Académique Documents

Professionnel Documents

Culture Documents

DFMA Assignment

Transféré par

Atul AswarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DFMA Assignment

Transféré par

Atul AswarDroits d'auteur :

Formats disponibles

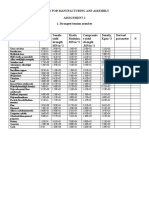

DESIGN FOR MANUFACTURING AND ASSEMBLY

ASSIGNMENT 2

LAST DATE OF SUBMISSION (Hard copy): 30 September 2019

Construct a spreadsheet for Table 1 shown below. Use this to rank materials for the six cases of minimum cost

criteria shown in Table 2. (Fill derived parameter column and Rank (N) column.) Prepare six separate sheets for

six cases. Identify the best and worst materials for each criteria. Do the best and worst materials remain same for

the six criteria? Write your comments on the rankings using various criterions.

Except the table, all calculations and comments should be submitted handwritten on A4 size paper.

Tables to be printed on A4 paper.

Table 1: Material Data

Generic Material Cost Tensile Elastic Compressive Density, Derived

$/kg yield Modulus, yield Kg/m^3 parameter N

strength MN/m^2 strength

MN/m^2 ,MN/m^2

Gray cast iron 2.86E-01 2.93E+02 1.34E+05 2.93E+02 7.21E+03

Ductile iron 3.52E-01 4.48E+02 1.65E+05 3.10E+02 7.13E+03

Malleable iron 4.18E-01 3.45E+02 1.60E+05 3.45E+02 7.38E+03

Mild steel(c.q. annealed) 9.90E-01 2.62E+02 2.07E+05 2.62E+02 7.77E+03

Alloy steel(high strength) 6.16E+00 1.38E+03 2.07E+05 1.38E+03 7.85E+03

Stainless steel 2.75E+00 2.48E+02 1.93E+05 2.48E+02 8.04E+03

Aluminium alloy(high 5.28E+00 1.93E+02 7.10E+04 1.93E+02 2.75E+03

strength)

Beryllium copper 3.85E+01 1.10E+03 1.28E+05 1.01E+03 8.27E+03

Copper, hard 2.86E+00 3.10E+02 1.17E+05 3.10E+02 8.96E+03

Magnesium 7.70E+00 2.34E+02 4.48E+04 2.34E+02 1.80E+03

Titanium 2.68E+01 9.45E+02 1.13E+05 9.45E+02 4.74E+03

Lead 2.86E+00 2.00E+01 1.52E+04 2.00E+01 1.14E+04

Epoxy(Glass reinforced) 5.28E+00 6.55E+01 3.10E+03 2.48E+02 1.91E+03

Polyethylene(high density) 7.48E-01 2.48E+01 8.27E+02 2.48E+01 9.71E+02

Polycarbonate(Glass 3.52E+00 1.59E+02 1.16E+04 1.45E+02 1.53E+03

reinforced)

Rubber( isoprene) 3.48E+00 2.76E+01 4.59E+00 2.76E+01 9.71E+02

Polyurethane foam 1.76E+00 1.52E+01 1.08E+02 1.72E+01 4.99E+02

Particle Board (Medium 3.52E-01 1.55E+01 2.93E+03 1.45E+01 6.02E+02

density)

Pine 2.05E+00 7.93E+01 8.27E+03 3.31E+01 3.61E+02

Diamond 7.26E+02 2.69E+02 1.03E+06 4.00E+03 3.52E+03

Silicon carbide(sintered) 6.60E+01 6.90E+01 3.31E+05 1.03E+03 2.97E+03

Tungsten carbide 2.64E+02 8.96E+02 3.39E+05 4.95E+03 1.33E+04

Glass(soda lime, general 3.30E-01 9.17E+01 7.31E+04 1.38E+03 2.47E+03

purpose)

Pottery 1.32E-01 3.31E+01 7.03E+04 5.00E+02 2.22E+03

Concrete 1.50E+00 1.65E+00 3.00E+04 2.48E+01 2.50E+03

Cork E+01 1.00E+00 2.00E+01 1.00E+00 1.39E+02

Table 2: Derived parameters (Cm = Material cost, Yt = tensile yield stress, Yc = Compressive yield stress, E = Young’s Modulus, ρ = density)

To obtain: Maximum performance Minimum weight Minimum cost

Strongest tension member Yt Yt/ρ Yt/ρCm

Strongest compression member Yc Y c/ ρ Yc/ ρCm

Strongest beam or plate Yt Yt0.5/ ρ Yt0.5/ ρCm

Stiffest structural member E E1/3/ ρ E1/3/ ρCm

Best coil or tension spring Yt2/E Yt2/ (Eρ) Yt2/ (EρCm)

