Académique Documents

Professionnel Documents

Culture Documents

Computer Aided Assembly Drawing PDF

Transféré par

Vinod RajTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Computer Aided Assembly Drawing PDF

Transféré par

Vinod RajDroits d'auteur :

Formats disponibles

Course Title: Computer Aided Assembly Drawing Course Code: 15AT43P

Credits (L:T:P) :0:2:4 Credit-3 Core/ Elective: Core

Type of course: Tutorial/Practical Total Contact Hours: 78

CIE- 25 Marks SEE- 50 marks

Prerequisites:

Basic knowledge of Engineering Graphics I&II studied in the previous semesters.

Course Objectives:

To know the concepts of Automobiles components assembly, machine drawing.

On successful completion of the course, the students will be able to attain CO:

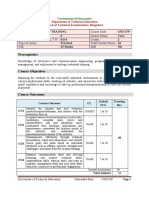

Course Outcome CL Experiments linked Linked Teaching

POs Hours

CO1 Interpret the machine Contents of UNIT1 10

drawings. U/A 1,2,3,4,8,9

and UNIT5

Understand the role of

Computers in Machine U/A Contents of UNIT2 1,2 03

CO2

Drawing

Demonstrate CAD Contents of UNIT3

CO3 U 1,2 12

commands. and 4

Draw different Contents of UNIT5

auto/machine U/A 1,2,3,4,8,9,10 53

CO4 and 6

component drawings.

Total

78

sessions

COURSE PO ATTAINMENT MATRIX:

Course Programme Outcomes

1 2 3 4 5 6 7 8 9 10

Computer aided assembly

drawing

3 3 3 3 - - - 3 3 3

Directorate of Technical Education Karnataka State 15AT43P Page 1

Level 3- Highly Addressed, Level 2-Moderately Addressed, Level 1-Low Addressed.

Method is to relate the level of PO with the number of hours devoted to the COs which address the given PO.

If >40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 3

If 25 to 40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 2

If 5 to 25% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 1

If < 5% of classroom sessions addressing a particular PO, it is considered that PO is considered not-addressed.

Course Delivery:

The course will be delivered through Tutorials, demonstration.

Course Content:

Unit I: Introduction to Machine Drawing

Requirements of machine drawing, drawing views – front – top - side, section plane, sectional views – full –

half – local - partial – revolved – removed – offset, conventions of section lines, conventional representation

of machine parts, production drawing – tolerance – hole basis system – shaft basis system, limits – upper –

lower, fits – clearance fit – interference fit - transition fit, surface roughness – representation of surface

roughness on drawings, assembly drawing – types – sequence of preparing assembly drawing.

Unit II: Computer Aided Drafting

Information about CAD – comparison between manual drawing & CAD – advantages of using CAD –areas

of applications, System requirements for CAD. Setting drawing area - coordinates – units - limits – grid –

snap – Osnap – Ortho mode.

Unit III: Drawing Entities

Draw/sketch tools- point – line – construction line – circle – arc – polygon – poly line – hatch – text – ellipse

– rectangle – spline – donut – modifying/changing entities properties.

Unit IV: Modifying Entities

Modify / Edit tools – erase – copy – array – move – mirror – offset – rotate – scale – stretch – trim – extend –

break – explode – join – chamfer – fillet.

Unit V:Assembly Drawing

Drawing detailed parts drawings – assembling the parts – drawing sectional front view –drawing top/side

view.

Unit VI: Dimensioning and Printout

Dimension the assembly in different views– setting the drawing for printing – printout.

