Académique Documents

Professionnel Documents

Culture Documents

Fully Corrected Numerical Exercise

Transféré par

Jigar GoswamiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fully Corrected Numerical Exercise

Transféré par

Jigar GoswamiDroits d'auteur :

Formats disponibles

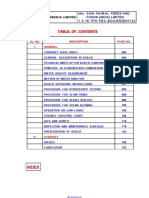

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 1

A/4. Numerical Exercise :

Key notes : Topic wise numerical questions along with their detailed solutions are

given hereby as below mention. For BOE Examination preparatory candidate it is most

important that they should try to solve all these numerical exercise himself. In case of

feeling any problem then they can refer for the solution. If you have any doubt or query

can discuss with author of this book. Kindly intimate us if you are sure about any

mistake are their in any part of solution.

A/4.1 : Air, Fuel & Combustion related Numerical :

Question -1 :In an APH, Gas inlet is 31kg/s with 3.5%oxygen in the outlet the oxygen content

increases to 4.2%. Find the leakage quantity of air and also find the increases in ID fan load %

due to the leakage. AP BOE-2013

Solution :

%Excess air=O2X100/(21-O2)

Excess air content at 3.5% O2=3.5x100/(21-3.5)=20%

Excess air content at 4.2% O2=4.2x100/(21-4.2)=25%

% Increment of excess air=25-20=5%

Leakage quantity= % Increment of excess air X Gas inlet flow =0.05x31= 1.55kg/s

Increase in ID fan loading% =Leakage quantityx100/Gas inlet flow =1.55X100/31=5%

Question -2 : Find the rise in temperature of air in a pre-heater if 16 kg of air is supplied per kg of

fuel burnt & temperature of flue gases drops in pre-heater is 139*c . The efficiency of pre-heater is

78% the specific heat of flue gases and air is 0.24 .

Solution : Heat transfer of flue gas to Air

=Flue gas mass on 1 Kg of fuel supplied (1 fuel+16 air) x Specific heat x temperature difference of flue

gas across the Air pre-heater= (1+16)x0.24x139 = 567.12 Kcals on supplied 1 Kg of fuel

Effective heat transfer from flue gas to Air= Heat transfer of flue gas to Air x Efficiency of air pre-heater

=567.12 x0.78 =442.3536 Kcal on supplied 1 Kg of fuel

Rise in temperature=

= Effective heat transfer from flue gas to Air/[Mass of air per kg of fuel x specific heat of air]

=442.3536/[16x0.24]

=442.3536/3.84 =115.2*C

Question -3 : In a coal sample it is found total moisture as received basis is 13%. Using suitable

formula calculate GCV of the Dry Coal if GCV of as received coal is 3400 kcal/kg.

Solution;

To obtain GCV value of coal after drying the GCV value as received basis is to be multiplied with

100/(100-TM%)

GCV of dry coal =3400(100/100-TM%)=3400(100/100-13)

=3908 kcal/kg

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 2

Question : 4 - Coal with 35% ash is fired in a boiler . Coal consumption is 80 tons on a specific

Day. Clinker is formed by 2% of the ash sticking to boiler tubes. How many Tons of ash are going

out of the boiler on same day .

Solution : Total ash generated by boiler in a specific day=

=80X0.35 =28tons

Total ash going out of the boiler on same day=

=Total ash generated by boiler in a specific dayX(100-sticking ash into boiler tubes)/100

=28x0.98

=27.44tons per day

Question -5 : On line oxygen analyzer of a boiler is showing 4.5%. Calculate the excess air

percentage at which the boiler is operating.

Solution; Excess air% ={(O2%x100)/(21-O2%)}

=(4.5x100)/(21-4.5) =27.27%

Question -6 : Assume the stochiometric air to fuel ratio of furnace oil is 14. The burner operates at

20% excess air . Calculate the mass of stack gas generated from combustion of one kg of oil.

Solution :

For stochiometric air requirement for furnace oil combustion

1 kg of furnace oil required 14 kg of air.

Including to excess air total air requirement

=14x1.20

=16.8 kg of air

After the combustion mass of flue gas generation

=16.8 kg of air+1 kg of furnace oil

=17.8 kg of flue gas

Question -7 : The percentage composition of a sample of coal on mass basis is as follows

Carbon 85%,Hydrogen 12%, Oxygen 3%

(a) Determine the minimum air required for complete combustion of 1kg of coal.

(b) If Air supplied is 1.5times the minimum air required, calculate the mass of dry product of

combustion per kg of coal burned.

© The heat carried away by the dry product of combustion leaving the boiler per kg of fuel burned.

Given average specific heat of dry flue gas is 1.005 Kj/kg*K and temperature of flue gas is 375*C

and boiler house temperature is 25*C. CG BOE-2014

Solution :

Given that, Carbon=85%,Hydrogen=12%,Oxygen=3%

Theoretical air requirement for complete combustion of 1 Kg of coal

=100/23x(2.67C+8H+S-O)

=100/23x(2.67x0.85+8x0.12+0-0.03)

=4.35x3.1995

=13.89 kg of air per kg of coal burnt (Answer)

While Excess air is 50% ,hence actual air requirements

=1.5x13.89 =20.84 kg of air per kg of coal burnt

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 3

Total excess air quantity

=20.84-13.89 =6.95 kg/kg of coal

Total product is of combustion here includes CO2,H2O,Excess O2,N2.

