta , R. L. Vollum(2011)[11] design methods for

mm may be difficult to place. As HSC is likely to be used in shear in reinforced concrete structures typically rely upon

highly reinforced sections, a higher workability should be shear transfer through cracks, which depends upon the crack

specified. To achieve desirable workability HSC super opening and sliding displacements and the roughness of the

plasticizers are used. Many modern super plasticisers can crack surfaces. The author also examined the contribution of

retain reasonable workability for a period of about 100 aggregate interlock to the shear strength of a parallel set of

minutes. Often, in order to avoid drastic decrease in slump and reinforced concrete beams, using the same types of aggregate

resultant difficulty in placing, super plasticisers are only partly as the push-off specimens. The mechanics of shear transfer

mixed on batching, the balance being added on site prior to through aggregate interlock is complex because several

pouring [5]. The bond strength does not increase at the same mechanisms are involved in which normal and shear stresses

rate as that of the compressive strength of concrete. This can interact. Cracks tend to ‗dilate‘ as they slide due to aggregate

lead to serious problems, particularly the beam- column joints particles sliding over each other. Normal stresses are

when the use of HSC is accompanied by the use of high introduced at the crack face if the crack widening is

strength steel. In this case the concrete can undergo significant constrained by reinforcement.

cracking even in the whole member is not under a net tension. J. Jayaprakash , Abdul Aziz Abdul Samad(2009)[15]

This cracking can significantly decrease the shear resistance of

investigated the effectiveness of CFRP as an external

such columns. [6].

reinforcement the results of shear transfer capacity and modes

B. Self Compacting Concrete of failure of the pre-cracked Reinforced Concrete (RC) push-

SCC flows under its own weight and does not require any off specimens. The tests were performed with pre-existing

external vibration for compaction, has revolutionized concrete crack along the shear plane of the push-off specimens prior to

placement. SCC, was first introduced in the late 1980‘s by the application of direct shear load. The shear transfer capacity

Japanese researchers [7], is highly workable concrete that can of push-off specimens has been extensively studied. It was

flow through restricted sections without segregation and found that the increase of reinforcement significantly

bleeding. Such concrete should have a relatively low yield increased the shear strength. Similar tests were conducted with

value to ensure high flow ability, a moderate viscosity to resist embedded reinforcing bar to study the strength and

segregation and bleeding, and must maintain its homogeneity deformation behaviour of normal and light weight concrete.

during transportation, placing. Researchers have set some Alan H. Mattock, L. Johal and H. C. Chow (1975)[12] It

guidelines for mixture proportioning of SCC, which include i) was observed that the shear transfer reinforcement need not be

reducing the volume ratio of aggregate to cementitious uniformly distributed over the shear plane but may be

material [7-8] (ii) increasing the paste volume and water- distributed so as to be more effective in resisting moment. If a

cement ratio (w/c); (iii) carefully controlling the maximum normal tension force acts across the shear plane, it may be

coarse aggregate particle size and total volume; and (iv) using provided for by providing reinforcement additional to that

various viscosity enhancing admixtures (VMA) [7]. Since, required for shear transfer and having yield strength equal to

self-compactibility is largely affected by the characteristics of the tension force. Failure was regarded as having occurred

materials and the mix proportions, it becomes necessary to when the load could not be increased further and slip

evolve a procedure for mix design of SCC. Okamura and increased rapidly The flexural cracks started in the top face of

Ozawa have proposed a mix proportioning system for SCC the stub column and propagated downward and towards the

[9]. shear plane. In some cases a flexural crack linked up with the

crack in the shear plane. If both moment and shear are to be

II. LITERATURE REVIEW transferred across a crack, then in order to be fully effective

The literature on the in plane shear behavior on NSC, SCC the shear transfer reinforcement should be located in the

and HSC is limited. However available literature were flexural tension zone. The shear friction provisions of Section

collected and systematically reviewed and presented as 11.15 of ACI 318-71 yield a conservative estimate of the shear

follows. Ravindra Gettu et al[10] reported in their study to transfer strength of reinforced concrete, both with and without

characterize the failure and toughness of SFRC subjected to a tension stress acting across the shear plane.

direct shear loading at the material level for NSC and HSC. K. Zilch and R. Reinecke(2000)[13] Studied the shear

