Académique Documents

Professionnel Documents

Culture Documents

Qweryv

Transféré par

Agung NugrahaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Qweryv

Transféré par

Agung NugrahaDroits d'auteur :

Formats disponibles

Feature Article

Diesel Power Plant

N Ravi Menon* and Hasliyanti Alias*

A

INTRODUCTION peak crop. This exercise will help the new

engineers to gain considerable knowledge

lmost all palm oil mills have stand on how to scientifically rate the DGS they

by diesel electricity generator sets want for their mills. Currently some of the

(DGS). There are alternating views mills have assorted inventory of DGS with

by mill managers on what criteria to adopt improper ratings. It is useful to enter the

when choosing the capacities of these DGS. data in a table to enable them to make a

It is quite obvious that the mill managers good decision. Samples of the data needed

did not spend enough time to analyse are shown in Table 1. The figures given are

the requirements in more details when not actual readings and not to be used for

requesting for diesel sets for their mills. The real assessments as they are only examples.

selection of a steam power plant is relatively Based on the figures compiled in Table 1, we

simple compared to DGS. Let us look at can easily size the steam turbine require-

the mill requirements when the mill is not ment with sufficient provision for 10% ad-

in operation. In the daytime, electricity is ditional load as it is normal for such expan-

needed for the operation of office equipment, sion. If a single turbo alternator is using a

office and mill lighting. In the night time, the 1250 kW, it would be a good choice. How-

security lighting and domestic load will add ever, it is prudent to choose two units so

on to the load. After midnight, the domestic that in case of a major breakdown the mill

load will drop until early morning. can still satisfy part of the process require-

ment. In this case, two 700 kW would be a

SELECTION CRITERIA FOR DGS good choice. The selection is very much a

subjective issue. There are many options to

It will be a good exercise for all palm oil choose from based on specific requirements.

mills to record hourly loads as accurately as

possible for a full year so that it can cover Now for the DGS although many mill

the periods of low crop, normal crop and managers may select two units of say 250

kW or slightly different combinations, the

* Malaysian Palm Oil Board, reason being that the two units it can sup-

6 Persiaran Institusi, Bandar Baru Bangi, ply at least half the electrical load in case the

43000 Kajang, Selangor, Malaysia. turbo alternator breaks down. This does not

E-mail: nravi@mpob.gov.my

PALM OIL ENGINEERING BULLETIN NO. 115 11

Feature Article

TABLE 1. DATA NEEDED FOR DIESEL GENERATOR SET SELECTION FOR A 60 TPH MILL

% to Time

No Electric load demand by kW

total (hr)

-1

a Mill: 60 tph@ 18 kW t 1 080 95 20 Based on maximum load (B)

1 135

b Only nut station operation 25% 270 23.8 Off-days

c Non- processing: base load: 40 3.5 4 am-8 am

(4 hr)

d Off-day: maintenance load 40 3.5 7 am-3 pm

e Compound lighting 10 0.9 7 pm-7 am

f Mill lighting 5 0.45 7 pm-7 am

g Office lighting/air conditioner 15 1.3 8 am-5 pm

h Domestic load- say 120 40, 20 3.5/1.7 7 pm-11 pm

personnel

TOTAL LOAD (approximate)

A Day: 7 am- 7 pm 1 080

B Evening: 7 pm- 12 pm (40kw) 1 135 a+ e+f+h+1 080+10+5+40 =

(maximum) 1 135

C Night: 12 pm- 7 am (20kw) 1 115 a+ e+f+h+1 080+10+5+20 =1 115

D Maintenance day 40 d

E Non-processing hours 40

F Public holidays (Evening+ 40

night)

Note: tph – tonne per hour.

seem to be a good selection criteria when sumption also will drop to 3 kWh per litre

we consider the breakdown of a single diesel at the optimum load of 65% to 75%. A

turbo alternator as then the entire process suggested selection is shown in Table 2.

steam will have to issue out of a pressure

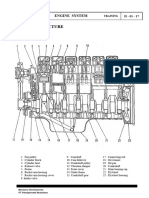

reducing valve without any work output DGS COMPONENTS

by the steam. It will be better to have addi-

tional steam turbine (third unit) as standby Apart from the engine, the associated other

than too many DGS. components that make up the whole plant

are some additional equipment also used

In this case, the DG’S capacity can be re- for improving the quality of exhaust gases

duced to a single unit of 80 kW that can op- to comply with the Department of Environ-

erate between 52 kW to 56 kW. This is all we ment’s (DOE) requirements:

need. No additional units are required. The • air intake system comprising air filter,

best efficiency for a DGS is at about 65% to ducting and turbo-chargers.

