Académique Documents

Professionnel Documents

Culture Documents

TSR (Root Type Blowers) PDF

Transféré par

igo badrTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TSR (Root Type Blowers) PDF

Transféré par

igo badrDroits d'auteur :

Formats disponibles

Roots Type Blowers

TSR

Printed on a recycled paper with soy ink -- Amenities from Technology

Evidence of our commitment to the environment for People and the Earth

ROOTS TYPE BLOWERS

TSR Series

Tsurumi TSR-series is a V-belt driven, roots type blower designed for compressing

air or creating vacuum. The precisely machined, well-balanced 3-lobe rotor reduces

the pulsating noise and vibration, and also it ensures stable performance.

The TSR-series is applicable to a wide variety of applications.

Applications Major Components & Specifications Performance Curves

• Wastewater Aeration

Discharge Bore mm 50 65 80 100 125 150 200

• Activated Sludge Process TSR2-50 TSR2-65 TSR2-80

Type Air

• Aquaculture Fluid min–1 min–1 min–1

Temperature 0 to 40℃ 4.0 9.0

• Combustion Furnace

Rotor 3-lobe, Spur Type 3.0

• Pneumatic Conveyance 8.0

Structure Shaft Seal Labyrinth

• Vacuum Packaging

Bearing Ball Bearings 3.0 7.0

Air Volume (m3/min)

Air Volume (m3/min)

Air Volume (m3/min)

Blower Casing Gray Cast Iron 2.0 6.0 2050

Accessories

2.2

2050

1.5

11

Shaft Chrome-molybdenum Steel 2050

3.

2.

1900

kW

3.7

5.

1900

3.

kW

7k

Material

5.

2k

kW

1900

5.

2.0 5.0

5k

5k

7k

• Silencer (Suction & Discharge)

7.

Rotor Gray Cast Iron

W

1750

kW

5k

1750

W

W

5k

W

1750

W

1600

W

• T-joint Gear Nickel-chrome-molybdenum Steel 1600 4.0 1600

1.0 1450 1450

1450

• Check Valve Type Drip-proof, Indoor Use 1300 1.0 1300 3.0

• Safety Valve Motor Pole 4-pole 1300

• Pressure Gauge Phase 3-phase 2.0

• Anti-vibration Joint Discharge Connection JIS 10kg/cm2 Flange 0 0 1.0

0 10 20 30 40 50 60 0 10 20 30 40 50 60 0 10 20 30 40 50 60

• Vibration Rubber Discharge Pressure (kPa) Discharge Pressure (kPa) Discharge Pressure (kPa)

• Anchor Bolt

Dimensions

TSR2-100 TSR2-125 TSR2-150

17

min–1 min–1 min–1

11.0 16 44

I H

10.0 15

40

14

9.0 13 36

1900

Air Volume (m3/min)

Air Volume (m3/min)

Air Volume (m3/min)

1900

2050 12

45

8.

8.0

15

JIS10kg/cm2 Flange 32

5k

1750

kW

1750

kW

1900 11

W

3.7k

15

K

5.5

37

11

7.5

7.0 28

kW

10 1600

kW

30

kW

11

1750 1600

kW

kW

W

22

kW

7.5

kW

18.

5.5

9

15k

E

kW

11kW

6.0 1450 24 1450

kW

1600

5kW

D

kW

W

8

5.0 1450 1300 1300

7 20

C

6 1150 1150

4.0 1300

16

5

3.0 4 12

H 4- J 0 10 20 30 40 50 60 0 10 20 30 40 50 60 0 10 20 30 40 50 60

L L

Discharge Pressure (kPa) Discharge Pressure (kPa) Discharge Pressure (kPa)

G

A

B Cross-Section

TSR2-200

Unit: mm No. Description min–1

48

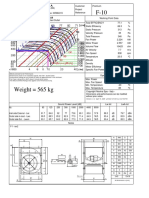

Model A B C D E F G H I J K L Weight (kg) 1 Shaft

TSR2-50 215 734 175 317 343 236 340 256 199 15 50 — 55 2 Side Cover 44

1450

3 17 2 6 4 2 13 20 10 12 11 3 Seal Case

TSR2-65 215 734 175 317 343 214 340 234 222 15 65 — 58

55

40

kW

Air Volume (m3/min)

