Académique Documents

Professionnel Documents

Culture Documents

Experiment 1 Ziegler Nichols Tuning: 1 Objective

Transféré par

HEMANT KUMARTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Experiment 1 Ziegler Nichols Tuning: 1 Objective

Transféré par

HEMANT KUMARDroits d'auteur :

Formats disponibles

Experiment 1

ZIEGLER NICHOLS TUNING

1 OBJECTIVE

Design the P, PI, PID controller for a given transfer function by using Ziegler

Nichols Tuning method.

2 THEORY

Ziegler and Nichols proposed rules for determining values of the proportional

gain, integral time and derivative time based on the transient response characteristics of

a given plant. Such determination of the parameters of PID controllers or tuning of PID

controllers can be made by engineers on-site by experiments on the plant.

There are two methods called Ziegler-Nichols tuning rules: the first method and

second method.

2.1 First Method

In the first method, we obtain step response of a plant experimentally. By using

that output curve we have to calculate delay time L and time constant T. The delay time

and time constant are determined by drawing a tangent line at the inflection point of the

(S-shaped) curve.

Fig.1. Response curve for ZN first method

TABLE.I Ziegler-Nichols tuning rule based on step response of plant

2.2 Second Method

In this method we have to calculate critical gain and corresponding time period

of a plant by using Routh Hurwitz Criteria.

3 ZIEGLER NICHOLS MATLAB CODE

%Hemant Kumar 19530006

%ZIEGLER NICHOLS TUNING

clear all;

close all;

num=[6];

din=[1 6 11 6];

G=tf(num,din) %plant transfer function

figure(1)

step(G)

CL_G=feedback(G,1)

figure(2)

step(CL_G)

Kc=margin(G)% using routh hurwitz criteria we can calculate

Kc=10

T=1.8945

figure(3)

% P controller design

Kp1=0.5*Kc con1=Kp1

com1=series(G,con1);

P_sys=feedback(com1

,1)

hold on

step(P_sys)

% PI controller design

Kp2=0.45*Kc

Ki2=(1/(0.83*T))*Kp2

con2=tf([Kp2 Ki2],[1 0])

com2=series(G,con2);

PI_sys=feedback(com2

,1)

hold on

step(PI_sys)

% PID controller design

Kp3=0.6*Kc

Ki3=(1/(0.5*T))*Kp3

Kd3=(0.125*T)*Kp3

con3=tf([Kd3 Kp3 Ki3],[1

0]) com3=series(G,con3);

PID_sys=feedback(com3,1

) step(PID_sys)

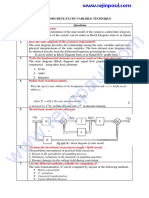

4 ZIEGLER NICHOLS MATLAB SIMULINK MODEL

Fig.2. Matlab Simulink model of PID controller with plant

5 OUTPUT OF ZIEGLER NICHOLS METHOD

Type of

Controller

P 5 ∞ 0

PI 4.5 2.862 0

PID 6 6.334 1.421

Fig.3. unit step response of the system

Fig.4.Unit step response with critical gain Kc=10

Fig.5. P controller output response

Fig.6. PI controller output response

Fig.7. PID controller output response

Vous aimerez peut-être aussi

- Advanced Techniques and Technology of Computer-Aided Feedback ControlD'EverandAdvanced Techniques and Technology of Computer-Aided Feedback ControlPas encore d'évaluation

- Ziegler Nichols Matlab PDFDocument8 pagesZiegler Nichols Matlab PDFMarco Arcos100% (2)

- Design of PID ControllerDocument13 pagesDesign of PID ControllershrikrisPas encore d'évaluation

- Lecture 7: System Performance and StabilityDocument20 pagesLecture 7: System Performance and StabilitySabine Brosch100% (1)

- Parameter Identification and Modelling of Separately Excited DC MotorDocument8 pagesParameter Identification and Modelling of Separately Excited DC MotorIJIERT-International Journal of Innovations in Engineering Research and TechnologyPas encore d'évaluation

- PID ControlDocument22 pagesPID ControlJessica RossPas encore d'évaluation

- Block diagram algebra and transfer functionsDocument7 pagesBlock diagram algebra and transfer functionsSheroz Rajab Ali SoomroPas encore d'évaluation

