Académique Documents

Professionnel Documents

Culture Documents

Static Structural Analysis of Crushing Rollers of Three Roller Sugar Mill IJERTV4IS051293

Transféré par

Sandeep YäðävCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Static Structural Analysis of Crushing Rollers of Three Roller Sugar Mill IJERTV4IS051293

Transféré par

Sandeep YäðävDroits d'auteur :

Formats disponibles

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

Static Structural Analysis of Crushing Rollers of

Three Roller Sugar Mill

Jitendra S. Khot Prof. M. B. Mandale

PG Student (CAD/CAM/CAE), Assistant Professor,

Dept. of Mechanical Engg. Department of Mechanical Engg.

Rajarambapu Institute of Technology Rajarambapu Institute of Technology

Islampur, India Islampur, India

Abstract— Sugarcane roller mill is the vital part of sugar Three rollers are used named as top, feed & discharge

industry. The main objective of milling is to separate the roller. The rollers are arranged in an isosceles triangle with

sucrose-containing juice from the cane. The extraction of juice a top angle of 720. The feed and discharge rollers are

in a mill is achieved by squeezing prepared cane between two placed at an angle of 35 & 37 respectively from the vertical

rolls. Finite Element Method is a numerical technique used to

below the top roller. The crushing of cane takes place first

carry out the stress analysis. In this method the solid model of

the component is subdivided into smaller elements, in top-feed roller and then in top-discharge roller. The shaft

constraints and loads are applied to the model. Geometrical of roller is made up of forged steel and shell of the roller is

model is created using 3D modeling software CATIA V5. The made up of cast iron. The shell is shrink fitted on the shaft.

static analysis of each component is carried out using analysis The power for crushing of sugarcane is given to the

software ANSYS WORKBENCH. The results for maximum top roller which rotates feed and discharge roller with

shear stress on the top, feed, discharge roller are calculated arrangement of pinion attached on one side of roller. The

analytically and compared with the results from software. direction of rotation of top and feed – discharge rollers is

Static analysis of all three rollers is done using different opposite. The D.C. power is given to the top roller for

materials for analyzing the variation in results. From these

crushing.

results conclusions were drawn.

Top roller is critical component amongst all. As the

Keywords— Crushing roller, Static analysis, Max. Shear drive torque, hydraulic load, crushing load is coming on the

stresss theory, ANSYS Workbench. top roller. The forces acting on the mill rolls give rise to

shearing, bending, torsion and compressive stresses. The

I. INTRODUCTION top roller is most highly stressed, since it consumes about

half of the mill torque. Out of total power 50% is taken by

The main objective of milling is to separate the sucrose- top roller, 35% is taken by discharge roller, 15% is taken

containing juice from the cane. The extraction of juice in a by feed roller [7].

mill is achieved by squeezing prepared cane between two

rolls. In three roller mill three rollers are arranged in II. LITERATURE REVIEW

triangular pattern for removing sucrose 95-97%. These

rollers are fed by two pressure feeder rollers which take Work related to static and dynamic analysis of crushing

prepared cane from a vertical chute and may be assisted by rollers by using the analysis software is very less.

an under feed roller at the exit from the chute. The

arrangement of rollers in three roller mill is as follows- A. B. Kakade et al. [1] investigated the friction and wear

behaviour of sugar mill roller shaft material EN8 under dry,

lubricated, contaminated, and Lubricated with

contaminated sliding conditions. As per their observations

wear is always on the top roller shaft. Initiation of crack

and wear on the surface of the shaft finally leads to crack

propagation. The conditions taken for experiment are same

as that of actual in industry. It is shown by result that

friction and wear volume increases in contaminated

condition. Also the very high weight of roller is only

responsible for failure of bearing.

Walmiki S Rathod et al. [5] has presented work related to

two roller sugar mill using FEA technique. They have

calculated bending moment analytically and by software.

Fig. No. 1– Three roller sugar mill [7] Also have given results that taper gives less value of stress

than the fillet.

