Académique Documents

Professionnel Documents

Culture Documents

13 - CH74,80 - Starting & Ignition System

Transféré par

aliTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

13 - CH74,80 - Starting & Ignition System

Transféré par

aliDroits d'auteur :

Formats disponibles

SECTION 13 - STARTING AND IGNITION SYSTEM

(ATA Chapters 74 and 80)

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Powerplant Electrical Connections

The diagram opposite details the electrical wiring diagram for

units located in and around the fan case of the engine. The

units identified are discussed in this section of the course

notes.

Units relative to this section

Units not relative to this section

Revision 6.0 Page 13 - Electrical

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

3028VC

3804VC

3030VC 4069KS T/R DCU J23 J3

Pylon/EEC Suitcase (Channel B)

T/R 3rd lock TAI HP Channel A

suitcase Switch Dsicon. 3001VC

A

discon 4070KS 4072KS P/T20

A Nosecowl

PCU OPU Discon.

J4

J22 (Channel A)

A

4005KS

Start Air

Valve B A A 3002VC

3010VC

Fancase/core P/T20

Fancase/core Discon. Nosecowl

Discon. Discon.

A A

4166KS 3009VC

T/R Ground

Safety

Switch JA1 B 4117KS

JA2 JA5 A Isol.Valve

JA3 Press.SW

A

4041KS JA4

Main Oil

Filter - Diff EEC

JA7 JA6

Press.Switch 4000KS

JA8 3024VC

3026VC JA9 Junct.box

Junct.box JA10 Suitcase

A Suitcase Discon.

4060KS1 Discon.

Oil Press.

Xmitr 4060KS2 A

Oil Press. 3801VC 3029VC

Xmitr 3006VC

Pylon- T/R DCU

N1/N2 (T) 3 EEC suitcase

A Discon. Channel B Discon.

4071KS B

FMU

B J4

J2

J1 J3 A A B

4018KS2 A A

4073KS 4073KS 4042KS1

TFuel

AOHE AOHE Oil Temp 4043KS 4076KS 4075KS

LVDT Torque T/Couple Fuel 4050KS

A B Scav Oil Fuel Low

Motor Filter Oil Qty Filter - Press.

DPSwitch Xmitr Switch Switch

4010KS

4018KS1 4042KS2

Fuel Flow

TFuel Oil Temp

xmtr

T/Couple

This page left blank intentionally

Starting Electrical Connections (1)

Revision 6.0 Page 13 - Electrical

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

This page left blank intentionally

Revision 6.0 Page 13 - 1

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Section Objectives

On completion of this section, you should be able to:

• Identify the sources of air available to start

a Trent 700 engine.

• Describe the major components in the

engine starting system.

• Define the maintenance practices

applicable to the Trent 700 starting

system.

Revision 6.0 Page 13 - 2

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Introduction

The engine starting system provides the power Air to operate the air starter motor comes from one

which turns the HP rotor to a speed at which an of three sources:-

engine start can occur.

. A ground air supply.

The system comprises:- . The auxiliary power unit (A.P.U.).

. The other running engine.

. An air starter motor

. A start control valve Ignition is provided by two ignition plugs which can

. Air ducting be operated together or individually. The operation

. Dual ignition system of one igniter plug is called single ignition, the

. Start control panels in the flight deck operation of both igniters is called dual ignition.

Single ignition is used for the first successful

Air is used to turn a turbine in the starter motor automatic ground start. Dual ignition is used for

which provides the torque at the starter output shaft. in-flight starts, auto-relight, for continuous ignition

The starter motor being fitted to the front face of the and for manual starts on the ground.

external gearbox turns the gears and drives a drive

shaft which spans the by-pass casing to the gas The E.E.C. controls the opening and closing of the

generator that will turn the HP rotor. start control valve and the electrical supply to the

ignition units through the PCU.

To start the engine it is necessary to:-

. Rotate the engine to induce an airflow

through.

. Provide the correct quantity of fuel to the

combustion chamber.

. Ignite the resultant air/fuel mixture.

Revision 6.0 Page 13 - 3

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 4

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Starting System

The starter air duct flanges are connected together

by 'V' band coupling clamps. Air leakage is

prevented by the 'E' type seals that are located

between the mating flanges. There are two flexible

joints which let the engine move in relation to the

aircraft pylon, to prevent damage to the ducts. These

flexible joints also help align the pylon duct with the

aircraft duct.

Revision 6.0 Page 13 - 5

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 6

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Description

Air Starter Motor

The air starter motors primary components consist The clutch mechanism has pawls which engage with

of:- the ratchet gear to turn the output shaft. When the

engine has reached self sustaining R.P.M. the

. A turbine rotor output drive shaft is turning faster than the ring gear

. A reduction gear configuration carrier and centrifugal force disengages the clutch

. A clutch mechanism pawls from the ratchet gear.