- Tutorial III Root Locus DesignDocument25 pagesTutorial III Root Locus Designapi-3856083100% (3)

- Transducer and Their ClassificationDocument2 pagesTransducer and Their ClassificationPujaChaudhuryPas encore d'évaluation

- Control System Engineering: Lab Report 01Document11 pagesControl System Engineering: Lab Report 01Zain UL ABIDINPas encore d'évaluation

- DC Motor Speed Control Using Sliding ModeDocument5 pagesDC Motor Speed Control Using Sliding ModeAbdullah ÇakanPas encore d'évaluation

- Understanding the Ziegler–Nichols Tuning Method for PID Speed Control of a DC MotorDocument13 pagesUnderstanding the Ziegler–Nichols Tuning Method for PID Speed Control of a DC MotorSaran SelvanPas encore d'évaluation

- Position Form & Velocity Form of PID ControllerDocument6 pagesPosition Form & Velocity Form of PID ControllerThefairman UnkownPas encore d'évaluation

- Lab Pid Motor ControlDocument17 pagesLab Pid Motor ControlacajahuaringaPas encore d'évaluation

- Duck Feeding TrialDocument5 pagesDuck Feeding TrialYugi MarshalPas encore d'évaluation

- Program 1: Write A Program Using MATLAB To Plot Pole Zero Map While Transfer Function Is GivenDocument21 pagesProgram 1: Write A Program Using MATLAB To Plot Pole Zero Map While Transfer Function Is GivenShruti BhatnagarPas encore d'évaluation

- Ziegler-Nichols Controller Tuning ExampleDocument6 pagesZiegler-Nichols Controller Tuning ExampleChristine AvdikouPas encore d'évaluation

- State Errors - Steady: Eman Ahmad KhalafDocument28 pagesState Errors - Steady: Eman Ahmad KhalafAhmed Mohammed khalfPas encore d'évaluation

- GCSE Bearings: Measuring Bearings Test Your UnderstandingDocument5 pagesGCSE Bearings: Measuring Bearings Test Your UnderstandingSamuel KalemboPas encore d'évaluation

- Lab Manual - EEE 402 - Exp01 July2014Document7 pagesLab Manual - EEE 402 - Exp01 July2014AhammadSifatPas encore d'évaluation

- Chapter 1 EbelingDocument28 pagesChapter 1 Ebelingrizqiaisyah100% (1)

- Understanding Pole-Zero Plots On The S PlaneDocument7 pagesUnderstanding Pole-Zero Plots On The S PlaneGwenShepherdPas encore d'évaluation

- Nyquist Stability CriterionDocument20 pagesNyquist Stability CriterionmoosuhaibPas encore d'évaluation

- Oscillator PDFDocument4 pagesOscillator PDFJoshua DuffyPas encore d'évaluation

- Sketching Graphs - GCSE Maths - Steps, Examples & WorksheetDocument25 pagesSketching Graphs - GCSE Maths - Steps, Examples & Worksheetsyl.sylvia000Pas encore d'évaluation

- Exp - No.6 - Transient Response of RLC CircuitsDocument3 pagesExp - No.6 - Transient Response of RLC Circuitsforest lifePas encore d'évaluation

- Transfer Function ProsesDocument34 pagesTransfer Function ProsesMalasari NasutionPas encore d'évaluation

- Transducer: Controller (Control Theory)Document5 pagesTransducer: Controller (Control Theory)Farrukh JamilPas encore d'évaluation

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument12 pagesMeasurement Systems: Application and Design by Ernest O. Doebelinvlsipranati100% (1)

- Steady State ErrorDocument10 pagesSteady State ErrorgigoPas encore d'évaluation

- Fuzzy Gain Scheduling of PID Controllers PDFDocument7 pagesFuzzy Gain Scheduling of PID Controllers PDFMiguel ZeaPas encore d'évaluation

- Unit 3 RMDocument47 pagesUnit 3 RMShrikant KalePas encore d'évaluation

- Electrical Machines I: Efficiency and All Day Efficiency of TransformersDocument9 pagesElectrical Machines I: Efficiency and All Day Efficiency of TransformersShraddha RautPas encore d'évaluation