70% loading. If the unit is well maintained, • fuel supply system comprising diesel

it will last for a long time. Since the DGS are storage tank, flow meter, pipe work,

not operated while the steam power plan is pumps, strainers, day tanks and float

in operational, there is ample time to main- level indicator. The fuel pump with

tain it in good condition. The diesel con- common rail and fuel injection nozzles.

12 PALM OIL ENGINEERING BULLETIN NO. 115

Feature Article

TABLE 2. A SIMPLE METHOD FOR THE SELECTION OF BOILERS AND POWER PLANT

Type of electric generators No Maximum

load

Steam turbo alternators 700 kW 2 1 135 kW Normal operation for 60 tph

Steam turbo alternators 700 kW 1 700 kW Stand by unit

Diesel generator set 80 kW 1 80 kW Back-up – non-processing and off-days hours

Boiler 20 tph 2 40 tph Capable of generating up to 1 500 kW

Boiler 20 tph 1 20 tph Capable of generating 750 kW / 40 tph FFB

Note: FFB – fresh fruit bunch. tph – tonne per hour.

• exhaust system with turbo-charger, si- THERMODYNAMIC FUNDAMENTALS

lencers and ducts.

• cooling systems comprising water circu- There is a distinct possibility for some mill

lating pumps, radiators, cooling towers, engineers to forget the basic fundamentals

water treatment system and pipes. related to diesel engines and that should

• lubricating system comprising lubricant not be the case. There are many areas of mill

circulating pump, oil tanks, oil filters, oil operations where the mill engineers will

purifiers and air compressor. get the thrill of intellectual interaction with

• the dedicated alternator. thermodynamics especially with wet steam.

• armoured feeder cables to control panel When we deal with steam we get an oppor-

bus bar. tunity to remember and experience the ap-

• electric control panel with relevant instru- plication of the two laws of thermodynam-

mentation and synchroniser. ics, the impact of Dalton’s law of partial

• noise insulation system for the whole en- pressures during sterilisation process and

gine so that the noise levels comply with the Rankine cycle during power genera-

the DOE’s set limits. tion. In a palm oil mill, the engineers have

• warning signs for visitors to use ear a great opportunity to work with all the

plugs, safety shoes and helmets. facets of mechanical engineering, generous

amount of electrical engineering, control

FUEL CONSUMPTION systems, civil engineering, accountancy, hu-

man resource management, environmental

Diesel consumption may be roughly taken protection and sustainability issues. A good

as 0.304 kg per kWh or 0.42 litre per kWh (at combination of this proportion is not of-

a diesel specific gravity of 0.73kg per litre). fered by most other industries.

For a 75 kW cummins engine, it is given as

0.37 litre per kWh. The specific fuel con- THE AIR STANDARD CYCLE FOR

sumption for different capacities and frac- DIESEL PLANT

tional loads are given in the Datasheet of

this bulletin. If the palm oil mill generator The diesel cycle was created by Rudolph

sets in Malaysia consume more diesel than Diesel in 1892 and in the original engine

say 0.5 litre per kWh, the mill engineers are powdered coal was blasted using com-

advised to conduct an investigation to rule pressed air and using hot bulb, the fuel was

out the possibility of diesel leakage from ignited unlike spark plug ignited petrol en-

submerged pipe joints as I personally ex- gines operating on Otto cycle. The cycle

perienced such a catastrophe in one of the used was called Diesel cycle comprising

mills. an isentropic compression followed by a

PALM OIL ENGINEERING BULLETIN NO. 115 13

Feature Article

reversible constant pressure heating, isen- Where,

tropic expansion during which the work

was done and a reversible constant volume cp and cv are specific heats at constant

cooling (Figure 1). In this case, the ignition pressure and constant volumes respectively;

took place when the piston reached the

top dead center (TDC) but now the diesel minin and mex are masses of fuel air

engines have undergone changes from the mixture injected at inlet and exhaust gases

original concept of firing only during the respectively.

constant pressure combustion.