. An output drive shaft

These components are contained in a case which

includes a containment ring, an air intake and an

exhaust. The containment ring is made to contain a

failure of the turbine rotor. The air starter motor also

has an oil filler plug, an oil level sight glass and drain

plug. The drain plug has a magnetic chip detector

(M.C.D.).

Air entering the air inlet will turn the turbine rotor at

high speed with low torque, the reduction gears

reduce the speed to the output drive shaft. This

reduction in speed produces high torque to the

output drive shaft. The torque is transmitted through

the ratchet gear on the ring gear carrier to the clutch

mechanism.

Revision 6.0 Page 13 - 7

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 8

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Description

Start Control Valve

The start control valve controls the flow of air to the

air starter motor. The solenoid contains a double coil

assembly which is controlled by electrical signals

from the E.E.C. One coil is connected to lane 'A' of

the E.E.C., the other to lane 'B'.

The valve also contains a butterfly valve operated

through linkage by two air operated pistons. An

extension of the butterfly shaft has a visual control

valve position indicator. The control valve position

indicator operates two micro switches one is

connected to lane 'A' the other to lane 'B' to give

indication to the E.E.C. of the valve position. Also

the extension is a square socket to permit manual

operation of the butterfly valve.

Revision 6.0 Page 13 - 9

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 10

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Operation

Allied-Signal Start Control Valve To close the start control valve

The primary components of the start control valve When the electrical power is removed from

are as follow:- the solenoid, the spring loaded plunger

• A valve assembly closes the air supply to the rate control servo.

• An actuator assembly At the same time the ball opens the vent and

• A rate control servo the air pressure on the piston is released.

• A solenoid The actuator spring on the piston then closes

the butterfly valve. The actuator spring will

To open the start control valve also close the butterfly valve if there is a

decrease in air pressure upstream of the

Air from immediately upstream of the butterfly butterfly valve.

valve is filtered and goes to the solenoid.

When the solenoid is energised, the spring

loaded plunger opens to let air get to the rate

control servo. At the same time the ball valve

closes the vent. The rate control servo

supplies air to the piston which controls the

rate at which the valve opens. The air

pressure on the piston is more than the force

on the actuator spring so it will move the

piston and compress the actuator spring. As

the piston moves with the shaft, the torsion

spring moves to open the butterfly valve.

Revision 6.0 Page 13 - 11

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 12

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Ignition System

Introduction

The ignition distribution system is in two parts, each

part has an ignition unit, an ignition lead and an

igniter plug.

The ignition units are mounted on bracket

assemblies on the lower left hand side of the L.P.

compressor case. The leads span the by-pass

casing inside the lower bifurcation to the igniter

plugs. The igniter plugs are adjacent numbers 10

and 16 fuel spray nozzles.

Description

Ignition Units

Each unit has a case assembly and an ignition

exciter. An input of 115 volts 400 Hz A.C. power is

supplied by the aircraft electrical system. This supply

is transmitted to a relay in the Power Control Unit

(P.C.U.) which is controlled by the E.E.C.

The exciter is a capacitive discharge circuit. The

exciter changes the input voltage to an output

voltage of 2.7 to 2.9 K volts. Energy is stored in the

ignition unit at 8 to 11.3 joules. This energy is

released by the exciter at the rate of 60 to 135

sparks per minute.

Revision 6.0 Page 13 - 13

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 14

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Description

Igniter Plugs

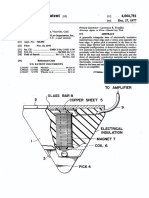

The igniter plug is a surface discharge type. It has a

body and a ground electrode, it also has a centre

wire with a centre electrode at the tip. The centre

wire is sealed with glass and has insulation along its

length.

The space between the centre electrode and the

ground electrode is filled with a semi-conductive

material. The igniter plug has a contact button which

touches the contact button in the ignition lead.

Operation

When the ignition system is energised an electrical

current flows through the centre wire and the centre

electrode of the igniter plug. The current flows

through the semi conductor to the ground electrode.

This current produces a magnetic field which ionises

gas near the igniter tip. This gives a low resistance

path for the energy from the ignition unit and a pulse

of energy occurs. The energy pulse gives a high

energy spark from the centre electrode to the outer

electrode. The electrical current flows through the

igniter plug body and to the outer conductor of the

ignition lead and on to the ignition unit case.

