Académique Documents

Professionnel Documents

Culture Documents

(Kurzweil) LCD Repair Guide PDF

Transféré par

Owen KalauTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

(Kurzweil) LCD Repair Guide PDF

Transféré par

Owen KalauDroits d'auteur :

Formats disponibles

MJS Audio

Kurzweil K2000 LCD Upgrade

Instruction Guide

Revision 2.0

Abstract:

This document describes parts and steps required to upgrade the Kurzweil K2000 LCD to a

CCFL back-light type. Advantages of this LCD over the factory type include greater

brightness, contrast, readability and viewing angle. This document accompanies a box of

pre-prepared components.

This document contains information confidential and proprietary to MJS Audio. It cannot be copied,

distributed or displayed in any form without the consent of MJS Audio. For more information, contact:

Michael Smithers E-mail: michael.smithers@mjsaudio.com

MJS Audio Web: http://www.mjsaudio.com/

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

Contents

1. Introduction...............................................................................................................4

1.1. Parts List................................................................................................................4

1.2. IMPORTANT information and Safety Instructions..............................................5

2. Upgrade Overview ....................................................................................................6

2.1. Connections ...........................................................................................................6

2.2. Electrical Characteristics .......................................................................................7

2.2.1. LCD...............................................................................................................7

2.2.2. DC to AC Inverter.........................................................................................7

2.3. Thermal Characteristics.........................................................................................7

2.4. Physical Dimensions .............................................................................................8

2.4.1. LCD...............................................................................................................8

2.4.2. Inverter ..........................................................................................................8

3. Upgrade Steps ...........................................................................................................9

3.1. Preparing the K2000..............................................................................................9

3.2. Removing the LCD .............................................................................................12

3.3. Modifying the K2000 case ..................................................................................12

3.4. Rerouting the Circuit Board Tracks ....................................................................13

3.5. Installing the new LCD.......................................................................................15

3.6. Replacing the Main-boards .................................................................................15

3.7. Installing the Inverter ..........................................................................................17

3.8. Contrast Adjustment............................................................................................19

4. Appendix A: Component Specifications.................................................................20

4.1. Toshiba TLX-1871-C3B LCD Display...............................................................20

Figures

Figure 2-1: Wiring Diagram..............................................................................................6

Figure 2-2: Comparison of LCD dimensions (all mm) .....................................................8

Figure 3-1: Fan Kit power socket......................................................................................9

Figure 3-2: Sampling Option analog wiring ...................................................................10

Figure 3-3: Main-board 1 ................................................................................................10

Figure 3-4: Main-board 2 ................................................................................................10

Figure 3-5: Earth Strap (lower right side of Main-board 2) ............................................11

Figure 3-6: New LCD and Surrounding Circuit board ...................................................11

Figure 3-7: LCD recess and surrounding circuit board – (before changes)....................12

Figure 3-8: LCD recess and surrounding circuit board – (after changes) .......................12

Figure 3-9: Enameled copper wire ribbon cable .............................................................14

Figure 3-10: Enameled copper wire ribbon cable (LHS closeup)...................................14

Figure 3-11: Enameled copper wire ribbon cable (RHS closeup). .................................14

Figure 3-12: Spacing washers .........................................................................................15

Figure 3-13: Top LCD mounting screws ........................................................................15

Figure 3-14: CCFL cables between the Main-baords .....................................................16

Figure 3-15: LCD Ribbon cable connection to Main-board 1 ........................................16

Figure 3-16: Mounting the inverter in the K2000 back panel.........................................17

Figure 3-17: Nylon inverter mounting bolts ...................................................................17

Figure 3-18: Inverter mounted on the K2000 case (closeup)..........................................18

Page 2 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

Figure 3-19: Fan kit and inverter wiring......................................................................... 18

Figure 3-20: Contrast adjusting trimpot.......................................................................... 19

Figure 4-1: LCD Pin Configuration................................................................................ 20

Tables

Table 2-1: Hard Disk connector pin-out & power supply ratings .................................... 7

Table 4-1: LCD Pin Configuration ................................................................................. 20

Glossary

EL Electro-Luminescent

LCD Liquid Crystal Display

CCFL Cold Cathode Fluorescent

CRO Cathode Ray Oscilloscope

04/10/01 Revision 2. Page 3 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

1. Introduction

The current factory installed LCD in the K2000 series keyboards can be

difficult to read in many circumstances. This due to its very soft EL back-light.

The K2500 series keyboards feature a different LCD that has a CCFL back.

This form of back- light results in a much brighter, more readable LCD display.

This document describes how the EL LCD in a Kurzweil K2000 series

keyboard can be replaced using a CCFL back- light LCD. It provides step by

step instructions, including pictures and diagrams, and should be read in its

entirety before commencing the upgrade. The CCFL LCD gives an almost

identical look and brightness to the LCD in the K2500 series keyboards. The

only difference being that the K2000 has a positive image, whilst the K2500 has

a negative image.

The document accompanies a box of components including the LCD (see

Section 1.1) that have been pre-prepared to allow easy installation. The CCFL

back-light on the new LCD requires a different power supply to the EL power

supply currently in the K2000. A small power inverter has been supplied for

this purpose (see section 1.1 and 3).

At any time after the upgrade has been installed, the new CCFL LCD can

be removed and the Kurzweil factory EL LCD re -installed. No circuitry

used by the factory LCD is changed by this upgrade.