IJERTV4IS051293 www.ijert.org 1521

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

. Radial component (Vertical) of force due to torque

M. Prabaharan et al. [4] has presented work related to (Fpv)= 705.566 KN

topology optimization. It is an optimization process which The load of crushing from discharge roller is acting at an

gives the optimum material layout according to the design angle of 530 from right side=590 tons=5900 KN

space and loading condition. The topology optimization is

applied to the 5 ton hydraulic press and scrap baling press The vertical component of load= 4711.94 KN

using ANSYS WORKBENCH. The weight of both press is The horizontal component of load=3550.7

reduced by 24%. They claimed 26.26 percent cost KN(left)

reduction in scrap baling press. Also they have developed

5ton hydraulic press with cost reduction of 24.54 %. The load of crushing from feed roller is acting at an angle

P. Dumbre et al.[3] has performed the structural analysis of of 550 from left side=275 ton=2750 KN

steering knuckle for weight reduction. The topology The vertical component of load=2252.668 KN

optimization is used for 11% weight reduction. The horizontal component of load=1577.3352 KN

HYPERMESH software is used for finite element (right)

modelling. The areas for redesign are located by optistruct

software. The weight of top roller is 32 ton which is acting

downwards.

S. Manokruang et al. [2] has presented Methodology of

Bus-Body structural redesign for lightweight productivity The total vertical load acting on the roller

improvement. Because of high bus structure there were = 6645KN

problem of high fuel consumption, high cost, low The total horizontal load acting on the roller

efficiency problem. The performance is increased by = 1973 KN

redesigning the structure of bus based on experts

knowledge. First the CAD model is generated by using The load of crushing is acting on the surface of roller so, it

CATIA & analysis is done by finite element method. The will be shown as uniformly distributed load on the loading

weight is reduced by taking out unnecessary elements. diagram-

III. THEORETICAL APPROACH Intensity of U.D.L. in vertical loading diagram

A. Analytical calculation for stresses on the top roller:-[6] (Wv)= (3)

The top roller is most highly stressed, since it consumes = 2.889 KN/mm

about half of the mill torque. The forces on the top roller

are because of power transmission, crushing, and hydraulic Intensity of U.D.L. in horizontal loading diagram

load. The loads on the roller are divided into horizontal and (Wh)= 0.8578 KN/mm

vertical component of loading.

Diameter of hydraulic Ram=460mm

Power(p)= 900 kw Oil pressure= 2.35 Kg/mm2

Roller Speed (n)= 5 rpm

Roller dia.= 1200 mm Total hydraulic load acting on the top roller

Shaft dia. at roller=710mm =2*Areaof piston*oil pressure (4)

Shaft dia. at bearing support=610mm

Shaft dia. at pinion=630mm = 2* (460)2 *2.35

Pitch circle dia. of crown pinion= 1136 mm = 7800KN

Drive torque = (1) Hydraulic load on each bearing=3900KN

= 1718.87 KNm 1) Vertical loading diagram:-

Out of the total torque 50% of torque is taken by top roller,

so-

Torque on the top roller= 859.435 KNm

Tangential component (Horizontal) of force due to torque

(Fph)= (2)

Fig. No.2 Vertical loading diagram

Fph =1513.0914 KN

IJERTV4IS051293 www.ijert.org 1522

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

Here,

L1= 650mm

4) Maximum shear stress:-

L=2300mm

L3=950mm According to maximum shear stress theory-[6]

L4=375mm

Fh1 and Fh2 are hydraulic forces =3900KN

Fpv=Vertical component of force due to torque=705.566 (5)

KN

= 101.306 N/mm2

W= Intensity of U.D.L= 2.889 KN/mm

Ra and Rg are reaction forces from bearing.

The material used for the roller is forged steel-

for forged steel Syt=380 N/mm2

After solving for vertical loading diagram-

Ra = 1469.257 KN Therefore Ssy=0.5*380=190 N/mm2 >

Rg = 391.308 KN Therefore shaft is safe according to maximum shear stress

Maximum bending moment is at point D = -4405.294 * 103 theory.

KN mm B. Analytical calculation for stresses on the Discharge

roller

2) Horizontal loading diagram:- Geometry and material of discharge roller is same as top

roller. The loads acting on the roller are due to crushing of

sugarcane between top and discharge roller and load due to

torque. Out of the total torque 35 % torque is taken by

discharge roller. The same procedure of horizontal and

vertical loading diagram is used for finding the value of

maximum shear stress.[7]

Resultant reaction at ‘a’ =6865.909 KN

Resultant reaction at ‘b’ = 2815.822 KN

Resultant bending moment at ‘D’ = 3301.950 * 103 KN

mm

Max. Shear stress = 75.3082 MPa

Therefore shaft is safe according to shear stress theory.[6]

Fig. No.3 Horizontal loading diagram

Here, C. Analytical calculation for stresses on the Feed roller:-

Fph=Horizontal component of force due to torque= Same Geometry and material of top roller is used for feed