To find the products of combustion is,

(i) Weight of CO2 formed per kg of coal= 3.67xC=3.67X0.85=3.1195Kg

(ii) Weight of H2O formed per kg of coal=9XH=9x0.12=1.08Kg

(iii) Weight of Excess O2 per kg of coal=0.23x6.96=1.5985Kg

(iv) Weight of N2 per kg of coal= 0.77x20.84=16.0468Kg

Out of 4 combustion product H2O is not considered in dry product of combustion.

Hence Dry flue gas of combustion consist of CO2,Excess O2,N2.

Therefore total weight of dry flue gases

w= 3.1195+1.5985+16.0468

=20.76 kg/kg of coal burnt (Answer)

Heat loss through dry flue gas =wxCpxΔT

=20.76x1.005x(375-25)

=7302.33 KJ/kg of coal

Heat carried away by dry flue gases of combustion

=heat carried away per kg of moisture in flue gas x weight of H2O formed per kg of coal

=2940x1.08 (2940 Kj/kg heat liberated through flue gas due to hydrogen present in fuel)

=3175.2 KJ/Kg

Total heat loss per kg of coal for heat carried away by flue gases

=7302.33+3175.2 =10,477.53 KJ/Kg (Answer)

Question :8. The following is the %age composition of coal on mass basis :

C=90%, H2=3.3%, O2=3%, S=0.9% and remaining ash

Calculate :

(a) The theoretical air required to burn 1Kg of coal completely.

(b) The %age composition of dry flue gases on mass basis if 50% excess air is supplied.

Assume air has 23% oxygen on mass basis.

CG BOE-2012

Solution :

a) Theoretical air qty required to burn 1 kg of coal = 4.35 x[ {(2.67x0.9)+(8x0.033)+0.009}-0.03]

=10.47 Kg/Kg of coal

b) Flue gas composition % on mass basis -

Mass of dry flue gas liberated from 1 kg coal burnt

= ( 1+EA/100)x theoretical air+ 1kg of coal

= [(1+50/100)x10.47]+1 =16.705 kg/kg of coal

1) C+O2 = CO2, Weight of CO2 formed for 1kg of coal= (44/12)x0.9=3.303 Kg

% co2 = 3.303/16.705 = 19.77%

2) 2H2+O2=2H2O, Weight of H2O formed for 1 kg of coal = (36/4)x0.033 =0.297 Kg

% H2O = 0.297/16.705= 1.78%

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 4

3) S+O2=So2, Weight of So2 formed for 1 kg of coal = (64/32)x0.009= 0.018 Kg

%So2 = 0.018/16.705=0.12%

4) Mass of NO2=0.77XAA=0.77X1.5X10.47=12.09Kg

%NO2=12.09/16.705=72.37%

Question -9 : A sample of coal with C=0.78,H2=0.05,O2=0.02,N2=0.02 and ash = 0.05 is burnt in a

furnace with 50% excess air. The flue gas enter the chimney at 325*c and atmospheric

temperature is 15*c . Take the Cp for CO2 , SO2 and air = 1.008 KJ/Kg K. Assume that the heat

carried away per kg of moisture in flue gases is 2940 KJ. Calculate the quantity of heat carried

away by the flue gases in KJ/Kg k .

Solution :

Given that

Carbon=78%,Hydrogen=5%,Oxygen=2% ,Sulpher=0% & Ash=5%

Theoretical air requirement for complete combustion of 1 Kg of coal

=100/23x(2.67C+8H+S-O)

=100/23x(2.67x0.78+8x0.05+0-0.02)

=4.35x2.4626

=10.71 kg of air per kg of coal burnt

While Excess air is 50% ,hence actual air requirements

=1.5x10.71

=16.065 kg of air per kg of coal burnt

Excess air quantity

=16.065-10.71

=5.355 kg/kg of coal

Total product is of combustion here includes CO2,H2O,Excess O2,N2.

To find the products of combustion is,

(i) Weight of CO2 formed per kg of coal= 3.67xC=3.67X0.78=2.8626Kg

(ii) Weight of H2O formed per kg of coal=9XH=9x0.05=0.45Kg

(iii) Weight of Excess O2 per kg of coal=0.23x5.355=1.23165Kg

(iv) Weight of N2 per kg of coal= 0.77x16.065=12.37005Kg

Out of 4 combustion product H2O is not considered in dry product of combustion.

Hence Dry flue gas of combustion consist of CO2,Excess O2,N2.

Therefore total weight of dry flue gases

w= 2.8626+1.23165+12.37005

=16.4643 kg/kg of coal burnt

Heat loss through dry flue gas

=wxCpxΔT

=16.4643x1.008x[(325+273)-(15+273)]

=5144.76 KJ/kg of coal

Heat carried away by dry flue gases of combustion

=heat carried away per kg of moisture in flue gas x weight of H2O formed per kg of coal

=2940x0.45

=1323 KJ/Kg of coal

Total heat loss per kg of coal for heat carried away by flue gases

=5144.76+1323

=6467.76 Kj/Kg (Answer)

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 5

Question-10: Following observations are noted during coal fired boiler trial :---

Ultimate analysis of coal : H2-2%, O2-5%, C-38%,S-1%, moisture-5%.