They investigated about the shear stress that can be transferred joint between the HSC precast element and the NSC was

across an open crack is of great importance for fracture investigated. During the experiments, practicality and the

mechanics-based design approaches, where residual and/or effects of surface preparation were evaluated and different

equivalent shear strengths could be integrated along the roughening methods were compared. To estimate the actual

sections of the structural element subjected to shear to bond characteristics of a joint between a HSC and a NSC two

calculate its shear load-carrying capacity. The failure different tests were performed. The characteristics of adhesion

mechanism appeared to be governed by splitting-tension rather and micro-mechanical resistance were verified by applying

than by shear. Nevertheless, the tensile stresses were shear forces on non-cracked joints. The second push-off test

approximately an order of magnitude smaller than the shear measured the effects of shear friction and the relation between

stresses and, consequently, shear cracking was expected to crack displacement and shear capacity by using specimens

dominate the failure when tensile cracking was restrained by with a slant shear joint. As a result, recommendations for an

the fibers. application of HSC in combination with NSC cast –inplace

ISBN 978-93-82338-01-7 | © 2012 Bonfring

Proceedings of International Conference on Advances in Architecture and Civil Engineering (AARCV 2012), 21st – 23rd June 2012 171

Paper ID SAM200, Vol. 1

concrete are given. 2000 [3]

L. Mahmoud*, N. Shafiq, W. Thanoon(2008)[14] Table 1: Mix Design for Nsc/M20, Scc/M30 And Hsc/M70

investigated CFRP externally bonded to concrete elements Concrete

was an efficient technique to improve the structural behavior Material NSC(M20) SCC/M30

of such elements under cyclic loading. Fatigue life of Cement 290 228.57 450 Kg/ cu

strengthened specimens was increased for about (6-7) times Water 145 157.39 654.65 m cu

Kg/

that of unstrengthened ones. The main purpose of this paper is Fine m cu

Kg/

696 840 1000

to study the effectiveness of using CFRP to improve aggregates m cu

Coarse 1429 690.50 150 Kg/

performance of R.C elements under cyclic shear loading. The aggregate

W/C ratio 0.5 0.32 50 -m

failure occurred in brittle manner by rupture of concrete and

Fly Ash - 337 Kg/ cu

CFRP plates. Existing studies suggest that the main failure m cu

Super - 6.78 Kg/

mode of FRP-to-concrete joints in shear tests is cracking of

Plastisizer

VMA - m

concrete under shear, occurring commonly at a few

millimeters from the adhesive-concrete interface. The shear Workability Slump Abraham‘s Vee-

strength should be strong enough to avoid brittle shear failure 00mm flow cone bee 8

occurring before flexure failure. This is so-called strong Final secs.

diameter

shear— weak-flexure philosophy. Thus, the shear strength V. EXPERIMENTAL

630 mmPROCEDURE

should be evaluated first for R.C beams subjected to cyclic To understand the in-plane shear behavior of concrete

loads. It is evident that in members with shear-dominated using push-off specimen, 18 specimens were prepared 6 of

behavior the hysteretic loops are narrower than in the flexure- each grade, along with 9 companion cubes of each grade were

dominated slender members and attain a pronounced inverted tested at the Structural Laboratory of the Dept of Civil

S-shape. Engineering at M.S.R.I.T Bangalore. After series of

Pedro serna , Estefania Cuenca(2010)[16] investigated the preliminary tests with various configuration, such as the width

shear behavior of reinforced ‗Z‘ shaped push-off specimens of the loading bar, boundary conditions, mode of control, and

made off SCC and SCC with fibres. Firstly the specimens loading rate, the dimensions of specimen were chosen as

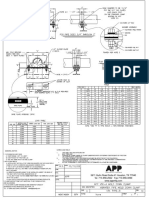

were precracked subjected to linear load along the shear plane. shown in Figure 1. Two notches of 75mm length were cut 60

Shear behavior along the shear plane was analyzed by means mm apart perpendicular to the axis of the specimen. Notch tips

of crack opening and shear displacement versus shear load define a vertical plane along which the load is applied, a shear

process. Analysis was focused on the study of aggregate crack is expected to occur along this plane. And therefore

interlocking. shear cracking is expected to dominate the failure if the tensile

cracking can be controlled. In the present set up, the distance

It was observed that the failure occurrence was better

between the notch tips is limited to 60mm in order to favour

controlled by the presence of fibers. It was also observed that

shear cracking while maintaining representive crack plane

the shear failure was more ductile. Shear failure of concrete

length.

elements can be brittle and fibers are able to increase the

ductility of concrete.

