Académique Documents

Professionnel Documents

Culture Documents

DB String - Bloxx 208 e 1501 002

Transféré par

Mr. S Sivakumar EEETitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DB String - Bloxx 208 e 1501 002

Transféré par

Mr. S Sivakumar EEEDroits d'auteur :

Formats disponibles

string.

bloxx 208 String Monitoring Solution

Key features:

8 Analog input for current measurements

± 26 A string current (calibrated), ± 208 A summary @60°C

1 Analog input for voltage measurement

0-1000 VDC string voltage

2 Input channels for temperature

Panel and switch cabinet temperature

3 Digital inputs

Monitoring of overvoltage protection and main switch

1 Digital output

Actuation of main switch

Signal conditioning

Effective PV Monitoring requires constant, solid and traceable Calculated DC Power, linearization, mean value, scaling, alarm

PV Plant monitoring data in order to determine actual

Integrated LC display

performance and fulfil owner/investor expectations.

Display of all readings, configuration

Operators are interested to identify errors and losses in a RS485 fieldbus interface

reliable way to trigger appropriate actions for maximizing energy Up to 115,2 kbps: Modbus-RTU, ASCII (optional OEM protocols)

harvest during the total system lifetime.

Connectivity

With the monitoring of PV Module strings, design and production Data logger (e. g. Q.reader) and gantner.webportal for worldwide

errors will be recognized on the DC side with high resolution access or other 3rd party applications

down to PV Module level.

Electromagnetic Compatibility

Using DC shunts (vs. Hall Effect sensors) the string.bloxx according to EN 61000-4 and EN 55011

provides current measurements typically 10 times more

Power Supply 10 .. 55 VDC

accurate and not susceptible to temperature variance. This

equates to higher accuracy measurements and better DIN rail or wall mounting according to DIN 50022

understanding of true system performance. In addition, string

voltage (up to 1000V) and DC power on every string can be

continuously monitored ensuring maximum system productivity.

Continuous measurement of both cabinet and panel

temperatures, along with overvoltage monitoring and main

switch control greatly and improves system diagnostics.

This accurate measurement is inverter independent and gives

feedback about losses due to inverter malfunction, soiling,

shading, PV Module degradation etc. .

The string.bloxx communication uses industry standard

Modbus protocols for easy and fast integration and reliable

data exchange with the data logger. For longer communication

distances fiber optic technology is used.

Gantner Instruments Environment Solutions GmbH · www.gantner-environment.com · office@gantner-environment.com

Am Mühlgraben 8 · D-08297 Zwönitz/Germany · Tel. +49 (0) 37754 3351-0 · Fax +49 (0) 37754 3351-20

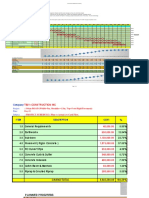

string.bloxx 208 String Monitoring Solution

Block diagram

Input Current

Max. Number 8

Range ± 26 A

Accuracy 0.25 %

Connection 0.25 mm² - 6 mm² push-in spring-cage connection

Current measurement

Max. 208 A

Connection M8 bolt connector for cable ring terminals

Voltage measurement

Number 1

Range 0-1000 VDC

Accuracy 0.2 %

Connection 0.25 mm² - 6 mm² push-in spring-cage connection

Input Temperature

Number 2

Type Pt1000, 2- and 4-wire

Range -40 till +160°C

Accuracy 0.5 %

Connection 0.25 mm² - 1.5 mm² push-in spring-cage connection

Digital Inputs

Number 3

Input State

Connection 0.25 mm² - 1.5 mm² push-in spring-cage connection

Gantner Instruments Environment Solutions GmbH · www.gantner-environment.com · office@gantner-environment.com

Am Mühlgraben 8 · D-08297 Zwönitz/Germany · Tel. +49 (0) 37754 3351-0 · Fax +49 (0) 37754 3351-20

string.bloxx 208 String Monitoring Solution

Digital Output

Number 1

Output State, alarm

Contact Relay change

Load 30 VDC/1000 mA (ohmic load)

Connection 0.25 mm² - 1.5 mm² push-in spring-cage connection

Power Supply

Power Supply 10 up to 55 VDC, overvoltage and overload protection

Power consumption approx. 1.5 W (0.4W at 30 seconds sample rate)

Connection 0.25 mm² - 1.5 mm² push-in spring-cage connection

Communication Interface

Standard RS-485, 2-wire

Data format 8e1

Protocols Modbus-RTU, ASCII: 19.200 bps up to 115.200 bps

Number of devices on the bus max. 250

Connection 0.25 mm² - 1.5 mm² push-in spring-cage connection

Environmental

Operating temperature -20°C up to +60°C @ max 208 A current

Operating temperature -20°C up to +75°C @ max 104 A current

Storage temperature -40°C up to +85°C

Relative humidity 5 % up to 95 % at 50°C, non-condensing

Mechanical

Case Polycarbonate

Dimensions (W x H x D) (221 x 142 x 55) mm

Weight approx. 470 g

Mounting DIN EN-rail or wall mount

Warm Up Time Valid from January 2015. Specification subject to change without prior notice.