Revision 6.0 Page 13 - 15

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 16

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Engine Start Control and Indication

The start controls consist of the following:- Rotary Selector

. Two master switches (levers) The rotary selector valve can be used in conjunction

. A rotary selector with the master switch and manual start push button

. Manual start push buttons to perform engine dry cranking, wet cranking, Pilot

control starting sequence, automatic starting and

The 'MAN START' button incorporates a blue 'ON' continuous ignition.

legend and is normally in the released position with

'ON' legend off. Pressing the switch will open the Manual Start Push Button

start control valve and illuminate the 'ON' legend.

The amber 'FAULT' warning light will illuminate when Selection of the manual start push button enables

a disagreement occurs between the start control the pilot to perform alternative engine starting i.e.

valve position and that commanded by the E.E.C. in manual start.

the 'AUTO' mode.

Master Switch

This switch is for the pilot to use as a master

'ON/OFF' switch for the engine.

. 'OFF' POSITION P.R.S.O.V. commanded

closed. F.A.D.E.C. system will behave as it

would in the de-powered state.

. 'ON' POSITION The E.E.C. will be able to

control the P.R.S.O.V. position, and the

F.A.D.E.C. system will perform engine

control functions.

Revision 6.0 Page 13 - 17

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 18

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Starting

During the starting sequence, the ignition and

starting parameters are displayed. During the start

sequence the nacelle temperature indications are

replaced by the following:-

. Ignition (A, B or AB).

. Start control valve position.

. Air pressure to the starter.

Revision 6.0 Page 13 - 19

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 20

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Electronic Control

Engine Interface Vibration Monitoring Unit

(E.I.V.M.U.)

This unit is located in the aircraft avionics bay. It

receives discrete electrical signals from the flight

deck. These signals are digitised and transmitted to

the E.E.C. The unit also sends discrete signals to

close the air conditioning pack flow valves and to

accelerate the auxiliary power unit (A.P.U.) if

required.

Engine Electronic Controller (E.E.C.)

Generates starter control valve opening and closing

signals from information received from the rotary

selector, master switch, manual start push button

and N3 signal.

The E.E.C. also generates warning and caution

messages for display in the flight deck through the

Electronic Centralised Aircraft Monitoring System

(E.C.A.M.)

Revision 6.0 Page 13 - 21

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

This page left blank intentionally

Revision 6.0 Page 13 - 22

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Start Procedures

Pre-Start This control is not available during manual start and

conventional pilot monitoring is required. Start abort

. Thrust Lever - Idle in both modes can be made by placing master

. Master Switch - Off switch to the 'OFF' position.

. Rotary Selector - Norm

. Manual Start Button - Off Dry Cranking (Rotation)

. Aircraft Booster Pumps - On

. Rotary Switch - Crank

Auto Start . Manual Start Button - On

. Engine Accelerates to Maximum Motoring

. Rotary Switch - Ign Start Speed

. Master Switch - On

. After Successful Start Rotary Switch - Norm During dry crank the starter motor operates but the

P.R.S.O.V. and both ignition systems remain

Manual Start inoperative.

. Rotary Switch - Ign Start Wet Cranking (Motoring)

. Manual Start Button - On

. When N3 reaches a pre-determined speed . Rotary Selector - Crank

pilot put master switch to On . Manual Start Switch - On

. After successful start Rotary Switch - Norm . Master Switch - On

. Manual Start Button - Off

During wet crank the selection of the master switch

NOTE: During auto start the E.E.C. monitors engine opens the P.R.S.O.V. but because crank is selected

speed and E.G.T. if hung or hot starts are detected, ignition is inoperative.

the P.R.S.O.V., start control valve, and ignition are

automatically shut off.

Revision 6.0 Page 13 - 23

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Start Procedures

In-Flight Re-Lighting Automatic start following 'flame out' will never be

automatically initiated by the E.E.C., but will be

Both automatic and alternative starting is available commanded by the pilot.

for in-flight re-lighting. The selection of switches is

the same as on the ground.

When alternative start is selected the E.E.C. will

always command starter assistance.

When automatic start is selected the E.E.C. will

determine, based on flight envelope and engine

parameters, whether a starter assisted start or a

windmilling start is required.

The E.E.C. will receive a signal from the E.I.V.M.U.

as to flight/ground status. The E.I.V.M.U. receives its

signal from the Landing Gear Control Interface Unit

(L.G.C.I.U.).

Continuous Ignition

Move rotary switch 'NORM' to 'IGN START'.

Automatic Re-Light

The F.A.D.E.C. system detects 'flame out' conditions

by low combustion chamber pressure and a change

in HP shaft speed. The E.E.C. will select dual

ignition while conditions last and for 10 seconds

afterwards.