Two-stroke internal combustion engines

Contrary to popular belief the diesel are mechanically simple compared to their

engines do not operate on diesel cycles four-stroke engines but are more complex

anymore. The cycle is a combination of in thermodynamic and aerodynamic

diesel and Otto cycle as shown in Figure 2. terms, according to Society of Automotive

The engine based on this cycle called dual Engineers (SAE) definitions. In a two-stroke

combustion cycle was invented by Ackroyd- engine, the four fundamental operations

Stuart in 1888. It is rather unfortunate that of the engine comprising air intake,

despite the fact that he formulated the dual compression, ignition and exhaust occur

combustion cycle four years before Diesel in one revolution of the crank shaft i.e. 360

presented his diesel cycle his name never mechanical degrees, while in a four-stroke

came to the fore front but faded away from engine these operations are done in two

history. In this cycle, the firing takes place complete revolutions or 720 mechanical

during the constant volume operation degrees. In a two-stroke engine, more

indicated by 2 to 3 as well as during the than one function occurs at any given

constant pressure operation represented by time during the engine’s operation. The

3 to 4. In this cycle there is a compression advantages and disadvantages of the two

ratio v1 /v2, an expansion ratio v3 /v2 as well stroke engines are given in Table 3.

as a pressure ratio p3 /p2.

• air intake takes place when the piston ap-

Heat supplied is given by the equation proaches the bottom dead center (BDC)

Hinput = min{ cv (T3 – T2) + cp (T4 –T3)} through the ports provided in the cylin-

der wall with or without valves. All two-

Heat rejected by exhaust gases = mex { cv (T5- stroke diesel engines need either an artifi-

T4)} cial aspiration system like a mechanically

Figure 1. Diesel cycle (1892). Figure 2. Dual combustion cycle

(replaced diesel cycle).

14 PALM OIL ENGINEERING BULLETIN NO. 115

Feature Article

TABLE 3. THE ADVANTAGES AND DISADVANTAGES OF

TWO-STROKE ENGINES

POSITIVE NEGATIVE INTERESTING

Do not have valves, Two-stroke engines don’t live as long The following comments are from

simplifying their as four-stroke engines. Columnist Michael Harrison of

construction. The lack of a dedicated lubrication Deep Science:

system means that the parts of a two- • Most of what is written on

stroke engine wear-out faster. advantages and disadvantages of

Two-stroke engines require a mix two-stroke vs four-stroke are not

of oil in with the gas to lubricate actually correct.

the crankshaft, connecting rod and • The comparisons are often made

cylinder walls. based on unequal basis. A two-

stroke motor cycle engine that

Fires every revolution Two-stroke oil can be expensive. mixes the lubricant with the fuel

(four-stroke engines Mixing ratio is about 1:40 ( burning cannot be compared with a four-

fire once every about 2 lit/1000 km). stroke power plant prime mover.

two revolution). This • It should be compared to a

gives two-stroke unit equal in size any large

engines a significant Caterpillar, or Detroit two-

power boost. stroke they have conventional

oil sumps, oil pumps and full

Two-stroke engines Cannot use fuel efficiently, gets less pressure fed lubrication systems

are lighter and cost km per lit. and they are also two-stroke.

less to manufacture. • The ports of two-stroke is

Two-stroke engines Two-stroke engines produce more claimed to be inefficient in

have the potential pollution from: scavenging exhaust gases

for about twice the • The combustion of the oil in the compared to the valves of four-

power in the same gas. stroke engines but the same

size because there • The oil makes all two-stroke valve system can be incorporated

are twice as many engines smoky to some extent, and in two stroke engines. The

power strokes per a badly worn two-stroke engine emission quality of some two-

revolution. can emit more oily smoke. stroke engines are as good as

• Each time a new mix of air/fuel four-stroke engines like Surrich/

is loaded into the combustion Orbital two-stroke design that

chamber, part of it leaks out Mercury outboards are using

through the exhaust port. - this is as clean burning as four-

stroke.