III. SCOPE OF INVESTIGATION

To obtain mix proportion for M30 and M70 SCC

concretes using 20mm and downsize.

Plain push off specimen were tested in the present

investigation to understand the in plane shear

behavior behaviour of M20NSC, M30SCC,

M70HSC

Comparison of shear stress values of different grades Figure 1: Push Off Specimen Dimensions

of concretes. The dimensions of the specimen is shown in Table 1

To observe the fracture surface of the tested

specimen for different grades of concretes. Table 1: Geometry of Specimen

NSC/20 20 150 150 260 75

IV. MATERIAL USED AND MIX PROPORTION

SCC/30 30 150 150 260 75

The constituent materials used in present experimental

work are as follows: Cement -53 grade OPC as per IS 12269, HSC/70 70 150 150 260 75

specific gravity = 3.15. Chemical admixture: Super plasticizer The specimen were casted using prism moulds of

– Napthalene based polymer (Conplast SP 430). Coarse 150x150x700mm, since the specimen used is only 260mm

aggregate – 20mm aggregate, specific gravity = 2.884, 10mm long the desired length of the prism was obtained by making

aggregate, specific gravity = 2.878, Fine aggregate: River partitions in the mould using steel plates. The mould was

sand, zone II, fineness module= 2.62, specific gravity = 2.605 lubricated with oil before casting. The edges of the mould

water absorption = 1.23% Water: potable water as per IS 456- were properly sealed using nut and bolt to prevent leakage of

ISBN 978-93-82338-01-7 | © 2012 Bonfring

Proceedings of International Conference on Advances in Architecture and Civil Engineering (AARCV 2012), 21st – 23rd June 2012 172

Paper ID SAM200, Vol. 1

cement slurry while casting of specimen. Standard procedure

has been followed for mixing, casting and curing of the test

specimens.

Figure 4: Surfacegranular Fracture of M20 (Inclined Crack)

Figure 2: Loading Arrangement

All the specimen were tested using universal testing

machine of 1000 kN capacity as shown in Figure 2. Two

notches of 75 mm length were cut 60 mm apart, perpendicular

to the axis of the specimen. The load is applied through steel

bars of 25 mm width,the fixed loading platens of the machine

and the bars to compensate for nonparallel loading surfaces.

The specimen to be tested was loaded symmetrically as shown

in Figure 2.

Figure 5: Failed Specimen

The ultimate shear stress of M20SCC was calculated and

tabulated as shown in Table 4 it has been observed from the

Table 3 and Table 4 the shear stress of M30SCC was less

compared over M20NSC

Figure 3: Transgranular Facture of HSC (Vertical Crack) Table 3: Ultimate Shear Stress of NSCM20

The compression test was conducted for determining the

shear strength of the specimen. Small increment of load is No Ultimate Area Ultimate Dispalce-

applied to bring the loading surface of the specimen with all Loading (mm2) Shear ment

attachment and then the load is released. Further small (kN) Stress mm

incriments of load was applied. First cracking load and (MPa)

ultimate load were observed. The entire testing of specimen 1 85 9000 9.44 1.7

requires 1.5 to 2 hours for all the specimens. On the day the 2 129.25 9000 14.36 1.1

specimen was tested, companion cubes were also tested to 3 120.3 9000 13.36 1.1

determine the concrete mean compressive strength (vide Table

2). 4 125.4 9000 13.93 1

MEAN 124.98 9000 13.88 1.06

The shear crack was vertical for HSC as shown in Fig 3

and it was not vertical for NSC represented in Fig 4 which

indicates the crack has passed through the aggregate in HSC

however in NSC crack has passed over the surface of the

aggregate. The failed specimen is shown in Fig 5 to observe

cracked surface. The ultimate shear stress of NSCM20 was

calculated and tabulated as shown in Table 3

Table 2: Cube Strength of Concretes

AVG 3 DAYS AVG 7 DAYS AVG 28

GRADE STRENGTH STRENGTH DAYS

(MPa) (MPa) STRENGTH

(MPa)

M20 12.35 16.13 30.53

M30 21.51 27.5 39.76

M70 39.7 58.6 75.5

ISBN 978-93-82338-01-7 | © 2012 Bonfring

Proceedings of International Conference on Advances in Architecture and Civil Engineering (AARCV 2012), 21st – 23rd June 2012 173

Paper ID SAM200, Vol. 1

Table 4: Ultimate Shear Stress of M30SCC [2] Chitra G.B ―Investigation on long term deflections of high strength

concrete beams‖ MTech Thesis, Dept. of civil engineering,

V.T.U,Belgaum 2005.

