Académique Documents

Professionnel Documents

Culture Documents

50mm Thick Lean Concrete

Transféré par

104 project0 évaluation0% ont trouvé ce document utile (0 vote)

369 vues2 pages50mm thick lean concrete

Titre original

50mm thick lean concrete

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document50mm thick lean concrete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

369 vues2 pages50mm Thick Lean Concrete

Transféré par

104 project50mm thick lean concrete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

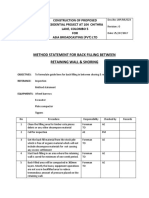

CONSTRUCTION OF PROPOSED Doc.

No: LHP/MS/013

RESIDENTIAL PROJECT AT 104 CHITHRA Revision:0

LANE, COLOMBO 5

FOR Date: 30//03/2017

ASIA BROADCASTING (PVT) LTD

METHOD STATEMENT OF SCREED CONCRETING FOR PILE CAPS,

FOOTINGS, BASE OF LIFT WELLS AND WALL FOUNDATIONS

OBJECTIVES: To formulate guide lines for placing, compacting and finishing of concrete work.

REFERANCE: Drawings

Tech. specifications and BS1881

Inspection and test plan

QA check list

EQUIPMENTS: Batching plant / Concrete mixer

Agitator trucks / Wheel barrows

Crane and skip buckets or pump car

Poker vibrators / Tampers

No Procedure Responsibility Checked by Records

1 Set out the pile cap allowing reasonable Foreman AE

working space & erect foam work 15mm thick

plywood & GI pipes including necessary brazing

to prevent collapsing of soil to working area.

2 Placing of 150mm thick layer of quarry dust or Foreman AE

quarry muck around pile cap

3 Establish bottom level of the pile cap around Foreman AE

the area add or remove quarry dust or quarry

muck and prepare the surface to the level

4 Fix and arranged the working platforms, guard Safety Officer AE

rails, ramps maintaining the safety requirement

to before proceeding concrete work

5 Request for inspection AE SM

6 Once obtaining the approval order ready mix Forman TO/AE

concrete or arrange the site mix according to

the grade & type as per specification.

7 Casting of cubes for testing AE SM

8 Pour & laid concrete well rammed/vibrate by Foreman AE

using a steel or wooden tamper/poker vibrator.

9 Coordinate with plant for avoid delays if use TO AE

ready-mix concrete.

9 Level the top surface using wooden floats & Forman AE

Trowel.

10 Ensure the HSE during the entire process Safety officer SM

OUTPUT RECORDS:

1 Laboratory test report

2 Ready mix dispatch

3 Pre inspection for concreting

Prepared by Approved by

Signature

Name Haritha Jayasinghe Rohith Thirimavithana

Designation AE SM

Date 31-03-2017 31-03-2017

Vous aimerez peut-être aussi

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

- Method Statement For Fixing of Water BarsDocument2 pagesMethod Statement For Fixing of Water Bars104 projectPas encore d'évaluation

- 50mm Thick Lean ConcreteDocument2 pages50mm Thick Lean Concrete104 projectPas encore d'évaluation

- MS372M006 Concreting of Pile Caps, Footing Foundation, Lift Base and Wall FoundationsDocument2 pagesMS372M006 Concreting of Pile Caps, Footing Foundation, Lift Base and Wall Foundations104 projectPas encore d'évaluation

- Method Statement For Back Filling Between Retaining Wall & ShoringDocument3 pagesMethod Statement For Back Filling Between Retaining Wall & Shoring104 projectPas encore d'évaluation

- Method Statement For Repairing of Unusual Formation of Concrete Walls & ColumnsDocument2 pagesMethod Statement For Repairing of Unusual Formation of Concrete Walls & Columns104 projectPas encore d'évaluation

- Construction Method Statement for Building LinesDocument2 pagesConstruction Method Statement for Building Lines104 projectPas encore d'évaluation

- A-Z Engineering & Management Services: Check Sheet For BlockworksDocument1 pageA-Z Engineering & Management Services: Check Sheet For BlockworkszawadimranPas encore d'évaluation