driven motor or a turbo-charger to charge cylinder it will reach a point where the

the cylinder with air. During the aspira- exhaust port is opened to expel the high

tion phase, the residual exhaust gas of the pressure combustion gases. Currently the

previous charge is also expelled out. concept has undergone some changes as

now the cylinder wall body ports have

• as the piston rises, the intake charge of given way to poppet valves and im-

air is compressed. Fuel is injected near proved exhaust gas evacuation. As the

the TDC to initiate the combustion as the piston moves downward, the air intake

compressed air temperature would be ports will be exposed in the cylinder wall

high enough to ignite the fuel. The high and the cycle will start again.

compression of the air is accomplished by

the downward movement of the piston. • the scavenging ports are symmetrically

As the piston moves downward in the o

set to open from 45 before BDC to 45

o

PALM OIL ENGINEERING BULLETIN NO. 115 15

Feature Article

after BDC whereas the exhaust port ‘charge air’ remains (scavenging may

settings being based on maximum be accomplished by Roots blowers, for

exhaust gas evacuation does not have charge air induction at slightly above

to be symmetrical. A single camshaft ambient, or EMD’s proprietary turbo-

operates the poppet-type exhaust valves compressor which acts as a blower

with the special injector systems using during start-up, and as a turbo-charger

three lobes: two for exhaust valves (either under normal operational conditions and

two valves on the smallest engines or four for charge air induction at significantly

valves on the largest; and the third for the above ambient, and which turbocharging

injector system). provides a 50% maximum rated power

increase over Roots-blown engines of the

There are hardly any major variations same displacement).

in the operational features of most of the

o

engines. The discharge ports can either • the compression stroke begins 16 later at

o o

open at 45 or before the piston reaches the 241 (225+16), to begin the compression

TDC. The scavenging ports are set to open stroke having a duration of 119o. By then

at any point from 45o before BDC to same o

the piston will be at 360 (241+119).

angle after BDC to keep it symmetrical. The

exhaust valves are set to allow maximum air • in present day engines with electronic

intake. According to Caterpillar’s Electro- fuel injection systems, the electronically-

Motive Diesel known widely as EMD, it controlled unit injector is used. But they

uses the following specifications for its two- are actuated mechanically, the amount

stroke engine operation system. of fuel fed into the plunger-type injector

pump is under the control of the Engine

o

The power stroke begins at 0 TDC. Control Unit replacing the Woodward

Fuel injection will start 4 before TDC 356o

o

governor or similar units or conventional

in order to ensure that fuel injection is unit injectors specific to General Motors

completed by the time the piston reaches (GM) two-stroke engines.

the TDC or slightly after. This is followed

by the fuel ignition and exhaust gas • the same procedure is followed by the

expulsion when the exhaust valves are GM/EMD 567 and the GM/Detroit

opened causing a reduction of combustion Diesel 6-71 engines as they were designed

gas pressure and temperature. The duration and developed by the same team of

of the power stroke is about 103o. engineers. Turbocharging provisions

were an optional extra in some of the

• the scavenging will begin 32o later EMD and Detroit Diesel engines that

or at 135o (103+ 32), or 45o before the employed turbocharging like for hybrid

BDC having a duration of 90o ending turbo-compressor system with inter

at 225o (135 + 90). The delay of 32o is cooling. For conventional units, Roots

for the scavenging ports to open and blowers were used for scavenging as a

another 16o delay after the scavenging hybrid turbo-compressor would elevate

ports are closed (thereby initiating the cost of the engines.

the compression stroke), maximises

scavenging effectiveness, thereby Some of the performance characteristics

maximising engine power output, while of EGT 6 truck are given in Table 4. The

minimising engine fuel consumption. negative temperature at zero throttle

opening shows that the drop in temperature

• towards the end of scavenging, all of the exhaust at inlet was faster than the

products of combustion have been gas turbine outlet as the gas picked up heat

forced out of the cylinder, and only from residual heat from the turbine casing.