1513.0914 KN roller. The loads acting on the roller are due to crushing of

sugarcane between top and Feed roller and load due to

W= Intensity of U.D.L= 0.8578 KN/mm torque. Out of the total torque 15 % torque is taken by Feed

Ra and Rg are reaction forces from bearing. roller. The same procedure of top roller is used for finding

the value of maximum shear stress.[7]

After solving for vertical loading diagram- Resultant reaction at ‘a’ =1568.6581 KN

Ra = 2898.879 KN Resultant reaction at ‘b’ = 1529.4969 KN

Resultant bending moment at ‘D’ = 1890.239 * 103 KN

Rg = 587.2119 KN mm

Maximum bending moment is at point A = -1437.436 * 103 Max. Shear stress = 42.8055 MPa

Therefore feed roller shaft is safe according to shear stress

KN mm theory.[6]

IV. THREE DIMENSIONAL CAD MODEL

3) Resultant of horizontal and vertical loading:- A three dimensional model of crushing roller is made

Resultant reaction at ‘a’ =3249.956 KN by using modeling software CATIA V5. CATIA is the

most powerful and widely used CAD software of its kind

Resultant reaction at ‘b’ = 705.648 KN in the world.

Resultant bending moment at ‘D’ = 4432.435 * 103 KN All three rollers i.e. top, feed and discharge roller

having same dimension and geometry.

mm

IJERTV4IS051293 www.ijert.org 1523

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

meshing. Total 1253187 elements and 1738482 nodes are

obtained after meshing.

Fig.No.4 3-D model of mill roller

V. FINITE ELEMENT APPROACH

The Finite Element Analysis (FEA) is a numerical Fig No.6 Meshing of Model

procedure for analysis of complicated shapes. In this

method the geometrical model is divided into small areas 2) Loading And Boundary conditions:-

called as elements. Each element is connected by some Boundary condition: - As roller is simply supported so all

nodes. Each node is having some degrees of freedom. degrees of freedom of roller are fixed at the bearing

Based on the no. Of nodes, degrees of freedom, material position.

properties element stiffness matrix is generated for each Loading Details:-

element. Stiffness matrixes of all elements are assembled The horizontal and vertical component of loads due to

for finding the stiffness matrix of component. Selection of crushing are applied on roller shell as Uniformly

type of element affects directly on the accuracy of results. Distributed Load (U.D.L).

Accuracy of result is increased either by increasing number Total vertical load= 6964.617 KN (up)

of element or by selecting higher order element. Total horizontal load= 1973 KN (left)

The Tangential (horizontal) and Radial (vertical)

A. Static Analysis of Top Roller:- components of load due to power transmission are applied

at pinion end of roller.

Static analysis of top roller is done for observing maximum Tangential Component = 1513.0914 KN

stresses and deformation of roller when different forces Radial Component = 705.566 KN

such as crushing, hydraulic, torque due to power Hydraulic load is applied at the bearing position. Which is

transmission etc. Are applied on it. Static structural 3900KN

analysis is done using ANSYS WORKBENCH. Standard earth gravity is applied). And is shown in fig.no-7

1) Mesh Generation:-

The CAD model in IGES format is imported in ANSYS

Workbench. Meshing is performed in the same software.

Meshing is the process of converting the model into

number of discrete parts called as element. SOLID187

element is used for meshing. It is higher order 3-D, 10-

node tetrahedral structural solid as shown in fig-no-5 [8]

Fig No7.- Loading and boundary condition details

Fig No.5 SOLID187 element[8]

3) Material Properties:-

The element has quadratic displacement behaviour and is

well suited to modelling irregular meshes(such as those Material for Crushing roller shaft is forged steel.

produced from various CAD/CAM systems). The element Material: - 40C8 steel

is defined by 10 nodes having three degree of freedom at Density: - 7850 Kg/m3

each node translations in the nodal X,Y,Z direction. Fine Modulus of Elasticity:- 200GPa

meshing is done at the portion where stress is maximum. Poisson’s ratio: - 0.3

10 mm mesh size is used for fine meshing and 30 mm for

Tensile yield strength: - 380 MPa

the area where stress is negligible. At the mesh size 10 &

30 mm stress values are nearly same so selected for Tensile ultimate strength: - 680 Mpa

IJERTV4IS051293 www.ijert.org 1524

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

4) Results of static analysis for top roller:- 1) Results of static analysis for discharge roller:-

Maximum shear stress, Total deformation are calculated as

static analysis results. Shown in below figures-

Fig.No8.- Maximum Shear Stress in top roller Fig. No. 10 Maximum Shear Stress in discharge roller

Maximum value of shear stress is 101.29 MPa which is at

bearing position of top roller. Maximum value of shear Maximum value of shear stress is 75.624 MPa which is at

stress is within limit so shaft is safe. Minimum value of bearing position of discharge roller. Maximum value of

shear stress is 1.7926e-4 MPa at bearing, shell and pinion shear stress is within limit so shaft is safe. Minimum value

end . of shear stress is 2.5069e-4 MPa at bearing, shell and

pinion end.