No Ultimate Area Ultimate Dispalcement [3] Ali Akbar Maghsoudi and Bengar Habib Akbarzade, ―Effect of tension

and compression reinforcement on the serviceability of HSC beams with

Loading (mm2) Shear mm relatively small Shear span to Depth Ratio‖ , The Arabian Journal for

(kN) Stress Science and engineering, vol32, Number2B.2007‖

(MPa) [4] Amer Bin Yusuff ― Behaviour of high strength reinforced concrete beam

1 87.8 9000 9.75 1.1 with metkaolin under static loading ― MTech Thesis ,Faculty of Civil

Engineering, University Technology Malaysia, APRIL 2005

2 76.4 9000 8.48 1.1 [5] BCA Academy ―Design guide of HSC to Singapore standards cp 65‖,BC

2,2008.

3 90.8 9000 10.08 1.2 [6] Meenakshi R.‖ Strength and deformability of high strength concrete

beams‖ MTech Thesis, Dept. of Civil Engineering, V.T.U, Belgaum

4 61.7 9000 6.85 1.3 2005.

5 91 9000 10.11 0.8 [7] Nagamoto N, Ozawa K ―Mixture properties of self compacting, high

performance concrete,proceedings‖ Third CANMET/ACI International

ME 86.5 9000 9.61 1.05 Conference on design and materials and recent concrete advances in

AN concrete technology, SP-172, V.M.Malhotra, ACI, Farminngton Hills,

Mich1997 , p623-637

[8] Khayat K.H , Ghezal A ―Utility of statistical models in proportioning

self-compacting concrete‖, proceeding, RILEM international symposium

on self compacting concrete, Stockholm,1999 p 345-359.

VI. OBSERVATIONS AND CONCLUSIONS [9] Okamura H, Ozawa K ―Mix design for self-compacting concrete‖‘

concrete library of Japanese society of civil engineers, june 1995, p107-

The specimens of NSC, SCC and HSC were tested using 120

push-off specimen and the following observations and [10] Bryan Barragán, Ravindra Gettu, Luis Agulló, and Raúl Zerbino ―Shear

conclusions are made. Failure of Steel Fiber-Reinforced Concrete Based on Push-Off Tests‖

ACI Materials Journal/July-August 2006.

Characterization of materials is very important for the mix [11] Sagaseta and Vollum ―Influence of aggregate fracture on shear transfer

proportion of concrete. through cracks in reinforced Concrete‖ Magazine of Concrete Research

Volume 63 Issue 2, Feb 2011

It was found that trail mixing is very much essential

[12] Alan H. Mattock,L. Johal and H. C. Chow ―Shear transfer in reinforced

before arriving at the final mix proportion. concrete with moment or tension acting across the shear plane‖ PCI

Workability of concrete is very important (there is no JOURNAL/July-August 1975,p 76-93

point doing research for the concrete with no workability) [13] K. Zilch and R. Reinecke ―capacity of shear joints between high-

strength precast Elements and normal-strength cast-in-place decks‖

The 28days strength of NSC/M20, SCC/M30 and Department of Concrete Structures, Technische Universität

HSC/M70 concrete was observed to be 30.52MPa, München,Munich, Germany.

39.76MPa and 75.5MPa respectively. [14] L. Mahmoud, N. Shafiq, M. F. Nuruddinl, W. Thanoon ―Interaction

Between CFRP Laminates and R.C Element subjected to Cyclic Shear

The first crack initiates on one of the notch faces at

Loading‖ ICCBT 2008 - C - (29) - pp319-326

approximately the notch tip and propagate towards the tip [15] J. Jayaprakash, Abdul Aziz Abdul Samad, Ashrabov Anvar Abbasvoch

of the other notch some of the specimens failed in above ―Experimental Investigation on Shear Capacity of Reinforced Concrete

the groove Precracked Push-off Specimens with Externally Bonded Bi-Directional

Carbon Fibre Reinforced Polymer Fabrics‖ Modern Applied Science,

It was observed that surface granular fracture for NSC Vol. 3, No. 7 ,p 86-98

and trans granular fracture was observed for HSC. [16] Pedro serna, Estefania Cuenca ―shear behavior of self compacting

As the grade of concrete increases the peak load increased concrete and fibre reinforced concrete using push-off specimen‖

gradually while deformation decreased gradually. design,placement ,production of self consolidating concrete,RILEM

Bookseries 1(2010), p429-437.