- Multi-Channel Virtual Oscilloscope and Signal GeneratorDocument9 pagesMulti-Channel Virtual Oscilloscope and Signal GeneratorAli ShafiquePas encore d'évaluation

- UNIT 6 Research ProjectDocument4 pagesUNIT 6 Research Projectchandni0810Pas encore d'évaluation

- Design Via Root Locus and Frequency ResponseDocument15 pagesDesign Via Root Locus and Frequency ResponseBran WzPas encore d'évaluation

- Unit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorDocument184 pagesUnit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorAgatha ChristiePas encore d'évaluation

- Parallel AdderDocument20 pagesParallel AddermdbelalrshdPas encore d'évaluation

- Ac Ac ConverterDocument56 pagesAc Ac ConverterPutri Hanifah SPas encore d'évaluation

- IMC Tuned PID Controller Improves DC Motor ControlDocument6 pagesIMC Tuned PID Controller Improves DC Motor ControljayaseelanPas encore d'évaluation

- Implementation of Standalone Hybrid Power System Using Matlab/simulinkDocument6 pagesImplementation of Standalone Hybrid Power System Using Matlab/simulinkIJIERT-International Journal of Innovations in Engineering Research and TechnologyPas encore d'évaluation

- Pneumatic to Electric Signal ConverterDocument4 pagesPneumatic to Electric Signal ConverterSyed Ghazanfar AliPas encore d'évaluation

- EMI Lecture Notes Week 5: Measurement of Inductance and Capacitance Using AC BridgesDocument34 pagesEMI Lecture Notes Week 5: Measurement of Inductance and Capacitance Using AC BridgesPavan KumarPas encore d'évaluation

- Improving A PID Controller Using Fuzzy LogicDocument29 pagesImproving A PID Controller Using Fuzzy LogicoshyenPas encore d'évaluation

- Digital Dice Using 555 TimerDocument15 pagesDigital Dice Using 555 Timerkazi shahadatPas encore d'évaluation

- Tutorial 2Document2 pagesTutorial 2kenny5shinPas encore d'évaluation

- Chapter 16 - Filter CircuitsDocument26 pagesChapter 16 - Filter CircuitsGeoFurrielPas encore d'évaluation

- Laboratory Exercise 1: Discrete-Time Signals: Time-Domain RepresentationDocument13 pagesLaboratory Exercise 1: Discrete-Time Signals: Time-Domain RepresentationNguyễn HưngPas encore d'évaluation

- Modelado Rotary Pendulum Workbook InstructorDocument60 pagesModelado Rotary Pendulum Workbook Instructorsolid34Pas encore d'évaluation

- Feedback and Control Systems: Activity No. 4 - Root Locus Analysis of SystemsDocument8 pagesFeedback and Control Systems: Activity No. 4 - Root Locus Analysis of SystemsYvesExequielPascua100% (1)

- Transducers 1Document40 pagesTransducers 1SagarPas encore d'évaluation

- Closed loop temperature controlDocument6 pagesClosed loop temperature controlsjsujiprasadPas encore d'évaluation

- Digital Control Engineering Chapter 1Document8 pagesDigital Control Engineering Chapter 1Ishmayne Shawarrma100% (1)

- 1 Flexible Link ProjectDocument15 pages1 Flexible Link Projectprasaad08Pas encore d'évaluation

- Chap 11Document18 pagesChap 11ashinkumarjerPas encore d'évaluation

- g9 Maths - BearingsDocument8 pagesg9 Maths - BearingsezPas encore d'évaluation

- Open-loop and closed-loop water temperature control tuningDocument13 pagesOpen-loop and closed-loop water temperature control tuningSingAnnPas encore d'évaluation

- PID Controller Tuning Using "Ziegler-Nichols" TechniqueDocument5 pagesPID Controller Tuning Using "Ziegler-Nichols" Technique;(Pas encore d'évaluation

