Académique Documents

Professionnel Documents

Culture Documents

020-046 Watermain Thrust Block Details-Model

Transféré par

Wynle OrgilTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

020-046 Watermain Thrust Block Details-Model

Transféré par

Wynle OrgilDroits d'auteur :

Formats disponibles

STOP VALVE, DEAD END & TEE

THRUST BLOCK TABLE

FITTING THRUST BEARING FACE

NOM. SIZE (kN) AREA (m2)

HOT DIP GALVANISED 100 13.75 0.275

STRAP 150 29.05 0.581

200 49.86 0.997

225 62.03 1.241

250 75.58 1.512

300 110.23 2.203

Min.

400

BEND THRUST BLOCK TABLE

THREADED BAR HORIZ. BEND THRUST BEARING FACE

UNDISTURBED DEFL. NOM. DIA. (kN) AREA (m2)

BEARING FACE

MATERIAL BEARING BEARING UNDISTURBED 100 2.70 0.054

BEARING FACE UNDISTURBED FACE FACE MATERIAL 150 5.69 0.114

MATERIAL UP TO 200 9.77 0.195

11 1/4° 225 12.16 0.243

ELEVATION OF STOP VALVE PLAN OF TEE FITTING PLAN OF HORIZONTAL AND 250 14.83 0.297

300 21.62 0.432

THRUST BLOCK DETAIL THRUST BLOCK DETAIL ELEVATION OF CONCAVE VERTICAL

100 5.37 0.107

REFER TO STOP VALVE REFER TO TEE FITTING THRUST BLOCK DETAIL REFER 150 11.34 0.227

UP TO 200 19.45 0.389

THRUST BLOCK TABLE THRUST BLOCK TABLE TO BEND THRUST BLOCK 22 1/2° 225 24.22 0.484

FOR DIMENSIONS FOR DIMENSIONS TABLE FOR DIMENSIONS 250 29.51 0.590

c 300 43.04 0.861

LO 100 10.52 0.210

END CAP FP THRUST BLOCK TO BE CENTRED ON

IPE THRUST FORCE AND BEARING FACE 150 22.25 0.445

UP TO 200 38.16 0.763

UNDISTURBED TO BE AT RIGHT ANGLES TO IT

45° 225 47.51 0.950

MATERIAL 250 57.88 1.158

300 84.42 1.688

100 19.43 0.389

400

Min.

THRUST 150 41.10 0.822

ON SAME PLANE UP TO 200 70.50 1.410

90° 225 87.78 1.756

UNDISTURBED

UST B ISECTS

MATERIAL BEARING OF THR 250 106.96 2.139

FACE ANGLE BEND ANGLE 300 156.00 3.120

PIPE

CONVEX VERTICAL BEND ANCHOR BLOCK TABLE

ELEVATION OF CONVEX VERTICAL PLAN OF DEAD END BLOCK

HORIZ. BEND THRUST

P IPE DEFL. NOM. DIA. (kN) VOLUME

BEND ANCHOR BLOCK DETAIL THRUST BLOCK DETAIL cL OF (m3)

REFER TO CONVEX VERTICAL REFER TO DEAD END 100 2.70 0.115

150 5.69 0.242

ANCHOR BLOCK TABLE FOR DIMENSIONS THRUST BLOCK TABLE UP TO 200 9.77 0.415

11 1/4° 225 12.16 0.517

FOR DIMENSIONS DETAIL SHOWING TYPICAL THRUST FORCE 250 14.83 0.630

AND THRUST BLOCK 300 21.62 0.918

100 5.37 0.228

ANCHOR DETAILS 150 11.34 0.482

UP TO

NOTES 22 1/2°

200 19.45 0.826

SAND BEDDING AND SAND SURROUND NOT SHOWN ON VIEWS FOR SAKE OF CLARITY. BEND OR BOLT, NUT 225 24.22 1.029

No. BOLTS STRAP No.