TSR2-80 257 934 190 372 466 277 420 297 259 15 80 — 116 4 Main Casing 1300

37

36

45

TSR2-100 257 934 190 385 466 254 420 274 281 15 100 — 131 5 Oil Casing

kW

kW

6 Rotor

22k

1150

TSR2-125 303 1060 235 445 530 292 450 317 314 19 125 — 223 32

30

kW

W

TSR2-150 329 1190 250 521 570 341 600 366 385 19 150 — 362 7 Bearing 28

18

1000

TSR2-200 235 1100 305 646 703 439 730 469 464 19 200 550 547 8 Spur Gear

.5k

9 Oil Seal 24

W

Weight excluding motor and silencer

15

850

kW

10 Washer 20

11 Nut 700

16

Unit: mm 12 Oil Splash 0 10 20 30 40 50 60

Discharge Pressure (kPa)

Pipe Bore A B C D E F 13 Oil Plug

C 50 680 165 660 165 155 110 14 Oil Drain

B 65 680 165 660 165 175 115 15 Screw

80 760 216 185 130 19 9 7 1 16 14 18 15 8 5 16 Oil Gauge

E

780 216

A

17 Grease Fittings

D

100 830 268 760 268 210 135

125 1010 280 1190 350 250 170 18 Plate Spring

F 150 1150 350 1190 350 280 180 19 Pulley

< Suction Silencer > < Discharge Silencer > < Anti-vibration Joint > 200 1575 500 1735 525 330 210 20 O-ring

Selection Table

Model Suction air volume at standard condition (Qs in m3/min) and required power (La in kW)

Speed

Discharge 10kPa (1020mmH2O) 20kPa (2040mmH2O) 30kPa (3060mmH2O) 40kPa (4080mmH2O) 50kPa (5100mmH2O) 60kPa (6120mmH2O)

(min-1)

