Académique Documents

Professionnel Documents

Culture Documents

PFA Plug Valves: 43 Series

Transféré par

AlexTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PFA Plug Valves: 43 Series

Transféré par

AlexDroits d'auteur :

Formats disponibles

www.swagelok.

com

P FA P lu g Val ves

43 Series

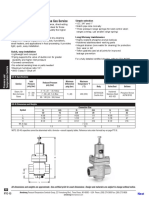

Features

■ Quarter-turn operation and full flow design.

■ Light in weight.

■ High-purity PFA material with low extractables for chemical

resistance.

■ 1/4 in. Swagelok® PFA tube fitting end connections for

consistent performance.

Oval handle indicates

open or closed position

Unique plug design

■ provides full flow

■ eliminates dead space

■ does not require system pressure

Positive handle to create a seal

stop ensures correct

■ is easily cleaned and purged

orifice position

1

Materials of Construction

Material Grade/

Component ASTM Specification 2

1 Handle insert➀

Bottom-loaded stem is One-piece body eliminates

2 Screw➀ PFA 440-HP

blowout-proof for safety multiple seal points

3 Handle➀ 3

Virgin PFA 440-HP/

Technical Data 4 Body, ferrules➀

D3307

Ordering Orifice Pressure Rating 5 Nut➀ PFA 440-HP

Number in. (mm) Cv at 70°F (20°C) Virgin PTFE/ 4

6 Stem

PFA-43S4 0.156 (4.0) 1.8 60 psig (4.1 bar) D1710

Lubricant PTFE-based

Wetted components listed in italics.

Pressure-Temperature Ratings ➀ Blue dyed.

5

Liquid Service Gas Service

Temperature

°F (°C) Working Pressure, psig (bar) Testing 6

0 (–17) to 50 (10) 60

(4.1) — Every 43 series PFA plug valve is

50

(10) to 70 (20) 60

(4.1) 60 (4.1) factory tested with nitrogen at two times

100 (37) 50

(3.4) 50 (3.4) the rated pressure for leakage at the

150 (65) 30

(2.0) 30 (2.0)

200 (93) 10

(0.68) —

seat to a maximum allowable leak rate of 0.1 std cm3/min. Body

seals are tested with helium at two times the rated pressure to

Operation in a stable temperature environment will maximize valve life

and performance.

a maximum allowable leak rate of 1 3 10 –3 std cm3/s.

Cleaning and Packaging

Flow Data at 70°F (20°C)

Every 43 series PFA plug valve is cleaned and packaged in

Pressure Drop to accordance with Swagelok Standard Cleaning and Packaging

Atmosphere (p) Air Flow Water Flow (SC-10), MS-06-62.

psi (bar) std ft3/min (std L/min) U.S. gal/min (L/min)

10

(0.68) 20

(566) 5.7

(21.5)

30

(2.0) 37

(1047) 9.9

(37.4)

60

(4.1) 62

(1755) 14.0

(52.9)

Dimensions Accessories

Dimensions, in inches (millimeters), are Panel Mount Bracket

for reference only and are subject to 316 stainless steel bracket enables To order a field assembly kit with

change. back or front mounting. mounting bracket and instructions, use

Ordering Number: PFA-43S4 To order a Swagelok PFA plug valve ordering number SS-MB-P43.

Weight: 0.13 lb (0.06 kg) with back mount assembly, add -PM to

the ordering number.

2.00

(50.8) Example: PFA-43S4-PM

Panel Hole Drill

Dimensions

1.25 7/32 (5.6) TYP

(31.8)

Not

required for

back mount

0.38 assembly

(9.7) 0.94 1.69

(23.8) (42.9)

2.53

(64.3) Back Mount Assembly 0.84

(21.4)

Dimensions shown with Swagelok nuts positioned

prior to swaging. Front Mount Assembly

Combined panel thickness and

screw head height above panel

must not exceed 1/4 in. (6.4 mm).

Other Swagelok PFA Products PFA Tubing PFA Tube PFA Needle

For more information about Swagelok PFA Fittings Valve

tubing and tools, see the Swagelok Hose

and Flexible Tubing catalog, MS‑01‑180.

For more information about Swagelok

PFA tube fittings, see the Swagelok

PFA Tube Fittings catalog, MS‑01‑05.

For more information about Swagelok

PFA needle valves, see the Swagelok

PFA Needle Valves catalog, MS-01-69.