Directorate of Technical Education Karnataka State 15AT43P Page 2

Course Assessment and Evaluation Scheme:

When/Where

Method

Max Evidence Course

What To whom (Frequency in

Marks collected outcomes

the course)

Manual

assignments Drawing/

10 1,2,3,4

( Average to Sketch book

Direct Assessment

CIE(Continuous be computed)

Internal IA Assembly

Evaluation) drawing &

Students

print outs 15 Print outs 1,2,3,4

(Average to be

computed)

SEE ( Semester

End End of the Answer scripts

End 50 1,2,3,4

Examination)

Exam course at BTE

Student Feedback on Middle of the Feedback 1&,2 Delivery

course course forms of course

Assessment

1,2,3,4

Indirect

Effectiveness

Students

End of the of Delivery of

End of Course Survey Questionnaires

course instructions &

Assessment

Methods

*CIE – Continuous Internal Evaluation *SEE – Semester End Examination

Note:

1. Average of manual assignments and assembly drawings/printouts shall be separately rounded off to

the next higher digit..

Directorate of Technical Education Karnataka State 15AT43P Page 3

MODEL OF RUBRICS FOR ASSESSING STUDENT ACTIVITY/ASSIGNEMENT

Note: Dimensions in the below table are only representatives and lecturer has to design/decide suitable dimensions based on the

activity given.

Dimension Scale Students Score

Unsatisfactory Developing Satisfactory Good Exemplary 1 2 3 4 5

1marks 2marks 3marks 4marks 5marks

1. Research and gather Does not collect Collects very Collects basic Collects more Collects a great 1

information information relate limited information, most information, most deals of

to topic information refer to the topic refer to the topic information, all

,some relate to refer to the topic

topic

2.Full fills teams roles Does not perform Performs very Performs nearly Performs almost Performs all 2

and duties any duties little duties all duties all duties duties of assigned

assigned to the team roles

team role

3.Shares work equally Always relies on Rarely does the Usually does the Always does the Always does the 3

others to do the assigned work, assigned work, assigned work, assigned work,

work often needs rarely needs rarely needs without needing

reminding reminding reminding. reminding

4. listen to other team Is always talking, Usually does Listens, but Listens and talks Listens and talks 4

mates never allows most of the sometimes talk a little more than a fare amount

anyone to else to talking, rarely too much, needed.

speak allows others to

speak

Grand Average/Total=1+2+3+4/4=10/4=2.5=3 3

Directorate of Technical Education Karnataka State 15AT43P Page 4

Resources

Reference books:

Sl no Title of book author publisher

1 Automobile Engineering Drawing R B Gupta Satya prakashan

N D Bhatt and V M

2 Machine Drawing Charotar Publishing

Panchal

3 Machine Drawing K R Gopalakrishna Subhas Stores

2. Software: Any Genuine CAD software or free and open source CAD software.

LAB EXERCISES

Assembly drawings of following automotive components:

Note: 1. each drawing should be drawn with proper border, title block and bill of materials.

2. Detailed drawing sheets should be provided to students, students have to draw detailed

drawings first then assembly drawing has to be drawn.

1. Piston with piston pin

2. Connecting rod assembly.

3. Single plate clutch

4. Synchromesh unit

5. Master cylinder

6. Wheel cylinder

7. Diesel Injector

8. SU carburetor

9. Balanced crank shaft

10. Universal coupling

Directorate of Technical Education Karnataka State 15AT43P Page 5

SCHEME OF EVALUATION

a. Internal evaluation

ÿ All the exercises are compulsory.

ÿ Students should draw the detailed parts drawings of each exercise manually at home in drawing

sketch/record book as assignment before attending the class to practice on that exercise in CAD

software.

ÿ Each in-time completed assignment carries 1 mark. (1X10 Exercise).

ÿ Each completed assembly drawing carries 1 mark & print out carries 0.5 marks. (1.5X10).

ÿ Printouts of assembly drawing are to be kept along with respective manual drawing in lab record.

b. Semester End examination

Serial no Description Marks

1 Drawing of detailed parts 20

2 Sectional front view 15

3 Top/side view 10

4 Dimensioning & Print out 05

Total 50

LAB FACILITIES REQUIRED:

1. Personnel computer with 17” color LED monitor, Intel core i5 fifth gen processor, 4 GB ram,

Graphics card with 2 GB RAM -20 numbers.