- 03.MOS For Suport Erection For Chilled Water Pipe-2Document5 pages03.MOS For Suport Erection For Chilled Water Pipe-2Jeeva ManiPas encore d'évaluation

- MS Building Earthining SystemDocument2 pagesMS Building Earthining System104 projectPas encore d'évaluation

- C8516-CLT-QMT-0033 - Rev-00 Inspection Checklist For Paving Block InstallationDocument1 pageC8516-CLT-QMT-0033 - Rev-00 Inspection Checklist For Paving Block InstallationJabin100% (1)

- MST-Gypsum Board Installation To CeilingDocument5 pagesMST-Gypsum Board Installation To Ceilingadeniyi abiolaPas encore d'évaluation

- Plumbing and Fire-fighting ChecklistsDocument25 pagesPlumbing and Fire-fighting ChecklistsUnna Malai50% (2)

- CP 300 (A) - QCP-040 Interlock Concrete Paving Blocks InstallatDocument7 pagesCP 300 (A) - QCP-040 Interlock Concrete Paving Blocks InstallattarekPas encore d'évaluation

- Water Supply Scheme Method StatementDocument19 pagesWater Supply Scheme Method StatementShahab KhanPas encore d'évaluation

- CP 300 (A) - QCP-039 Installation of Ceramic Floor TilesDocument6 pagesCP 300 (A) - QCP-039 Installation of Ceramic Floor TilestarekPas encore d'évaluation

- Checklist For BrickworkDocument1 pageChecklist For BrickworkzawadimranPas encore d'évaluation

- C8516-CLT-QMT-0032 - Rev-00 Inspection Checklist For Kerbstone Installation WorksDocument1 pageC8516-CLT-QMT-0032 - Rev-00 Inspection Checklist For Kerbstone Installation WorksJabin100% (2)

- SKEB-ED-MS-002 (Method Statement For Piling Work, 06.09.2021)Document52 pagesSKEB-ED-MS-002 (Method Statement For Piling Work, 06.09.2021)Tira LakPas encore d'évaluation

- CP 300 (A) - QCP-049 Repair of Ground Floor Slab & Wall ExpansiDocument6 pagesCP 300 (A) - QCP-049 Repair of Ground Floor Slab & Wall ExpansitarekPas encore d'évaluation

- Precasting PSC Girder MethodologyDocument5 pagesPrecasting PSC Girder MethodologyAkhilesh Dwivedi50% (2)

- Checklist For Supervision of Reinforced Soil Wall PDFDocument4 pagesChecklist For Supervision of Reinforced Soil Wall PDFChin Thau WuiPas encore d'évaluation

- BQ-Piling N Pile CapDocument8 pagesBQ-Piling N Pile CapRubbyRd100% (2)

- DCTM-SOP-34140-FDN-Blowing The Shaft Bench-Rev. 04Document7 pagesDCTM-SOP-34140-FDN-Blowing The Shaft Bench-Rev. 04oscar andradePas encore d'évaluation

- Bored Pile Construction MethodDocument11 pagesBored Pile Construction MethodBrahmam GuruPas encore d'évaluation

- Checklist For VDFDocument1 pageChecklist For VDFGabriel GabePas encore d'évaluation

- Checklist - Reinforced Earth SoilDocument4 pagesChecklist - Reinforced Earth SoilGnabBangPas encore d'évaluation

- Work Procedure For Steel Fab & ErectionDocument5 pagesWork Procedure For Steel Fab & ErectionHiren Thakkar100% (1)

- Mathodologies of Various ActivityDocument17 pagesMathodologies of Various Activitynikunj patelPas encore d'évaluation

- Checklist For PlasteringDocument1 pageChecklist For PlasteringGururaj TavildarPas encore d'évaluation

- MS For Grouting ApplicationDocument20 pagesMS For Grouting ApplicationmarckePas encore d'évaluation

- Inspection report for grouting of 300 MW thermal power plant foundationDocument1 pageInspection report for grouting of 300 MW thermal power plant foundationRitesh kumarPas encore d'évaluation