Installation Instructions

PFA tubing MUST be grooved for use with PFA tube fittings. Use the Swagelok groove cutter tool.

1. Insert grooved PFA tubing into the 2. While holding fitting body steady, 3. Continue tightening until the nut and

Swagelok PFA tube fitting until a tighten the blue nut until there is no body hexes are aligned.

clicking sound is heard. gap between the nut and body hexes.

Safe Product Selection Warranty Information

When selecting a product, the total system design must Swagelok products are backed by The Swagelok Limited

be considered to ensure safe, trouble-free performance. Lifetime Warranty. For a copy, visit swagelok.com or contact

Function, material compatibility, adequate ratings, your authorized Swagelok representative.

proper installation, operation, and maintenance are the

responsibilities of the system designer and user.

Swagelok—TM Swagelok Company

© 2002–2010 Swagelok Company

Caution: Do not mix or interchange parts with those of Printed in U.S.A., GLI

other manufacturers. December 2010, R7

MS-01-56

Vous aimerez peut-être aussi

- PFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateDocument8 pagesPFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateOscar NavarroPas encore d'évaluation

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariPas encore d'évaluation

- High Pressure Full Flow Bi-Directional FilterDocument7 pagesHigh Pressure Full Flow Bi-Directional FilterOscar NavarroPas encore d'évaluation

- Leakage Detection Butterfly Valves L Line Sudmo LeafletDocument2 pagesLeakage Detection Butterfly Valves L Line Sudmo LeafletChemicalProgrammerPas encore d'évaluation

- Regulator HF Series (MS-01-156) R0Document4 pagesRegulator HF Series (MS-01-156) R0herysyam1980Pas encore d'évaluation

- Brochure HPKL9 Cross K10Document8 pagesBrochure HPKL9 Cross K10Andrian TamsirPas encore d'évaluation

- Needle Valves (MS 01 69) R4Document4 pagesNeedle Valves (MS 01 69) R4herysyam1980Pas encore d'évaluation

- Convoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1Document2 pagesConvoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1herysyam1980Pas encore d'évaluation

- Sanitary Fittings (MS 02 124 E) R2Document4 pagesSanitary Fittings (MS 02 124 E) R2herysyam1980Pas encore d'évaluation

- Datasheet TC5YCA-743Document2 pagesDatasheet TC5YCA-743AdrenalPas encore d'évaluation

- Asco Valve 8298a002 ReplacementDocument4 pagesAsco Valve 8298a002 ReplacementAugusto Leudo AngelPas encore d'évaluation

- SS CHF12 1Document1 pageSS CHF12 1prasad336Pas encore d'évaluation

- HF TETPOR HT-Rev 3ADocument2 pagesHF TETPOR HT-Rev 3AbuattugasmetlitPas encore d'évaluation

- Tomoe Valve-ManualDocument2 pagesTomoe Valve-Manualphuc nguyenPas encore d'évaluation

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongPas encore d'évaluation

- DR Fike Axius SCDocument3 pagesDR Fike Axius SCCamilaPas encore d'évaluation

- Ms-02-303 (1) Ball Valve General PurposeDocument8 pagesMs-02-303 (1) Ball Valve General PurposeYong Lin Albon TiongPas encore d'évaluation

- Hsro-390-Ff & Hsro-4040-FfDocument2 pagesHsro-390-Ff & Hsro-4040-FfYasser Mahmoud ZiadaPas encore d'évaluation

- Pumps DynaJet DatasheetDocument2 pagesPumps DynaJet DatasheetdamiencwalkerPas encore d'évaluation

- Hsro 390 FFDocument3 pagesHsro 390 FFAlejandro OdioPas encore d'évaluation

- High-Flow, Manual Gas Pressure Regulators: HF SeriesDocument8 pagesHigh-Flow, Manual Gas Pressure Regulators: HF Seriesherysyam1980Pas encore d'évaluation

- JISKOOT Extreme Temperature Cells 210P, 210P-HP and 210EH, 210EH-HPDocument4 pagesJISKOOT Extreme Temperature Cells 210P, 210P-HP and 210EH, 210EH-HPmobinczuPas encore d'évaluation

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDocument4 pagesFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesPas encore d'évaluation