1.1. Parts List

The accompanying box should contain the following components:

⇒ Toshiba TLX-1781-C3B LCD display. It should have both 20 way

ribbon cable and 2 core black silicon cable attached.

⇒ TDK CXA-K0505-VJL Inverter. It should have both 4 way ribbon

cable and 2 core silicon black cable attached.

⇒ 8 core enameled copper wire ribbon cable.

⇒ Packet of M3 (3.0mm) nylon and steel nuts, bolts and washers.

In addition to the components above, there are a number of other CCFL

LCD displays and inverters, available from various ma nufacturers, which

are suitable for this upgrade. Contact MJS Audio for more information.

Page 4 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

1.2. IMPORTANT information and Safety Instructions

Kurzweil WARRANTY

Both the modifications described in this document and the changing of the LCD

breach or void any Kurzweil warranty for the K2000 series keyboards. MJS

Audio accepts no liability for damage resulting from this upgrade.

HARD DISK

This upgrade cannot be installed into a K2000 keyboard that has, or will

have, an internal Hard Disk. The CCFL LCD back- light uses the power

supply normally used for the Hard Disk. This power supply does not have the

capacity to drive both the back- light and a hard disk (see Section 2.2.2). MJS

Audio is currently investigating an alternative power supply for the CCFL

back-light. Contact MJS Audio for details.

FAN KIT

The K2000 Keyboard being upgraded should have the Kurzweil Fan Kit

installed since the CCFL LCD dissipates more heat than the factory EL LCD

(see Section 2.3).

HIGH VOLTAGES

The new CCFL LCD display requires high voltages (up to 1500VAC) to

power the back-light. Care must be exercised at all times to avoid electric

shock from the LCD and the power inverter (see Section 2.2.2 and Section 3.7).

STATIC ELECTRICITY

The electronics inside the K2000 are susceptible to damage from static

electricity. It is recommended that at all times during this upgrade, the K2000

be kept on an anti-static surface. The technician performing the upgrade should

also wear a grounded wrist strap.

HARD RESET

This upgrade involves disconnecting the PRAM backup batteries. Ensure

all important memory is backed up onto disk before commencing this upgrade.

Contrast Adjustment

Slight contrast adjustment may be necessary 10 to 20 minutes after the K2000

keyboard is powered up. This is normal for LCD displays. As the LCD

warms up due to the CCFL tube, the contrast of the LCD changes slightly (see

Section 2.3).

04/10/01 Revision 2. Page 5 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

2. Upgrade Overview

The overall steps involved with this upgrade are as follows.

1. Removing the current factory LCD

2. Removing sections of the circuit board and K2000 case surrounding the

LCD. This also involves rerouting a number of circuit board tracks.

3. Installing the new CCFL LCD.

4. Installing the power inverter required for the CCFL back-light.

These steps will be discussed in detail in Section 3.

2.1. Connections

Figure 2-1 below shows the wiring and components required for this upgrade.

The display has a CCFL tube above the LCD window. This tube is driven by a

DC to AC Inverter which derives its power supply from the Fan Kit wiring.

TDK CXA-K0505-VJL

DC to AC Inverter 500V-1500V

AC

1

Hard Drive

Connector (Plug)

Pin Signal 2 circuit

1 NC Molex Receptacle 51021-0500 JST Housing BHR-03VS-1 connector

2 NC (Molex Terminals 50079 or 50058) (JST Contacts SBH-001T-P0.5) (A)

3 GND (5V) Pin Signal Pin Signal

4 +5VDC (0.4A 1 +5VDC 1 AC Out

Average) 2 GND 2 NC

3 +5VDC 3 AC Return

This plug connects to the 4 GND

Hard Drive socket which is 5 NC

already part of the fan kit. 2 circuit High Voltage

connector Black Silicone

(B) Rubber Cable

Toshiba TLX-1781-C3B

CCFL LCD Display

IDC Socket Through Hole /

(20 Way Ribbon Cable 20C Transition

Bump (goes behind LCD) IDC Connector

polarised) (20 Way,

behind LCD)

Figure 2-1: Wiring Diagram

Of the components supplied in the accompanying box, the JST connector is not

present, as it could not be sourced in Australia. Other terminals have been used

in its place and soldered directly to the pins on the inverter. The soldered

terminals have been covered in Silicon for insulation.

Page 6 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

Note also that the polarity of the AC signal between the inverter and the CCFL

tube is not important. Although these signals are marked AC OUT and AC

RETURN, they are both floating and can be connected either way.

2.2. Electrical Characteristics

2.2.1. LCD

The K2000 uses a 240x64-pixel display based around a Toshiba T6963C

controller chip (also used by many other manufacturers). The Toshiba TLX-

1871-C3B LCD display is pin compatible with the current factory LCD display

that is either a Sharp or a Samsung. See section 4.1 for the pin configuration.

2.2.2. DC to AC Inverter

The TDK CXA-K0505-VJL inverter converts +5VDC to between 500-

1500VAC (sine wave). It connects to the power supply normally reserved for

an internal Hard Disk (see Section 3.7 for installation details). This Hard Drive

power socket is part of the Fan Kit wiring and supplies the following signals

(the current ratings are taken from the Kurzweil web-site).