2. Laser jet Printer-02.

3. UPS 5KV.

4. Genuine CAD software / Free and open source CAD software.

5. LCD Projector.

Directorate of Technical Education Karnataka State 15AT43P Page 6

Vous aimerez peut-être aussi

- Two-Minute Math Drills, Grades 3 - 5: Multiplication & DivisionD'EverandTwo-Minute Math Drills, Grades 3 - 5: Multiplication & DivisionPas encore d'évaluation

- 4.engg Graphics IDocument13 pages4.engg Graphics IsathishPas encore d'évaluation

- Prerequisite: Knowledge of English Comprehension. Course Objectives: Will Learn and Understand The Basics of Computers and Apply TheDocument6 pagesPrerequisite: Knowledge of English Comprehension. Course Objectives: Will Learn and Understand The Basics of Computers and Apply TheFaizan shahidPas encore d'évaluation

- 5.basic Computer Skill Lab PDFDocument8 pages5.basic Computer Skill Lab PDFRavikumarPas encore d'évaluation

- Diploma CAED LAB SyllabusDocument9 pagesDiploma CAED LAB SyllabusVikasVicky0% (1)

- Model MakingDocument2 pagesModel MakingPrashant SunagarPas encore d'évaluation

- DownloadDocument14 pagesDownloadRamesh GuptaPas encore d'évaluation

- 6.basic Workshop Practice-I PDFDocument13 pages6.basic Workshop Practice-I PDFPreethamgowda PreciousPas encore d'évaluation

- Course Plan CM Cie 3153 - 2020 (3 Credit)Document5 pagesCourse Plan CM Cie 3153 - 2020 (3 Credit)Don KarthikeyaPas encore d'évaluation

- Practical's Core: Course Outcome Experiment CL LinkedDocument5 pagesPractical's Core: Course Outcome Experiment CL Linkedmanasa nagarajPas encore d'évaluation

- 4.engineering Drawing II 1Document20 pages4.engineering Drawing II 1mohanPas encore d'évaluation

- COmputer LabDocument9 pagesCOmputer LabpnkjinamdarPas encore d'évaluation

- Board of Technical Examinations, BangaloreDocument17 pagesBoard of Technical Examinations, BangaloreSanjay PatilPas encore d'évaluation

- PDFDocument9 pagesPDFShilpa K.V.Pas encore d'évaluation

- 6.concepts of Computer LabDocument10 pages6.concepts of Computer LabSandesh SandeshPas encore d'évaluation

- Course Syllabus: University of Kyrenia Maritime Vocational School Department of EngineDocument4 pagesCourse Syllabus: University of Kyrenia Maritime Vocational School Department of EngineUmar50% (2)

- Computer Aided Engineering Drawing: Teaching HoursDocument4 pagesComputer Aided Engineering Drawing: Teaching HourspriyankarPas encore d'évaluation

- Department of Technical Education Board of Technical Examinations, BengaluruDocument9 pagesDepartment of Technical Education Board of Technical Examinations, BengaluruArindam SenPas encore d'évaluation

- Elements of Aeronautical EngineeringDocument6 pagesElements of Aeronautical Engineeringyexov33854Pas encore d'évaluation

- Department of Technical EducationDocument17 pagesDepartment of Technical EducationPiya SharmaPas encore d'évaluation

- Network Administration Lab Syllabus For Diploma 3rd Sem CSDocument6 pagesNetwork Administration Lab Syllabus For Diploma 3rd Sem CSVishal Raj.VPas encore d'évaluation

- BITSF110 Course HandoutDocument3 pagesBITSF110 Course HandoutultimatePas encore d'évaluation

- C - Programming LABDocument5 pagesC - Programming LABPepe AkashPas encore d'évaluation