The shear stress of NSC/M20 , SCC/M30 and HSC/M70 [17] Bureau of Indian standards ―Design Aid to reinforced concrete IS 456-

are 10.05MPa, 9.61MPa and 13.88MPa respectively. 2000‖

Increase in shear stress with increase in concrete grade [18] Perumal and Sundararajan (2003), ―Experimental investigation on High

Performance Concrete using silica fume and superplasticizer‖,

was observed. Proceedings of the Incontest 2003.z e

Since the fines are more in SCC therefore shear stress [19] J. A. Hofbeck, I. O . Ibrahim and Alan H. Mattock‖ Shear Transfer in

compared over NSC observed to be less. Reinforced Concrete‖ Journal Proceedings,v66 p 119-128

The ultimate deformation decreases with increase in the

grade of the concrete.

ACKNOWLEDGEMENT

We acknowledge the support of Management of MSRIT,

Principal, HOD, Faculty and staff of Civil Dept in particular

we express our deep sense of gratitude to Mr Pramod and Mr

Srinivasan R.

REFERENCES

[1] ―State of art report on HSC‖ American concrete institute ACI363r-

92.1992

ISBN 978-93-82338-01-7 | © 2012 Bonfring

Vous aimerez peut-être aussi

- Effect of Tension Lap Splice On The Behavior of High Strength Self Compacted Concrete BeamsDocument10 pagesEffect of Tension Lap Splice On The Behavior of High Strength Self Compacted Concrete BeamsMaruf MuhammadPas encore d'évaluation

- 1 Shear fb73Document10 pages1 Shear fb73Dr.K.Rajeswara RaoPas encore d'évaluation

- MBTDocument21 pagesMBTMamaru ManayePas encore d'évaluation

- 1 s2.0 S235201242300108X MainDocument13 pages1 s2.0 S235201242300108X MainSaidronaPas encore d'évaluation

- 19J018 Synopsis Phase-2Document15 pages19J018 Synopsis Phase-2GopiPas encore d'évaluation

- C StructuralRehab BlackDocument3 pagesC StructuralRehab Blackimde2Pas encore d'évaluation

- 3 - (VIP) Behavior of RC Beams With Tension Lap Splices Confined With Transverse Reinforcement Using Different Types of Concrete Under Pure BendingDocument14 pages3 - (VIP) Behavior of RC Beams With Tension Lap Splices Confined With Transverse Reinforcement Using Different Types of Concrete Under Pure Bendingsokamantyyahoo.com.phPas encore d'évaluation

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaPas encore d'évaluation

- Engineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemDocument13 pagesEngineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemprasanthPas encore d'évaluation

- 1 s2.0 S1687404814000972 MainDocument12 pages1 s2.0 S1687404814000972 MainAhmed AjelPas encore d'évaluation

- Experimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024Document13 pagesExperimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024KRISHNA MURARIPas encore d'évaluation

- Testing and Numerical Modelling of Steel-Concrete - Steel With Stud Bolts ConnectorsDocument22 pagesTesting and Numerical Modelling of Steel-Concrete - Steel With Stud Bolts ConnectorsGogyPas encore d'évaluation

- 1 s2.0 S0263823122006772 MainDocument18 pages1 s2.0 S0263823122006772 MainJeff DatinguinooPas encore d'évaluation

- ChemicalDocument8 pagesChemicalبركان معتصم مطشرPas encore d'évaluation

- ThesisDocument73 pagesThesisPrashant GargPas encore d'évaluation

- Flexural Behavior of Self-Compacting Concrete Beams Strengthened With Steel Fiber ReinforcementDocument11 pagesFlexural Behavior of Self-Compacting Concrete Beams Strengthened With Steel Fiber ReinforcementNurul'Ain Haniyun Mohamad FodziPas encore d'évaluation

- @constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Document11 pages@constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Phan Đào Hoàng HiệpPas encore d'évaluation

- 1 s2.0 S2352012419301985 MainDocument13 pages1 s2.0 S2352012419301985 MainSaidronaPas encore d'évaluation

- (Asce) st.1943-541x.0000973 78Document12 pages(Asce) st.1943-541x.0000973 78Marimuthu KaliyamoorthyPas encore d'évaluation