Pin Signal Current rating

1 +12V DC < 1.0 A Startup, < 0.75 A Continuous

2 GND (12V) NA

3 GND (5V) NA

4 +5V DC < 0.625 A Startup, < 0.625 A Continuous

Table 2-1: Hard Disk connector pin-out & power supply ratings

The inverter connects to pins 3 & 4 and draws 0.4A average current with 0.58A

current peaks (including startup current). This has been measured using a CRO

and is safely within the ratings specified in Table 2-1.

With the inverter connected to this power supply, there is negligible current

available on the +5VDC line to power a Hard Disk. For this reason, this LCD

upgrade must not be installed in a K2000 that has, or will have, an internal Hard

Disk.

MJS Audio is currently investigating alternative DC power supplies for use

with the inverter. For example a low profile 110VAC/6VAC transformer could

be installed to provide a DC power supply completely independent of all other

power supplies in the K2000. Also a separate rectifier and voltage regulator

could be connected to the secondary windings of the current factory installed

transformer.

2.3. Thermal Characteristics

No formal temperature measurements have been made for previous installations

of this upgrade. However informal measurements (using fingers, hands) show a

definite increase in LCD temperature, above room temperature. To avoid

04/10/01 Revision 2. Page 7 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

problems in the K2000 it is recommended that the Fan Kit always be present or

installed, even if the Fan Kit (hence Hard Disk connector) is not used as the

source of power for the inverter.

It is a common fact that the contrast of LCD displays change with temperature,

hence the CONTRAST parameter in the K2000 software. As the new LCD

warms up, due to the CCFL tube, its contrast will noticeably change. The

CONTRAST parameter will sometimes need adjustment 10-20 minutes after

powering up the K2000.

2.4. Physical Dimensions

2.4.1. LCD

Figure 2-2 shows a comparison between the new CCFL back- light display and

the current EL back-light display. Both displays are approximately the same

thickness however the CCFL display is 9 mm taller. To install the CCFL LCD,

some of the K2000 case and circuit board above the current EL LCD must be

removed (see Section 3.3)

CCFL LCD Display

14.5

27 50

70

7.5

176

180

14 Max

EL LCD Display 5.5

27 54

65

176 5.4

180

12 Max

Figure 2-2: Comparison of LCD dimensions (all mm)

Note also that the vertical distance between the mounting holes is not the same.

This will be addressed in Section 3.5.

2.4.2. Inverter

The inverter is extremely small at 87 x 16.5 x 6 mm and can be mounted almost

anywhere inside the K2000 (see Section 3.7).

Page 8 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

3. Upgrade Steps

This section provides step by step instructions on how to perform the upgrade.

Note: Main-board 1 refers to the circuit board that holds the EPROM’s and

the sample DRAM

Main-board 2 refers to the circuit board with the Digitech effects

processor and analog output circuitry.

3.1. Preparing the K2000

• Place the K2000 upside down with the keys facing away. Make sure the

K2000 is supported at both ends so as not to damage the Mod. and Pitch

Bend wheels.

• Remove the 6 back panel screws and remove the back panel. Unplug the

fan wiring from Main-board 2 (see Figure 3-1: the Fan Kit power socket is

circled).

Figure 3-1: Fan Kit power socket

• Unplug all the connectors, including ribbon connectors and power

connectors, from the two main-boards. If the sampling option is installed,

the sampling option analog cable is soldered to the top right of Main-board

2 (see Figure 3-2) – leave this in place but be careful when removing the

main-boards as the solder can easily.

• Remove the 12 screws holding the two main-boards in place (see Figure 3-3

and Figure 3-4: the screws are circled).

04/10/01 Revision 2. Page 9 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

Figure 3-2: Sampling Option analog wiring

Figure 3-3: Main-board 1

Figure 3-4: Main-board 2

Page 10 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

• Unscrew the nut and washers (lower right of Main-board 2) and remove the

earth strap (see Figure 3-5).

Figure 3-5: Earth Strap (lower right side of Main-board 2)

• Gently remove Main-boards 1 & 2 - the boards are joined in the middle and

have a common metal back-plane (be careful not to break the sampling

option analog cables which are still soldered to the top of Main-board 2).

The factory LCD and a number of ribbon cables can now be seen. Figure

3-6 shows this with the new LCD in place, not the old – everything else is

the same.

Figure 3-6: New LCD and Surrounding Circuit board

• Remove the sticky tape holding the ribbon cables to the LCD and circuit

board, and move the ribbon cables out of the way of the LCD. Keep the

tape as it will be used to tape down the ribbon cables when the new LCD is

in place.

What should now be visible is the factory LCD held in by four screws.

04/10/01 Revision 2. Page 11 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

3.2. Removing the LCD

• Remove the four screws that hold the LCD in place, and lift out the LCD.

Keep the screws as they will be needed to screw the new LCD in place.

There will be a rectangle of spongy foam stuck to the front of the LCD. This

creates a seal between the LCD and the window of the K2000 case.

• Gently pull the foam off the LCD and stick it onto the new CCFL LCD.

The foam will most likely stretch as it is pulled off. If this occurs, cut

sections out of the foam to ensure its size remains the same when placed on

the new LCD.

3.3. Modifying the K2000 case

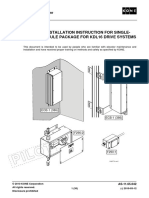

What can now be seen is the LCD recess (Figure 3-7). The window has a

blackened edge surrounding the clear center LCD viewing area.