16 PALM OIL ENGINEERING BULLETIN NO. 115

Feature Article

TABLE 4. SHOWS THE PERFORMANCE OF A ‘POWER STROKE OF EGT 6 TRUCK’

At gas turbine inlet At gas turbine outlet ∆T TPS MPH

Throttle

Turbine- Turbine- Temperature

Turbine-in Turbine-in position Miles

RPM 0 out temp out temp difference

temp (F) temp ( C) sensor (hr)

(F) (0C) in-out (F)

(%)

3 900 950 510 720 382 128 (230) 22 55.7

3 800 1 060 571 740 393 178 (270) 57 53

2 500 1 030 554 760 404 150(270) 60 53.8

2 500 660 349 540 282 67 (120) 0 44.4

2 400 980 527 750 399 128 (230) 55 52.4

1 700 1 040 560 800 427 133 (240) 48 54.1

650

690 366 705 374 -8 (-15) 0 65.8

(Idle)

Fuel savings in terms of efficiency, the IMPORTANT TIPS ON BASIC DIESEL

diesel engines fair better than gas engines ENGINE MAINTENANCE

mainly due to the higher calorific value

of the diesel oil (7% higher) but some Sometimes the gas engines will get

diesel engine manufacturer’s claim of 30% overheated due to poor coolant performance

increase in efficiency needs verification. or continuous overloading of the engine. In

such instances, the mill engineers seldom

DIESEL ENGINE IMPORTANT have a clue as to how the problem can be

MAINTENANCE TIPS resolved. The right thing to do is to give it a

break for a few minutes and restart when

As diesel engine works on the principle of the temperature comes back to normal. The

compressing the air that is drawn into the use of a fan will be of great help and as such

cylinder during the suction stroke so that it is prudent to have a fan permanently

the compressed air temperature is sufficient stationed near the gas engine. This may

to ignite the fuel injected into it at close to even prevent the occurrence of overheating.

the TDC, there is no need for any electrical Overheating of a diesel engine should never

components like the spark plugs or induc- be allowed even for short periods.

tion coil.

If a temperature rise is observed on a

In diesel engines, the cylinder walls are diesel engine, take any precaution that can

thicker than petrol engines due to the high prevent such occurrence as once it happens

compression ratio. The temperature is also there is a good possibility for the cylinder

high resulting in additional demand for gaskets to be damaged. Now let us look at

an efficient cooling system that has to be some of the measures that would help the

closely monitored. Abnormal temperature preventions of such catastrophe. The use

rise should be avoided in order to ensure of fan can be tried out but if the tempera-

prolonged engine life and to prevent engine ture rise cannot be arrested check the cooler

getting seized or gasket get damaged. Gas- tubes to remove any scales. If that does not

ket must be replaced as a set. bring the desired results, the best solution

PALM OIL ENGINEERING BULLETIN NO. 115 17

Feature Article

would be renewal of cooler tubes with big- of gaskets. When this happens immediate

ger tubes or add another cooler in series or attention should be given to change as a set

parallel based on the available space. This to prevent further damage to the engine.

should solve the problem amicably.

Great care must be directed to the

In order to safeguard the engine parts, condition of the oil filter. In palm oil mills,

it is usual to have filters on the run line to additional care will be needed and as such

separate any dirt accumulated in the cool- it is advisable to implement more than the

ant while it circulates through the engine manufacturer’s recommendation based on

cooling circuit. Some engine manufactur- the operating hours as the environment in

ers also provide coolant purification system the palm oil mill is very dusty and a shorter

so that the possibility of damage to engine period would be more appropriate.

parts by the coolant contaminants is effec-

tively eliminated. Some of the coolant fil- Ensure that the diesel fuel storage is done

ters carry out multiple functions specially according to prescribed methods. It must be

designed to protect the engines but they all enclosed in a concrete tank having a volume

add to the cost. equivalent to the storage tank so that in

case of a leak through a leak or otherwise

It is not a common practice in palm oil the escaping diesel oil can be contained

mills to assign an engineer or artisan to without getting it into the monsoon drain.

monitor the condition of the diesel engine The day tank also must have the same

and this weakness has been responsible provision. Both the storage tank and the

for many costly engine breakdowns. If the day tank must have level indicators with

mill engineers had been marine engineers identification signage and statement on the

before joining palm oil mills, they would tank capacity. It is preferable to install a

have known how to maintain diesel power flow meter or a remote flow recorder close

plants. Regular check on all the bolts and to the engine with isolating valves and a

nuts to ensure the recommended torque filter.

is the starting point as over a period of

time we can expect the nuts to work itself Ensure that all spare parts used for the

loose setting in motion a series of problems engine are original parts. Imitation parts

culminating in overheating and damage can damage the engine.