- Check LisDocument3 pagesCheck Lishaneenapt94Pas encore d'évaluation

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikPas encore d'évaluation

- Metode Kerja PileCap and Ground FloorDocument13 pagesMetode Kerja PileCap and Ground FloorDio AgungPas encore d'évaluation

- Civil Works Abstract for Educational InstitutionDocument34 pagesCivil Works Abstract for Educational InstitutionyogeshPas encore d'évaluation

- Construction of Water Tanks Work InstructionDocument6 pagesConstruction of Water Tanks Work InstructionHiren ThakkarPas encore d'évaluation

- Interior & Exterior Plastering Method StatementDocument7 pagesInterior & Exterior Plastering Method StatementGabriel GabePas encore d'évaluation

- Good Construction Practise - Handouts - ConcreteDocument18 pagesGood Construction Practise - Handouts - Concretehitesh16Pas encore d'évaluation

- Check List For Excavation/ Pile Drilling: TP1000/OES/SEC/CW0001Document18 pagesCheck List For Excavation/ Pile Drilling: TP1000/OES/SEC/CW0001EngrAneelKumarAkhaniPas encore d'évaluation

- Method Statement 001 Civil Works Rev01Document5 pagesMethod Statement 001 Civil Works Rev01Christian Nicolaus MbisePas encore d'évaluation

- Request For Inspection ReportDocument8 pagesRequest For Inspection ReportArchie Joseph LlanaPas encore d'évaluation

- 4. Work Procedure Auger Bore Secant Pile Sta 8.600 Pt.ejjv -HjblDocument7 pages4. Work Procedure Auger Bore Secant Pile Sta 8.600 Pt.ejjv -Hjblejjv.indonesia.123Pas encore d'évaluation

- SS - Gen10 - Working On Gas LineDocument3 pagesSS - Gen10 - Working On Gas LinemadhulikaPas encore d'évaluation

- Installation Record: RCC PilesDocument12 pagesInstallation Record: RCC PilesErMelvinDiasPas encore d'évaluation

- MS Basement Slab Casting (Completed)Document72 pagesMS Basement Slab Casting (Completed)Hafiz Kamarudin100% (2)

- MS-B01 Roof Terrace Floor Crack RectificationDocument27 pagesMS-B01 Roof Terrace Floor Crack RectificationaruanPas encore d'évaluation

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleDocument10 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleImho TepPas encore d'évaluation

- Larsen & Toubro Limited - Ecc Division: Page 1 of 3Document3 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 3Akhilesh DwivediPas encore d'évaluation

- CP 300 (A) - QCP-038 Kerbs Pre-Casting & InstallationDocument7 pagesCP 300 (A) - QCP-038 Kerbs Pre-Casting & InstallationtarekPas encore d'évaluation

- Amended BOQ (Vol.3)Document103 pagesAmended BOQ (Vol.3)Herman NdauPas encore d'évaluation

- ChecklistDocument2 pagesChecklistbyleekkPas encore d'évaluation

- Erection Procedure For Floating Roof TankDocument10 pagesErection Procedure For Floating Roof Tankabdul1207100% (2)

- MOS-CVL-08Pile Foundation + Bentonite MOSDocument4 pagesMOS-CVL-08Pile Foundation + Bentonite MOSWaqar Ahmad MalikPas encore d'évaluation

- Grouts Standards and TestingDocument12 pagesGrouts Standards and TestingmithileshPas encore d'évaluation

- Name of Project: Structure MLCP + Commercial Building + Office (Poonamalle Side)Document36 pagesName of Project: Structure MLCP + Commercial Building + Office (Poonamalle Side)mohan sundarPas encore d'évaluation

- 3.RCC Structural Works MethodologyDocument9 pages3.RCC Structural Works MethodologyEyutt HghghPas encore d'évaluation

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosPas encore d'évaluation

- BH-04, Final ReportDocument16 pagesBH-04, Final ReportcivilceejiPas encore d'évaluation