- Camd CoDocument10 pagesCamd CoMohammed FaizPas encore d'évaluation

- Course File Sujatha T (Dc-2020-21)Document5 pagesCourse File Sujatha T (Dc-2020-21)T Sujatha AI002117Pas encore d'évaluation

- Course Plan - FEMDocument5 pagesCourse Plan - FEMnarasimha raoPas encore d'évaluation

- Acad Budget PlanDocument3 pagesAcad Budget PlanNoel Jun LinganayPas encore d'évaluation

- Pre-Requisite: Knowledge of Survey, Construction Technology, Building MaterialsDocument12 pagesPre-Requisite: Knowledge of Survey, Construction Technology, Building MaterialsMital DamaniPas encore d'évaluation

- Heba - Arman SyllabusDocument2 pagesHeba - Arman Syllabusافنان ديريةPas encore d'évaluation

- 7.inplant TrainingDocument5 pages7.inplant TrainingV H HarshaPas encore d'évaluation

- 2.lesson - Plan (2021-2022 ODD) - CS8591-C SECTIONDocument10 pages2.lesson - Plan (2021-2022 ODD) - CS8591-C SECTIONslogeshwariPas encore d'évaluation

- Me-Pse Curriculum and SyllabusDocument73 pagesMe-Pse Curriculum and SyllabuslvijayanandPas encore d'évaluation

- Graphics SyllabusDocument9 pagesGraphics SyllabusAdarsh RPas encore d'évaluation

- Computer Engineering Syllabus Sem Viii Mumbai UniversityDocument44 pagesComputer Engineering Syllabus Sem Viii Mumbai UniversityDaivik ChaulkarPas encore d'évaluation

- RTM Nagpur University Syllabus (Theory)Document4 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarPas encore d'évaluation

- Comp B 60 DLDA Term Work Shashank RaiDocument51 pagesComp B 60 DLDA Term Work Shashank Raishashank raiPas encore d'évaluation

- Cad 7th SemDocument4 pagesCad 7th SemSourav ShuklaPas encore d'évaluation

- University of Cebu (Main Campus) Course GuideDocument8 pagesUniversity of Cebu (Main Campus) Course GuideChanchan LebumfacilPas encore d'évaluation

- Mechanical Drafting Course Code: 4321902: Page 1 of 13Document13 pagesMechanical Drafting Course Code: 4321902: Page 1 of 13HK PatelPas encore d'évaluation

- CSC103 Outline 1st 2021-2022Document4 pagesCSC103 Outline 1st 2021-2022A QanasPas encore d'évaluation

- OPTIDocument3 pagesOPTISARANSH AGARWALPas encore d'évaluation

- 7.project work-II On Design of Mechatronics System and Industrial VisitsDocument7 pages7.project work-II On Design of Mechatronics System and Industrial VisitsNIKHIL ASPas encore d'évaluation

- Department of Mechanical Engineering 17-7-2015Document44 pagesDepartment of Mechanical Engineering 17-7-2015Manu K VasudevanPas encore d'évaluation

- 3.machine DesignDocument17 pages3.machine DesignAmitPas encore d'évaluation

- Basic Cad in Civil EngineeringDocument6 pagesBasic Cad in Civil EngineeringazayPas encore d'évaluation

- 6.CAD LabDocument5 pages6.CAD LabNIKHIL ASPas encore d'évaluation

- Competency Placement of Item: Lalawigan National High School Table of SpecificationDocument1 pageCompetency Placement of Item: Lalawigan National High School Table of SpecificationSanja ShishinPas encore d'évaluation

- Image Processing TechiniqueDocument11 pagesImage Processing TechiniqueAtul DrawsPas encore d'évaluation

- DBMS - Course PackDocument11 pagesDBMS - Course PackPrashant jainPas encore d'évaluation

- Camd 3331906 PDFDocument7 pagesCamd 3331906 PDFjayyadavvpcPas encore d'évaluation