Fig.No9- Total deformation of top roller

Fig.No.11- Total deformation of Discharge roller

Maximum value of total deformation is 0.35016 mm at the

pinion end of top roller, which is within limit. Minimum Maximum value of total deformation is 0.24424 mm at

value of deformation is 0 mm which is at bearing position. pinion end of discharge roller.

B. Static Analysis of Discharge Roller:- C. Static Analysis of Feed Roller:-

CAD model, meshing, material, boundary conditions are CAD model, meshing, material, boundary conditions are

same as that of top roller. same as that of top roller.

The horizontal and vertical component of loads due to The horizontal and vertical component of loads due to

crushing are applied on roller shell as Uniformly crushing are applied on roller shell as Uniformly

Distributed Load (U.D.L). Distributed Load (U.D.L).

Total vertical load= 4711.949 KN (down) Total vertical load= 2252.668 KN (down)

Total horizontal load= 3550.708 KN (right) Total horizontal load= 1577.335 KN (left)

The Tangential (horizontal) and Radial (vertical) The Tangential (horizontal) and Radial (vertical)

components of load due to torque are applied at pinion end components of load due to torque are applied at pinion end

of roller. of roller

Tangential Component = 1059.1619 KN Tangential Component = 453.9269 KN

Radial Component = 493.895 KN Radial Component = 211.6695 KN

Standard earth gravity (self weight is applied). Standard earth gravity (self weight is applied).

IJERTV4IS051293 www.ijert.org 1525

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

1) Results of static analysis for Feed roller:- Maximum shear stress values by analytical calculations and

by software are nearly same, so results are validated.

VII. RESULTS OF STATIC ANALYSIS OF ROLLERS WITH

DIEFFERENT MATERIALS

Static analysis of all three rollers is done using different

materials for analyzing the variation in maximum shear

stress, total deformation and mass of the rollers. Results are

shown in below tables-

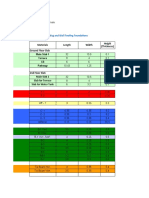

Table No.- 2 Results of static analysis for top roller

Material Max.shear Total Mass(Kg)

stress (MPa) defomation

(mm)

Forged Steel 101.29 0.35016 29283

Fig. No.12 Maximum Shear Stress in Feed roller

Aluminium 99.809 0.97192 10333

Maximum value of shear stress is 41.327 MPa which is at alloy

bearing position of feed roller. Maximum value of shear

Copper alloy 99.249 0.62969 30962

stress is within limit so shaft is safe. Minimum value of

shear stress is 2.6254e-4 MPa at bearing, shell and pinion Magnesium 98.66 1.5218 6714.6

end. alloy

Titanium alloy 98.025 0.71331 17234

Table No.- 3 Results of static analysis for discharge roller

Material Max.shear Total Mass(Kg)

stress (MPa) defomation

(mm)

Forged Steel 75.624 0.24424 29283

Aluminium 72.246 0.67589 10333

alloy

Copper alloy 72.416 0.43918 30962

Magnesium 70.296 1.0575 6714.6

alloy

Titanium alloy 69.859 0.4964 17234

Fig.No.13- Total deformation of Feed roller

Maximum value of total deformation is 0.10665 mm at Table No.- 4 Results of static analysis for Feed roller

pinion end of Feed roller. Material Max.shear Total Mass(Kg)

stress (MPa) defomation

VI. COMPARISON OF RESULTS (mm)

Maximum shear stress value by theoretical and numerical Forged Steel 41.327 0.10665 29283

are compared for validation of results.

Aluminium 39.636 0.29133 10333

Table No.-1 Comparison of results alloy

Roller Max. Shear stress Max. Shear stress

(By Analytical) MPa (By Software) MPa Copper alloy 39.799 0.19196 30926

Top Roller 101.306 101.29 Magnesium 38.678 0.45471 6714.6

alloy

Discharge Roller 75.3082 75.624

Titanium alloy 38.503 0.2149 17234

Feed Roller 42.8055 41.327

IJERTV4IS051293 www.ijert.org 1526

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 05, May-2015

VIII. CONCLUSIONS

3-D modeling and analysis is done for top, feed and

discharge roller both analytically and by software. Also

static analysis is done for different materials. From the

results it is concluded that-

1) Maximum shear stress value for top, feed and

discharge roller is less than yield strength in shear of

material so, all three shafts are safe.