- Case Studies in Structural Engineering: Ammar N. Hanoon, M.S. Jaafar, Farzad Hejazi, F.N.A. Abd AzizDocument19 pagesCase Studies in Structural Engineering: Ammar N. Hanoon, M.S. Jaafar, Farzad Hejazi, F.N.A. Abd AzizWil Santander LPas encore d'évaluation

- EFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729Document10 pagesEFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729chaitanya krishnaPas encore d'évaluation

- Experimental Study On Shear Strength of High-Strength Concrete BeamsDocument8 pagesExperimental Study On Shear Strength of High-Strength Concrete BeamsHuda JawadPas encore d'évaluation

- An Experimental Investigation of The Stress-Strain Distribution in High Strength Concrete Deep BeamsDocument10 pagesAn Experimental Investigation of The Stress-Strain Distribution in High Strength Concrete Deep BeamsBurhan ManzoorPas encore d'évaluation

- Concrete StrengthDocument5 pagesConcrete StrengthJournalNX - a Multidisciplinary Peer Reviewed JournalPas encore d'évaluation

- Shear Strength of Normal and High-Strength Fiber Reinforced Concrete Beams Without StirrupsDocument9 pagesShear Strength of Normal and High-Strength Fiber Reinforced Concrete Beams Without StirrupsMsheer Hasan AliPas encore d'évaluation

- Predicting Pull-Out Behaviour of 4D 5D Hooked End Fibres Embedded in Normal-High Strength ConcreteDocument14 pagesPredicting Pull-Out Behaviour of 4D 5D Hooked End Fibres Embedded in Normal-High Strength ConcreteChristopher KevinlyPas encore d'évaluation

- Shear Strength of High-Strength Concrete Beams Modeling and DesignDocument7 pagesShear Strength of High-Strength Concrete Beams Modeling and Designchristian rodriguezPas encore d'évaluation

- Aslani2012 Bond SCCDocument20 pagesAslani2012 Bond SCCEslam Abd El-Latif SolimanPas encore d'évaluation

- Cement and Concrete Composites: M.J.H. Wijffels, R.J.M. Wolfs, A.S.J. Suiker, T.A.M. SaletDocument14 pagesCement and Concrete Composites: M.J.H. Wijffels, R.J.M. Wolfs, A.S.J. Suiker, T.A.M. SaletJulián Andrés PuentesPas encore d'évaluation

- Adom Asamoah2017Document11 pagesAdom Asamoah2017Jorge HernandezPas encore d'évaluation

- Crack Width Control with SHFRCCDocument12 pagesCrack Width Control with SHFRCCharshitPas encore d'évaluation

- Performance of channel and angle shear connectors in high strength concreteDocument11 pagesPerformance of channel and angle shear connectors in high strength concreteFernando CastañedaPas encore d'évaluation

- Research PaperDocument8 pagesResearch PaperMuhammad JunaidPas encore d'évaluation

- 10.5923.j.cmaterials.20120203.02Document10 pages10.5923.j.cmaterials.20120203.02ashenafiPas encore d'évaluation

- Efficient Assumption of Design Variables For Stress Ribbon FootbridgesDocument11 pagesEfficient Assumption of Design Variables For Stress Ribbon FootbridgesJORGE BARRERAPas encore d'évaluation

- Optimized Mix Design For 180 Mpa Ultra-High-Strength ConcreteDocument16 pagesOptimized Mix Design For 180 Mpa Ultra-High-Strength ConcreteAkashPas encore d'évaluation

- 7.KSCE Journal of Civil Engineering (2015)Document12 pages7.KSCE Journal of Civil Engineering (2015)Ahmet TükenPas encore d'évaluation

- Irjet V6i6579Document7 pagesIrjet V6i6579ShinkaSihhahPas encore d'évaluation

- Behaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignDocument8 pagesBehaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignAlper BuyukkaragozPas encore d'évaluation

- materials-15-04665Document19 pagesmaterials-15-04665ashenafiPas encore d'évaluation

- Engineering Structures: M.H. Lai, Y.W. Liang, Q. Wang, F.M. Ren, M.T. Chen, J.C.M. Ho TDocument17 pagesEngineering Structures: M.H. Lai, Y.W. Liang, Q. Wang, F.M. Ren, M.T. Chen, J.C.M. Ho TAdarsh Kumar ManwalPas encore d'évaluation