O2 in flue gas : 3%

Flue gas temperature at boiler exist : 140*C

Ambient air temperature : 40*C

GCV of coal : 3400 kcal/kg

Specific heat of flue gas : 0.23 kcal/kg*C

Specific heat of superheated steam : 0.45 kcal/kg*C

Calculate :--

(a) % Heat loss due to dry flue gas

(b) %Heat loss due to evaporation of water formed due to hydrogen in fuel.

(c) %Heat loss due to evaporation of moisture present in combustion air. MH BOE-2014

Solution :

Theoretical air requirement for coal =100/23x(2.67C+8H+S-O)

=4.35x(2.67x0.38+8x0.02+0.01-0.05)

=4.35x(1.0146+0.16+0.01-0.05)

=4.35x1.1346=4.93551 kg of air/kg of coal

Excess air =[O2x100]/[21-O2] =[3x100]/[21-3]=300/18=16.67%

Actual air requirement =4.93551x1.1667=5.758 kg of air/kg of coal

Flue gas generation =1+5.758=6.758 kg of flue gas/kg of coal

(a) Heat loss due to dry flue gas =[mxCpx(Tf-Ta)x100]/GCV of fuel

=[6.758x0.23x(140-40)x100]/3400

=4.57 %

(b) %Heat loss due to evaporation of water formed due to hydrogen in fuel=

=[9xH2x{584+Cp(Tf-Ta)}x100]/GCV of fuel

=[{9x0.02x{584+0.45x(140-40)}x100]/3400

=[9x0.02x{584+45}x100]/3400=3.33%

© %Heat loss due to evaporation of moisture present in combustion air=

=[Mx{584+Cp(Tf-Ta)}x100]/GCV of fuel

=[0.05x{584+0.45x(140-40)}x100]/3400

=[0.05x629x100]/3400=0.925 %

Question -11 : The percentage composition of a sample of a liquid fuel by weight is carbon-

84.8% and hydrogen-15.2%. Calculate

(a) The weight of air required for the combustion of 1kg of fuel.

(b) The volumetric composition of the product of combustion if 15% excess air is

supplied. UP BOE-2014

Solution :

(a) Weight of air required to burn 1 kg of liquid fuel

= 4.35 x {(2.67x0.848)+(8x0.152)} =4.35x{2.26416+1.216} =15.14 Kg/Kg of liquid fuel

(b) Flue gas %composition on mass basis=Mass of dry flue gas liberated from 1 kg fuel burnt

= ( 1+EA/100)x theoretical air+ 1kg of fuel = [(1+15/100)x15.14]+1 =18.411 kg/kg of fuel

Composition of flue gas on the basis of mass

(i) CO2 by mass = (44/12)x0.848=3.109 Kg/kg of fuel

% CO2 = 3.109/18.411 = 16.87%

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 6

(ii) H2O by mass = (36/4)x0.152 =1.368 Kg/kg of fuel

% H2O = 1.368/18.411= 7.43%

(iii) O2 by mass=(23/100)x(AAS-TAS)

=0.23x(17.411-15.14)=0.522 Kg/kg of fuel

% O2=0.522/18.411=2.83%

(iv) N2 by mass=(77/100)xAAS=0.77x17.411=13.41 Kg/kg of fuel

%N2=13.41/18.411=72.84%

Calculation of flue gas on the basis of Volume

Constitue % Mass of Atomic Specific volume c/£ M % Volume

nts F/G(a) weight(b) c=(a/b)

CO2 16.87 44 0.38 0.38/3.48 10.92%

H2O 7.43 18 0.41 0.41/3.48 11.78%

O2 2.83 32 0.09 0.09/3.48 2.59%

N2 72.84 28 2.6 2.6/3.48 74.71%

£M 3.48

Answer : Product of composition on volume basis ; CO2=10.92%,H2O=11.78%,O2=2.59% &

N2=74.71%

Question -12 :In a 200MW unit, coal of 3500 kcal/kg GCV is fired. The ash content in the coal is

40%. If the un-burnt in bottom ash is 3.5% and in fly ash it is 0.5%, Calculate the efficiency loss in

percentage due to un-burnt ( take the ratio of bottom ash to fly ash is 20:80. The GCV of carbon

may be taken as 8130kcal/kg.

Solution :

Total ash in coal per kg=1x 40/100 =0.4 kg.

Quantity of bottom ash per kg coal=0.4x0.2=0.08 kg

Quantity of fly ash per kg coal=0.4x0.8=0.32 kg

Un-burnt in bottom ash =0.08 x 0.035= 0.0028 kg

Un-burnt in fly ash=0.32 X 0.005=0.0016 kg

%efficiency loss due to un-burnt in bottom ash =0.0028 x 8130x100/3500 = 0.6504%

%efficiency loss due to un-burnt in fly ash=0.0016 x 8130x100/3500 = 0.3716%

Total % efficiency loss due to un-burnt =0.6504%+0.3716% = 1.022% Ans.