2) As the value of max. Shear stress is very less than

yield strength in shear of material, so there is scope for

weight optimization.

3) Maximum shear stress values by analytical

calculations and by software are nearly same, so

results are validated.

4) Based on the total deformation and cost of raw

materials, forged steel is the best among given

materials.

5) As material is a changed value of max. Shear stress is

nearly same.

ACKNOWLEDGMENT

I would like to express my deep sense of gratitude towards

my co-guide Mr.Ankush Kadam (Vice President Design &

Engg. SAISIDHA Sugar Equipment & Engg.) For his

continuous encouragement and support and the valuable

feedback he provided throughout the project.

REFERENCES

[1] A.B. Kakade, Sudeep P. Ingole, Dhananjay V. Bhatt, Jyoti V.

Menghani (2013), Tribological behavior of sugar mill roller shaft in

laboratory simulated conditions, Wear 302 (2013) 1568–1572.

[2] S. Manokruang, S. Butdee, (2009) Methodology of Bus-Body

Structural Redesign for Lightweight Productivity Improvement,

AIJSTPME 2(2): 79-87.

[3] P. Dumbre, A. K. Mishra, V. S. Aher (2014), Structural Analysis of

Steering Knuckle for Weight Reduction, International Journal of

Emerging Technology and Advanced Engineering Volume 4, Issue

6, June 2014

[4] M. Prabaharan, V.Amarnath (2011), Structural Optimization of

5Ton Hydraulic Press and Scrap Baling Press for Cost Reduction by

Topology, International Journal of Modeling and Optimization, Vol.

1, No. 3, August 2011.

[5] Walmiki S.Rathod, Chetan T. Rathod (2012), Design and Analysis

of Two Roller Sugar mill using FEA Technique, International

Journal of Scientific Engineering and Technology, volume No. 1,

Issue No.3, pg:148-152

[6] V.B. Bhandari (2010), Design of machine element,Tata McGraw

Hill publications .

[7] E.Hugot (1986) Handbook of cane sugar engineering third edition,

Elsevier science publishers.

[8] ANSYS workbench help.

IJERTV4IS051293 www.ijert.org 1527

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Vous aimerez peut-être aussi

- Análisis Estructural Estático de Rodillos Trituradores de Molino de Azúcar de Tres Rodillos.Document8 pagesAnálisis Estructural Estático de Rodillos Trituradores de Molino de Azúcar de Tres Rodillos.Juan Altamirano RojasPas encore d'évaluation

- The Failure Analysis of Worm Wheel For Ash Brick Factory - A Case StudyDocument4 pagesThe Failure Analysis of Worm Wheel For Ash Brick Factory - A Case StudyMarlon TevePas encore d'évaluation

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument16 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologySai Krishna SKPas encore d'évaluation

- Failure Analysis of Camshaft - A ReviewDocument4 pagesFailure Analysis of Camshaft - A ReviewInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Wear Mechanism Analysis of Engine Exhaust Valve Seats With A Laboratory SimulatorZhao97Document11 pagesWear Mechanism Analysis of Engine Exhaust Valve Seats With A Laboratory SimulatorZhao97enjpetPas encore d'évaluation

- Failure Analysis of Bridle Roll Shaft Failure in Continuous Process IndustryDocument5 pagesFailure Analysis of Bridle Roll Shaft Failure in Continuous Process IndustryVipin KhangarPas encore d'évaluation

- Irjet-V8i12267 2Document7 pagesIrjet-V8i12267 2Om SinghPas encore d'évaluation

- Ijirt151158 Paper PDFDocument2 pagesIjirt151158 Paper PDFNukul MahajanPas encore d'évaluation

- R. D. S. O.: Summer Training ReportDocument16 pagesR. D. S. O.: Summer Training ReportLegendary AshPas encore d'évaluation

- Crack Cause Analysis of Pulverizing Wheel in Fan Mill of 600 MWDocument14 pagesCrack Cause Analysis of Pulverizing Wheel in Fan Mill of 600 MWPhoenix RomeoPas encore d'évaluation

- Measurement and Prediction of The Surface Temperature in Polymer Gears and Its Relationship To Gear WearDocument6 pagesMeasurement and Prediction of The Surface Temperature in Polymer Gears and Its Relationship To Gear WearAHMED WALIDPas encore d'évaluation