- B.tech CSE Syllabus 2020-24-09-Apr-20 VNDocument191 pagesB.tech CSE Syllabus 2020-24-09-Apr-20 VNsatyam sharmaPas encore d'évaluation

- Se Course PlanDocument5 pagesSe Course Planrandom personPas encore d'évaluation

- EM IndexDocument2 pagesEM IndexSharmatt GadekarPas encore d'évaluation

- 1.design of Reinforced Cement Concrete 15ce51tDocument15 pages1.design of Reinforced Cement Concrete 15ce51tNagesh RamannaPas encore d'évaluation

- CV 5th Sem PDFDocument126 pagesCV 5th Sem PDFHELLO WORLDPas encore d'évaluation

- Auto Cad PDFDocument14 pagesAuto Cad PDFKanekiPas encore d'évaluation

- B.Tech CSE 2021 v2Document196 pagesB.Tech CSE 2021 v2Lalit ChoudharyPas encore d'évaluation

- FP Tech I Curriculum 22 Aug 2013Document121 pagesFP Tech I Curriculum 22 Aug 2013Meenal SwarnakarPas encore d'évaluation

- EDUCATION DATA MINING FOR PREDICTING STUDENTS’ PERFORMANCED'EverandEDUCATION DATA MINING FOR PREDICTING STUDENTS’ PERFORMANCEPas encore d'évaluation

- Prediction of Torque Converter CharacteristicsDocument6 pagesPrediction of Torque Converter CharacteristicsJohnnyPas encore d'évaluation

- Computer Aided Assembly Drawing PDFDocument6 pagesComputer Aided Assembly Drawing PDFVinod RajPas encore d'évaluation

- ISCA RJEngS 2013 010Document9 pagesISCA RJEngS 2013 010Vinod RajPas encore d'évaluation

- PG Teach AppDocument5 pagesPG Teach AppVinod RajPas encore d'évaluation

- Computer Aided Assembly Drawing PDFDocument6 pagesComputer Aided Assembly Drawing PDFVinod RajPas encore d'évaluation

- Reg Pay Degree 020110Document16 pagesReg Pay Degree 020110SRINIVASA RAO GANTAPas encore d'évaluation

- Shape Memory AlloysDocument1 pageShape Memory AlloysVinod RajPas encore d'évaluation

- B.E./B.Tech. Degree Examination, May/ June 2007. Fourth Semester Automobile Engineering at 236 - Automotive ChassisDocument2 pagesB.E./B.Tech. Degree Examination, May/ June 2007. Fourth Semester Automobile Engineering at 236 - Automotive ChassisVinod RajPas encore d'évaluation

- Computer Aided Assembly Drawing PDFDocument6 pagesComputer Aided Assembly Drawing PDFVinod RajPas encore d'évaluation

- List of Software and Hardware Requirement To Conduct ICT Mode ProgrammeDocument1 pageList of Software and Hardware Requirement To Conduct ICT Mode ProgrammeVinod RajPas encore d'évaluation

- Shape Memory AlloysDocument1 pageShape Memory AlloysVinod RajPas encore d'évaluation

- Pue Gs RulesDocument12 pagesPue Gs RulesVinod RajPas encore d'évaluation

- Rubrics ModelDocument1 pageRubrics ModelVinod RajPas encore d'évaluation

- Setting Up Local Chapter of National Innovation ClubDocument6 pagesSetting Up Local Chapter of National Innovation ClubVinod RajPas encore d'évaluation

- Shape Memory AlloysDocument1 pageShape Memory AlloysVinod RajPas encore d'évaluation

- Ortho - Objects: Autocad Plant 3D 2015Document1 pageOrtho - Objects: Autocad Plant 3D 2015이동우Pas encore d'évaluation

- CV - Sid SenadheeraDocument3 pagesCV - Sid Senadheerasid_senadheeraPas encore d'évaluation

- Lab Manual: Cad 3DDocument25 pagesLab Manual: Cad 3DnaveenPas encore d'évaluation