CROSS

SECTION

CIRCUIT BOARD

K2000

CLEAR

WINDOW

~ 6.5 mm

8 THIN COPPER TRACKS K2000 CASE

Figure 3-7: LCD recess and surrounding circuit board – (before changes)

CROSS

SECTION

CIRCUIT BOARD

K2000

CLEAR

WINDOW

~ 14 mm

~ 8 mm

~ 1.0 mm

8 THIN COPPER TRACKS

K2000 CASE

Figure 3-8: LCD recess and surrounding circuit board – (after changes)

Page 12 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

• The circuit board and the K2000 case have to be cut away to make room for

the CCFL back- light above the LCD (see Figure 3-8). Approximately 8 mm

of the circuit board must be cut away, and approximately 14 mm of the

K2000 case.

The cutting can performed using a Dremel or Arlec super-tool with a small

rotating disc/blade. The copper tracks on the circuit board will be severed and

repaired later in section 3.4.

Ensure that a vacuum cleaner is held near the blade when cutting the K2000

case and circuit board. Plastic and circuit board dust tends to go everywhere!

Place the new LCD in the recess at any time to test if more case needs to be cut

away. Ensure that there is a gap of 1 or 2 mm between the cut away circuit

board and CCFL tube. The LCD should fit comfortably however the LCD

circuit board will sit a little above the screw holes (where the LCD is held into

place). This is because the front of the new LCD is approximately 2 mm deeper

than the previous LCD: this difference will be padded up with washers when

the LCD is screwed into place.

Important: When cutting the K2000 case, do not cut or remove the case all the

way to the clear window. Leave about 1mm thickness of the case,

otherwise light from the back- light will appear through the case.

Be careful also not to scratch the thin black coating on the clear

window –unwanted back- lighting will appear through the scratch.

3.4. Rerouting the Circuit Board Tracks

• Take the pre-prepared ribbon cable made from the enamel copper wire and

place it on the circuit board as shown in Figure 3-9.

• Solder the ends of the enameled copper wire to the severed circuit board

tracks (see Figure 3-10 and Figure 3-11) by first:

• trimming each cable to a suitable length so that they meet each track

neatly,

• scraping away a small section of the green enameled coating on each of

the circuit board tracks, and

• scraping away the enamel on the ends of the copper wires.

Important: Make sure the copper wires are soldered to the correct tracks –

i.e. ensure the tracks are in the same order at both ends. When

soldering is complete, test track continuity with a multi- meter.

04/10/01 Revision 2. Page 13 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

Figure 3-9: Enameled copper wire ribbon cable

• Glue or tape the enameled copper ribbon cable to the circuit board so that it

doesn’t move or fall into the LCD recess.

Figure 3-10: Enameled copper wire ribbon cable (LHS closeup).

Figure 3-11: Enameled copper wire ribbon cable (RHS closeup).

Page 14 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

3.5. Installing the new LCD

• Screw the LCD in place in the LCD recess using screws in the top two holes

(pointed to in Figure 3-13). Use 4 or 5 of the steel washers (supplied in the

box components) between the LCD circuit board and the K2000 case (see

Figure 3-12). These washers are required because the front of the new LCD

is approximately 2 mm deeper than the old LCD. The exact number of

washers may depend on how compact the foam on the front of the LCD is.

SCREW SPLIT WASHER

LCD CIRCUIT BOARD

WASHERS

K2000 CASE

Figure 3-12: Spacing washers

The two screw holes nearest the K2000 keys will be out of alignment by 4 mm.

If necessary, drill two new holes in the K2000 case (lining up with the LCD

holes) using a M2 (2 mm) drill bit. Be careful not to drill right through the

case. Screw in the remaining two screws. Again ensure that washers are used

to fill the gap between the LCD circuit board and the K2000 case.

Figure 3-13: Top LCD mounting screws

3.6. Replacing the Main-boards

• Tape down the ribbon cables over the circuit board and the new LCD – as

they were prior to removing the old LCD. Fold the ribbon cable from the

new LCD at right angles in the same place as the ribbon cable from the old

LCD. This allows the ribbon cable to pass behind and plug into Main-board

1 (see Figure 3-15).

• Gently replace the two Main-boards. Allow the black silicone cables

coming from the CCFL tube to pass between the two Main-boards (the

04/10/01 Revision 2. Page 15 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

cables are shown in white in Figure 3-14). Ensure that connector (A) from

Figure 2-1 stays underneath the main-boards.

Figure 3-14: CCFL cables between the Main-baords

• Screw down the two main-boards and reconnect all cabling, including the

new LCD’s ribbon cable (see Figure 3-15).

Figure 3-15: LCD Ribbon cable connection to Main-board 1

• Reconnect the earth strap in Figure 3-5.

Page 16 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

3.7. Installing the Inverter

The inverter can be installed in a number of different places. Probably the best

location is shown in Figure 3-16. Here the inverter is screwed to the K2000

back panel, approximately 400 mm from the fan end.

TO CCFL

INVERTER BACK-LIGHT

CONNECTOR

(B)

400 mm TO K2000 MAINBOARD

FAN

FAN WIRING

HARD DISK

CONNECTOR

Figure 3-16: Mounting the inverter in the K2000 back panel

The nylon bolts provided in the box of components can be used to hold the

inverter in place. This involves drilling right through the back panel using a

M3 (3 mm) drill and countersinking the bolt heads (see Figure 3-17). The

nylon washers are used as spacers to prevent the inverter circuitry, especially

the high voltage output, touching or conduction to the K2000 case.