BEARING FACE OF THRUST BLOCKS TO BE CAST AGAINST UNDISTURBED MATERIAL. BEARING FACE OF UNDISTURBED FITTING & WASHER

REQUIRED SIZE STRAPS 250 29.51 1.254

MATERIAL TO BE TRIMMED SQUARE TO THE DIRECTION OF THRUST AND ALL LOOSE MATERIAL REMOVED. NOM. DIA. SIZE 300 43.04 1.828

AN ALLOWABLE SOIL BEARING CAPACITY OF 50kPa HAS BEEN ASSUMED FOR THRUST BLOCK DIMENSIONING. 100 M20 2 50x8 1 100 10.52 0.448

THIS CAPACITY IS TYPICAL FOR SOFT CLAY. TO VARY BEARING AREA FOR DIFFERENT MATERIAL, 150 M20 2 50x8 1 150 22.25 0.945

CONSULT THE DESIGN ENGINEER. 200 M20 4 50x8 2 UP TO 200 38.16 1.621

225 M20 4 50x8 2 45° 225 47.51 2.018

ALL CONCRETE TO BE 20MPa. 250 M20 4 50x8 2 250 57.88 2.459

VALVE OR FITTING TO HAVE ONE LAYER OF PETROLATUM COMPOUND OR BITUMEN 300 M24 4 50x10 2 300 84.42 3.586

IMPREGNATED TAPE PLACED BETWEEN STRAP AND VALVE OR FITTING.

D. MAUNDER 31/08/2016

VALVE OR FITTING TO HAVE A BOND BREAKING LAYER PLACED BETWEEN THE VALVE OR FITTING

Dept of Public 1 1

AND THE CONCRETE BLOCK.

Infrastructure NTS

BOLTS ARE TO BE GRADE 230R HOT DIP GALVANISED ROUND BAR, THREADED AT ONE END

FOR SUFFICIENT LENGTH TO ALLOW GALVANISED WASHER AND NUT TO BE ATTACHED.

WATERMAIN A3 020-046

JB

BOLTS TO BE BENT WITH A STANDARD COG OR HOOK FOR THAT DIAMETER BAR.

BOLTS MUST NOT BE FULLY TIGHTENED UNTIL CONCRETE HAS AT LEAST ONE DAYS CURING STRENGTH CIM/PJN

AND BOLTS MUST NOT BE OVER TIGHTENED. THRUST BLOCK DETAILS MW 020-046.dwg 31/08/2016

Vous aimerez peut-être aussi

- NDS SD 208Document1 pageNDS SD 208mengineeringPas encore d'évaluation

- TOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkDocument14 pagesTOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkSumantra ChattopadhyayPas encore d'évaluation

- C22-YS20-S-7962 - A - Package Layout - PS2 PDFDocument1 pageC22-YS20-S-7962 - A - Package Layout - PS2 PDFsartajPas encore d'évaluation

- Design Calculation Report Shelter Guebiba BaseDocument35 pagesDesign Calculation Report Shelter Guebiba BaseAkram FerchichiPas encore d'évaluation

- Road CrossingDocument5 pagesRoad CrossingMahata PriyabrataPas encore d'évaluation

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document614 pagesAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13Pas encore d'évaluation

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EDocument361 pagesCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiPas encore d'évaluation

- 1.JMX-XXX-XX-CAL-001-00 Rev.B1Document18 pages1.JMX-XXX-XX-CAL-001-00 Rev.B1Farid Ferdiansyah Tambunan0% (1)

- Barabanki Stability AnalysisDocument2 pagesBarabanki Stability AnalysisAnonymous sfkedkymPas encore d'évaluation

- Chirukhistsqali Weir RHS Manhole Chamber Calculation ReportDocument36 pagesChirukhistsqali Weir RHS Manhole Chamber Calculation Reporthasan_kygszPas encore d'évaluation