- Series GD45Document2 pagesSeries GD45JJMEDINA REUNIONESPas encore d'évaluation

- Caustic Soda Mix Tank PsDocument2 pagesCaustic Soda Mix Tank PsDaniel Pandapotan MarpaungPas encore d'évaluation

- HF 745 / HF 748 Series: in Line High Pressure FiltersDocument24 pagesHF 745 / HF 748 Series: in Line High Pressure FilterssitnikovsPas encore d'évaluation

- DS2006 Classic Eu enDocument5 pagesDS2006 Classic Eu enkicsnerPas encore d'évaluation

- Safety and Relief Products: Kunkle Model 140 Liquid Relief ValveDocument2 pagesSafety and Relief Products: Kunkle Model 140 Liquid Relief ValveSamuel OlmosPas encore d'évaluation

- Sanitary Diaphragm Valve: Type 612Document6 pagesSanitary Diaphragm Valve: Type 612Hilux PabloPas encore d'évaluation

- HF 725 Series: in Line High Pressure FiltersDocument16 pagesHF 725 Series: in Line High Pressure FilterssitnikovsPas encore d'évaluation

- Industrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesDocument2 pagesIndustrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesPoro ChanPas encore d'évaluation

- PD42-S50 Piloted 3-Way Spool: Directional ValvesDocument2 pagesPD42-S50 Piloted 3-Way Spool: Directional ValvescaiPas encore d'évaluation

- PDN1000 2us - WDV3 GDocument1 pagePDN1000 2us - WDV3 GVicktorPas encore d'évaluation

- Flush Bottom Valve Steam IMI PBM - PB-FD5 - 2020Document2 pagesFlush Bottom Valve Steam IMI PBM - PB-FD5 - 2020Mauricio Villanova Do AmaralPas encore d'évaluation

- Mooney Flexflo 887 Surge RelieversDocument6 pagesMooney Flexflo 887 Surge RelieversSajjad MehdiPas encore d'évaluation

- Single-Round High Flow Cartridge Filter Housings: Fiberglass Reinforced Plastic (FRP)Document2 pagesSingle-Round High Flow Cartridge Filter Housings: Fiberglass Reinforced Plastic (FRP)saradhi sravan kumarPas encore d'évaluation

- BRAY F15 Ball ValveDocument12 pagesBRAY F15 Ball ValveRicardoPas encore d'évaluation

- Filter Regulator LFR-1/2-D-7-O-MIDI: Data SheetDocument1 pageFilter Regulator LFR-1/2-D-7-O-MIDI: Data SheetRichard Rodriguez GarciaPas encore d'évaluation

- Alpha SLS 65CDocument6 pagesAlpha SLS 65CJosé Antonio CuberoPas encore d'évaluation

- Instruction Manual Fisher c483 2Document12 pagesInstruction Manual Fisher c483 2stphn_maturinPas encore d'évaluation

- Industrial Excess Flow Valves: SEFV SeriesDocument4 pagesIndustrial Excess Flow Valves: SEFV SeriesToty DzPas encore d'évaluation

- SSTC10 075Document2 pagesSSTC10 075suphanat joomjanPas encore d'évaluation

- Filmtec Sw30hrle 440i Pds 45 d00965 enDocument2 pagesFilmtec Sw30hrle 440i Pds 45 d00965 encarlospPas encore d'évaluation

- J6 Series, MS-02-214 R1Document2 pagesJ6 Series, MS-02-214 R1herysyam1980Pas encore d'évaluation

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalPas encore d'évaluation

- Series: Line FilterDocument4 pagesSeries: Line Filterramaik achiemPas encore d'évaluation

- Needle Valves GU Series (MS-02-312-E) R1Document6 pagesNeedle Valves GU Series (MS-02-312-E) R1herysyam1980Pas encore d'évaluation

- Fisher D2 FloPro Control ValveDocument24 pagesFisher D2 FloPro Control ValvehugoheloPas encore d'évaluation

- Single Seat Valves SVP Select Sudmo Leaflet v2110 enDocument2 pagesSingle Seat Valves SVP Select Sudmo Leaflet v2110 enMark JonesPas encore d'évaluation

- HF 735 Series: in Line High Pressure FiltersDocument20 pagesHF 735 Series: in Line High Pressure FilterssitnikovsPas encore d'évaluation

- Relief Valves RH4 SeriesDocument6 pagesRelief Valves RH4 SerieslorenzoPas encore d'évaluation

- Convoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R2Document2 pagesConvoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R2herysyam1980Pas encore d'évaluation

- King 7470 Series DatasheetDocument2 pagesKing 7470 Series DatasheetMacro MediciónPas encore d'évaluation

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoPas encore d'évaluation

- Gas Filters: FC SeriesDocument4 pagesGas Filters: FC SeriesHeryanto SyamPas encore d'évaluation

- Swagelok T SeriesDocument6 pagesSwagelok T SeriesAkmalPas encore d'évaluation

- 2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-65Document13 pages2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-6588jdccPas encore d'évaluation

- DS2300 2300 8802 Yg Eu enDocument16 pagesDS2300 2300 8802 Yg Eu enLucas Vinícius CostaPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexPas encore d'évaluation

- Welding Purge Panel WPP Series: Features and BenefitsDocument2 pagesWelding Purge Panel WPP Series: Features and BenefitsAlexPas encore d'évaluation

- Swagelok Welding System: M200 Power SupplyDocument4 pagesSwagelok Welding System: M200 Power SupplyAlexPas encore d'évaluation

- Swagelok Welding System: M200 Power SupplyDocument4 pagesSwagelok Welding System: M200 Power SupplyAlexPas encore d'évaluation

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexPas encore d'évaluation

- Pressure Gauges: For Panel Builders PBG SeriesDocument2 pagesPressure Gauges: For Panel Builders PBG SeriesAlexPas encore d'évaluation

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexPas encore d'évaluation

- Intensive, Hands-On Training For Ma Ximum Results: Who Should AttendDocument2 pagesIntensive, Hands-On Training For Ma Ximum Results: Who Should AttendAlexPas encore d'évaluation

- eDTR Software Installation GuideDocument29 pageseDTR Software Installation GuideAlexPas encore d'évaluation

- Stream Selector System: For Process Analyzer ApplicationsDocument12 pagesStream Selector System: For Process Analyzer ApplicationsAlexPas encore d'évaluation

- Gaugeable Chromatograph and Column End Fittings: FeaturesDocument2 pagesGaugeable Chromatograph and Column End Fittings: FeaturesAlexPas encore d'évaluation

- High-Purity PFA Fine Thread Flare FittingsDocument12 pagesHigh-Purity PFA Fine Thread Flare FittingsAlexPas encore d'évaluation

- Process Ball Valve Vent Options: E X Ternal and Internal Ball VentsDocument4 pagesProcess Ball Valve Vent Options: E X Ternal and Internal Ball VentsAlexPas encore d'évaluation

- PDFDocument3 pagesPDFAlexPas encore d'évaluation

- Orbital Welding System: Micro Weld HeadsDocument4 pagesOrbital Welding System: Micro Weld HeadsAlexPas encore d'évaluation

- 031310Document3 pages031310AlexPas encore d'évaluation

- VCO O-Ring Face Seal FittingsDocument12 pagesVCO O-Ring Face Seal FittingsAlexPas encore d'évaluation

- If You NeedDocument5 pagesIf You NeedAlexPas encore d'évaluation

- Process Ball Valve Handle Options: Handle Kits and Factor Y-Installed HandlesDocument6 pagesProcess Ball Valve Handle Options: Handle Kits and Factor Y-Installed HandlesAlexPas encore d'évaluation

- The Swagelok Tube Fitting Advantage: SAT12 Patented Surface Hardening ProcessDocument2 pagesThe Swagelok Tube Fitting Advantage: SAT12 Patented Surface Hardening ProcessAlexPas encore d'évaluation

- Swagelok Adapters, Reducers and Port Connectors Are To Be Used ONLY in Swagelok Tube Fittings. Do Not Mix or Interchange Parts With Those of Other ManufacturersDocument1 pageSwagelok Adapters, Reducers and Port Connectors Are To Be Used ONLY in Swagelok Tube Fittings. Do Not Mix or Interchange Parts With Those of Other ManufacturersAlexPas encore d'évaluation

- SAF 2507 Seamless Super Duplex Tubing: Fractional SizesDocument2 pagesSAF 2507 Seamless Super Duplex Tubing: Fractional SizesAlexPas encore d'évaluation

- Olp Lesson PlanDocument2 pagesOlp Lesson Planapi-654865620Pas encore d'évaluation