The bolt heads will be visible from the outside of the K2000. This mounted

inverter can be seen in Figure 3-18 and Figure 3-19.

M3 NYLON BOLT

K2000 CASE

NYLON WASHERS

INVERTER CIRCUIT NYLON NUT

BOARD

Figure 3-17: Nylon inverter mounting bolts

An alternative to using the Nylon bolts wo uld be to drill thin 1.5 or 2 mm holes

from the inside of the case and use self- tapping screws to hold the inverter in

place. This prevents holes from being seen from the outside of the K2000 case

but care must be taken to ensure the self- tapping screws do not short any

circuitry on the inverter.

04/10/01 Revision 2. Page 17 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

Figure 3-18: Inverter mounted on the K2000 case (closeup)

Figure 3-19: Fan kit and inverter wiring

Page 18 of 20 Revision 2. 04/10/01

MJS Audio Kurzweil K2000 LCD Upgrade

Instruction Guide

3.8. Contrast Adjustment

• Connect the CCFL black silicone wiring and the inverter together at

connector (B) (from Figure 2-1).

• Plug the Fan Kit wiring to Main-board 2 (see Figure 3-1).

• Plug the inverter to the Fan Kit wiring by connecting the Hard Drive plug &

socket (see Figure 3-19: lower right hand side).

The K2000 is now ready to be powered up!

• Connect 110VAC mains power and turn the K2000 on. The LCD should be

glowing a bright blue but most likely will not be displaying anything. This

is because the displays contrast needs adjustment.

• Raise the K2000 slightly so the display is visible.

• Turn the Black trimpot (see Figure 3-20) slightly in either direction until

characters become visible on the LCD. This trimpot adjusts the LCD drive

voltage (VEE in Table 4-1) and works in addition to the software

CONTRAST parameter in the K2000.

The software CONTRAST parameter should currently be zero, since the K2000

has just come out of a hard reset due to the batteries being disconnected.

Figure 3-20: Contrast adjusting trimpot

• Turn off the K2000 and unplug the 110 VAC mains power.

• Screw the back panel back onto the K2000

The upgrade is now finished!

04/10/01 Revision 2. Page 19 of 20

Kurzweil K2000 LCD Upgrade MJS Audio

Instruction Guide

4. Appendix A: Component Specifications

4.1. Toshiba TLX-1871-C3B LCD Display

CCFL TUBE

2 1

LCD Surface

20 19

Figure 4-1: LCD Pin Configuration

Pin No. Signal Function

1 FGND Frame Ground (0V)

2 GND Ground (Signal ground 0V)

3 VDD Power Supply for Logic

4 VEE Power Supply for LCD drive (should be variable)

5 WR Data write (write data to the LCD module at “L”)

6 RD Data read (write data to the LCD module at “L”)

7 CE Chip enable for the LCD module

8 C/D WR=”L”, C/D=”H” : Command write

WR=”L”, C/D=”L” : Data write

RD=”L”, C/D=”H” : Status read

RD=”L”, C/D=”L” : Data read

9 NC No connection

10 RESET Module reset (controller reset)

11-18 D0 – D7 Data Input/Output (LSB-D0, MSB-D7)

19 FS Font select: Connect to VDD : 6x8 pixels/char

Connect to GND : 8x8 pixels/char

20 RV Reverse Connect to VDD : Positive Mode

Connect to GND : Negative Mode

Table 4-1: LCD Pin Configuration

Page 20 of 20 Revision 2. 04/10/01

Vous aimerez peut-être aussi

- AN-31 Amplifier Circuit Collection PDFDocument42 pagesAN-31 Amplifier Circuit Collection PDFcasagrandePas encore d'évaluation

- SW Radio PDFDocument5 pagesSW Radio PDFAhmed BoubakerPas encore d'évaluation

- Triacs and DiacsDocument4 pagesTriacs and Diacsssami670Pas encore d'évaluation

- Zener Diod PDFDocument11 pagesZener Diod PDFالزهور لخدمات الانترنيتPas encore d'évaluation

- Proteus VSM Sample FilesDocument35 pagesProteus VSM Sample FilesBujji RK0% (1)

- PSpice - A Tutorial - L.H. Fenical (1992)Document364 pagesPSpice - A Tutorial - L.H. Fenical (1992)Suyuk MadikPas encore d'évaluation

- Beginner's Guide to 4NEC2 Antenna Simulation SoftwareDocument5 pagesBeginner's Guide to 4NEC2 Antenna Simulation Softwarephanvanvinh86Pas encore d'évaluation

- Induction Cooking Theory and Operation GuideDocument37 pagesInduction Cooking Theory and Operation GuideShri KulkarniPas encore d'évaluation

- Einsy Rambo SchematicDocument11 pagesEinsy Rambo Schematicbob de visPas encore d'évaluation

- DC AC InvertorDocument61 pagesDC AC InvertorPaul TodericPas encore d'évaluation

- Electronic Thermostat Circuit Using TransistorsDocument2 pagesElectronic Thermostat Circuit Using Transistorstim schroderPas encore d'évaluation

- Mosfet Notes 1Document9 pagesMosfet Notes 1Anil SaiPas encore d'évaluation

- How To Use NUCLEO-F401RE and MbedDocument14 pagesHow To Use NUCLEO-F401RE and MbedmavisXzeref 17Pas encore d'évaluation