Best diaphragm spring Yt1.5/E Yt1.5/(Eρ) Yt1.5/(EρCm)

Vous aimerez peut-être aussi

- Design For Manufacturing and Assembly Assignment 2 1. Strongest Tension MemberDocument1 pageDesign For Manufacturing and Assembly Assignment 2 1. Strongest Tension MemberMadhupriya KalahastiPas encore d'évaluation

- Informe 2 Corrosion 2018.es - enDocument14 pagesInforme 2 Corrosion 2018.es - enKenny SalazarPas encore d'évaluation

- Analisa STR Atas Jembatan Ketos R00Document35 pagesAnalisa STR Atas Jembatan Ketos R00Gunawan Prc2020Pas encore d'évaluation

- 121 FormulasDocument7 pages121 Formulasapi-612741311Pas encore d'évaluation

- Main Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsDocument5 pagesMain Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsKevin HuangPas encore d'évaluation

- Power Losses in Wound Components PDFDocument12 pagesPower Losses in Wound Components PDFPedPas encore d'évaluation

- Electroplating Costs CalculationDocument19 pagesElectroplating Costs CalculationmosesPas encore d'évaluation

- Introduction To Magnesium PDFDocument12 pagesIntroduction To Magnesium PDFjuneePas encore d'évaluation

- List of Figures: ST STDocument12 pagesList of Figures: ST STTotinham FinancePas encore d'évaluation

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuPas encore d'évaluation

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuPas encore d'évaluation

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuPas encore d'évaluation

- Electroplating Cost Calculation - RefDocument12 pagesElectroplating Cost Calculation - RefJitendra PatilPas encore d'évaluation

- Plating RateDocument20 pagesPlating RateFrancisco BocanegraPas encore d'évaluation

- CostCurves PDFDocument63 pagesCostCurves PDFashikhmd4467Pas encore d'évaluation

- Isolated Footing DesignDocument10 pagesIsolated Footing DesignSemahegn Gebiru100% (1)

- Homework CastingDocument6 pagesHomework CastingYassineZklPas encore d'évaluation

- Kumar SirDocument29 pagesKumar SirRoshan KejariwalPas encore d'évaluation

- Free Metal Workers Theory n1 Question Memo DownloadDocument16 pagesFree Metal Workers Theory n1 Question Memo DownloadThembelihle HadebePas encore d'évaluation

- Piping Support and Foundation-Note de Calcul Rev02Document27 pagesPiping Support and Foundation-Note de Calcul Rev02Ashraf AmmarPas encore d'évaluation

- Ribbed Slab 1Document20 pagesRibbed Slab 1ephrem100% (2)

- Slab Design NoteDocument112 pagesSlab Design NoteBeza Getachew100% (1)

- TPE - DOP.008 İSK EN 10255 Performans BeyanıDocument4 pagesTPE - DOP.008 İSK EN 10255 Performans BeyanıMBMPas encore d'évaluation

- Facade Notes - Euro CodeDocument6 pagesFacade Notes - Euro CodeKhalid DaferPas encore d'évaluation

- Appendices March 2005 - HookstonDocument22 pagesAppendices March 2005 - Hookstonoly WlyPas encore d'évaluation

- Appendix E Mechanical Properties of Engineering MaterialsDocument3 pagesAppendix E Mechanical Properties of Engineering MaterialsBrhane W YgzawPas encore d'évaluation

- Switchyard Earthing Report - AkkareipattuDocument12 pagesSwitchyard Earthing Report - AkkareipattuManjithaGeethadharaGunarathnePas encore d'évaluation

- Magnetics Design Tables: Appendix 2Document6 pagesMagnetics Design Tables: Appendix 2Gopichand GaddamPas encore d'évaluation

- Mandrel Staad Pro EuroCode 700x19tDocument3 pagesMandrel Staad Pro EuroCode 700x19tYap HSPas encore d'évaluation

- Closure Temperature ExerciseDocument2 pagesClosure Temperature Exercisematthias_bernetPas encore d'évaluation

- Task 2.2Document15 pagesTask 2.2Mordecai de ValoisPas encore d'évaluation

- Converter - ALL - Purpose - Worksheet (Conversions)Document49 pagesConverter - ALL - Purpose - Worksheet (Conversions)Rafsanul HaquePas encore d'évaluation

- Base PLate Calculation SeparatorDocument15 pagesBase PLate Calculation Separatorrudi 01Pas encore d'évaluation

- 08 - Chapter 2Document17 pages08 - Chapter 2Nelson VillatePas encore d'évaluation

- Structural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Document9 pagesStructural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Nenad GajicPas encore d'évaluation