18 PALM OIL ENGINEERING BULLETIN NO. 115

Vous aimerez peut-être aussi

- Safari - 15 Nov 2019 at 10:13 PMDocument1 pageSafari - 15 Nov 2019 at 10:13 PMcrescente galendezPas encore d'évaluation

- Emerson Hybrid PresentationDocument22 pagesEmerson Hybrid PresentationPhani Chand GangipamulaPas encore d'évaluation

- Internal Combustion (Ic) Engine Used in Generation of ElectricityDocument46 pagesInternal Combustion (Ic) Engine Used in Generation of ElectricitynatarajansiyerPas encore d'évaluation

- DG SetDocument42 pagesDG Setgaurang1111Pas encore d'évaluation

- Diesel Generator Set: (A Wholly Owned Subsidiary of Compass Group PLC)Document38 pagesDiesel Generator Set: (A Wholly Owned Subsidiary of Compass Group PLC)sayedmhPas encore d'évaluation

- 12M55 Series: Powerkit EngineDocument3 pages12M55 Series: Powerkit EngineAlberto F. Apablaza MezaPas encore d'évaluation

- MSGasProduct PDFDocument33 pagesMSGasProduct PDFMilad ManzourPas encore d'évaluation

- 3 CH 9Document16 pages3 CH 9Pradeep Srivastava SrivastavaPas encore d'évaluation

- An Overview of Combined Cycle Power PlantDocument71 pagesAn Overview of Combined Cycle Power PlantDreamie Blue100% (2)

- Reduce Diesel Consumption Today in Your DG Set.10400343Document4 pagesReduce Diesel Consumption Today in Your DG Set.10400343jereer7774662Pas encore d'évaluation

- Nergie-: Diesel Engine Starting Batteries Guide and WorksheetDocument7 pagesNergie-: Diesel Engine Starting Batteries Guide and WorksheetAlexander OngPas encore d'évaluation

- Information Sheet # 09: Your Reliable Guide For Power SolutionsDocument2 pagesInformation Sheet # 09: Your Reliable Guide For Power SolutionsMd ShPas encore d'évaluation

- DG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofDocument14 pagesDG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofJitendra PatilPas encore d'évaluation

- 3.9 DG Sets - Revised (Table Format)Document8 pages3.9 DG Sets - Revised (Table Format)mundagodPas encore d'évaluation

- Tech Ref. ManualDocument72 pagesTech Ref. Manualgigo_dreamPas encore d'évaluation

- LEXE1561-01 Issues With Peak DemandDocument4 pagesLEXE1561-01 Issues With Peak DemandDave HeardPas encore d'évaluation

- MTU 16V4000G63 Diesel Generating Sets Technical DataDocument6 pagesMTU 16V4000G63 Diesel Generating Sets Technical DataMahnooshPas encore d'évaluation

- Diesel Electric Powerplant Lab ActDocument5 pagesDiesel Electric Powerplant Lab ActAndrei BarbazaPas encore d'évaluation

- 4.DG SetDocument24 pages4.DG Setprati121Pas encore d'évaluation

- DG Set SystemDocument14 pagesDG Set Systemankur yadavPas encore d'évaluation

- AC DC Kilns (Drives, Cement Plant)Document10 pagesAC DC Kilns (Drives, Cement Plant)RajuPas encore d'évaluation

- Power Palnt Performance PDFDocument161 pagesPower Palnt Performance PDFrafik1995100% (1)

- Powerplant PerformanceDocument161 pagesPowerplant PerformancePhanindra Kumar J100% (1)