- RF Circuit Design Theory and Applications Volume 1Document8 pagesRF Circuit Design Theory and Applications Volume 1Nirav SolankiPas encore d'évaluation

- Note On HFSS Field Calculator PDFDocument34 pagesNote On HFSS Field Calculator PDFpasquale_dottorato0% (1)

- (Dos, Don'Ts, and Common Pitfalls) : Compactpci SystemsDocument4 pages(Dos, Don'Ts, and Common Pitfalls) : Compactpci SystemsMadhavesh KulkarniPas encore d'évaluation

- Color Television ReceiverDocument42 pagesColor Television ReceiverTesfaye Mengistie ZewdePas encore d'évaluation

- Zener Diode Applications and Working PrincipleDocument17 pagesZener Diode Applications and Working PrincipleAdnan AhmedPas encore d'évaluation

- DC Characteristics of A MOS Transistor (MOSFET) : Solved With COMSOL Multiphysics 4.4Document18 pagesDC Characteristics of A MOS Transistor (MOSFET) : Solved With COMSOL Multiphysics 4.4shree_rs81Pas encore d'évaluation

- Dell s2810dn TsDocument156 pagesDell s2810dn TsTaur1968Pas encore d'évaluation

- DC-DC Step-Down FelixDocument31 pagesDC-DC Step-Down FelixGFGHJHKPas encore d'évaluation

- 22.power MOSFETDocument35 pages22.power MOSFETArpan ChoudhuryPas encore d'évaluation

- Charge Pump 4Document15 pagesCharge Pump 4r96221029Pas encore d'évaluation

- Laplace Transforms1Document110 pagesLaplace Transforms1nileshsawPas encore d'évaluation

- Circuit Theory and Design of Power Factor Correction Power SuppliesDocument51 pagesCircuit Theory and Design of Power Factor Correction Power Supplies양영주Pas encore d'évaluation

- Work Bench PDFDocument25 pagesWork Bench PDFJimi DbonoPas encore d'évaluation

- Darlington PairDocument5 pagesDarlington PairHubert Sheldon Diaz100% (1)

- Teccor Electronics Non-Sensitive Gate SCR Technical SpecificationsDocument12 pagesTeccor Electronics Non-Sensitive Gate SCR Technical SpecificationsGerardo Luis Velázquez GarcíaPas encore d'évaluation

- Three Valve ReceiversDocument25 pagesThree Valve ReceiversSam100% (4)

- X Ray LithographyDocument59 pagesX Ray LithographyMohammad RameezPas encore d'évaluation

- Photo LithographyDocument112 pagesPhoto LithographyNaveen VachipalliPas encore d'évaluation

- Single Transistor Crystal Oscillator CircuitsDocument3 pagesSingle Transistor Crystal Oscillator CircuitsNiko GlamuzinaPas encore d'évaluation

- Soft Ferrite Cores User Guide PDFDocument52 pagesSoft Ferrite Cores User Guide PDFPrithvi ScorpPas encore d'évaluation

- 555 Timer - Oscillator TutorialDocument14 pages555 Timer - Oscillator TutorialfgaluppoPas encore d'évaluation

- I2c TsopDocument7 pagesI2c TsopChayan ShahPas encore d'évaluation

- Magnetic Polarity Detector Circuit Using Hall Effect SensorDocument11 pagesMagnetic Polarity Detector Circuit Using Hall Effect SensorKoushik MaityPas encore d'évaluation

- Optocoupler DevicesDocument7 pagesOptocoupler Devicesjimdigriz100% (2)

- ADS Session1Document14 pagesADS Session1Văn CôngPas encore d'évaluation

- (Ebook - PDF) - How Networks Work, Fourth Edition PDFDocument71 pages(Ebook - PDF) - How Networks Work, Fourth Edition PDFNorakrith KhenPas encore d'évaluation

- Vtu Final Report HowtoDocument18 pagesVtu Final Report HowtohemarajaaPas encore d'évaluation

- A Simple Physical Derivation of Child-Langmuir Space-Charge-LimitedDocument4 pagesA Simple Physical Derivation of Child-Langmuir Space-Charge-LimitedajdsauipqazmmPas encore d'évaluation

- lbp2410 eDocument270 pageslbp2410 evaleri kinshakovPas encore d'évaluation

- As 2401.1-1994 Battery Chargers For Lead-Acid Batteries - Domestic Type Battery Chargers For Vented CellsDocument7 pagesAs 2401.1-1994 Battery Chargers For Lead-Acid Batteries - Domestic Type Battery Chargers For Vented CellsSAI Global - APACPas encore d'évaluation

- Jackson 14.1Document9 pagesJackson 14.1CMPaulPas encore d'évaluation

- Power Electronics Laboratory User Manual: Safety Precautions and Power-pole Board FamiliarizationDocument56 pagesPower Electronics Laboratory User Manual: Safety Precautions and Power-pole Board FamiliarizationNebojsa VuksanPas encore d'évaluation

- Theory of Oscilloscope: Introduction To CADDocument23 pagesTheory of Oscilloscope: Introduction To CADHifdzul Malik ZainalPas encore d'évaluation

- Electronics Projects For School StudentsDocument62 pagesElectronics Projects For School StudentsRamasamy ChinnasamyPas encore d'évaluation