- Irjet V5i4722Document3 pagesIrjet V5i4722wendiezemene2124Pas encore d'évaluation

- Analyzing The Car Disc Brake Using A Combination of Modelling and Static Structural TechniquesDocument7 pagesAnalyzing The Car Disc Brake Using A Combination of Modelling and Static Structural TechniquesInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Ijme V5i11p104 PDFDocument3 pagesIjme V5i11p104 PDFRomiel CaballeroPas encore d'évaluation

- 3 IjmeitDocument10 pages3 IjmeitsenaPas encore d'évaluation

- 712-Article Text-1366-1-10-20210127Document6 pages712-Article Text-1366-1-10-20210127ssPas encore d'évaluation

- Design and Analysis of Ventilated Disc Brake by Using Different Materials and GeometryDocument11 pagesDesign and Analysis of Ventilated Disc Brake by Using Different Materials and GeometryInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Failure of CamshaftDocument3 pagesFailure of Camshaftsultanu89Pas encore d'évaluation

- Failure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillDocument7 pagesFailure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillymsyaseenPas encore d'évaluation

- Engineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunDocument10 pagesEngineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunBima SorayaPas encore d'évaluation

- 51Document9 pages51Dirajen Pullay MardayPas encore d'évaluation

- An Evaluation Method of Brake Pads For New Titanates - Kamada2009Document4 pagesAn Evaluation Method of Brake Pads For New Titanates - Kamada2009Diego ChavezPas encore d'évaluation

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedPas encore d'évaluation

- The Effect of Unbalance On Bearing LifeDocument8 pagesThe Effect of Unbalance On Bearing Lifemans2014100% (2)

- Irjet V7i3911Document7 pagesIrjet V7i3911The OpenstudioPas encore d'évaluation

- Impact of Piecing Index On Combed Yarn QualityDocument4 pagesImpact of Piecing Index On Combed Yarn QualityEditor IJTSRD100% (1)

- Test Rig Design and Testing Performance of Linear Ball BearingDocument6 pagesTest Rig Design and Testing Performance of Linear Ball BearingthisisjineshPas encore d'évaluation

- Abrasive Wear Behavior of Graphite Filled E-Glass Fibre Reinforced Polyester CompositesDocument4 pagesAbrasive Wear Behavior of Graphite Filled E-Glass Fibre Reinforced Polyester Compositesmsudheerm2002Pas encore d'évaluation

- Torsional Vibration DamperDocument5 pagesTorsional Vibration DamperSatbir SinghPas encore d'évaluation

- Hydrodynamic Journal BearingDocument3 pagesHydrodynamic Journal BearingJournalNX - a Multidisciplinary Peer Reviewed JournalPas encore d'évaluation

- Modeling and Stress Analysis of Crankshaft Using Fem Package AnsysDocument7 pagesModeling and Stress Analysis of Crankshaft Using Fem Package AnsysShreyas PaiPas encore d'évaluation

- Optimizing Gear Geometry For Minimum Transmission Error, Mesh Friction Losses and Scuffing Risk Through Computer - Aided EngineeringDocument10 pagesOptimizing Gear Geometry For Minimum Transmission Error, Mesh Friction Losses and Scuffing Risk Through Computer - Aided EngineeringGoffardPas encore d'évaluation

- Fatigue Analysis of An Automobile Wheel Rim: AbstractDocument10 pagesFatigue Analysis of An Automobile Wheel Rim: AbstractSagar APas encore d'évaluation

- Flatness Defect in Cold RollingDocument11 pagesFlatness Defect in Cold RollingEwo50 NewPas encore d'évaluation

- Crankshaft Failure Due To Fatigue-ADocument7 pagesCrankshaft Failure Due To Fatigue-Aaschutsehay0123Pas encore d'évaluation

- Static and Fatigue Simulation of Telescopic Fork Suspension System Used For MotorcycleDocument5 pagesStatic and Fatigue Simulation of Telescopic Fork Suspension System Used For MotorcycleRasbin SharmaPas encore d'évaluation

- Stress and Thermal Analysis of Clutch Plate: Udit Singhal, Rakshit Kumar and Ghogare Shubham ShursenDocument8 pagesStress and Thermal Analysis of Clutch Plate: Udit Singhal, Rakshit Kumar and Ghogare Shubham ShursenUdit SinghalPas encore d'évaluation