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 7

Question -13 : In a 500MW unit, coal of 4000 kcal/kg GCV is fired. The un-burnt in bottom ash is

2.8%. and in fly ash is 0.4%. If the ash content in coal is 36%. Calculate the amount of loss due to

combustibles in ash in terms kcal/kg coal fired. ( The GCV of carbon may be taken as 8130kcal/kg

and the ratio of bottom ash to fly ash collected is 15:85) CG BOE-2014

Solution :

Total ash in per kg of coal =1x 36/100 =0.36 kg.

Quantity of bottom ash per kg of coal=0.36x0.15=0.054 Kg

Quantity of fly ash per kg of coal=0.36x0.85=0.306 kg

Un-burnt in bottom ash =0.054 x 0.028= 0.001512 kg

Un-burnt in fly ash=0.306 X 0.004=0.001224 kg

Therefore,Amount of loss for un-burnt in bottom ash is= 0.001512 X 8130

=12.29256 kcal/kg coal burnt

Amount of loss for un-burnt in bottom ash is= 0.001224 X 8130

=9.95112 kcal/kg coal burnt

Total heat loss due to combustible in ash =12.29256+9.95112

=22.24368 Kcal/kg of coal burnt (Ans.)

Question -14 : For a 5 TPH capacity furnace oil fired , estimate the rise to temperature of water in

a economizer which brings down the flue gas temperature from 280*C to 180*C. Air to fuel ratio

and Evaporation ratio of the boiler are 20 & 10 respectively. Assume condensate recovery is Nil &

Specific heat of the flue gas is 0.23Kcal/kg*C.

Solution :

Evaporation Ratio =Mass of steam generation/Mass of fuel consumption

Or Mass of fuel consumption =Mass of steam generation/Evaporation ratio

=5x1000/10=500Kg/hr

Mass of flue gas generation =Mass of fuel consumption + Mass of air consumption

=500+20x500=10,500 kg/hr

Total heat transfer of flue gas =Mass of F/G x Specific heat x(temperature difference)

=10,500x0.23x(280-180)

=2,41,500 Kcals per hour

Rise of feed water temp =Heat transfer/Mass of feed water flow

=2,41,500/5000 =48.3*C

Question -15 : For a coal containing 5% hydrogen ( GCV = 5500 kcal/kg ) , estimate the percentage

of sensible and latent heat loss due to evaporation of water formed due to hydrogen in the fuel, if

the flue gas temperature is 180c and combustion air temperature is 40c.

( latent heat of vapours= 584 Kcal/Kg , specific heat of vapours = 0.45 Kcal/Kg/c)

Solution : Percentage Heat loss due to hydrogen present in fuel

=[9xH2x(584+CpxΔt)x100]/GCV of fuel

=[9x0.05x(584+0.45x140)x100]/5500

=[0.45x647x100]/5500 =5.29%

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 8

Question-16: The following data was obtaining during a test on two boilers working under similar

conditions, except that the draught in the first boiler was produced by an induced draught fan and

in the second fan by a forced draught fan:-

Air supplied/kg of fuel burnt: 19kg

Density of air under given conditions: 1.205kg/m3

Density of flue gases at the specific temp 0.769kg/m3

Combustion rate 150kg of fuel/hr

Fan draught produced in each case 75mmwc

Efficiency of fan in both cases 50%

Calculate Brake Horsepower of fan in each case. <MH BOE-2014>

Solution :

BHP = Q x SP / (6356 x Fan Eff.)

Where , • BHP = Break Horsepower • Q = Air flow rate in CFM • SP = Static pressure in-WG

st nd

Calculation of BHP in 1 Case (ID Fan) Calculation of BHP in 2 Case (FD Fan)

Flow rate of flue gas ‘Q”= Flow rate of air ‘Q”=

=150x(19+1)=3000kg/hr=50kg/min=50/0.769m3/min =150x19=2850kg/hr=47.5kg/min=47.5/1.205

=65.02m3/min=65.02x35.31CFM m3/min=39.42m3/min=39.42x35.31CFM

=2295.86CFM =1391.92CFM

Brake horsepower(BHP) of ID fan= Brake horsepower(BHP) of FD fan=

=2295.86x75/(6356x0.50) =1391.92x75/(6356x0.50)

=172189.5/3178=54.18HP =104394/3178=32.85HP

A/4.2: Steam & their properties related numerical :

Question-17: Calculate the total heat of 1kg of steam at a pressure of 9kg/cm2(g) ,when :-

(i) Steam is wet having dryness fraction is 0.85.

(ii) Steam is dry saturated.

(iii) Steam is superheated at 205*C. Considering specific heat of superheated steam(Cp) is 0.55.

<MH BOE-2014>

Solution :

From steam table of [Table No.2] Saturated pressure table :

Steam at the pressure 9kg/cm2(g) or 10kg/cm2(abs)

hf =762.6 kj/kg & hg=2776.2 kj/kg

Saturated steam temp ‘ts’= 179.9*C

(a) Total enthalpy of wet steam = hf+x.hfg

=762.6+0.85x2013.6 =2474.16kj/kg

=591.62 kcal/kg

(b) Total enthalpy of dry saturated steam =hf+x.hfg =hg

=2776.2 kj/kg

=663.85 kcal/kg

© Total heat of superheated steam = hg+Cp(Tsup-Tsat)

=663.85+0.55(205-179.9)

=677.655 Kcal/kg

Question-18: Find the volume of 1 Kg of steam at a pressure of 14kg/cm2(g), in each of the

following case:--

(i) When steam is dry saturated.