Revision 6.0 Page 13 - 24

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance Practices

Igniter Plug Removal/Installation CAUTION

Do not bend the ignition lead too much when

NOTE you disconnect the electrical connector. The

Only warnings that are applicable to the ignition lead can be damaged and can cause

ignition system and have not been previously electrical circuit failure.

mentioned appear on this page.

. Open fan cowl doors.

WARNING . Open C-ducts.

You must not touch the ignition units for at . Disconnect input lead connector to ignition

least 3 minutes after you have pulled the unit.

applicable circuit breakers. The engine . Disconnect and remove ignition lead.

ignition system uses very large voltages which . Using socket wrench UT1152 remove igniter

are dangerous. The electricity is sufficiently plug.

strong to cause an injury or kill you. . Fit blanks, covers, and plugs to all openings

and electrical connectors.

WARNING . If the igniter plug is to be used in the same

You must isolate the power supply at least 3 position again, keep the adjusting washers. If

minutes before you do work on the ignition a different igniter plug is to be used a depth of

system. This will allow the system current to immersion check is required as explained

decrease to a safe value. later.

The ignition system current is very large and

can cause injury or kill you.

Revision 6.0 Page 13 - 25

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 26

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance Practices

Igniter Plug Removal/Installation Continued

Installation of the igniter plug is straight forward but

Before installation of the igniter plug use the remember the following points:-

protrusion gauge HU38434 as follows:-

. Apply dry film lubricant to the threads of the

. Move the locking collar, locating plate and igniter plug (OMat 4/20).

body up against the indicator and install the . If the same igniter plug is being fitted in the

protrusion gauge in the applicable igniter plug same position, fit the same adjusting

hole. Make sure indicator notch points to rear washers.

of engine. . Use correct socket wrench UT1152 and

. Carefully move the indicator until probe foot torque load.

touches igniter sleeve. Use the probe foot to . Clean ignition lead contact button with OMat

feel if the igniter sleeve is in the correct 5/43 emery paper, remove dust with a clean

position and has not become loose. If the lint free cloth.

igniter sleeve is not in the correct position or . Connect the ignition lead and torque load.

has become loose - reject the engine. Safety the ignition lead with OMat 238

lockwire.

CAUTION . If a different igniter plug is being installed then

Remove protrusion gauge carefully to prevent a depth of immersion check is required.

damage to combustion chamber coating.

Revision 6.0 Page 13 - 27

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 28

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance Practices

Igniter Plug Depth of Immersion Check

a. Set protrusion gauge HU38434 to the igniter . Measure dimension 'X' again (Step 3) take the

plug depth (Step 1) as follows:- initial dimension 'X' from the new dimension

'X'. The result is the thickness of adjustment

. Remove any adjustment washers. washer(s) necessary to get the correct igniter

. Put the igniter plug against protrusion gauge immersion.

(Step 1) and measure dimension 'X' with a . Fit the minimum number of adjustment

depth gauge. washers to give a thickness of between 0.265

and 0.280 in. (6,72 and 7,12 mm).

b. Install protrusion gauge HU38434 to engine

(Step 2) as follows: c. Remove the protrusion gauge:-

CAUTION . Loosen the locking collar and push the

Install protrusion gauge carefully to prevent indicator down, turn the indicator until the

damage to the combustion liner. notch points to the rear of the engine and

remove the protrusion gauge.

. Move the locking collar, the locating plate and . Install the igniter plug with the adjustment

the body up against the indicator. washers in the applicable igniter plug

. Install protrusion gauge into the applicable hole (see removal/installation procedure).

igniter plug location hole. Ensure indicator

notch points to the rear of the engine. NOTE: You must always use the 0.13in

. Ensure the arrow on the locating plate points (3,20mm) washer in the adjustment.

to the front of the engine and the locating

plate aligns with one of the three bolts.

. Turn indicator until the notch points to the

front of the engine.

. Carefully pull the indicator up until the probe

foot touches the combustion liner.

. Lightly tighten the locking collar.

Revision 6.0 Page 13 - 29

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 30

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance Practices

Filling the Starter Motor Oil System

NOTE NOTE

Only warnings that are applicable to the Only oil approved by Rolls-Royce can be

starting system and have not been previously used in the starter motor. It is the same oil as

mentioned appear on this page. used in the engine lubrication system and is

listed in Chapter 5 of these course notes.

WARNING

You must be careful when you move the . Open left hand fan cowl door.

starter motor because it weighs 46lb (20.8 . Remove oil filler plug, discard sealing ring.

Kg), an injury can occur. . Add approved oil until correct level is shown

on the sight glass.

WARNING . Fit new sealing ring to oil filler plug.

Air pressure in the starter motor duct could . Fit oil filler plug and torque load.

cause injury to persons if it is not released . Wire lock filler plug.

before dismantling air duct. Air must be . Close left hand fan cowl door.

released before dismantling air duct.