All declarations are valid after a warm up time of 45 minutes. DB_string.bloxx_208_E_1501.docx

Gantner Instruments Environment Solutions GmbH · www.gantner-environment.com · office@gantner-environment.com

Am Mühlgraben 8 · D-08297 Zwönitz/Germany · Tel. +49 (0) 37754 3351-0 · Fax +49 (0) 37754 3351-20

Vous aimerez peut-être aussi

- Inteliats2 70 Datasheet - 2Document4 pagesInteliats2 70 Datasheet - 2gustavocortez2824501Pas encore d'évaluation

- Inteligen 500 g2 DatasheetDocument4 pagesInteligen 500 g2 DatasheetBan Juan OoiPas encore d'évaluation

- InteliMains 210 DatasheetDocument4 pagesInteliMains 210 DatasheetMaylen Rivas0% (1)

- InteliMains 210 Datasheet PDFDocument4 pagesInteliMains 210 Datasheet PDFMaylen RivasPas encore d'évaluation

- TCM 94N 1 - TCM 94N 2Document3 pagesTCM 94N 1 - TCM 94N 2luat1983Pas encore d'évaluation

- Inteli - AIN8TC DatasheetDocument2 pagesInteli - AIN8TC DatasheetMaylen RivasPas encore d'évaluation

- Inteli - AIN8TC Datasheet PDFDocument2 pagesInteli - AIN8TC Datasheet PDFMaylen RivasPas encore d'évaluation

- 2940 Ast3pDocument3 pages2940 Ast3pPirooz MakooeiPas encore d'évaluation

- GW gm1000gm3000gm1000d Quick Installation Guide-EnDocument10 pagesGW gm1000gm3000gm1000d Quick Installation Guide-EnJakub BohdálekPas encore d'évaluation

- Digital Ac Volt Meter (True RMS) Digital DC Volt MeterDocument3 pagesDigital Ac Volt Meter (True RMS) Digital DC Volt Meterluat1983Pas encore d'évaluation

- InteliATS2 50 - Datasheet - 2023-03Document4 pagesInteliATS2 50 - Datasheet - 2023-03zanoveliPas encore d'évaluation

- Afisaj WiebrockDocument2 pagesAfisaj Wiebrockgheorghecosovan0% (1)

- TMST110Document3 pagesTMST110Sara ArroyavePas encore d'évaluation

- Masibus 5002U-P - R1F - 0616 - Digital Process ControllerDocument2 pagesMasibus 5002U-P - R1F - 0616 - Digital Process ControllerabhimanyuPas encore d'évaluation

- Inteligen 500 Datasheet Rev 2Document4 pagesInteligen 500 Datasheet Rev 2NikolayPas encore d'évaluation

- Ultrasonic Gas FlowmeterDocument6 pagesUltrasonic Gas Flowmeterhk168100% (1)

- World-Class Environmental Datalogger: Accurate, Rugged, ReliableDocument2 pagesWorld-Class Environmental Datalogger: Accurate, Rugged, ReliableRuber TorresPas encore d'évaluation

- Signo 723.5Document6 pagesSigno 723.5David LozanoPas encore d'évaluation

- Baykon Tx13 Transmitter CatalogueDocument2 pagesBaykon Tx13 Transmitter CatalogueIvailo ZapryanovPas encore d'évaluation

- Baykon tx13 Transmitter Catalogue PDFDocument2 pagesBaykon tx13 Transmitter Catalogue PDFIvailo ZapryanovPas encore d'évaluation

- Sicam-A8000 Booklet enDocument21 pagesSicam-A8000 Booklet enD RAJANPas encore d'évaluation

- SERIES: D3000: IndumartDocument2 pagesSERIES: D3000: Indumarttaleb 6269Pas encore d'évaluation

- NewNewMasibus UT94 - R4F - 1216 - Universal TransmitterDocument2 pagesNewNewMasibus UT94 - R4F - 1216 - Universal TransmitterArchire SigjhPas encore d'évaluation

- 1U Sub RackDocument2 pages1U Sub RackPhạm NamPas encore d'évaluation

- MP 26 Digital Process Transmitter: Product ProfileDocument2 pagesMP 26 Digital Process Transmitter: Product ProfileHeri YantoPas encore d'évaluation