- Fundamentals of Electronic Circuit DesignDocument59 pagesFundamentals of Electronic Circuit DesignKanza KhanPas encore d'évaluation

- Time-Harmonic Electromagnetic FieldDocument39 pagesTime-Harmonic Electromagnetic Fieldatom tuxPas encore d'évaluation

- Charge Pump Low Voltage Op AmpDocument2 pagesCharge Pump Low Voltage Op AmpapproposePas encore d'évaluation

- Theory From LCDDocument80 pagesTheory From LCDjannijsPas encore d'évaluation

- Manual Servico TV Sony KDL 22bx325Document62 pagesManual Servico TV Sony KDL 22bx325Robson Santos100% (1)

- On 220w LCD TV Power SupplyDocument22 pagesOn 220w LCD TV Power Supplysontuyet82Pas encore d'évaluation

- Philips+VES1 1E+LA PDFDocument79 pagesPhilips+VES1 1E+LA PDFotmestiPas encore d'évaluation

- Philips Chassis Ves1 1e La PDFDocument77 pagesPhilips Chassis Ves1 1e La PDFVukica Ivic100% (2)

- CC2511 Dongle User Manual Rev. 1.0Document24 pagesCC2511 Dongle User Manual Rev. 1.0Devrim Deniz MarcosPas encore d'évaluation

- Emergency Batterie RescueDocument30 pagesEmergency Batterie Rescuesamuel_ventura4Pas encore d'évaluation

- Funai Lt850 m32Document76 pagesFunai Lt850 m32fox7878Pas encore d'évaluation

- AOC LCD Monitor 786LS Service ManualDocument36 pagesAOC LCD Monitor 786LS Service ManualEduardo Hernandez BautistaPas encore d'évaluation

- KSS Formation Kone 2006Document52 pagesKSS Formation Kone 2006henrique nogueira100% (3)

- Ibm Thinkpad 390E Notebooks: Affordable Easy-To-Use Business NotebooksDocument4 pagesIbm Thinkpad 390E Notebooks: Affordable Easy-To-Use Business NotebooksOwen KalauPas encore d'évaluation

- Ensoniq DP4 Service ManualDocument33 pagesEnsoniq DP4 Service ManualOwen KalauPas encore d'évaluation

- 1992 Toyota Vacuum DiagramsDocument18 pages1992 Toyota Vacuum DiagramsOscar Niebla100% (2)

- Professional Control Surface / Firewire Audio-Midi InterfaceDocument42 pagesProfessional Control Surface / Firewire Audio-Midi InterfaceOwen KalauPas encore d'évaluation

- Emglo Troubleshooting PDFDocument1 pageEmglo Troubleshooting PDFOwen KalauPas encore d'évaluation

- CFAG24064A TTI TZDatasheetReleaseDate2017!08!09Document11 pagesCFAG24064A TTI TZDatasheetReleaseDate2017!08!09Owen KalauPas encore d'évaluation

- 1992 Toyota Vacuum DiagramsDocument18 pages1992 Toyota Vacuum DiagramsOscar Niebla100% (2)

- Manual pb48Document4 pagesManual pb48Hugo FrancoPas encore d'évaluation

- Ibanez Ph99 SchematicDocument1 pageIbanez Ph99 SchematicOwen KalauPas encore d'évaluation

- 1990 Honda Civic Hatchback-Sedan Owners ManualDocument131 pages1990 Honda Civic Hatchback-Sedan Owners ManualLisa Marsh100% (1)

- 3828w5a4131 enDocument28 pages3828w5a4131 enOwen KalauPas encore d'évaluation

- Parts Manual: Generator SetDocument84 pagesParts Manual: Generator SetJames Scott Valderrama Risco100% (5)

- Lab ReportDocument3 pagesLab ReportSudharani SwainPas encore d'évaluation

- Electrical SORDocument70 pagesElectrical SORsanjaysonerPas encore d'évaluation

- Electrical AnalysisDocument41 pagesElectrical AnalysisAbinash MandalPas encore d'évaluation

- EdcDocument21 pagesEdcThiaga RajanPas encore d'évaluation

- GEYA ELECTRICAL CO.,LTD Instruction Manual for Single-function Time Relay GRT8-A&BDocument2 pagesGEYA ELECTRICAL CO.,LTD Instruction Manual for Single-function Time Relay GRT8-A&BSanny HamdaniPas encore d'évaluation

- MK Fireman SwitchDocument2 pagesMK Fireman SwitchTommy MuiPas encore d'évaluation

- 5B3 Fact Sheet (New) PDFDocument4 pages5B3 Fact Sheet (New) PDFDave ChaudhuryPas encore d'évaluation

- Electronic switchgear and accessories BEG rectifiers setting the standardDocument48 pagesElectronic switchgear and accessories BEG rectifiers setting the standardGENTA NUSA ATLANTISPas encore d'évaluation

- Product Details: Brush DC Motor 14204S005Document1 pageProduct Details: Brush DC Motor 14204S005Vicente A. ApolonioPas encore d'évaluation

- Hyundai Accent - BCM Connectors - Body Control Module (BCM) - Schematic Diagrams - BCM (Body Control Module) - Body Electrical SystemDocument2 pagesHyundai Accent - BCM Connectors - Body Control Module (BCM) - Schematic Diagrams - BCM (Body Control Module) - Body Electrical SystemRomeo HinogPas encore d'évaluation