- Specification For Concrete Work and GroutDocument29 pagesSpecification For Concrete Work and GroutAria ZulhamPas encore d'évaluation

- Comment Resolution SheetDocument1 pageComment Resolution SheetRenante GordovePas encore d'évaluation

- S AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Document17 pagesS AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Mohammad Al JedyPas encore d'évaluation

- Civil Works MtoDocument28 pagesCivil Works MtoNassim SabriPas encore d'évaluation

- Spreader Beam Design ExamplesDocument3 pagesSpreader Beam Design ExamplesBogdan DSAPas encore d'évaluation

- SP 10 16Document7 pagesSP 10 16Ak OraPas encore d'évaluation

- Watermain STD dwgs-101101 PDFDocument37 pagesWatermain STD dwgs-101101 PDFPete APas encore d'évaluation

- CS-Guide CalculationDocument27 pagesCS-Guide Calculationduf fuPas encore d'évaluation

- RCC51 Column Load Take-Down DesignDocument7 pagesRCC51 Column Load Take-Down DesignMohammad Twaha JaumbocusPas encore d'évaluation

- EXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100Document14 pagesEXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100CA JamesPas encore d'évaluation

- 3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalDocument6 pages3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalStacy JohnsonPas encore d'évaluation

- SC348-ME-FDN-006 - RE - Foundation DrawingDocument6 pagesSC348-ME-FDN-006 - RE - Foundation DrawingsajanPas encore d'évaluation

- Structural Design ManhoursDocument3 pagesStructural Design ManhoursSiva ShankarPas encore d'évaluation

- TORSION9Document13 pagesTORSION9Mukesh JangidPas encore d'évaluation

- DMI-DB-50-001-A4 Spec For Civil, Structural REv.2Document49 pagesDMI-DB-50-001-A4 Spec For Civil, Structural REv.2Adhitiya Rizki Pratama100% (1)

- Water MainDocument207 pagesWater MainPete A100% (1)

- Pipes. Wall Thickness Calculation According ASME - B31.3Document98 pagesPipes. Wall Thickness Calculation According ASME - B31.3acildePas encore d'évaluation

- SEPA15014 MFSTD CV 00 SPC 003 - Structural Steel Works - Rev 0Document26 pagesSEPA15014 MFSTD CV 00 SPC 003 - Structural Steel Works - Rev 0Pruthviraj JuniPas encore d'évaluation

- GSPL203-73-1513 R-0Document37 pagesGSPL203-73-1513 R-0api-3846497Pas encore d'évaluation

- GB1516 Sac 240 CV MS 0001 - 0Document12 pagesGB1516 Sac 240 CV MS 0001 - 0kkkkPas encore d'évaluation

- NER NER: Cable Duct To Electrical BuildingDocument1 pageNER NER: Cable Duct To Electrical Buildingsartaj100% (1)

- TP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp ReportDocument224 pagesTP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp Reportramesh_madkatte1082Pas encore d'évaluation

- Procedure of CrossingDocument68 pagesProcedure of Crossingrusli bahtiarPas encore d'évaluation

- 10753-Ep 4-1-1Document37 pages10753-Ep 4-1-1FcosmePas encore d'évaluation

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverDocument20 pagesNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapPas encore d'évaluation

- Geo5 Gabion Sample ReportDocument9 pagesGeo5 Gabion Sample ReportAhmadBadawiKasyfurRahmanPas encore d'évaluation

- STAAD GeneratorDocument5 pagesSTAAD GeneratorSrikanth SikhaPas encore d'évaluation

- 293-1-Spc-002 Specification For Grouting, Rev. ADocument10 pages293-1-Spc-002 Specification For Grouting, Rev. ABasitPas encore d'évaluation

- Hen 0000 Me SP 0003 - B4Document16 pagesHen 0000 Me SP 0003 - B4shervinyPas encore d'évaluation

- GB1516 Sac 240 CV RP 0004 - BDocument69 pagesGB1516 Sac 240 CV RP 0004 - BkkkkPas encore d'évaluation