- Visvesvaraya Technological University: Jnana Sangama, Belagavi - 590 014Document84 pagesVisvesvaraya Technological University: Jnana Sangama, Belagavi - 590 014Nithesh KumarPas encore d'évaluation

- Trends in Apparel Manufacturing TechnologyDocument8 pagesTrends in Apparel Manufacturing TechnologyAmit SinghPas encore d'évaluation

- Machine Design - I: Tutor: Dr. Owaisur Rahman ShahDocument18 pagesMachine Design - I: Tutor: Dr. Owaisur Rahman Shahpoke manPas encore d'évaluation

- Aec - 3-4 2008 PDFDocument36 pagesAec - 3-4 2008 PDFNoureddine SemaraPas encore d'évaluation

- Autocad Lab ManualDocument84 pagesAutocad Lab ManualRaghu RamPas encore d'évaluation

- Auto Paln Author HelpDocument137 pagesAuto Paln Author HelpSagar Gowda75% (4)

- Catalogue ZWCAD 2017 For ReadingDocument10 pagesCatalogue ZWCAD 2017 For ReadingSakthi VelPas encore d'évaluation

- Mechanical Engineering ResumeDocument2 pagesMechanical Engineering ResumeZohaib KhanPas encore d'évaluation

- Xforce BIM 360 Design 2014 Keygen PDFDocument4 pagesXforce BIM 360 Design 2014 Keygen PDFBrianPas encore d'évaluation

- Laser Cutting MachineDocument17 pagesLaser Cutting MachineSotara RenPas encore d'évaluation

- Autodesk All Programs Key Gen 2012 Crack Team XDocument3 pagesAutodesk All Programs Key Gen 2012 Crack Team XJesus Edilberto Miranda Clavijo0% (1)

- RoboticsDocument2 pagesRoboticsaoi_blue89Pas encore d'évaluation

- Solid Edge Tips and TricksDocument42 pagesSolid Edge Tips and TricksNanda SagarPas encore d'évaluation

- Ship Building Computer AidsDocument4 pagesShip Building Computer AidsAnkit MauryaPas encore d'évaluation

- GRED HD User ManualDocument107 pagesGRED HD User ManualSimon GleedPas encore d'évaluation

- Author - Rapid Tooling - Technologies and Industrial ApplicationsDocument9 pagesAuthor - Rapid Tooling - Technologies and Industrial ApplicationsMarcelo CarvalhoPas encore d'évaluation

- Atari ST-3D Graphics Programming TextDocument364 pagesAtari ST-3D Graphics Programming TextratapiojosaPas encore d'évaluation

- AEC (UK) CAD Standards For Layer Naming v3.0Document45 pagesAEC (UK) CAD Standards For Layer Naming v3.0Richard CleePas encore d'évaluation

- AnsaDocument8 pagesAnsaLakshman KumarPas encore d'évaluation

- On Aircraft Conceptual Design - Linkoping PDFDocument52 pagesOn Aircraft Conceptual Design - Linkoping PDFkearnscribdPas encore d'évaluation

- Metal 2006Document38 pagesMetal 2006Mohamed IbrahimPas encore d'évaluation

- Super Asia PresentationDocument23 pagesSuper Asia PresentationHajiPas encore d'évaluation

- snappyHexMesh On HPCDocument23 pagessnappyHexMesh On HPCxiaochi36Pas encore d'évaluation

- BIMandSDS2 Issue 1Document73 pagesBIMandSDS2 Issue 1Chandra KamalapuramPas encore d'évaluation

- Pir Khalid CV 2024Document2 pagesPir Khalid CV 2024Farzand AliPas encore d'évaluation

- Catia Multicax Installation GuideDocument42 pagesCatia Multicax Installation GuidedhareeshPas encore d'évaluation

- NISA Modeling TutorialDocument22 pagesNISA Modeling Tutorialkeshav1980Pas encore d'évaluation