- RFIA Push Button CatalogueDocument89 pagesRFIA Push Button CatalogueBio Eng Eslam TahaPas encore d'évaluation

- 33 KV SS EarthingDocument31 pages33 KV SS Earthingrahul SinghPas encore d'évaluation

- Releasing Control Panel: FeaturesDocument2 pagesReleasing Control Panel: FeaturesTanveer AzizPas encore d'évaluation

- 52 5320 Diagr A019854Document164 pages52 5320 Diagr A019854RasmusKoefoedPas encore d'évaluation

- Forklift Truck Fuses: Special PurposeDocument4 pagesForklift Truck Fuses: Special PurposeRizqy Fadry LazimPas encore d'évaluation

- Clii-9jqn8v R0 enDocument2 pagesClii-9jqn8v R0 enDezső GálfyPas encore d'évaluation

- Foxboro Evo™ SCD6000 Wide Range Input Power Supply ModuleDocument8 pagesFoxboro Evo™ SCD6000 Wide Range Input Power Supply ModuleWisnu HartonoPas encore d'évaluation

- Electrical Layout of Residential BuildingDocument6 pagesElectrical Layout of Residential BuildingmooorthuPas encore d'évaluation

- GPMR 72 P (72X72) Operation: (12 and 24vcc)Document3 pagesGPMR 72 P (72X72) Operation: (12 and 24vcc)carlosmarciosfreitas50% (2)

- PLF-77 Servive ManualDocument26 pagesPLF-77 Servive Manualapi-3711045100% (1)

- UGC05 - BOQ - STATIONS - MEP Elect - ICTDocument83 pagesUGC05 - BOQ - STATIONS - MEP Elect - ICTManglesh SinghPas encore d'évaluation

- Electrical Installation CourseDocument4 pagesElectrical Installation Coursetdcgam26Pas encore d'évaluation

- Bac HD 230 Holiday Detector: FeaturesDocument1 pageBac HD 230 Holiday Detector: FeaturesAhmed MagdiPas encore d'évaluation

- SS341 ManualDocument6 pagesSS341 ManualLuis Migeru VelascoPas encore d'évaluation

- Applications and Working of PMBLDC MotorsDocument8 pagesApplications and Working of PMBLDC MotorsvlkumashankardeekshithPas encore d'évaluation

- I T5 A LVN: Street Light Fittings With Lower CoverDocument1 pageI T5 A LVN: Street Light Fittings With Lower Coverionelg834549Pas encore d'évaluation

- Ijsrp p3626 PDFDocument4 pagesIjsrp p3626 PDFMohamed Taleb100% (1)

- Saturn F5 TSBDocument5 pagesSaturn F5 TSBlamping_apPas encore d'évaluation

- HV Igbt Includes Active ClampingDocument2 pagesHV Igbt Includes Active ClampingdhruvPas encore d'évaluation

- Chip War: The Quest to Dominate the World's Most Critical TechnologyD'EverandChip War: The Quest to Dominate the World's Most Critical TechnologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (227)

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002D'EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Évaluation : 5 sur 5 étoiles5/5 (1)

- Chip War: The Fight for the World's Most Critical TechnologyD'EverandChip War: The Fight for the World's Most Critical TechnologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (82)

- 8051 Microcontroller: An Applications Based IntroductionD'Everand8051 Microcontroller: An Applications Based IntroductionÉvaluation : 5 sur 5 étoiles5/5 (6)

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102D'EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Évaluation : 5 sur 5 étoiles5/5 (2)

- Amazon Web Services (AWS) Interview Questions and AnswersD'EverandAmazon Web Services (AWS) Interview Questions and AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XD'EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XÉvaluation : 3 sur 5 étoiles3/5 (2)

- Model-based System and Architecture Engineering with the Arcadia MethodD'EverandModel-based System and Architecture Engineering with the Arcadia MethodPas encore d'évaluation

- Dancing with Qubits: How quantum computing works and how it can change the worldD'EverandDancing with Qubits: How quantum computing works and how it can change the worldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Creative Selection: Inside Apple's Design Process During the Golden Age of Steve JobsD'EverandCreative Selection: Inside Apple's Design Process During the Golden Age of Steve JobsÉvaluation : 4.5 sur 5 étoiles4.5/5 (49)

- 2018 (40+) Best Free Apps for Kindle Fire Tablets: +Simple Step-by-Step Guide For New Kindle Fire UsersD'Everand2018 (40+) Best Free Apps for Kindle Fire Tablets: +Simple Step-by-Step Guide For New Kindle Fire UsersPas encore d'évaluation

- Hacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxD'EverandHacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxPas encore d'évaluation

- From Cell Phones to VOIP: The Evolution of Communication Technology - Technology Books | Children's Reference & NonfictionD'EverandFrom Cell Phones to VOIP: The Evolution of Communication Technology - Technology Books | Children's Reference & NonfictionPas encore d'évaluation

- Electronic Dreams: How 1980s Britain Learned to Love the ComputerD'EverandElectronic Dreams: How 1980s Britain Learned to Love the ComputerÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionD'EverandCancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionÉvaluation : 5 sur 5 étoiles5/5 (2)

- The No Bull$#!£ Guide to Building Your Own PC: No Bull GuidesD'EverandThe No Bull$#!£ Guide to Building Your Own PC: No Bull GuidesPas encore d'évaluation