- Product Submittals For ProjectDocument46 pagesProduct Submittals For ProjectJavier GarcíaPas encore d'évaluation

- 09 Endurica Beutler Rubber Boot SealDocument11 pages09 Endurica Beutler Rubber Boot SealSrashmiPas encore d'évaluation

- 1 C-HS-DM-003R0 Structural Analysis of Penstocks of ZungeruDocument32 pages1 C-HS-DM-003R0 Structural Analysis of Penstocks of Zungerurotimi olalekan fataiPas encore d'évaluation

- Example 4Document4 pagesExample 4dane05Pas encore d'évaluation

- Data Processing Task SheetDocument3 pagesData Processing Task SheetSarthak AhujaPas encore d'évaluation

- Name σ (S/m) εr Tan (δ) δ (°) Media Frecuency (Hz)Document3 pagesName σ (S/m) εr Tan (δ) δ (°) Media Frecuency (Hz)Joel Andres Garcia HenaoPas encore d'évaluation

- 1 General DescriptionDocument2 pages1 General DescriptionHaji RashidPas encore d'évaluation

- FT Ros en 11Document2 pagesFT Ros en 11wc8bqrhwtjPas encore d'évaluation

- Marking Scheme Chemistry Perfect Score Module Form 4 Set 5Document6 pagesMarking Scheme Chemistry Perfect Score Module Form 4 Set 5Roni SopainPas encore d'évaluation

- Calculation Notes of KnaufDocument20 pagesCalculation Notes of KnaufAhmed EgyPas encore d'évaluation

- Structural Design IndustrialDocument127 pagesStructural Design IndustrialAndreja GjureskiPas encore d'évaluation

- 1 1 1 0 1 Moment 0 0 3 0 0 0 0 1 0 0: Orientation DiagramsDocument168 pages1 1 1 0 1 Moment 0 0 3 0 0 0 0 1 0 0: Orientation Diagramsali jamiilPas encore d'évaluation

- Deign Final Project Review (120me0012) (Autosaved)Document14 pagesDeign Final Project Review (120me0012) (Autosaved)VfhhdfvhhPas encore d'évaluation

- EX Cercha Laminate CalculusDocument40 pagesEX Cercha Laminate CalculussarrpaPas encore d'évaluation

- B-20MET201 Mechanics of Solids First SeriesDocument3 pagesB-20MET201 Mechanics of Solids First SeriesJASON CHERIAN MEPas encore d'évaluation

- Developmentand Performance Evaluationofan Improved Vibrating Tablefor WCBProductionDocument10 pagesDevelopmentand Performance Evaluationofan Improved Vibrating Tablefor WCBProductionShir AtiaPas encore d'évaluation

- Fea Project ReportDocument58 pagesFea Project ReportAvnish DubeyPas encore d'évaluation

- Mechanics of Composite Coursework 18045371Document21 pagesMechanics of Composite Coursework 18045371Adham SamanoudyPas encore d'évaluation

- Mektek AsistensiDocument23 pagesMektek AsistensiAstity HardiantiPas encore d'évaluation

- Lab ReportDocument8 pagesLab Reportnatshehh32Pas encore d'évaluation

- Column ReportDocument45 pagesColumn ReportOkechukwu BenjaminPas encore d'évaluation

- Bonding Question.Document5 pagesBonding Question.hui sin limPas encore d'évaluation

- Industrial Chemistry of Oxides for Emerging ApplicationsD'EverandIndustrial Chemistry of Oxides for Emerging ApplicationsPas encore d'évaluation

- 3-QEM-7 Basic ToolsDocument29 pages3-QEM-7 Basic ToolsAtul AswarPas encore d'évaluation

- MPADocument84 pagesMPAAtul AswarPas encore d'évaluation

- © Dr. Dhananjay A Jolhe QEM 2Document7 pages© Dr. Dhananjay A Jolhe QEM 2Atul AswarPas encore d'évaluation

- AE See 2 PDFDocument35 pagesAE See 2 PDFAtul AswarPas encore d'évaluation

- Ch-4 LatheDocument99 pagesCh-4 LatheMANJEET KUMARPas encore d'évaluation

- Automobile Engg NotesDocument35 pagesAutomobile Engg NotesAtul AswarPas encore d'évaluation

- Automation and Robotics 2019 by S K Mondal PDFDocument51 pagesAutomation and Robotics 2019 by S K Mondal PDFDivyanshu YadavPas encore d'évaluation

- Important Topics For GATE PDFDocument3 pagesImportant Topics For GATE PDFDivyanshu YadavPas encore d'évaluation

- L. Saavedra, E. M. Hebert, C. Minahk, P FerrantiDocument49 pagesL. Saavedra, E. M. Hebert, C. Minahk, P FerrantiLeidy UribePas encore d'évaluation