Bore in mm Qs La Qs La Qs La Qs La Qs La Qs La

1300 1.56 0.76 1.35 1.11 1.21 1.43 1.08 1.76 0.95 2.13 0.81 2.45

1450 1.79 0.88 1.58 1.25 1.42 1.60 1.27 1.97 1.12 2.35 1.00 2.73

TSR2-50 1600 2.02 0.95 1.80 1.38 1.65 1.79 1.49 2.21 1.35 2.64 1.23 3.06

(50) 1750 2.25 1.03 2.03 1.50 1.87 1.98 1.72 2.44 1.57 2.93 1.45 3.40

1900 2.51 1.13 2.27 1.66 2.10 2.18 1.94 2.71 1.77 3.25 1.64 3.77

2050 2.77 1.24 2.51 1.81 2.32 2.39 2.15 2.97 1.97 3.56 1.83 4.14

1300 2.04 1.00 1.79 1.42 1.59 1.79 1.39 2.18 1.25 2.53 1.08 2.80

1450 2.35 1.11 2.08 1.59 1.84 2.01 1.63 2.48 1.46 2.91 1.34 3.42

TSR2-65 1600 2.70 1.24 2.39 1.77 2.15 2.28 1.94 2.86 1.77 3.41 1.63 4.05

(65) 1750 3.04 1.37 2.70 1.95 2.46 2.55 2.25 3.24 2.07 3.91 1.92 4.67

1900 3.38 1.49 3.00 2.13 2.73 2.79 2.50 3.55 2.30 4.29 2.15 5.15

2050 3.71 1.62 3.29 2.31 3.00 3.02 2.75 3.86 2.54 4.66 - -

1300 4.32 1.56 3.92 2.40 3.56 3.09 3.27 3.77 2.97 4.37 2.74 5.24

1450 5.09 1.80 4.68 2.79 4.33 3.65 4.04 4.58 3.75 5.45 3.52 6.32

TSR2-80 1600 5.77 1.96 5.36 3.05 5.02 4.04 4.72 5.11 4.43 6.15 4.20 7.18

(80) 1750 6.46 2.12 6.05 3.31 5.70 4.43 5.40 5.64 5.12 6.85 4.88 8.05

1900 7.20 2.31 6.74 3.62 6.36 4.84 6.04 6.17 5.72 7.49 5.46 8.82

2050 7.94 2.51 7.44 3.93 7.02 5.25 6.68 6.69 6.33 8.14 6.04 9.60

1300 5.83 1.98 5.42 3.13 5.06 4.20 4.75 5.36 4.48 6.51 4.25 7.67

1450 6.71 2.21 6.31 3.50 5.96 4.72 5.65 5.93 5.37 7.22 5.13 8.52

TSR2-100 1600 7.56 2.39 7.16 3.83 6.81 5.23 6.50 6.62 6.22 8.01 5.98 9.44

(100) 1750 8.41 2.58 8.01 4.15 7.66 5.74 7.35 7.31 7.07 8.80 6.83 10.37

1900 9.35 2.81 8.91 4.52 8.53 6.25 8.19 7.98 7.88 9.59 7.62 11.32

2050 10.29 3.04 9.81 4.89 9.39 6.76 9.03 8.66 8.69 10.39 8.40 12.27

1150 7.97 2.58 7.49 4.16 7.06 5.72 6.69 7.29 6.45 8.87 6.15 10.45

1300 9.22 2.96 8.75 4.78 8.32 6.60 7.95 8.43 7.71 10.29 7.40 12.24

TSR2-125 1450 10.61 3.34 10.10 5.41 9.73 7.48 9.34 9.56 9.02 11.70 8.77 14.04

(125) 1600 11.87 3.68 11.36 5.97 10.99 8.25 10.60 10.55 10.28 12.96 10.03 15.48

1750 13.13 4.03 12.63 6.52 12.26 9.02 11.88 11.53 11.57 14.23 11.32 16.92

1900 14.66 4.42 14.16 7.13 13.79 9.90 13.42 12.70 13.12 15.74 - -

1150 21.65 6.05 20.52 10.01 19.48 14.10 18.77 18.32 18.06 22.48 17.34 26.58

1300 24.79 6.88 23.66 11.38 22.62 16.02 21.91 20.88 21.19 25.62 20.48 30.42

TSR2-150 1450 27.97 7.70 26.86 12.74 25.94 17.94 25.23 23.45 24.52 28.77 23.91 34.26

(150) 1600 31.11 8.50 30.00 14.20 29.08 20.00 28.37 26.16 27.66 32.13 27.05 38.14

1750 34.81 9.30 33.71 15.65 32.81 22.06 32.11 28.86 31.40 35.49 30.71 42.03

1900 38.71 10.15 37.55 17.09 36.59 24.08 35.86 31.56 35.15 38.89 - -

700 20.56 5.93 19.96 9.97 19.30 14.22 18.70 18.48 18.10 22.41 17.50 26.23

850 25.53 7.04 24.80 12.08 24.16 17.25 23.43 22.43 22.90 27.18 22.46 31.82

TSR2-200 1000 30.93 8.39 30.06 14.32 29.30 20.68 28.60 26.82 27.93 32.53 27.53 38.38

(200) 1150 35.93 9.74 35.06 16.38 34.30 23.78 33.60 30.85 32.93 37.41 32.53 44.14

1300 40.93 10.75 40.06 18.43 39.30 26.60 38.60 34.59 37.93 42.12 37.53 49.92

1450 47.19 11.76 46.33 20.47 45.23 29.43 44.33 38.33 43.76 46.83 - -

1.5kW 5.5kW 15kW 30kW 55kW

2.2kW 7.5kW 18.5kW 37kW

3.7kW 11kW 22kW 45kW

Note The above motors have been selected with minimum 5% margin.