- Preliminary Exam (Primark)Document4 pagesPreliminary Exam (Primark)Zybel RosalesPas encore d'évaluation

- Research Proposal Sample OutlineDocument17 pagesResearch Proposal Sample OutlineGuidance and Counseling OfficePas encore d'évaluation

- Thetford c250 InstallationDocument19 pagesThetford c250 InstallationCatalin Bejan100% (1)

- Business Communication MCQ PDFDocument54 pagesBusiness Communication MCQ PDFHimanshu ShahPas encore d'évaluation

- Perfume 130Document3 pagesPerfume 130Gurdeep BhattalPas encore d'évaluation

- The Mystery of Putins DissertationDocument16 pagesThe Mystery of Putins DissertationDoinaCebanuPas encore d'évaluation

- Accomplishment Report Filipino Values MonthDocument4 pagesAccomplishment Report Filipino Values MonthIan Santos B. Salinas100% (10)

- Central Venous PressureDocument3 pagesCentral Venous PressureHuy NguyễnPas encore d'évaluation

- Breaking News EnglishDocument13 pagesBreaking News English32. Nguyễn OanhPas encore d'évaluation

- Historic Trial of Ali Brothers and Shankaracharya-1921Document276 pagesHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- What Is StevedoringDocument10 pagesWhat Is StevedoringMinhaj KmPas encore d'évaluation

- Questions 1Document3 pagesQuestions 1krp_212003Pas encore d'évaluation

- CongressWatch #197: RA 1337-Innovative Startup ActDocument1 pageCongressWatch #197: RA 1337-Innovative Startup ActMakati Business ClubPas encore d'évaluation

- 3.6 A 40Nm Cmos Highly Linear 0.4-To-6Ghz Receiver Resilient To 0Dbm Out-Of-Band BlockersDocument3 pages3.6 A 40Nm Cmos Highly Linear 0.4-To-6Ghz Receiver Resilient To 0Dbm Out-Of-Band Blockershaoyue huangPas encore d'évaluation

- Negotiation SimulationDocument11 pagesNegotiation SimulationJade Arbee BarbosaPas encore d'évaluation

- PGT Computer Science Kendriya Vidyalaya Entrance Exam Question PapersDocument117 pagesPGT Computer Science Kendriya Vidyalaya Entrance Exam Question PapersimshwezPas encore d'évaluation

- Number SystemsDocument25 pagesNumber SystemsMehwish BilalPas encore d'évaluation

- Cultivation and Horticulture of SandalwoodDocument2 pagesCultivation and Horticulture of SandalwoodAnkitha goriPas encore d'évaluation

- Jeep TJ Torque SpecsDocument4 pagesJeep TJ Torque SpecsmaulotaurPas encore d'évaluation

- 13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledDocument5 pages13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledRomany AllamPas encore d'évaluation

- Australia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyDocument8 pagesAustralia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyFree Rain Garden ManualsPas encore d'évaluation

- CNL DivisionDocument38 pagesCNL DivisionaniketnarePas encore d'évaluation

- Low Voltage Alternator - 4 Pole: 25 To 60 kVA - 50 HZ / 31.5 To 75 kVA - 60 HZ Electrical and Mechanical DataDocument12 pagesLow Voltage Alternator - 4 Pole: 25 To 60 kVA - 50 HZ / 31.5 To 75 kVA - 60 HZ Electrical and Mechanical DataDjamel BeddarPas encore d'évaluation

- Reading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Document8 pagesReading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Arun Stanley100% (2)

- Report Text The Duck Billed Platypus: (Ornithorhynchus Anatinus)Document2 pagesReport Text The Duck Billed Platypus: (Ornithorhynchus Anatinus)Lilis IndriyaniPas encore d'évaluation

- Tle10 Cookery DLL Q1-Week1 Sy2022-2023Document4 pagesTle10 Cookery DLL Q1-Week1 Sy2022-2023Edmar S AguilarPas encore d'évaluation

- Kentucky Economic Development Guide 2010Document130 pagesKentucky Economic Development Guide 2010Journal CommunicationsPas encore d'évaluation

- Basic Elements of The Communication ProcessDocument13 pagesBasic Elements of The Communication ProcessMech JTubao67% (3)

- 02 Height and Distance - NIMCET Free Study MatrerialDocument2 pages02 Height and Distance - NIMCET Free Study MatrerialIshang VashishthaPas encore d'évaluation