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Miscellaneous - 077154C 000 JSS 2000 003 - CDocument7 pagesMiscellaneous - 077154C 000 JSS 2000 003 - CStructures ProductionPas encore d'évaluation

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318Pas encore d'évaluation

- Igat6 D PL Pi SPC 0002 Rev02 Spec For Prefabricated Hot BendDocument22 pagesIgat6 D PL Pi SPC 0002 Rev02 Spec For Prefabricated Hot Bendamini_mohiPas encore d'évaluation

- Nioec SP 00 04 PDFDocument21 pagesNioec SP 00 04 PDFamini_mohiPas encore d'évaluation

- Nitoseal 777 PDFDocument4 pagesNitoseal 777 PDFmilanbrasinaPas encore d'évaluation

- April 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument25 pagesApril 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeToni Garrote FerreroPas encore d'évaluation

- Control Building Static Calculations: Design of Roof Beam 02 CalculationDocument21 pagesControl Building Static Calculations: Design of Roof Beam 02 Calculationisaacjoe77Pas encore d'évaluation

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGDocument36 pages(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikPas encore d'évaluation

- 00 MS Cofferdam Rev 1Document11 pages00 MS Cofferdam Rev 1williamPas encore d'évaluation

- GA-EN-TS00-PR-SPE-001-0 Specification For Surge Relief PackageDocument21 pagesGA-EN-TS00-PR-SPE-001-0 Specification For Surge Relief PackageChesterPas encore d'évaluation

- Weld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is AdequateDocument9 pagesWeld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is Adequatechristian abogadoPas encore d'évaluation

- Reinforced Underground Valve ChamberDocument2 pagesReinforced Underground Valve ChamberchrisPas encore d'évaluation

- Engineering Services by KBR Technical Services, IncDocument23 pagesEngineering Services by KBR Technical Services, IncswatkoolPas encore d'évaluation

- Ga of Ot Module PDFDocument1 pageGa of Ot Module PDFBalaji YPas encore d'évaluation

- Chilled Water and Condensor Water Pump Head CalculaitonDocument3 pagesChilled Water and Condensor Water Pump Head CalculaitonYusuf RampPas encore d'évaluation

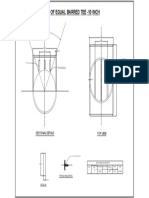

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocument1 pageFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Bore Log - Final1Document5 pagesBore Log - Final1Rakesh RoshanPas encore d'évaluation

- Section A-A End View of Assembly Top View of Assembly: 27134PSLADocument1 pageSection A-A End View of Assembly Top View of Assembly: 27134PSLAmoma52Pas encore d'évaluation

- Am-2692 PVC Joint Plate NovoDocument1 pageAm-2692 PVC Joint Plate Novovictor moacoPas encore d'évaluation

- Budget Meal 3.0Document7 pagesBudget Meal 3.0Wynle OrgilPas encore d'évaluation

- CS Form No. 212 Personal Data Sheet RevisedDocument4 pagesCS Form No. 212 Personal Data Sheet RevisedJean Castro76% (106)

- Acknowledgement Receipt 20190526 151008Document2 pagesAcknowledgement Receipt 20190526 151008Arman PenalosaPas encore d'évaluation

- Mondo Liquid Seal BrochureDocument2 pagesMondo Liquid Seal BrochureWynle OrgilPas encore d'évaluation

- SAP B1 IIS InstallDocument21 pagesSAP B1 IIS InstallHilal RidoPas encore d'évaluation

- Elasticsearch PyDocument107 pagesElasticsearch Pysrinivas eevuriPas encore d'évaluation

- LogDocument7 pagesLoglialove085Pas encore d'évaluation

- Acing Systems of Industrial Buildings (Lecture 2)Document14 pagesAcing Systems of Industrial Buildings (Lecture 2)Ovidiu GalPas encore d'évaluation