The standard condition is difined as the temperature of 20℃, absolute pressure of 101.3kPa, and relative humidity of 65%.

In case of operating at 60kPa (6120mmH2O), please contact your dealer or Tsurumi representative.

We reserve the right to change the specifications and designs for improvement without prior notice.

Your Dealer

Printed in Japan CAT. IA105-A HB-E-G-Q

Vous aimerez peut-être aussi

- ROOT BLOWER SPEK TEKNIS Tsurumi-Tsr PDFDocument3 pagesROOT BLOWER SPEK TEKNIS Tsurumi-Tsr PDFmakmuntohirPas encore d'évaluation

- Lobe Pump Research PaperDocument10 pagesLobe Pump Research PaperReview DragonsPas encore d'évaluation

- Lab Manual Cycle 1Document66 pagesLab Manual Cycle 1Kaustubh SathePas encore d'évaluation

- Instructions BAH 6/10 to BAH 40/60 DI 6H to DI 40H BlowersDocument40 pagesInstructions BAH 6/10 to BAH 40/60 DI 6H to DI 40H BlowersvictoraghiPas encore d'évaluation

- TsurumiDocument3 pagesTsurumiRikrik Jajantara100% (1)

- Hibon PD BlowerDocument3 pagesHibon PD BlowerAbhinav SaiPas encore d'évaluation

- Atex A1-020-03-En PDFDocument8 pagesAtex A1-020-03-En PDFherrerafaridPas encore d'évaluation

- An Investigation of The Volumetric. Efficiency of A Roots BlowerDocument9 pagesAn Investigation of The Volumetric. Efficiency of A Roots BlowershreemugPas encore d'évaluation

- Sample Problem - Pump Power Calculations - EnggcyclopediaDocument6 pagesSample Problem - Pump Power Calculations - EnggcyclopediaMuhammadObaidullahPas encore d'évaluation

- Forced Draft BlowerDocument108 pagesForced Draft BlowerTrevor ChandlerPas encore d'évaluation

- Blower and Compressor Selection for Membrane AerationDocument42 pagesBlower and Compressor Selection for Membrane AerationSuryaprakashPas encore d'évaluation

- Ec Fans 2012 WebDocument14 pagesEc Fans 2012 WebOscar Alvitez DominguezPas encore d'évaluation

- Optical Coating Facilities Roots Blower Setup Operation MaintenanceDocument8 pagesOptical Coating Facilities Roots Blower Setup Operation Maintenancejamjam1062Pas encore d'évaluation

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalPas encore d'évaluation

- Calculating Aeration Flow and Pressure RequirementsDocument34 pagesCalculating Aeration Flow and Pressure RequirementsFelipe BrainPas encore d'évaluation

- Jet Pump Technical Data for Pumping GasesDocument11 pagesJet Pump Technical Data for Pumping GasesIdelia Cutipa Yauri100% (1)

- Blower Calculation ExampleDocument2 pagesBlower Calculation Exampledondapatikirankumar1Pas encore d'évaluation

- Training DuctingDocument20 pagesTraining Ductingpanji utePas encore d'évaluation

- Impeller DesignDocument6 pagesImpeller Design19MECH052 SYED YOUNUS100% (1)

- Centrifugal Fans GREENHECKDocument10 pagesCentrifugal Fans GREENHECKValentin LupascuPas encore d'évaluation

- Thermocompressors Improve Paper Machine Dryer DrainageDocument8 pagesThermocompressors Improve Paper Machine Dryer DrainageclintoncPas encore d'évaluation

- HandteFarr APC - Wet Scrubbers STZV, Catalogo)Document12 pagesHandteFarr APC - Wet Scrubbers STZV, Catalogo)mario aviles torresPas encore d'évaluation

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874Pas encore d'évaluation

- CRS Manual - PPPU PumpDocument27 pagesCRS Manual - PPPU PumpRishabh VermaPas encore d'évaluation