- TCW241 Ethernet I O Module User Manual R4.2Document49 pagesTCW241 Ethernet I O Module User Manual R4.2Rodolfo OliveiraPas encore d'évaluation

- 7KM21120BA003AA0 Datasheet enDocument6 pages7KM21120BA003AA0 Datasheet enАндреи ПрокаPas encore d'évaluation

- Smart SYS N1540180R48 - Datasheet - 180222Document2 pagesSmart SYS N1540180R48 - Datasheet - 180222Will F AlvesPas encore d'évaluation

- ION8650 DatasheetDocument11 pagesION8650 DatasheetAlthaf Axel HiroshiPas encore d'évaluation

- iDPN Vigi - A9XMSB11Document3 pagesiDPN Vigi - A9XMSB11pmyilsamyPas encore d'évaluation

- 7KM32201BA011EA0Document6 pages7KM32201BA011EA0Alejandro MagnePas encore d'évaluation

- Inteli - AIN8 - DatasheetDocument2 pagesInteli - AIN8 - DatasheetMaylen RivasPas encore d'évaluation

- Data Sheet: VSPC VSPC 1Cl 24Vdc RDocument5 pagesData Sheet: VSPC VSPC 1Cl 24Vdc RYudda PermannaPas encore d'évaluation

- Sprint 210: Modular Two Way Communicate and Optional Load ControlDocument2 pagesSprint 210: Modular Two Way Communicate and Optional Load ControlBrandon LevinePas encore d'évaluation

- Data Sheet Inverter INV222 48VDCDocument2 pagesData Sheet Inverter INV222 48VDCSharmin SultanaPas encore d'évaluation

- Data Sheet: VSPC VSPC 1Cl 24Vdc RDocument9 pagesData Sheet: VSPC VSPC 1Cl 24Vdc RYudda PermannaPas encore d'évaluation

- InteliLite 4 AMF 25 Datasheet - 2Document4 pagesInteliLite 4 AMF 25 Datasheet - 2FeritPas encore d'évaluation

- Idpn Vigi A9xmsb11Document3 pagesIdpn Vigi A9xmsb11Paul RyanPas encore d'évaluation

- 7KM211 SheetDocument7 pages7KM211 SheetsuadPas encore d'évaluation

- Ria 250Document8 pagesRia 250nebojsa_maletin100% (2)

- TT2780 enDocument5 pagesTT2780 enPaulius TranavičiusPas encore d'évaluation

- 2nd Review DocumentDocument6 pages2nd Review DocumentBrightworld ProjectsPas encore d'évaluation

- InteliGen 500 Datasheet PDFDocument4 pagesInteliGen 500 Datasheet PDFSandro Muniz SouzaPas encore d'évaluation

- Revpi Di: Technical DataDocument2 pagesRevpi Di: Technical DatasebadansPas encore d'évaluation

- Intelilite 4 Mrs 16 Datasheet - 2Document4 pagesIntelilite 4 Mrs 16 Datasheet - 2juadogonPas encore d'évaluation

- Airpax PDFDocument46 pagesAirpax PDFvjPas encore d'évaluation

- Inline Function Terminal - IB IL SGI 2/F-PAC - 2878638: Product DescriptionDocument9 pagesInline Function Terminal - IB IL SGI 2/F-PAC - 2878638: Product DescriptionThandayudhapani VeeraputhiranPas encore d'évaluation

- InteliSys-NTC Hybrid - DatasheetDocument4 pagesInteliSys-NTC Hybrid - DatasheetMaylen RivasPas encore d'évaluation

- A1350 Flyer eDocument2 pagesA1350 Flyer eBojan IlievPas encore d'évaluation

- PowerMax EM 6000 Series Data SheetDocument4 pagesPowerMax EM 6000 Series Data SheetAbhishek Dave0% (1)

- Prometer 100: In-Built IEC 61850 SupportDocument4 pagesPrometer 100: In-Built IEC 61850 SupportsatheeshkumarPas encore d'évaluation

- 118L Digital BulletinDocument4 pages118L Digital Bulletinmbk.2k3Pas encore d'évaluation

- InteliGen 200 DatasheetDocument4 pagesInteliGen 200 DatasheetMaylen Rivas100% (1)

- Masibus 408-2IN - R2F - 0516 - Indicator Cum On-Off ControllerDocument2 pagesMasibus 408-2IN - R2F - 0516 - Indicator Cum On-Off ControllerArun GuptaPas encore d'évaluation

- RAC18-IP Installation Instruction DIM433en v1.0Document3 pagesRAC18-IP Installation Instruction DIM433en v1.0idreesali8654Pas encore d'évaluation

- PID+Fuzzy Temperature ControllerDocument23 pagesPID+Fuzzy Temperature ControllerWilly TurdoPas encore d'évaluation