(ii) When steam is wet having a dryness fraction of 0.9.

(iii) When steam is superheated, the degree of superheat being 40*C. <MH BOE-2014>

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 9

Solution :

(i) From steam table (Table No.-2, Saturated pressure table)

Volume of dry saturated steam at 15kg/cm2(abs) v=vg=0.13167m3/kg

(ii) Volume of wet steam at 15kg/cm2(abs) v=x.vg=0.9x0.13167=0.118503m3/kg

(iii) From steam table (Table No.-3, Specific volume of superheated steam)

Saturation temperature at 15kg/cm2(abs) is 198.3*C

Degree of superheat is 40*C

Temperature of the superheated steam=198.3+40=238.3*C

Volume of superheated steam at 15kg/cm2(abs) & 238.3*C =0.1474136 m3/kg

Question -19 : A boiler is operating at 100bar and 535*C with steam flow rate is 105TPH, the

superheater temperature maintained by 2 stage attemperation. Attemperation feed water supplied

at 156*C and super heated steam temperature of second stage to be maintained at 490*C to

maintain the main steam temperature. The first stage attemperator inlet steam temperature is

515*C. Find the attemperation water flow in the first stage attemperation to maintain the outlet at

490*C[Inlet steam enthalpy, spray water enthalpy and outlet steam enthalpy are

3413.63KJ/KG,658.12KJ/KG and 3349.18KJ/Kg respectively]. AP BOE-2013

Solution :

Suppose “S” is the attemperation water flow rate in Kg/hr.

Inlet steam enthalpy =3413.63KJ/Kg=816.27kcal/kg

Spray water enthalpy =658.12KJ/Kg =157.37kcal/kg

Outlet steam enthalpy =3349.18KJ/Kg=800.86kcal/kg

“F” is the steam flow rate after water spray=105TPH=105000 Kg/hr

Inlet heat +Spray heat=Outlet heat

Or (F-S)X816.27+Sx157.37=(F)x800.86

Or (105000-S)x816.27+Sx157.37=105000x800.86

Or 85708350-816.27S+157.37S=84090300

Or 85708350-84090300=816.27S-157.37S

Or 1618050=658.9S

Or S=1618050/658.9=2455.68 kg/hr

Attemperation water flow = 2.45568TPH

Question : 20 - Steam at a pressure of 15 kg/cm2(g) if flashed to a lower pressure of 2kg/cm2(g) . If

the steam flow rate is 1000 kg/hr . Calculate the % of flash steam & flow rate of flash steam.

Solution :

S1: Hf ,Sensible heat at higher pressure at 15kg/cm2(g) i.e. 16Kg/cm2(abs)

=858.5kj/kg=205.28Kcal/kg

S2:hf, Sensible heat at lower pressure at 2kg/cm2(g) i.e. 3kg/cm(abs)

=561.5kj/kg=134.27Kcal/kg

L2:hfg, Latent heat at lower pressure at 2kg/cm2(g) i.e.3kg/cm2(abs)

=2163.2Kj/kg=517.26Kcal/kg

% Flash steam=(S1-S2)X100/L2 =(205.28-134.2)X100/517.26 =13.74%

Flow rate of flash steam= %flash steam X Steam flow rate

=0.1374X1000kg/hr =137.4Kg/hr

Question -21 : One kg of steam at a pressure 14ata and temperature of 294.3 degC is reduced in

pressure to 3 ata and de-superheated by means of water sprayed at 20 degC and all the water is

converted into dry steam. Find out the quantity of water sprayed. The specific heat of superheated

steam maybe taken as 0.55.

Solution : 14 ata =14.18bar, Hg=666kcal/kg, ts=195.6degc.

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 10

Enthalpy of steam at 14 ata=hg+cp(tsup-ts)

= 666+ 0.55(294.3-195.6)=720.285 kcal/kg

Total Enthalpy of steam=Mass of steamx enthalpy of SH steam

=1X720.285=720.285Kcals

At 3ata, ts=133.5degC, hg=650.75kcal/kg.

Total Enthalpy of dry saturated steam= Mass of steamx enthalpy of dry saturated

steam=1x650.75+Mx20

In throttling process total enthalpy will be remain constant

720.285=650.75+20M

M=(720.285-650.75)/20

Mass of water spray “M”=3.47675Kg

Question -22 : Steam is generated in a boiler at 110 kg/cm2 and 520*c Drum pr. Of the boiler is

118 Kg/cm2 .Calculate- 1) Saturated steam temperature 2) Degree of superheat 3) Enthalpy of the

steam

Solution;

1) From the steam table saturated temperature corresponding to 110 Kg/cm2 is 318*c

2) Degree of super heat is the difference of superheated steam temperature & saturated steam

temperature=520-318=202*c

3) Enthalpy of the superheated steam as found from steam table corresponding to 110kg/cm2 and 520*c

is 816 kcal/kg

2 0

Question -23 : 200 TPH steam is generated in a boiler at 100 kg/cm Pressure and 500 c temp. if

0

feed water inlet temp. is 135 c and 52 ton of coal is consumed per hour than calculate.