- FANS AT WORK IN BOILERS: CASE STUDIES ON FAN AND DRAFT SYSTEM DESIGNDocument23 pagesFANS AT WORK IN BOILERS: CASE STUDIES ON FAN AND DRAFT SYSTEM DESIGNAli BariPas encore d'évaluation

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Document2 pagesCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalPas encore d'évaluation

- Fan Selection Guide PDFDocument16 pagesFan Selection Guide PDFHarsh KhatriPas encore d'évaluation

- Measuring Flow with a Venturi MeterDocument11 pagesMeasuring Flow with a Venturi MeterPrakein RajPas encore d'évaluation

- Computer Assisted Design of Thermal Systems: Actual Compressor CalculationsDocument6 pagesComputer Assisted Design of Thermal Systems: Actual Compressor CalculationsmrinalbhadurioPas encore d'évaluation

- Testing and Balancing AcsDocument10 pagesTesting and Balancing Acsroshan jaiswalPas encore d'évaluation

- Comparing Pneumatic Spring Diaphragm and Cylinder ActuatorsDocument3 pagesComparing Pneumatic Spring Diaphragm and Cylinder ActuatorsVivi Oktavianti100% (1)

- Influence of The Nature of The Roots Blower On Pressure Fluctuations in A Fluidized BedDocument13 pagesInfluence of The Nature of The Roots Blower On Pressure Fluctuations in A Fluidized BedcoolcupidguyPas encore d'évaluation

- By Pass RotameterDocument6 pagesBy Pass Rotameterkrishna kumarPas encore d'évaluation

- Blower InformationDocument36 pagesBlower InformationshreemugPas encore d'évaluation

- Filter MaintenanceDocument6 pagesFilter MaintenanceTanmay MajhiPas encore d'évaluation

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimPas encore d'évaluation

- Coal FeedDocument8 pagesCoal FeedaakashtrivediPas encore d'évaluation

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistPas encore d'évaluation

- T30Document4 pagesT30V P Singh0% (1)

- Materials Used For Construction: 1. Reciprocating CompressorDocument6 pagesMaterials Used For Construction: 1. Reciprocating CompressorEdemPas encore d'évaluation

- Clarifications To NTPC CommentsDocument224 pagesClarifications To NTPC CommentsnishantPas encore d'évaluation

- Fan Selection SheetDocument1 pageFan Selection Sheetsamikhoury83Pas encore d'évaluation

- Performance Characteristics of Axial FansDocument4 pagesPerformance Characteristics of Axial Fanskutts76Pas encore d'évaluation

- Different Type Air DryerDocument9 pagesDifferent Type Air DryermishtinilPas encore d'évaluation

- Screw CompressorDocument2 pagesScrew CompressorRiti AdhikariPas encore d'évaluation

- CP PetDocument4 pagesCP PetjayeshPas encore d'évaluation

- Chapter-6 Fans and BlowersDocument62 pagesChapter-6 Fans and Blowersye htutkyawme100% (1)

- CAGI/PNEUROP BL 300-2016 Performance Test CodeDocument65 pagesCAGI/PNEUROP BL 300-2016 Performance Test Codeharry jangPas encore d'évaluation

- 1/2Document3 pages1/2konainglincho001Pas encore d'évaluation

- ThermExcel - Aeroduct USDocument12 pagesThermExcel - Aeroduct USTuankhanh DangPas encore d'évaluation

- Condenser 69-83Document15 pagesCondenser 69-83DIPAK VINAYAK SHIRBHATEPas encore d'évaluation

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarPas encore d'évaluation

- Surface Water Treatment Process A Review On Variou PDFDocument10 pagesSurface Water Treatment Process A Review On Variou PDFWilda Safira RahmaniaPas encore d'évaluation

- Fan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataDocument10 pagesFan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataany onePas encore d'évaluation

- Oprema Oprema: Staircase Swirl Diffuser, Type IRDocument3 pagesOprema Oprema: Staircase Swirl Diffuser, Type IRAnonymous KB3AksTpBPas encore d'évaluation