- Engineering Structures: J.C.M. Ho, J.Y.K. Lam, A.K.H. KwanDocument12 pagesEngineering Structures: J.C.M. Ho, J.Y.K. Lam, A.K.H. KwanGuilhermeFregoneziPas encore d'évaluation

- Seismic - Shear WallsDocument13 pagesSeismic - Shear WallsVasil GeorgievPas encore d'évaluation

- 1 s2.0 S2352710222009986 MainDocument21 pages1 s2.0 S2352710222009986 MainAngel Jesus Ñiquen SalgueroPas encore d'évaluation

- 1 s2.0 S2590123023000099 MainDocument9 pages1 s2.0 S2590123023000099 MainFijo MjPas encore d'évaluation

- Flexural Behavior of Prefabricated High-Strength Steel-Concrete Composite Beams With Steel Block ConnectorsDocument14 pagesFlexural Behavior of Prefabricated High-Strength Steel-Concrete Composite Beams With Steel Block ConnectorsSakib 31Pas encore d'évaluation

- A State of Art - Review of Composite Deck Systems: October 2016Document5 pagesA State of Art - Review of Composite Deck Systems: October 2016Prapa KaranPas encore d'évaluation

- Shear Strength Prediction For Reinforced Concrete Beams Without StirrupsDocument8 pagesShear Strength Prediction For Reinforced Concrete Beams Without Stirrupsjuan carlos molano toroPas encore d'évaluation

- Research 2Document11 pagesResearch 2chaitanya krishnaPas encore d'évaluation

- Journal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuDocument12 pagesJournal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuPrapa KaranPas encore d'évaluation

- Shear and Flexural Stiffnesses of Reinforced ConcrDocument19 pagesShear and Flexural Stiffnesses of Reinforced ConcrKillian WismanPas encore d'évaluation

- 1 s2.0 S2214509522001644 MainDocument12 pages1 s2.0 S2214509522001644 Mainadnan-651358Pas encore d'évaluation

- High Performance Repairing of Reinforced Concrete StructuresDocument7 pagesHigh Performance Repairing of Reinforced Concrete StructuresCarlos CallePas encore d'évaluation

- Flexural Behavior of RC Beams Strengthened With Steel Wire Mesh and Self-Compacting Concrete Jacketing D Experimental Investigation and Test ResultsDocument18 pagesFlexural Behavior of RC Beams Strengthened With Steel Wire Mesh and Self-Compacting Concrete Jacketing D Experimental Investigation and Test ResultsIbrahim HaddamPas encore d'évaluation

- Behavior of Steel Fiber-Reinforced Concrete Deep Beams With Large OpeningDocument12 pagesBehavior of Steel Fiber-Reinforced Concrete Deep Beams With Large OpeningSuman.SPas encore d'évaluation

- 10 1016@j JCSR 2020 105947 PDFDocument10 pages10 1016@j JCSR 2020 105947 PDFbistsushantPas encore d'évaluation

- Bond Strength and Transfer Length of Pre-Tensioned Bridge GirdersDocument17 pagesBond Strength and Transfer Length of Pre-Tensioned Bridge Girders429e10d421Pas encore d'évaluation

- Applications of High Strength Concrete For Highway BridgesDocument30 pagesApplications of High Strength Concrete For Highway Bridgesaji raPas encore d'évaluation

- Journal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariDocument24 pagesJournal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariMekides KassayePas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Predicting The Strength of Fiber Reinforced HighDocument16 pagesPredicting The Strength of Fiber Reinforced HighSilvio JúniorPas encore d'évaluation

- Aggregate Interlock Push-Off Test Results of Self-Consolodating Concrete (SCC) For Use in Infrastructure ElementsDocument7 pagesAggregate Interlock Push-Off Test Results of Self-Consolodating Concrete (SCC) For Use in Infrastructure ElementsSilvio JúniorPas encore d'évaluation

- Mohamad 2015Document14 pagesMohamad 2015Silvio JúniorPas encore d'évaluation

- Lam 2005Document12 pagesLam 2005Silvio JúniorPas encore d'évaluation

- Constantinescu H Jaes Issue2 2011Document6 pagesConstantinescu H Jaes Issue2 2011Silvio JúniorPas encore d'évaluation

- Jayapraksh, 2009Document14 pagesJayapraksh, 2009Silvio JúniorPas encore d'évaluation

- Dias Da Costa2011Document12 pagesDias Da Costa2011Silvio JúniorPas encore d'évaluation