0

1. Equivalent evaporation from and at 100 c

0

2. Equivalent evaporation from and at 100 c per ton of coal

3. Boiler HP.

Solution;

0

1. Equivalent evaporation in the quality of water evaporated from and at 100 c to produce dry saturated

0

steam at 100 c by absorbing the same amount of heat equal to actual operating condition.

o

(Latent heat of dry saturated steam at 100 C is 539 kcal/kg)

Specific heat of steam at 100 kg /cm² pressure , 500°c temperature is 809 kcal/kg.

Meq={Mact(H- Hfw)}/539={200(809-135)}/539=250TPH

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 11

2. To find equivalent evaporation from and at 100°c per ton of coal Mact is taken as actual steam

generation per unit quantity of fuel.

Mact in this case = 200/52 = 3.85 tons of steam per ton of coal

So Meq = {3.85(809-135)}/539=4.81TPH

3. One Boiler HP is the capacity to evaporate 15.653 kg of feed water per hour at 100° c into dry

saturated steam at 100° c.

Boiler HP = equivalent evaporation from and at 100 ° c (kg/hr)/15.653

=250x1000/15.653 =15971HP

Question-24: During the test of an oil fired water tube boiler, the following data was obtained:-

Steam pressure 16kg/cm2(ab)

Weight of water evaporated 283kg/min

Boiler feed water temp 76*C

Quality of steam 99%

Weight of fuel burnt 22.45kg/min

Calculate –

(a) Actual evaporation per kg of fuel oil

(b) Factor of equivalent evaporation

(c) Equivalent evaporation from and at 100*C

(d) Boiler horsepower MH BOE-2014

Solution :

(a) Evaporation rate ‘Mact”=283/22.45=12.61 kg of steam/kg of fuel oil

(b) Specific enthalpy of steam under the operating condition at 16kg/cm2(abs)

=hf+x.hfg

=205.28+0.99x462.27

=662.93 Kcal/kg

Factor of equivalent evaporation ‘F” =(H-Hwt)/539=(662.93-76)/539=1.089

© Equivalent evaporation from and at 100*C =[(283x60/1000)x[(662.93-76)]/539

=[16.98x586.93]/539 =18.49TPH

(d) One Boiler HP is the capacity to evaporate 15.653 kg of feed water per hour at 100*C into dry

saturated steam at 100*C.

Boiler HP = 18.49x1000/15.653=1181.24HP

Question -25 : Water is supplied to the boiler at 15 bar and 80*C and steam is generated at the

same pressure at 0.9 dryness. Determine the heat supplied to the steam in passing through the

boiler and change in entropy.

Solution :

Enthalpy of boiler inlet water at 80*C hf=334.9Kj/kg

Enthalpy of boiler outlet dry saturated steam at 15bar with 0.9 dryness factor

=hf+x.hfg =844.6+0.9x1945.3=2595.37kj/kg

Heat supplied to the steam is passing through the boiler=

=Enthalpy at boiler outlet-Enthalpy at boiler inlet

=2595.37-334.9=2260.47Kj/kg

Entropy at boiler inlet water=1.075kj/kg*K

Entropy at boiler outlet steam “s”=Sf+x.Sfg

=2.314+0.9x4.127

=6.0283 Kj/kg*K

Change in Entropy =6.0283-1.075 =4.9533 Kj/Kg*K

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 12

A/4.3: Stack (Chimney) related numerical :

Question :26- Estimate SO2 emission through chimney in Tons/annum. Data as follows:

Days considered: 340 Fuel used : Furnace oil Specific gravity : 0.94

Sulphur content : 3.8% Quantity of FO consumption : 3.5KL/hr

And If measured O2 in flue gas is 2.5%, Find % Excess air level. MH BOE-2013

Solution :

Quantity of Sulphur in Kg/Annum = 3.5x1000x0.94x24x340x0.038

= 1020163.2 Kg/Annum

S + O2 =SO2

32 +2x16 =64

As per above equation of sulphur emission ,1 Kg of Sulphur will generate 2 Kg of SO2.

Hence SO2 emission through chimney = 2x1020163.2 = 2040326.4 Kg/ Annum

= 2040.3264 Tons/ Annum

% Excess air = [O2%x100] / ( 21-O2%)

= [2.5x100] / ( 21-2.5)

= 13.51 %

Question -27 : A chimney is 28 mtr high and the temperature of hot gases inside the chimney is

320*c and the furnace is supplied with 15 kg of air per kg of coal burnt. Calculate

a- Theoretical draught in mm of water .

b- Draught head in meters of hot gasaes .

c- The velocity of flue gases in the chimney if 60% of draught is lost in friction of grate and

passages.

Solution :

(a) Supposed Ta (Ambient temp) is 25*C=25+273=298*K

Given as H=28meters ,T=320*C=320+273=593*K ,w=15kg/kg of coal burnt

Theoretical draught h=353H(1/Ta-w+1/wx1/T) mmWc

h=353x28(1/298-16/15x1/593)

h=9884x(0.00336-1.06667x0.00169)

h=9884x0.001557

h=15.39 mm of water column (Answer)

(b) Available draught is 40% of the theoretical draught.