- 1008VDocument14 pages1008VRaju Sk0% (1)

- A220Document2 pagesA220HenrypuchoPas encore d'évaluation

- It Is Vital To Good Project Management To Be Meticulously Honest in Estimat Ing The Time Required To Complete Each of The Various Tasks Included in The Project. Note ThatDocument16 pagesIt Is Vital To Good Project Management To Be Meticulously Honest in Estimat Ing The Time Required To Complete Each of The Various Tasks Included in The Project. Note ThatSuraj SinghalPas encore d'évaluation

- Quiz 3Document4 pagesQuiz 3Kereen Pearl PascuaPas encore d'évaluation

- What Are You Doing LiveworksheetDocument18 pagesWhat Are You Doing LiveworksheetRizki Novela WatiPas encore d'évaluation

- Micom P40 AgileDocument386 pagesMicom P40 AgilesanthoshPas encore d'évaluation

- Mastery 3 (MIL)Document2 pagesMastery 3 (MIL)Jude Mandal MetantePas encore d'évaluation

- Ezchrom Elite Manual EspañolDocument1 pageEzchrom Elite Manual EspañolYrvin Narro Lucano0% (3)

- Chapters 1 - 6: - Chapter 6Document51 pagesChapters 1 - 6: - Chapter 6Delasdriana WiharjaPas encore d'évaluation

- Bojan Ramsak - RTV SLODocument10 pagesBojan Ramsak - RTV SLObatto1Pas encore d'évaluation

- Adrian - Borbe - CHAPTER 1 5 1Document149 pagesAdrian - Borbe - CHAPTER 1 5 1ecilaborbe2003Pas encore d'évaluation

- Unit 1 Real Numbers - Activities 1 (4º ESO)Document3 pagesUnit 1 Real Numbers - Activities 1 (4º ESO)lumaromartinPas encore d'évaluation

- STA 1610 Work Book PDFDocument251 pagesSTA 1610 Work Book PDFKefiloe MoatshePas encore d'évaluation

- Delft3D-QUICKIN User ManualDocument100 pagesDelft3D-QUICKIN User ManualAnonymous K02EhzPas encore d'évaluation

- Chapter 16IT Controls Part IIDocument10 pagesChapter 16IT Controls Part IIChene Soriano100% (1)

- Web2Project User Guide V1Document26 pagesWeb2Project User Guide V1Freddy VergaraPas encore d'évaluation

- Using IComparer IComparable For Sorting in WPFDocument6 pagesUsing IComparer IComparable For Sorting in WPFAbhiPas encore d'évaluation

- Seminar Report On CyberneticsDocument67 pagesSeminar Report On CyberneticsSimmi JoshiPas encore d'évaluation

- Radio Network OptimizationDocument18 pagesRadio Network OptimizationgpaulcalPas encore d'évaluation

- Variable Range Led VoltmeterDocument1 pageVariable Range Led VoltmeterweberpermetersquarePas encore d'évaluation

- Design Systems Formatted PDFDocument66 pagesDesign Systems Formatted PDFOleksiy OsiychukPas encore d'évaluation

- Data Quality DMB Ok Dam A BrasilDocument46 pagesData Quality DMB Ok Dam A BrasilforleviPas encore d'évaluation

- Dm2023 0029 2023 GIDA Annual UpdatingDocument4 pagesDm2023 0029 2023 GIDA Annual UpdatingNeil Victor Ongco PajugotPas encore d'évaluation

- Ajcpath125 0016Document10 pagesAjcpath125 0016Asad AliPas encore d'évaluation

- Json CacheDocument10 pagesJson Cachebenjaminmishael20Pas encore d'évaluation

- Endterm Exam Answers:jimenea PDFDocument5 pagesEndterm Exam Answers:jimenea PDFGilianne JimeneaPas encore d'évaluation

- Engineering Graphics (EG)Document8 pagesEngineering Graphics (EG)Sudalai MadanPas encore d'évaluation

- Month: January 2020 Cash BookDocument9 pagesMonth: January 2020 Cash BookAbidPas encore d'évaluation

- CSProxyCache DLLDocument36 pagesCSProxyCache DLLRadient MushfikPas encore d'évaluation

- Lathe - LVDocument23 pagesLathe - LVakshaygiitmPas encore d'évaluation

- International Automotive Task Force TS16949 To IATF16949 Transition StrategyDocument44 pagesInternational Automotive Task Force TS16949 To IATF16949 Transition StrategyyatheendravarmaPas encore d'évaluation

- Dwi Hadianti, S.E: Mypersonal Profile Work ExperienceDocument1 pageDwi Hadianti, S.E: Mypersonal Profile Work ExperienceBumn Kuala Tungkal HebatPas encore d'évaluation