- Push-Off Shear Strength With Inadequately Anchored Interface ReinforcementDocument9 pagesPush-Off Shear Strength With Inadequately Anchored Interface ReinforcementSilvio JúniorPas encore d'évaluation

- Experimental and Numerical Study On The Behaviour of RC and SFRC Push-Off SpecimensDocument18 pagesExperimental and Numerical Study On The Behaviour of RC and SFRC Push-Off SpecimensSilvio JúniorPas encore d'évaluation

- Rate Analysis BOOKDocument374 pagesRate Analysis BOOKSachin KothvalPas encore d'évaluation

- Non-slam check valve applicationsDocument5 pagesNon-slam check valve applicationsRicardo BarrosPas encore d'évaluation

- References 2009 ADocument8 pagesReferences 2009 ArizgazoPas encore d'évaluation

- Chair Making ProceduresDocument17 pagesChair Making ProceduresabduPas encore d'évaluation

- 2018 Excela-Flange BOBTAIL PDFDocument22 pages2018 Excela-Flange BOBTAIL PDFJimmy RojasPas encore d'évaluation

- Chiranj Shah Only Material - Rev1Document39 pagesChiranj Shah Only Material - Rev1RIMAL SHALWALAPas encore d'évaluation

- Versa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesDocument2 pagesVersa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesdeepaPas encore d'évaluation

- Identify clamp screw and wrench partsDocument18 pagesIdentify clamp screw and wrench partsFabian MogroPas encore d'évaluation

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaDocument21 pagesThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanPas encore d'évaluation

- Aalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51Document13 pagesAalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51kartik spectomsPas encore d'évaluation

- MEP Sanitary Fixtures Installation ChecklistDocument36 pagesMEP Sanitary Fixtures Installation ChecklistankurPas encore d'évaluation

- Thermal Conductivity and Hardened Behavior of Eco-Friendly Concrete Incorporating Waste Polypropylene As Fine AggregateDocument6 pagesThermal Conductivity and Hardened Behavior of Eco-Friendly Concrete Incorporating Waste Polypropylene As Fine AggregateShaker QaidiPas encore d'évaluation

- Ferrous MetalDocument26 pagesFerrous MetalEdbert TulipasPas encore d'évaluation

- SE SOVENT DESIGN MANUAL 101o New011007Document24 pagesSE SOVENT DESIGN MANUAL 101o New011007VishnuPas encore d'évaluation

- A Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarDocument23 pagesA Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarManu K MohanPas encore d'évaluation

- Exercises 6.1, 7.1, 8.1 and 9.1Document2 pagesExercises 6.1, 7.1, 8.1 and 9.1peter vanderPas encore d'évaluation

- Especificacion Tuberias R08Document226 pagesEspecificacion Tuberias R08Lenin Casanova CPas encore d'évaluation

- MTC PipeDocument1 pageMTC PipeMathavan ABMPas encore d'évaluation

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabePas encore d'évaluation

- Din 2463Document13 pagesDin 2463dunknown15Pas encore d'évaluation

- Lecture 1 Cement - AmanDocument25 pagesLecture 1 Cement - AmanAdharsh SelvarajPas encore d'évaluation

- Steel-1 7131Document1 pageSteel-1 7131H. BeatsPas encore d'évaluation

- Post-tensioned slab design criteriaDocument3 pagesPost-tensioned slab design criteriaShamim Ahsan Zubery100% (1)

- Bolted Bamboo Joints Reinforced With Fibers: SciencedirectDocument7 pagesBolted Bamboo Joints Reinforced With Fibers: SciencedirectMario Cruz BaPas encore d'évaluation

- Dartar Berat BesiDocument12 pagesDartar Berat BesiIskak UnoPas encore d'évaluation

- Series: Question BookletDocument32 pagesSeries: Question BookletRishant ThakurPas encore d'évaluation

- VTK Type B With Loads Table-Model-000Document1 pageVTK Type B With Loads Table-Model-000tylerstearnsPas encore d'évaluation

- Why materials matterDocument4 pagesWhy materials matterMoch RizaPas encore d'évaluation

- S1239 Epoxy Primer: DescriptionDocument2 pagesS1239 Epoxy Primer: DescriptionELEJONDO Pablo - VCPas encore d'évaluation

- Steel Material ScienceDocument15 pagesSteel Material Science04352Pas encore d'évaluation