- IJE Volume 31 Issue 3 Pages 473-479Document7 pagesIJE Volume 31 Issue 3 Pages 473-479Juan AsarcadoPas encore d'évaluation

- Análisis de Fallas de Los Elementos de Una Junta Forzada Que Opera enDocument12 pagesAnálisis de Fallas de Los Elementos de Una Junta Forzada Que Opera enjohnny orePas encore d'évaluation

- Failure Analysis of An Automobile Coil SpringDocument8 pagesFailure Analysis of An Automobile Coil Springdarkace00000Pas encore d'évaluation

- Caterpillar Applied Failure Analysis Threaded Fasteners Service TrainingDocument9 pagesCaterpillar Applied Failure Analysis Threaded Fasteners Service Trainingcarolyn98% (44)

- International Journal of Engineering Technology Research & ManagementDocument8 pagesInternational Journal of Engineering Technology Research & ManagementSatish RengarajanPas encore d'évaluation

- Project FinalDocument16 pagesProject FinalEkta JaunjalPas encore d'évaluation

- The in Uence of Method and Environment in Torquing Screws Used in Bucket Wheel To Stacker-Reclaimer MachineDocument10 pagesThe in Uence of Method and Environment in Torquing Screws Used in Bucket Wheel To Stacker-Reclaimer MachinetuannbPas encore d'évaluation

- Tesla Wang 2014Document10 pagesTesla Wang 2014Anonymous SlyvspdBPas encore d'évaluation

- R. Nachoul - Flatness Defect in Thin Strip Cold Rolling and The Friction Impact On ItDocument11 pagesR. Nachoul - Flatness Defect in Thin Strip Cold Rolling and The Friction Impact On ItMochamad Kamal IhsanPas encore d'évaluation

- Re-Engineering of Stators of Three Phase Traction Motors Type 6FRA 6068 Used inDocument13 pagesRe-Engineering of Stators of Three Phase Traction Motors Type 6FRA 6068 Used inSridhar NarayananPas encore d'évaluation

- Design and Analysis of Chain Sprocket Using ReversDocument9 pagesDesign and Analysis of Chain Sprocket Using ReversAhmed MohamedPas encore d'évaluation

- Effects of Damping Parameters On Damping Force of Two Wheeler Front Suspension IJERTV2IS70190 PDFDocument9 pagesEffects of Damping Parameters On Damping Force of Two Wheeler Front Suspension IJERTV2IS70190 PDFvijayPas encore d'évaluation

- Analysis of An Intermediate Rear Axle Shaft Failure: January 2015Document4 pagesAnalysis of An Intermediate Rear Axle Shaft Failure: January 2015Ranjodh SinghPas encore d'évaluation

- Irjet V8i8150Document6 pagesIrjet V8i8150secularguy69Pas encore d'évaluation

- A Mechatronic Conception of A New Intelligent Braking SystemDocument6 pagesA Mechatronic Conception of A New Intelligent Braking SystemSunil YadavPas encore d'évaluation

- Stress Analysis in Wheel Rim by Using Dynamic Cornering Fatigue Test Under Different ConditionsDocument6 pagesStress Analysis in Wheel Rim by Using Dynamic Cornering Fatigue Test Under Different Conditionsesmaeel ghafariPas encore d'évaluation

- Cad14 PDFDocument7 pagesCad14 PDFvishalPas encore d'évaluation

- Irjet V4i6386Document7 pagesIrjet V4i6386MINDWORKZ MECHPas encore d'évaluation

- 01 - Failure Analysis of A Sugracane Loader Rear Shaft (Brazil-2020)Document8 pages01 - Failure Analysis of A Sugracane Loader Rear Shaft (Brazil-2020)Jose Martin ChaconPas encore d'évaluation

- Shock Absorber Test RigDocument14 pagesShock Absorber Test RigOmKar GunjalPas encore d'évaluation

- Design and Manufacturing of Hydro Pulper - 1604658130Document7 pagesDesign and Manufacturing of Hydro Pulper - 1604658130vanhuuduc102031Pas encore d'évaluation

- Effects of Residual Stress and Shape of Web Plate On The Fatigue LifeDocument15 pagesEffects of Residual Stress and Shape of Web Plate On The Fatigue Lifeabdurhman suleimanPas encore d'évaluation

- OPTIMIZATION OF MilLING PERFORMANCE OF A SUGAR Mil PDFDocument7 pagesOPTIMIZATION OF MilLING PERFORMANCE OF A SUGAR Mil PDFSandeep YäðävPas encore d'évaluation