- Solid State Sintering in The of Iron Ore Pellets IndurationDocument10 pagesSolid State Sintering in The of Iron Ore Pellets IndurationCamila Barata CavalcantiPas encore d'évaluation

- Chapter 3-Structure and Stereochemistry of Alkanes: N 2n+2 27 56 N 2n+2 42 86Document18 pagesChapter 3-Structure and Stereochemistry of Alkanes: N 2n+2 27 56 N 2n+2 42 86張湧浩Pas encore d'évaluation

- TD Altosonic IV en 060424Document8 pagesTD Altosonic IV en 060424Anonymous cui5pddkPas encore d'évaluation

- Chapter 5 FiltrationDocument26 pagesChapter 5 FiltrationRalph Evidente100% (1)

- Pharmaceutical Sector Analysis With The Help of Porter's Five Forces ModelDocument4 pagesPharmaceutical Sector Analysis With The Help of Porter's Five Forces ModelBhargavi KharePas encore d'évaluation

- Waste-Management EDITEDDocument20 pagesWaste-Management EDITEDpshantanu123Pas encore d'évaluation

- B 921 - 02 - QJKYMQ - ISO 8015 Tolerancing StandardsDocument2 pagesB 921 - 02 - QJKYMQ - ISO 8015 Tolerancing Standardsjameswood20100% (1)

- Lecture Notes 19 - Accuracy and PrecisionDocument5 pagesLecture Notes 19 - Accuracy and PrecisionSurendra RamkissoonPas encore d'évaluation

- Concrete Society - Concrete Advice No 26 - RC Bund StructuresDocument3 pagesConcrete Society - Concrete Advice No 26 - RC Bund StructuresKarishma JuttunPas encore d'évaluation

- Ammonia Waste WaterDocument19 pagesAmmonia Waste WaterAnonymous GfPSYi4nPas encore d'évaluation

- Organic ChemicalsDocument55 pagesOrganic ChemicalsjajajaPas encore d'évaluation

- F.E Forensic PDFDocument22 pagesF.E Forensic PDFMarcel CataynaPas encore d'évaluation

- Bell & Gosset PumpDocument8 pagesBell & Gosset Pumprogel_ganaPas encore d'évaluation

- Chapter 12 Power Point 5e HPDocument83 pagesChapter 12 Power Point 5e HPsweetgirl_24_6_9630Pas encore d'évaluation

- Notes For Teacher: Thin Layer Chromatography Analysis and Purification of Aspirin by RecrystallizationDocument3 pagesNotes For Teacher: Thin Layer Chromatography Analysis and Purification of Aspirin by RecrystallizationCleraPas encore d'évaluation

- Primacs TOC Analyser: Chapter 1: IntroductionDocument12 pagesPrimacs TOC Analyser: Chapter 1: IntroductionAnonymous 2LYCWDPuiuPas encore d'évaluation

- E&DPlan 0506Document44 pagesE&DPlan 0506Farhan ShahPas encore d'évaluation

- Hazard Communication-"Right To Know": OSHA 29 CFR 1910.1200Document38 pagesHazard Communication-"Right To Know": OSHA 29 CFR 1910.1200vhlactaotaoPas encore d'évaluation

- Test To Check Quality of Bitumen For Use in Road WorkDocument13 pagesTest To Check Quality of Bitumen For Use in Road WorkTajdaarPas encore d'évaluation

- PaintDocument28 pagesPaintAnna KateurinaPas encore d'évaluation

- Plant CompetitionDocument4 pagesPlant CompetitionEugenTutunaruPas encore d'évaluation

- Proteins and Amino AcidsDocument50 pagesProteins and Amino Acidsraddag100% (2)

- Variation of Soil Microbial Population in Different Soil HorizonsDocument4 pagesVariation of Soil Microbial Population in Different Soil HorizonsprabhatPas encore d'évaluation

- Practise School - ChemistryDocument64 pagesPractise School - ChemistrySonakshi BhatiaPas encore d'évaluation

- Sebia Minicap Protein ElectrophoresisDocument11 pagesSebia Minicap Protein ElectrophoresisMas Aditya Senaputra100% (1)

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitPas encore d'évaluation

- Rouge Monitoring Published ND 2011 ADocument6 pagesRouge Monitoring Published ND 2011 Agabriel silva100% (1)

- The Pneumatics Installation GuideDocument186 pagesThe Pneumatics Installation GuideHAMIT100% (1)

- 120 - Modern Perspectives in RC ObturationDocument14 pages120 - Modern Perspectives in RC ObturationLarissa ClipaciucPas encore d'évaluation