- Method Statement For PCC & RCC WorksDocument11 pagesMethod Statement For PCC & RCC WorkspoovazhaganPas encore d'évaluation

- VO-32-SF Variation Conduit PathDocument1 pageVO-32-SF Variation Conduit Path104 projectPas encore d'évaluation

- Gypsum Board Ceiling ProfilesDocument26 pagesGypsum Board Ceiling Profiles104 projectPas encore d'évaluation

- Micro Schedule For External Painting 1702Document3 pagesMicro Schedule For External Painting 1702104 projectPas encore d'évaluation

- Micro Schedule and ProgressDocument4 pagesMicro Schedule and Progress104 projectPas encore d'évaluation

- Colombo Heart GF-Furniture Layout SchemeDocument1 pageColombo Heart GF-Furniture Layout Scheme104 projectPas encore d'évaluation

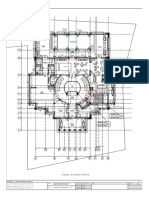

- Fist FloorDocument1 pageFist Floor104 projectPas encore d'évaluation

- Colombo Heart FF-Furniture Layout SchemeDocument1 pageColombo Heart FF-Furniture Layout Scheme104 projectPas encore d'évaluation

- THK Rate For DBDocument2 pagesTHK Rate For DB104 projectPas encore d'évaluation

- Colombo Heart SF-Furniture Layout SchemeDocument1 pageColombo Heart SF-Furniture Layout Scheme104 projectPas encore d'évaluation

- Micro Schedule For External Painting 1702Document3 pagesMicro Schedule For External Painting 1702104 projectPas encore d'évaluation

- Micro Schedule For Bath Room Work ProgressDocument2 pagesMicro Schedule For Bath Room Work Progress104 projectPas encore d'évaluation

- Micro Schedule For Bath Room WorkDocument2 pagesMicro Schedule For Bath Room Work104 projectPas encore d'évaluation

- Extended SlabDocument1 pageExtended Slab104 projectPas encore d'évaluation

- Ground FloorDocument1 pageGround Floor104 projectPas encore d'évaluation

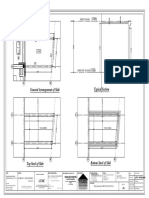

- Currected RF DetailsDocument1 pageCurrected RF Details104 projectPas encore d'évaluation

- Basement LayoutDocument1 pageBasement Layout104 projectPas encore d'évaluation

- Arch at Master Wash Room VanityDocument1 pageArch at Master Wash Room Vanity104 projectPas encore d'évaluation

- Door Painting Micro ScheduleDocument1 pageDoor Painting Micro Schedule104 projectPas encore d'évaluation

- 3rd FloorDocument1 page3rd Floor104 projectPas encore d'évaluation

- 2nd FloorDocument1 page2nd Floor104 projectPas encore d'évaluation

- Micro Schedule For Bath Room WorkDocument2 pagesMicro Schedule For Bath Room Work104 projectPas encore d'évaluation

- Door Painting Micro ScheduleDocument2 pagesDoor Painting Micro Schedule104 projectPas encore d'évaluation

- Trial MixDocument1 pageTrial Mix104 projectPas encore d'évaluation

- Micro Schedule and ProgressDocument3 pagesMicro Schedule and Progress104 projectPas encore d'évaluation

- MS For FW For Retaining Wall222Document2 pagesMS For FW For Retaining Wall222104 projectPas encore d'évaluation

- AgendaDocument1 pageAgenda104 projectPas encore d'évaluation

- THK Rate For DBDocument2 pagesTHK Rate For DB104 projectPas encore d'évaluation

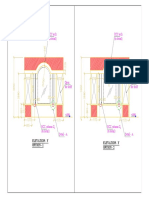

- Water BarsDocument1 pageWater Bars104 projectPas encore d'évaluation

- MS For Retaining Wall ConcretingDocument2 pagesMS For Retaining Wall Concreting104 projectPas encore d'évaluation