- Arcing Electrodes For Sugar Mills: Special Product/Exclusive ProductDocument1 pageArcing Electrodes For Sugar Mills: Special Product/Exclusive ProductSandeep YäðävPas encore d'évaluation

- 0901d196807fe195 REP Brochure - 18072 EN - TCM - 12 455097 PDFDocument8 pages0901d196807fe195 REP Brochure - 18072 EN - TCM - 12 455097 PDFSandeep YäðävPas encore d'évaluation

- KJHGDocument18 pagesKJHGSandeep Yäðäv100% (1)

- Twilight PrincessDocument49 pagesTwilight PrincessHikari DiegoPas encore d'évaluation

- Niir Integrated Organic Farming Handbook PDFDocument13 pagesNiir Integrated Organic Farming Handbook PDFNataliePas encore d'évaluation

- Kinematics in One DimensionDocument4 pagesKinematics in One DimensionAldrin VillanuevaPas encore d'évaluation

- Updated G10 Class Routine Effective From 12 January 2023Document1 pageUpdated G10 Class Routine Effective From 12 January 2023NiloyPas encore d'évaluation

- Runyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechDocument28 pagesRunyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechThe New Vision50% (2)

- Fundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistDocument346 pagesFundamentals of Pain Medicine: Jianguo Cheng Richard W. RosenquistMayPas encore d'évaluation

- 2022 Audi e Tron 22Document318 pages2022 Audi e Tron 22Alejandro Alberto Robalino MendezPas encore d'évaluation

- Toshiba: ® A20SeriesDocument12 pagesToshiba: ® A20SeriesYangPas encore d'évaluation

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanPas encore d'évaluation

- Crouse Hinds XPL Led BrochureDocument12 pagesCrouse Hinds XPL Led BrochureBrayan Galaz BelmarPas encore d'évaluation

- Effects of Climate ChangeDocument3 pagesEffects of Climate Changejiofjij100% (1)

- Cynosure Starlux 500 Palomar Technical Service ManualDocument47 pagesCynosure Starlux 500 Palomar Technical Service ManualJF SilvaPas encore d'évaluation

- Rekomendasi AnimeDocument11 pagesRekomendasi Animeosvaldo manurungPas encore d'évaluation

- Better - Homes.and - Gardens.usa - TruePDF December.2018Document136 pagesBetter - Homes.and - Gardens.usa - TruePDF December.2018MadaMadutsaPas encore d'évaluation

- Data Bulletin Group Motor Installations:: Understanding National Electrical Code (NEC) 430.53 RequirementsDocument8 pagesData Bulletin Group Motor Installations:: Understanding National Electrical Code (NEC) 430.53 RequirementsshoaibPas encore d'évaluation

- IV. Network Modeling, Simple SystemDocument16 pagesIV. Network Modeling, Simple SystemJaya BayuPas encore d'évaluation

- 3200AMMe - Part 4Document207 pages3200AMMe - Part 4Tanja Kesic100% (1)

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocument25 pagesContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- Case Studies of Transportation Public-Private Partnerships Around The WorldDocument158 pagesCase Studies of Transportation Public-Private Partnerships Around The WorldzhenhuaruiPas encore d'évaluation

- Astm C892 - 00Document5 pagesAstm C892 - 00reneePas encore d'évaluation

- G1CDocument12 pagesG1CKhriz Ann C ÜPas encore d'évaluation

- Main Girders: CrossDocument3 pagesMain Girders: Crossmn4webPas encore d'évaluation

- The FOA Reference For Fiber Optics - Fiber Optic TestingDocument19 pagesThe FOA Reference For Fiber Optics - Fiber Optic TestingvsalaiselvamPas encore d'évaluation

- Bhil Tribal Mobilisation in AlirajpurDocument14 pagesBhil Tribal Mobilisation in Alirajpurrahul banerjeePas encore d'évaluation

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Document31 pagesArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008Pas encore d'évaluation

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsDocument5 pagesIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqPas encore d'évaluation

- 07ercoskun 05 01 PDFDocument23 pages07ercoskun 05 01 PDFjagmadridPas encore d'évaluation

- IMO Ship Waste Delivery Receipt Mepc - Circ - 645Document1 pageIMO Ship Waste Delivery Receipt Mepc - Circ - 645wisnukerPas encore d'évaluation

- GROSS Mystery of UFOs A PreludeDocument309 pagesGROSS Mystery of UFOs A PreludeTommaso MonteleonePas encore d'évaluation

- Shree New Price List 2016-17Document13 pagesShree New Price List 2016-17ontimePas encore d'évaluation