(1) Make sure the external air supply is

disconnected from the bleed air system and

the Auxiliary Power Unit (A.P.U.) is shut

down.

(2) Put a tool into the square socket to

manually open the butterfly of the starter

control valve. This will release any air

remaining in the air duct.

Revision 6.0 Page 13 - 31

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 32

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance practices

Starter Removal/Installation

. Align master splines on starter motor and

. Open fan cowl doors. adapter by keeping the oil drain plug at

. Disconnect vee clamp and remove lower bottom dead centre when installing the starter

starter duct and E-seals. motor.

. Support starter motor and remove Quick . Fit Q.A.D. clamp and torque load.

Attach Detach (Q.A.D.) clamp. . Install lower starter duct ensuring E-seals

. Move starter forward to disengage Q.A.D. have been fitted correctly.

adapter splines and starter splines. . Fit vee clamps and torque load.

. Remove starter motor and discard sealing . Fill starter motor oil system.

ring. . Close fan cowl doors.

. Fit applicable blanks/caps over all openings.

NOTE

If it is necessary to remove Q.A.D. adapter it is not a There is a correct procedure for fitting the

difficult job but remember the following points. Q.A.D. and vee clamps which must be

adhered to. The procedure is shown in

. There is a sealing ring between adapter and Standard Practices Chapter 70 of the AMM.

gearbox that needs to be replaced.

. There is a dowel to ensure correct location. NOTE

. Apply a thin film of approved jointing The serviceability of the E-seals must be

compound to mating surfaces when refitting. checked before fitting. This check is shown in

Standard Practices Chapter 70 of the AMM.

Installation of starter motor is carried out as follows:-

. Remove blanks/caps from openings.

. Fit new sealing ring.

Revision 6.0 Page 13 - 33

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 34

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Maintenance Practices

Starter Control Valve Removal/

Installation

. Fit vee clamps and torque load.

• Open fan cowl doors. . Remove blanks/caps from electrical

. Disconnect vee clamps and remove lower connectors.

starter duct and E-seals. . Connect the electrical connectors.

. Fit blanks/caps over openings. . Close fan cowl doors.

. Disconnect electrical connectors and fit

blanks/caps. NOTE

. Hold starter control valve and disconnect vee There is a correct procedure for fitting vee

clamp and E-seals. clamps which must be adhered to. The

. Remove starter control valve. procedure is shown in Standard Practices

. Fit blank/caps to all openings. Chapter 70 of the AMM.

Installation of the starter control valve is carried out NOTE

as follows:- The serviceability of the E-seals must be

checked before fitting. This check is

. Remove blanks/caps from all openings. shown in Standard Practices Chapter 70 of

. Fit starter control valve to upper air starter the AMM.

duct ensuring E-seals have been fitted

correctly. NOTE

. Make sure arrow on the valve body is pointing Using an inspection light and mirror examine

in the direction of airflow and that the marks the air ducts for security of attachments.

on the duct and control valve are aligned. Examine support links for damage, wear and

. Fit vee clamp and torque load. loss of adjustment. Examine ducts for leaks,

. Install lower air duct ensure E-seals have cracks and dents. Damage accept/reject limits

been fitted correctly. standards are given in the AMM.

Revision 6.0 Page 13 - 35

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

Revision 6.0 Page 13 - 36

© Rolls-Royce plc 2003

Trent 700 Line Maintenance Starting and Ignition Systems

End of Section

Revision 6.0 Page 13 - 37

Vous aimerez peut-être aussi

- 04 CH77,31 Engine IndicatingDocument44 pages04 CH77,31 Engine IndicatingaliPas encore d'évaluation

- 08 Ch75 Airflow Control SystemDocument38 pages08 Ch75 Airflow Control SystemaliPas encore d'évaluation

- Done By:: Indian Institute of Space Science and Technology ThiruvananthapuramDocument48 pagesDone By:: Indian Institute of Space Science and Technology Thiruvananthapuramsrijani pal100% (1)

- ATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyDocument86 pagesATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyZbor ZborPas encore d'évaluation

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- Undercowl Pocket Guide RRDocument32 pagesUndercowl Pocket Guide RRbnmmauricio100% (3)

- V2500 Line and Base Maintenance Power PlantDocument42 pagesV2500 Line and Base Maintenance Power PlantHENIGUEDRIPas encore d'évaluation

- 1 - Cowling&EBU (CF6-80E1)Document9 pages1 - Cowling&EBU (CF6-80E1)Chabou_r1627100% (3)

- Ata 79 CF6-80C2Document19 pagesAta 79 CF6-80C2ccoyure100% (1)