- Manual Do ProprietárioDocument51 pagesManual Do ProprietárioRonaldo FariaPas encore d'évaluation

- Case Study - Floating HousesDocument6 pagesCase Study - Floating HousesAkari MeiPas encore d'évaluation

- R0 - Internal Electrical-BoqDocument11 pagesR0 - Internal Electrical-Boqshruti widhaniPas encore d'évaluation

- Brochures I NXDocument12 pagesBrochures I NXZeeshanPas encore d'évaluation

- Introduction To Structural EngineeringDocument45 pagesIntroduction To Structural EngineeringAizha JhayPas encore d'évaluation

- The EU Approach Towards: Co-Operative Systems For Safer and More Efficient Transportation EnvironmentDocument37 pagesThe EU Approach Towards: Co-Operative Systems For Safer and More Efficient Transportation EnvironmentHarshith ShettyPas encore d'évaluation

- 1012 Command Line InterfaceDocument795 pages1012 Command Line Interfaceanon_263153185100% (2)

- DSR 07-LatestDocument165 pagesDSR 07-LatestRamakrishna MahantiPas encore d'évaluation

- Citylink Manual RevDDocument153 pagesCitylink Manual RevDVassiliy PevnevPas encore d'évaluation

- 4 3 OSPF Solution PDFDocument6 pages4 3 OSPF Solution PDFnzabanita64Pas encore d'évaluation

- Request For Quotation (RFQ) Amendment 1: Mechanical Design"Document47 pagesRequest For Quotation (RFQ) Amendment 1: Mechanical Design"Saptarshi RoyPas encore d'évaluation

- SingleRAN GSM UMTS LTE - New Product Introduction v2.0Document9 pagesSingleRAN GSM UMTS LTE - New Product Introduction v2.0angicar100% (3)

- Working Drawings HandbookDocument124 pagesWorking Drawings Handbookshipwreckwave100% (3)

- Artemis Korkokiou - Architect Engineer - 2014Document76 pagesArtemis Korkokiou - Architect Engineer - 2014Gregory MoralesPas encore d'évaluation

- Architectural Research QuarterlyDocument9 pagesArchitectural Research Quarterlyananraj choudhuryPas encore d'évaluation

- MSP 430 F 2132Document81 pagesMSP 430 F 2132rickseltPas encore d'évaluation

- Thesis - 051 Chapter 5 Case Study PDFDocument19 pagesThesis - 051 Chapter 5 Case Study PDFpiangphet100% (1)

- How To Use Git With Android StudioDocument124 pagesHow To Use Git With Android StudioCHU KIMPas encore d'évaluation

- I2C Bus ManualDocument51 pagesI2C Bus Manualapi-26349602100% (6)

- LDAP TutorialDocument28 pagesLDAP Tutorialzorrito26Pas encore d'évaluation

- Red Hat Enterprise Linux-7-SELinux Users and Administrators Guide-En-USDocument172 pagesRed Hat Enterprise Linux-7-SELinux Users and Administrators Guide-En-USNawfel GzamPas encore d'évaluation

- Materials of Floating Architecture DissertationDocument59 pagesMaterials of Floating Architecture DissertationJCB100% (7)

- EUROPA 2 - EuroconfortDocument4 pagesEUROPA 2 - EuroconfortPeradPas encore d'évaluation

- 2.13 Transmittal Log (PO-PGB-MUWH-0001) (VDL)Document32 pages2.13 Transmittal Log (PO-PGB-MUWH-0001) (VDL)zhangPas encore d'évaluation

- Geometry in Islamic ArtDocument21 pagesGeometry in Islamic ArtGülüş Art GeometryPas encore d'évaluation

- As5506 - AADL - V1.6 03152008 Merged PHF PDFDocument342 pagesAs5506 - AADL - V1.6 03152008 Merged PHF PDFjuanblas86Pas encore d'évaluation