P=0.4X15.39=6.156 mmwc=6.156X9.81N/m2

Now this pressure is caused by height of gas column Hg

Hgx353(w+1)/wxTx9.81=6.156X9.81

Or Hgx353(15+1)/(15x593)x9.81=6.156x9.81

Or Hgx0.635=6.156

Draught head of hot gasses is Hg=9.694m(Answer)

© Velocity of flue gas in chimney=

V=√(2xgxHg) =√(2x9.81x9.694) =13.79 m/sec (Answer)

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 13

Question -28 : Find out the height of a chimney on bases of following data:

Static draught: 30 mmwc, Flue gas temp 230 degC, Ambient temp:30degC.

(Air and Flue gas density NTP are 1.293 and 1.34kg/m3 respectively).

Solution : suppose H is the height of chimney,

Density of air at 30 degC= 1.293 x 273/303=1.165kg/m3

Density of flue gas at 230 degC=1.34 x 273/503=0.7273 kg/m3

Now , Draught produced by chimney =(H x density of air)-(H x density of flue gas)

30= H x (1.165-.7273)

H =68.54 meter. Ans.

Question -29 : Calculate the minimum height of chimney required to produce a draft of 19mm of

water column if 18kg of air is required per kg of fuel burnt on the grate. The mean temperature of

the gas inside the chimney is 357*C and that of atmospheric air 24*C UP BOE-2014

Solution: Suppose H=Height of chimney to produce a draft

Given That, Ta (Ambient temp) is 24*C=297*K

T=357*C=630*K , h=19mmWC

w=18kg/kg of coal burnt

Theoretical draught “h”=353H(1/Ta-{w+1/w}x1/T)

19=353xH(1/297-{19/18}x1/630)

19=353xH(0.0034-1.0556x0.00159)

19=353xH(0.0034-0.00168)

19=353xH(0.00172)

19=Hx0.60716

H=19/0.60716=31.29 meter (Answer)

A/4.4: Boiler Efficiency related numerical :

Question-30 : A 250TPH , 110kg/cm2,500*C boiler consumes 1300 tons of fuel per day with GCV of

3800 Kcal/kg. Feed water inlet temperature is 140*C and make-up water is negligible. [Enthalpy of

steam 803 Kcal/kg].

(i) Calculate efficiency of Boiler by direct method.

(ii) Calculate equivalent evaporation in Tons per hour from and at 100*C.

MH BOE-2015

Solution :

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 14

(i) Efficiency of Boiler=MX(Hs-Hf)/QXGCV

=[250000X(803-140)]/[(1300000/24)X3800] =165750000/205833333.3

=0.8053=80.53%

Mact =250/(1300/24)=4.615

H=Total specific enthalpy of steam under operating condition =803 Kcal/kg

Hwt= Specific enthalpy of feed water Kcal/kg at 140*c=140kcal/kg

Factor of equivalent evaporation “F” =(H-Hwt)/539

=(803-140)/539=663/539=1.23

(ii) Equivalent evaporation from and at 100*C per tons of coal

=Mact X F =4.615X1.23=5.67645

Question -31 :A boiler working on 100kg/cm2, 535*C. Steam flow is 95 TPH.The economizer inlet

water temperature is 210*C. Find the coal flow in Tonnes per hour when boiler efficiency is 87%

and fuel GCV is 3200 Kcal/kg[Steam enthalpy and water enthalpy are 3464.33KJ/Kg and

897.631Kj/Kg respectively]. AP BOE-2013

Solution :

Steam enthalpy= 3464.33KJ/Kg =828.39Kcal/kg

Water enthalpy =897.631Kj/Kg=214.64kcal/kg

Coal flow rate=[Mass of steam flowx(Enthalpy of steam-Enthalpy of water)]/(Efficiency x GCV of coal)

=[95X1000x(828.39-214.64)]/(0.87x3200)

=58306250/2784 =20943.3369 Kg per hour=20.94 TPH

Question :32.The following readings were obtained during a boiler trial of 6 hours duration

Main steam pressure : 14Kg/cm2(g)

Weight of steam generated : 24000kg

Mean dryness fraction : 0.9

Mean feed water temperature : 28*C

Weight of coal used : 4800Kg

Calorific value of coal : 5500Kcal/kg

Calculate

(i) Factor of equivalent evaporation

(ii) Equivalent evaporation from & at 100*c

(iii) Efficiency of Boiler

Solution :

Mact=Actual mass of steam generated per unit mass of fuel burnt=24000/4800=5

H=Total specific enthalpy of steam under operating condition at 15Kg/cm2(abs)

=hf+x.hg

=201.96+0.9X465.16 =620.604 Kcal/kg

Hwt= Specific enthalpy of feed water Kcal/kg at 28*c=28kcal/kg

(i) Factor of equivalent evaporation F =(H-Hwt)/539=(620.604-28)/539=774.4/539 =1.099

(ii) Equivalent evaporation from & at 100*C

=MactXF =5X1.099 =5.495

(iii) Efficiency of Boiler= MX(Hs-Hf)/QXGCV =24000X(620.604-28)/4800X5500

=14222496/26400000 =53.87%

Note: This is a very worst case of any boiler. Boiler efficiency will be usually in the range of 70% to 85%,

lets your calculation found in out of this range, please check your calculation once again.