- Study Questionnaire Ata 70-80 B1Document9 pagesStudy Questionnaire Ata 70-80 B1suriya100% (2)

- Trent 1000 Bsi 23122016Document1 pageTrent 1000 Bsi 23122016Mohamed AbdelSalamPas encore d'évaluation

- Trent 700 Series Issue 03Document9 pagesTrent 700 Series Issue 03HelloWorldPas encore d'évaluation

- LBM Day8Document9 pagesLBM Day8Genaro RodriguezPas encore d'évaluation

- ATA 70 POWER PLANT (RR Trent 700)Document340 pagesATA 70 POWER PLANT (RR Trent 700)Sohaib Aslam ChaudharyPas encore d'évaluation

- VBV System: Lisbon A320/CFM56-5/5B Focus Team Conference June 2012Document21 pagesVBV System: Lisbon A320/CFM56-5/5B Focus Team Conference June 2012Goutam Saha0% (1)

- CTC-070 Answerbook Oct13Document57 pagesCTC-070 Answerbook Oct13Giovanny Colorado100% (2)

- Ata 71 CF6-80C2Document28 pagesAta 71 CF6-80C2ccoyure100% (1)

- Ata 74 CF6-80C2Document9 pagesAta 74 CF6-80C2ccoyure100% (1)

- 70 Power Plant CFM 56Document322 pages70 Power Plant CFM 56Agam Septiana100% (1)

- TR - A320 MLG - ServicingDocument23 pagesTR - A320 MLG - ServicingJohn Detrick100% (2)

- CFM Flight Ops Support A320Document143 pagesCFM Flight Ops Support A320MarcinPas encore d'évaluation

- Trent 700 - L & B Maintenance TrainingDocument1 pageTrent 700 - L & B Maintenance TrainingIrfan05Pas encore d'évaluation

- Ctc-214 Basic EngineDocument365 pagesCtc-214 Basic Engineernesto rodriguezPas encore d'évaluation

- Fan Lub CFM56-7 - HandbookDocument44 pagesFan Lub CFM56-7 - HandbookANDRAPas encore d'évaluation

- Iae V2500 Engine Questions: TH THDocument12 pagesIae V2500 Engine Questions: TH THRafael SantosPas encore d'évaluation

- A330ge 71..80 B12 1aug2015Document474 pagesA330ge 71..80 B12 1aug2015Egor RogulkinPas encore d'évaluation

- 2 Engine GeneralDocument23 pages2 Engine GeneralChabou Rafik100% (1)

- A330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APUDocument110 pagesA330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APULuiz Fernando MibachPas encore d'évaluation

- HPC Shroud & VSV System ImprovementsDocument15 pagesHPC Shroud & VSV System Improvementsali100% (2)

- Choice Global Support Capability: Flight HoursDocument9 pagesChoice Global Support Capability: Flight HoursGenaro Rodriguez100% (2)

- A330 Rolls-Royce RB211-Trent 700 Virtual Reality 360Document20 pagesA330 Rolls-Royce RB211-Trent 700 Virtual Reality 360Edison Vianney Cardona Montoya100% (2)

- CFM56-7B Fan Blade Lubrication CESM-005Document2 pagesCFM56-7B Fan Blade Lubrication CESM-005Keith Humphrey0% (2)

- Ata 70-80 Power Plant Iae V2500 PDFDocument434 pagesAta 70-80 Power Plant Iae V2500 PDFAnonymous QRVqOsa5100% (1)

- How To Use TSMDocument26 pagesHow To Use TSMAhmed ElFekyPas encore d'évaluation

- General Familiarization Course - t4 (Ge Cf6) Part 1Document608 pagesGeneral Familiarization Course - t4 (Ge Cf6) Part 1Evangelos KopanakisPas encore d'évaluation

- A330 Important PointsDocument4 pagesA330 Important PointsArindam Dutta100% (1)

- Engine MaintenanceConceptsPresentation PDFDocument46 pagesEngine MaintenanceConceptsPresentation PDFEnrico Gambini100% (1)

- A380-Level II&III - Ata 29 Hydraulic PowerDocument56 pagesA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Pas encore d'évaluation

- CFM56 5C - Ang 2Document2 pagesCFM56 5C - Ang 2pullu p josePas encore d'évaluation

- A318/A319/A320/A321 (CFM56) : StructureDocument132 pagesA318/A319/A320/A321 (CFM56) : StructureRaby Abidi100% (1)

- Ata 75 CFM56-3Document17 pagesAta 75 CFM56-3ccoyure100% (1)

- IAE V2500 Under Cowl GuideDocument61 pagesIAE V2500 Under Cowl GuideWalter Radzewicz100% (1)