- University of Basrah For Gas and Oil College of Oil and Gas Engineering Department of Chemical and Petroleum Refining EngineeringDocument13 pagesUniversity of Basrah For Gas and Oil College of Oil and Gas Engineering Department of Chemical and Petroleum Refining Engineeringsajad jasmPas encore d'évaluation

- Chemical Engineering Lab Experiment on Process Control SystemsDocument12 pagesChemical Engineering Lab Experiment on Process Control SystemsMd Abid AfridiPas encore d'évaluation

- Design Stress and FatigueDocument30 pagesDesign Stress and FatigueAshok DargarPas encore d'évaluation

- PPST OrientationDocument66 pagesPPST OrientationRaymund Dagdag100% (1)

- Ropes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Document6 pagesRopes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Rohit SinghPas encore d'évaluation

- Air CasterDocument25 pagesAir CasterPrabir Kumar Pati100% (1)

- Book 3 - Revised 2017-2Document41 pagesBook 3 - Revised 2017-2sales zfPas encore d'évaluation

- Slit LampDocument20 pagesSlit LampTricia Gladys SoRiano80% (5)

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Document62 pagesIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- A Simple Method To Transfer The SelectedDocument2 pagesA Simple Method To Transfer The SelectedrekabiPas encore d'évaluation

- FSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansDocument23 pagesFSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansпавелPas encore d'évaluation

- Idea of CultureDocument28 pagesIdea of CultureGustavo Dias VallejoPas encore d'évaluation

- IGNOU FEG-02 (2011) AssignmentDocument4 pagesIGNOU FEG-02 (2011) AssignmentSyed AhmadPas encore d'évaluation

- Rosalind FranklinDocument1 pageRosalind FranklinMichael SmithPas encore d'évaluation

- SNS Bank XS0382843802Document7 pagesSNS Bank XS0382843802Southey CapitalPas encore d'évaluation

- This Study Resource Was: Practice Questions and Answers Inventory Management: EOQ ModelDocument7 pagesThis Study Resource Was: Practice Questions and Answers Inventory Management: EOQ Modelwasif ahmedPas encore d'évaluation

- International Financial Management 7th Edition Eun Test BankDocument25 pagesInternational Financial Management 7th Edition Eun Test BankMatthewRosarioksdf100% (58)

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiPas encore d'évaluation

- MMA Electrode ClassificationDocument3 pagesMMA Electrode ClassificationRathnakrajaPas encore d'évaluation

- SAPA Presentation - 8-31-18Document34 pagesSAPA Presentation - 8-31-18Roi AlcaidePas encore d'évaluation

- A Review of Solar Parabolic Trough CollectorDocument7 pagesA Review of Solar Parabolic Trough Collectoraxel_oscPas encore d'évaluation

- Research Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGDocument3 pagesResearch Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGFiya ShahPas encore d'évaluation

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDocument12 pagesTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasPas encore d'évaluation

- Big Five Personality TestDocument3 pagesBig Five Personality Testchandu_jjvrpPas encore d'évaluation

- Mathematics 10 Performance Task 1Document2 pagesMathematics 10 Performance Task 1SnowPas encore d'évaluation

- Individual tone frequencies have hidden qualitiesDocument7 pagesIndividual tone frequencies have hidden qualitiesArnauPas encore d'évaluation

- As 1463-1988 Polyethylene Pipe Extrusion CompoundsDocument6 pagesAs 1463-1988 Polyethylene Pipe Extrusion CompoundsSAI Global - APACPas encore d'évaluation

- CASE ANALYSIS: DMX Manufacturing: Property of STIDocument3 pagesCASE ANALYSIS: DMX Manufacturing: Property of STICarmela CaloPas encore d'évaluation

- Functional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationDocument10 pagesFunctional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationAnanthakishnanPas encore d'évaluation

- Open Newel StaircaseDocument4 pagesOpen Newel StaircaseSujan Dhoj KhadkaPas encore d'évaluation

- Lesson 5: Cultural Relativism: Learning OutcomesDocument4 pagesLesson 5: Cultural Relativism: Learning OutcomesGanda GandaPas encore d'évaluation

- Prologue - Life InsuranceDocument4 pagesPrologue - Life InsuranceCamila Andrea Sarmiento BetancourtPas encore d'évaluation