- ptd06 18enDocument2 pagesptd06 18enLuis LopezPas encore d'évaluation

- Engineering ManualDocument8 pagesEngineering ManualSreenubabu KandruPas encore d'évaluation

- Filter Engineering Standards, Regulations, Recommendations: Year Reference Type of Test ClassificationDocument4 pagesFilter Engineering Standards, Regulations, Recommendations: Year Reference Type of Test ClassificationDuy TùngPas encore d'évaluation

- Filter Engineering Standards, Regulations, Recommendations: Year Reference Type of Test ClassificationDocument1 pageFilter Engineering Standards, Regulations, Recommendations: Year Reference Type of Test ClassificationQuang nguyen duyPas encore d'évaluation

- Filter Engineering Standards, Regulations, Recommendations: Fed STD 209D - ISO 14644-1 GuideDocument1 pageFilter Engineering Standards, Regulations, Recommendations: Fed STD 209D - ISO 14644-1 GuideZalionPas encore d'évaluation

- Brosur - UF Membrane (A) PDFDocument8 pagesBrosur - UF Membrane (A) PDFigo badr100% (1)

- Surat Edaran Kewaspadaan COVID-19 - 20200302192555 PDFDocument3 pagesSurat Edaran Kewaspadaan COVID-19 - 20200302192555 PDFigo badrPas encore d'évaluation

- UF Module Parameters ComparisonDocument8 pagesUF Module Parameters Comparisonigo badrPas encore d'évaluation

- The inversion of the yield curve in the US this year has provided a stronger signal that an economic crisis in the US would happen sometime in mid of next yearDocument14 pagesThe inversion of the yield curve in the US this year has provided a stronger signal that an economic crisis in the US would happen sometime in mid of next yearigo badrPas encore d'évaluation

- Brosur EbaraDocument17 pagesBrosur Ebaraigo badrPas encore d'évaluation

- POMPADocument1 pagePOMPAigo badrPas encore d'évaluation

- The inversion of the yield curve in the US this year has provided a stronger signal that an economic crisis in the US would happen sometime in mid of next yearDocument14 pagesThe inversion of the yield curve in the US this year has provided a stronger signal that an economic crisis in the US would happen sometime in mid of next yearigo badrPas encore d'évaluation

- Legend STP FRP: A D B B C EDocument1 pageLegend STP FRP: A D B B C Eigo badrPas encore d'évaluation

- STP 10m3 Fibre-FabrikasiDocument1 pageSTP 10m3 Fibre-Fabrikasiigo badrPas encore d'évaluation

- Price List Accesories Ku - Pt. Mni 2019 PDFDocument3 pagesPrice List Accesories Ku - Pt. Mni 2019 PDFigo badrPas encore d'évaluation

- Vac Lt. Dasar PDFDocument1 pageVac Lt. Dasar PDFigo badrPas encore d'évaluation

- Arti Singkatan Notam PDFDocument0 pageArti Singkatan Notam PDFdeibzm100% (1)

- The STP Guide-Design, Operation and MaintenanceDocument74 pagesThe STP Guide-Design, Operation and MaintenanceRajesh ShenoyPas encore d'évaluation

- Codeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)Document1 pageCodeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)igo badrPas encore d'évaluation

- Flow Chart: Air BlowerDocument1 pageFlow Chart: Air Blowerigo badrPas encore d'évaluation

- Arti Singkatan Notam PDFDocument0 pageArti Singkatan Notam PDFdeibzm100% (1)

- Top Front View PDFDocument1 pageTop Front View PDFigo badrPas encore d'évaluation

- 2010 Final Exam (Answers)Document10 pages2010 Final Exam (Answers)T FPas encore d'évaluation

- Stanley I. Sandler: Equations of State For Phase Equilibrium ComputationsDocument29 pagesStanley I. Sandler: Equations of State For Phase Equilibrium ComputationscsandrasPas encore d'évaluation