- Line and Base: Pw1100G-JMDocument16 pagesLine and Base: Pw1100G-JMGenaro Rodriguez100% (1)

- Borescope BelendingDocument2 pagesBorescope BelendingArabyAbdel Hamed SadekPas encore d'évaluation

- Engine Change BootstrapDocument5 pagesEngine Change Bootstrapolegprikhodko2809Pas encore d'évaluation

- The Rolls-Royce Trent 7000 Engine: Key Facts at A GlanceDocument3 pagesThe Rolls-Royce Trent 7000 Engine: Key Facts at A GlanceAshwiniPas encore d'évaluation

- cfm56 5b PDFDocument6 pagescfm56 5b PDFTURBOJATO100% (1)

- 4 Power Generation and DistributionDocument51 pages4 Power Generation and DistributionFanhang ZhangPas encore d'évaluation

- CTC-224 Engine SystemsDocument331 pagesCTC-224 Engine Systemsjivomir100% (1)

- Pw4000-100 - Opencowl Inspection GuideDocument63 pagesPw4000-100 - Opencowl Inspection Guidegayathrisicwai100% (8)

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument20 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyPas encore d'évaluation

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Equipment/FurnishingsDocument182 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Equipment/FurnishingsAnurag MishraPas encore d'évaluation

- 09 - CH75 - Engine Cooling & Sealing Air SystemDocument26 pages09 - CH75 - Engine Cooling & Sealing Air SystemaliPas encore d'évaluation

- 05 - CH73,76 - Full Autority Digital Engine Control FADECDocument54 pages05 - CH73,76 - Full Autority Digital Engine Control FADECali100% (1)

- Kenwood CT 203 HU Service ManualDocument20 pagesKenwood CT 203 HU Service Manualβασίλιος ΝικηφόροςPas encore d'évaluation

- D D D D D D: Description/ordering InformationDocument11 pagesD D D D D D: Description/ordering InformationSandro RodrigoPas encore d'évaluation

- Saudi Arabian Oil Company: VA-291301 001 P 0A2 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: VA-291301 001 P 0A2 K11 Restrictedsaleem naheedPas encore d'évaluation

- D D D D D D: Description/ordering InformationDocument10 pagesD D D D D D: Description/ordering Informationgerardo ramosPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- CFM56 7B SB Rev 72-0986 TSN.03 R 20181030Document15 pagesCFM56 7B SB Rev 72-0986 TSN.03 R 20181030aliPas encore d'évaluation

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliPas encore d'évaluation

- 2020 AMC ProgramDocument247 pages2020 AMC ProgramaliPas encore d'évaluation

- Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636Document8 pagesAccomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636aliPas encore d'évaluation

- Dozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgDocument4 pagesDozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgaliPas encore d'évaluation

- Engine FailureDocument2 pagesEngine Failuresaudia686100% (18)

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliPas encore d'évaluation

- Type-Certificate Data Sheet: An Agency of The European UnionDocument28 pagesType-Certificate Data Sheet: An Agency of The European UnionaliPas encore d'évaluation

- A320 NEO Vs CEO Comparison StudyDocument15 pagesA320 NEO Vs CEO Comparison StudyArpit Saraswat100% (4)

- Course Title: Stud. Qualif.: Instructors:: Thematic PlanDocument1 pageCourse Title: Stud. Qualif.: Instructors:: Thematic PlanaliPas encore d'évaluation

- Cross Section Inf Cfm56-7B PDFDocument1 pageCross Section Inf Cfm56-7B PDFaliPas encore d'évaluation

- A320 Automation PDFDocument1 pageA320 Automation PDFaliPas encore d'évaluation

- Engine Yearbook 2017Document5 pagesEngine Yearbook 2017ali100% (1)

- Ecu Software - cfm56Document9 pagesEcu Software - cfm56aliPas encore d'évaluation

- Type-Certificate Data Sheet: An Agency of The European UnionDocument24 pagesType-Certificate Data Sheet: An Agency of The European UnionaliPas encore d'évaluation

- Achivment Cwcs - cfm56Document16 pagesAchivment Cwcs - cfm56aliPas encore d'évaluation

- Combustor Cwcs - cfm56Document21 pagesCombustor Cwcs - cfm56ali100% (2)

- Thrust Rating Summary 11-6-2009Document2 pagesThrust Rating Summary 11-6-2009aliPas encore d'évaluation

- Nacelle cfm56Document13 pagesNacelle cfm56aliPas encore d'évaluation

- Https Cwcs - cfm56 HPT BladeDocument8 pagesHttps Cwcs - cfm56 HPT Bladeali100% (1)