- Generater TrainingDocument28 pagesGenerater Trainingiraqi.tfPas encore d'évaluation

- DG Sizing of GeneratorDocument23 pagesDG Sizing of GeneratorRamji RamakrishnanPas encore d'évaluation

- Marine Electrics Made Simple or How to Keep the Batteries ChargedD'EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedPas encore d'évaluation

- Hoppecke Fnceh PDFDocument7 pagesHoppecke Fnceh PDFkamal_khan85Pas encore d'évaluation

- Ipa14 e 150Document6 pagesIpa14 e 150Ryan PermanaPas encore d'évaluation

- Thermodynamics Palm Oil MillDocument9 pagesThermodynamics Palm Oil MillWilliam MansoPas encore d'évaluation

- E50001 W410 A105 V1 4A00 - SolarbroschuereDocument4 pagesE50001 W410 A105 V1 4A00 - SolarbroschuereWilfredo Rojo CastañoPas encore d'évaluation

- Generator FactsDocument9 pagesGenerator Factsjester772001Pas encore d'évaluation

- 3.1 Turbine and GoverningDocument90 pages3.1 Turbine and GoverningYudo Heru PribadiPas encore d'évaluation

- Marine Electric Power Generation: Jim Bertsch Marine Program ManagerDocument27 pagesMarine Electric Power Generation: Jim Bertsch Marine Program ManagerFarhan Arif SantosoPas encore d'évaluation

- CT575 CT635S (KTA19 60Hz)Document3 pagesCT575 CT635S (KTA19 60Hz)M. ShaatPas encore d'évaluation

- Chapter 3.9 DG Set System PDFDocument14 pagesChapter 3.9 DG Set System PDFgoudappa6Pas encore d'évaluation

- Power Conversion FormulasDocument21 pagesPower Conversion Formulasahmadgce04Pas encore d'évaluation

- T312X CumminsDocument5 pagesT312X CumminsJose Merardo ParraPas encore d'évaluation

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShPas encore d'évaluation

- LG550P 50 HZDocument5 pagesLG550P 50 HZKomang SemadiPas encore d'évaluation

- Quote 30 & 40kvaDocument10 pagesQuote 30 & 40kvaTiffany NunezPas encore d'évaluation

- 4 Diesel PropulsionDocument52 pages4 Diesel Propulsionsudhanshu22kumar22Pas encore d'évaluation

- Spec Sheet C15 60Hz 410ekw PrimeDocument3 pagesSpec Sheet C15 60Hz 410ekw PrimePrejit Radhakrishna100% (1)

- Diesel Generator Sizing - REV0Document8 pagesDiesel Generator Sizing - REV0alinaghib100% (2)

- Feasibility Report About: Steam Power PlantDocument13 pagesFeasibility Report About: Steam Power Plantjsmith84Pas encore d'évaluation

- Fiche A4 4M11 2020Document2 pagesFiche A4 4M11 2020DHINAKARAN KumarPas encore d'évaluation

- Conditional Monitoring in Textile Spinning Mill 2183808.345121653Document3 pagesConditional Monitoring in Textile Spinning Mill 2183808.345121653selvamuthukumarPas encore d'évaluation

- C9 Part3 V2Document33 pagesC9 Part3 V2Emin ÇelikPas encore d'évaluation

- 3.1 GL For Selection of Turbine and GoverningDocument96 pages3.1 GL For Selection of Turbine and GoverningBehailu FelekePas encore d'évaluation

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantD'EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantPas encore d'évaluation

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesD'EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesÉvaluation : 3 sur 5 étoiles3/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Bangladesh Industrial Technical Assistance CenterDocument38 pagesBangladesh Industrial Technical Assistance CenterJunaed Ahmed SaifPas encore d'évaluation

- Diesel EngineDocument29 pagesDiesel EngineRavi KumarPas encore d'évaluation

- Interview Questions: Solution 1e)Document19 pagesInterview Questions: Solution 1e)vipsdgr8Pas encore d'évaluation

- DDFP Detroit 12 SER V71 PDFDocument92 pagesDDFP Detroit 12 SER V71 PDFzona amrullohPas encore d'évaluation