- MS For FW For Retaining Wall222Document2 pagesMS For FW For Retaining Wall222104 projectPas encore d'évaluation

- Password CrackingDocument13 pagesPassword CrackingBlue MagicPas encore d'évaluation

- Jodi Ridgeway vs. Horry County Police DepartmentDocument17 pagesJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsPas encore d'évaluation

- Air Cycle Refrigeration:-Bell - Coleman CycleDocument21 pagesAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- QDA Miner 3.2 (With WordStat & Simstat)Document6 pagesQDA Miner 3.2 (With WordStat & Simstat)ztanga7@yahoo.comPas encore d'évaluation

- Technical Skills:: Surabhi SrivastavaDocument3 pagesTechnical Skills:: Surabhi SrivastavaPrasad JoshiPas encore d'évaluation

- Payroll Canadian 1st Edition Dryden Test BankDocument38 pagesPayroll Canadian 1st Edition Dryden Test Bankriaozgas3023100% (14)

- Admission Checklist (Pre-) Master September 2021Document7 pagesAdmission Checklist (Pre-) Master September 2021Máté HirschPas encore d'évaluation

- Synopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaDocument5 pagesSynopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaAnu GraphicsPas encore d'évaluation

- Building A Computer AssignmentDocument3 pagesBuilding A Computer AssignmentRajaughn GunterPas encore d'évaluation

- Factory Hygiene ProcedureDocument5 pagesFactory Hygiene ProcedureGsr MurthyPas encore d'évaluation

- Quality Risk ManagementDocument29 pagesQuality Risk ManagementmmmmmPas encore d'évaluation

- The Punjab Commission On The Status of Women Act 2014 PDFDocument7 pagesThe Punjab Commission On The Status of Women Act 2014 PDFPhdf MultanPas encore d'évaluation

- nrcs143 009445Document4 pagesnrcs143 009445mdsaleemullaPas encore d'évaluation

- ADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationDocument22 pagesADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationAdrian SuPas encore d'évaluation

- Leyte Geothermal v. PNOCDocument3 pagesLeyte Geothermal v. PNOCAllen Windel BernabePas encore d'évaluation

- A. Readings/ Discussions Health and Safety Procedures in Wellness MassageDocument5 pagesA. Readings/ Discussions Health and Safety Procedures in Wellness MassageGrace CaluzaPas encore d'évaluation

- BCM Risk Management and Compliance Training in JakartaDocument2 pagesBCM Risk Management and Compliance Training in Jakartaindra gPas encore d'évaluation

- Lesson 3 - Materials That Undergo DecayDocument14 pagesLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- I-Parcel User GuideDocument57 pagesI-Parcel User GuideBrian GrayPas encore d'évaluation

- EDP/LRP Well Intervention System OverviewDocument22 pagesEDP/LRP Well Intervention System OverviewJerome LIKIBIPas encore d'évaluation

- Amos Code SystemDocument17 pagesAmos Code SystemViktor KarlashevychPas encore d'évaluation

- Renewable and Sustainable Energy ReviewsDocument13 pagesRenewable and Sustainable Energy ReviewsMohammadreza MalekMohamadiPas encore d'évaluation

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinPas encore d'évaluation

- Manual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteDocument94 pagesManual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteAlexandra DumitruPas encore d'évaluation

- 【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1Document36 pages【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1RioNorte LojaPas encore d'évaluation

- S4H - 885 How To Approach Fit To Standard Analysis - S4HANA CloudDocument16 pagesS4H - 885 How To Approach Fit To Standard Analysis - S4HANA Cloudwai waiPas encore d'évaluation

- Marketing Management NotesDocument115 pagesMarketing Management NotesKajwangs DanPas encore d'évaluation

- ThesisDocument18 pagesThesisapi-29776055293% (15)

- Article 4Document31 pagesArticle 4Abdul OGPas encore d'évaluation

- Survey Analyzes India's Toll Collection SystemsDocument15 pagesSurvey Analyzes India's Toll Collection SystemsmohitvermakspPas encore d'évaluation