- CSC-246 Cross Section Cfm56-5C PDFDocument1 pageCSC-246 Cross Section Cfm56-5C PDFaliPas encore d'évaluation

- Fuel cfm56Document12 pagesFuel cfm56aliPas encore d'évaluation

- 7B - Line Maintenance - EGT - CFM Symposium 2017Document7 pages7B - Line Maintenance - EGT - CFM Symposium 2017aliPas encore d'évaluation

- ASA Aft Sump Leak - Customer Exp - 2017 WTTDocument9 pagesASA Aft Sump Leak - Customer Exp - 2017 WTTaliPas encore d'évaluation

- CFM56 FH Feb 2016 PDFDocument35 pagesCFM56 FH Feb 2016 PDFaliPas encore d'évaluation

- 21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017Document15 pages21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017aliPas encore d'évaluation

- 7B - MyCFMportal - CFM Symposium 2017Document14 pages7B - MyCFMportal - CFM Symposium 2017aliPas encore d'évaluation

- 7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017Document10 pages7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017aliPas encore d'évaluation

- Application of Pinnipedvibrissae To AeropropulsionDocument31 pagesApplication of Pinnipedvibrissae To AeropropulsionShahzadPas encore d'évaluation

- III Sem Jan 2010 Examination Results SwatisDocument21 pagesIII Sem Jan 2010 Examination Results SwatisAvinash HegdePas encore d'évaluation

- Remuz TreeDocument608 pagesRemuz TreeEdward JonesPas encore d'évaluation

- Sch40 80 ASTM A53 - Brochure - 042512Document2 pagesSch40 80 ASTM A53 - Brochure - 042512Fallo SusiloPas encore d'évaluation

- Sony Video Camera Manual PDFDocument118 pagesSony Video Camera Manual PDFGary Hoehler100% (1)

- Total Productive Maintenance WorksheetDocument2 pagesTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- Short Notes On Building ConstructionDocument20 pagesShort Notes On Building Constructionlarnz0% (1)

- Ultrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookDocument84 pagesUltrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookrancidPas encore d'évaluation

- A White Paper On IExpense Features in R12Document17 pagesA White Paper On IExpense Features in R12Balaji ShindePas encore d'évaluation

- Turbine BladeDocument27 pagesTurbine BladesrtanandPas encore d'évaluation

- SDLCDocument2 pagesSDLCTahseef RezaPas encore d'évaluation

- Python - Tutorial: #!/usr/bin/python Print "Hello, Python!"Document174 pagesPython - Tutorial: #!/usr/bin/python Print "Hello, Python!"ankitPas encore d'évaluation

- Tolerance RingsDocument13 pagesTolerance Ringspai mjrPas encore d'évaluation

- Project Reoprt On JSW SteelsDocument30 pagesProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- HR Report ON Moser BaerDocument77 pagesHR Report ON Moser BaerKomal DhaliwalPas encore d'évaluation

- Architectural, Museology, Urban DesignDocument201 pagesArchitectural, Museology, Urban DesignAbby VernonPas encore d'évaluation

- Kumar Saurabh Resume (SAP IBP)Document6 pagesKumar Saurabh Resume (SAP IBP)SaurabhSinhaPas encore d'évaluation

- Recruitment of Junior Associates (Customer Support & Sales) PDFDocument2 pagesRecruitment of Junior Associates (Customer Support & Sales) PDFSingh ShivamPas encore d'évaluation

- Guideline G6 Certification Process v2 0Document18 pagesGuideline G6 Certification Process v2 0Wong Wong WLPas encore d'évaluation

- Cyber Bully ArticleDocument2 pagesCyber Bully ArticleCharline A. Radislao100% (1)

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Document3 pagesU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXPas encore d'évaluation

- Cap 1Document10 pagesCap 1Oscar Bello LemusPas encore d'évaluation

- RRLDocument3 pagesRRLNeil RosalesPas encore d'évaluation

- Stand-mount/Books Helf Louds Peaker System Product SummaryDocument1 pageStand-mount/Books Helf Louds Peaker System Product SummaryCatalin NacuPas encore d'évaluation

- Nyuszi SzabásmintaDocument3 pagesNyuszi SzabásmintaKata Mihályfi100% (1)

- ch46Document15 pagesch46jose perezPas encore d'évaluation

- Z PurlinDocument2 pagesZ PurlinAddrien DanielPas encore d'évaluation

- Operation & Service Manual: Murzan IncDocument38 pagesOperation & Service Manual: Murzan IncgokulPas encore d'évaluation

- An 4160Document8 pagesAn 4160aurumstar2000Pas encore d'évaluation

- ES Service Transition PlanDocument7 pagesES Service Transition PlanShamsher Singh BainsPas encore d'évaluation