- 2020catalogue Gasoline GeneratorDocument26 pages2020catalogue Gasoline GeneratorRavikant SainiPas encore d'évaluation

- Model Komatsu Wa1200-3 Caterpillar 994F Letourneau L-1350 GeneralDocument5 pagesModel Komatsu Wa1200-3 Caterpillar 994F Letourneau L-1350 GeneralCAROLPas encore d'évaluation

- KDE11-100SS GENERATOR SET Maintenance ManalDocument105 pagesKDE11-100SS GENERATOR SET Maintenance ManalDuvan Garridt MillanPas encore d'évaluation

- Service ManualDocument2 384 pagesService ManualBrandon McMahonPas encore d'évaluation

- First Part Review Questions Agricultural Mechanization and Machinery, Farm Power and Energy, Farm Economics, Farm Management, Farm Marketing, and Farm ShopDocument77 pagesFirst Part Review Questions Agricultural Mechanization and Machinery, Farm Power and Energy, Farm Economics, Farm Management, Farm Marketing, and Farm ShopKeith Elysah Monoy EspinaPas encore d'évaluation

- Tender Tech Spec Gen 51-75 KVADocument11 pagesTender Tech Spec Gen 51-75 KVANurul AlamPas encore d'évaluation

- Diesel EngineDocument8 pagesDiesel EngineFidel Alejandro RamirezPas encore d'évaluation

- Shipbulding Technology 7th & 8th Semester SyllabusDocument39 pagesShipbulding Technology 7th & 8th Semester SyllabusDiploma in Engineering Shipbuilding TechnologyPas encore d'évaluation

- Ae LabDocument53 pagesAe LabAnkit DahiyaPas encore d'évaluation

- Brochure EC750D T3Document16 pagesBrochure EC750D T3Prithvipal SinghPas encore d'évaluation

- Term Paper of Fluid MechanicsDocument2 pagesTerm Paper of Fluid MechanicsMahi KaurPas encore d'évaluation

- Sym Joyride Servicemanual PDFDocument203 pagesSym Joyride Servicemanual PDFkamal ishakPas encore d'évaluation

- Mechanical SyllabusDocument33 pagesMechanical SyllabusRocker byPas encore d'évaluation

- 14264A Construction Mechanic Basic Chapters 5 6 PDFDocument102 pages14264A Construction Mechanic Basic Chapters 5 6 PDFMaghfiroh GhafaraPas encore d'évaluation

- Theory and Design of Automotive Engines - Dinesh Prabhu PDFDocument288 pagesTheory and Design of Automotive Engines - Dinesh Prabhu PDFhenevil100% (2)

- Ic Engine Research PaperDocument7 pagesIc Engine Research Paperh03ch3b4100% (1)

- 02 EngineDocument17 pages02 EngineSantosa NagoyaPas encore d'évaluation

- Bosch K-Jetronic Fuel Injection Manual - Boschtech-12d PDFDocument42 pagesBosch K-Jetronic Fuel Injection Manual - Boschtech-12d PDFdada100% (6)

- 1 IntroductionDocument81 pages1 IntroductionThanawat SojiratanakulPas encore d'évaluation

- Edoc - Pub - Weichai WD 10 Workshop Manual PDFDocument163 pagesEdoc - Pub - Weichai WD 10 Workshop Manual PDFdarmadi100% (2)

- 1 BME BT 203 First Year Unit V Part 1 Dr. Anil Singh YadavDocument14 pages1 BME BT 203 First Year Unit V Part 1 Dr. Anil Singh YadavZahid RahmanPas encore d'évaluation

- 08-02 B10 PR 220bar IT 23 0-100% Performance ReportDocument10 pages08-02 B10 PR 220bar IT 23 0-100% Performance ReportEswar Asish AndeyPas encore d'évaluation

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTAPas encore d'évaluation

- Terex DG TroubleshootingDocument48 pagesTerex DG TroubleshootingImtiaz Ahmed100% (2)

- Aircraft General Knowledge ATPLDocument51 pagesAircraft General Knowledge ATPLYahya Yıldırım94% (16)

- Propulsion DieselDocument314 pagesPropulsion DieselAlejandro Navarro GonzalezPas encore d'évaluation