- OCEN 201 Introduction To Ocean & Coastal EngineeringDocument28 pagesOCEN 201 Introduction To Ocean & Coastal EngineeringbalumaxPas encore d'évaluation

- PronunciationDocument5 pagesPronunciationHưng NguyễnPas encore d'évaluation

- Quenching & TemperingDocument4 pagesQuenching & Temperingkgkganesh8116Pas encore d'évaluation

- 8th Grade GT Science SyllabusDocument2 pages8th Grade GT Science Syllabusapi-420198655Pas encore d'évaluation

- Particulate Contamination in Aviation Fuels by Laboratory FiltrationDocument11 pagesParticulate Contamination in Aviation Fuels by Laboratory FiltrationMuhammad KhairuddinPas encore d'évaluation

- SCHEMACSC520Document3 pagesSCHEMACSC520fazaseikoPas encore d'évaluation

- Jason Capital Screw Jobs PDFDocument50 pagesJason Capital Screw Jobs PDFДжек П100% (3)

- eManmanualNo15623hark 599 Brochure - Eca PDFDocument2 pageseManmanualNo15623hark 599 Brochure - Eca PDFKimberly VillanuevaPas encore d'évaluation

- Airtel Case Study Channel StrategyDocument2 pagesAirtel Case Study Channel StrategyTushar GuptaPas encore d'évaluation

- Future Time ClausesDocument7 pagesFuture Time ClausesAmanda RidhaPas encore d'évaluation

- Measure RPA ROI with KPIsDocument4 pagesMeasure RPA ROI with KPIsAdnan FarooqPas encore d'évaluation

- Positive Role The Indian Youth Can Play in PoliticsDocument2 pagesPositive Role The Indian Youth Can Play in PoliticsArul ChamariaPas encore d'évaluation

- Soil Compaction: A. General PrinciplesDocument6 pagesSoil Compaction: A. General PrinciplesIcha EstradaPas encore d'évaluation

- ASME PTC 6 - 1996 Steam Turbine Performance Test CodeDocument124 pagesASME PTC 6 - 1996 Steam Turbine Performance Test CodeKristianPas encore d'évaluation

- Investment Banking Interview Strengths and Weaknesses PDFDocument15 pagesInvestment Banking Interview Strengths and Weaknesses PDFkamrulPas encore d'évaluation

- GCMS-QF 15 - Calibration (IMTE) Form - MPSDocument7 pagesGCMS-QF 15 - Calibration (IMTE) Form - MPSMobin Thomas AbrahamPas encore d'évaluation

- Ethics PresentationDocument2 pagesEthics PresentationAbhinavGuptaPas encore d'évaluation

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanPas encore d'évaluation

- Department of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADDocument2 pagesDepartment of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADAbdul MalikPas encore d'évaluation

- IP BookDocument96 pagesIP Booknew mediaPas encore d'évaluation

- Digital Bending Machine User Manual - BD SeriesDocument7 pagesDigital Bending Machine User Manual - BD SeriesTatiane Silva BarbosaPas encore d'évaluation

- MSDS Chrome Catalyst Safety SheetDocument4 pagesMSDS Chrome Catalyst Safety Sheetstavros7Pas encore d'évaluation

- Analytical ExpositionDocument7 pagesAnalytical ExpositionEman FakotPas encore d'évaluation

- Conflict MangementDocument35 pagesConflict Mangementmadhuri_bind100% (1)

- GA 33 KV VCB HT Panel - Siddharth Nagar Project. UPDocument17 pagesGA 33 KV VCB HT Panel - Siddharth Nagar Project. UPaayushPas encore d'évaluation

- British Airways Case Study SolutionDocument2 pagesBritish Airways Case Study SolutionHassan ZafarPas encore d'évaluation

- Latka March2020 DigitalDocument68 pagesLatka March2020 DigitalDan100% (2)

- 7 Robert Boyle and Experimental Methods: © 2004 Fiona KisbyDocument8 pages7 Robert Boyle and Experimental Methods: © 2004 Fiona Kisbydaveseram1018Pas encore d'évaluation