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 15

Question :33- In a boiler trial of 24 hours duration, 1600 Kg of coal were consumed to evaporate

12,800 Kg of water. The Main steam pressure was 7.5 bar. The coal contained 3% moisture and

3.9% ash on mass basis. The feed water temperature was 35*C. CV of coal is 30300Kj/kg. The

steam produced is dry saturated with enthalpy of 2766.4Kj/Kg.

Determine :

(a) Thermal Efficiency of the Boiler

(b) The equivalent evaporation from and at 100*C per kg of dry coal, and

(c) The equivalent evaporation from and at 100*C per kg of combustible.

CG BOE-2012

Solution :

(a) Efficiency of Boiler=

=MX(Hs-Hf)/QXGCV

=12800X(661.5-35)/1600X7245.34

=8019200/11592544

=69.18%

Mact =on dry coal basis=12800/(1600X0.97)=8.25

=on combustible basis=12800/(1600X0.931)=8.59

H=Total specific enthalpy of steam under operating condition at 7.5bar

=2766.4 KJ/kg=661.5Kcal/Kg

Hwt= Specific enthalpy of feed water Kcal/kg at 35*c=35kcal/kg

Factor of equivalent evaporation F =(H-Hwt)/539=(661.5-35)/539=626.5/539=1.16

(b) Equivalent evaporation from and at 100*C per kg of dry coal

=MactXF =8.25X1.16=9.57

(c) Equivalent evaporation from and at 100*C per kg of combustible

=MactXF =8.59X1.16=9.96

Question -34 : A boiler generates 40,000 kg of steam per hour at a pressure of 17.5ata superheated

to a temperature of 295 degC. From water at a temperature of 25 degC. If GCV of fuel is 7400

kcal/kg and boiler efficiency is 76%. Calculate the weight of the fuel burnt per hour. Take Cp of

superheated steam as 0.55 UP BOE-2003

Solution : 17.5ata=17.5x 1.013=17.73bar & at 295*C

From steam table, hg=668.29kcal/kg, ts=206.34 degC

Therefore enthalpy of superheated steam per kg ‘hs’=hg+cp(tsup-ts)

= 668.29+0.55(295-206.34)= 717.053kcal/kg.

Now heat input =40,000x 717.053 kcal.

Say, fuel burnt per hour= f kg.

Now, efficiency of boiler =heat output/heat input

0.76= [40,000x(717.053-25)]/f x 7400

f=(40,000x692.053)/(0.76x 7400) = 4922.14kg/hr=4.92214 ton/hr.

Question -35 : Find out the efficiency and evaporation ratio of a coal fired boiler by direct

method with the data given below:

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 16

Quantity of steam(dry saturated) generated 8 TPH

2

Steam pressure/ temperature 10 kg/cm (g)/180*C

Quantity of coal consumed 1.8 TPH

Feed water temperature 85*C

GCV of coal 3200 Kcal/kg

2

Enthalpy of steam at 10kg/cm pressure 665 Kcal/kg UP BOE-2014

Solution :

Efficiency of boiler by direct method

={(8x1000)x(665-85)}x100/{1.8x1000x3200} =464000000/5760000 =80.56% Answer

Evaporation ratio = Quantity of steam generated/quantity of fuel consumption

=8/1.8 =4.44 Answer

Question -36 : The efficiency of a boiler on GCV basis is 85%. The fuel contains 1% moisture and

12% hydrogen. The GCV of fuel is 10,000Kcal/kg. What is the boiler efficiency on the basis of NCV

(Net calorific value).

Solution :

NCV =GCV-[9+(H+M)x584]

=10,000-[9+(0.12+0.01)x584]

=9,915.08 Kcal/kg

Efficiency of boiler on NCV basis =Efficiency of boiler GCV basis x(GCV/NCV)

=0.85x(10,000/9,915.08)=0.8573 =85.73%

Question -37 : The following observation were taken during a test on a steam boiler :

Quantity of coal burnt per hour 750kg

Feed water supplied per hour 7000kg

Calorific value of coal fired 8100kcal/kg

Temperature of feed water entering into economizer 20*C

Temperature of feed water leaving from economizer 80*C

Steam pressure 10Kgf/cm2

Dryness fraction of steam leaving boiler drum 0.97

Temperature of steam leaving super heater 250*C

Determine the thermal efficiency of the plant also calculate the heat absorbed by feed water in

various components as a % of the total heat absorbed.

From steam table

at 10kgf/cm2 ts=179.04*C hf=181.2kcal/kg hfg=482kcal/kg

at 10kgf/cm2 & 250*C hsup=702.4Kcal/kg

MP BOE-2000

Solution :

Thermal efficiency of the boiler =heat output/heat Input =M(hsup-hf)/(QxGCV)

=7000x(702.4-20)/(750x8100)

=4776800/6075000=0.7863=78.63%

Heat absorbed by feed water in various components into the Boiler:

1. In Economizer =MxsxΔt=7000x1x(80-20)=420000 Kcals

% heat absorption in economizer=420000/4776800=0.0879=8.79%

2. In Evaporator =Mx{(hf+x.hfg)-heco)

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 17

=7000x{[181.2+0.97x482]-80}

=7000x(648.837-80)=7000x568.837=3981180 Kcals

% heat absorption in evaporator=3981180/4776800=0.8335=83.35%

3. In Super heater =Mx{hsup-{(hf+x.hfg)}

=7000x{702.4-(181.2+0.97x482)}

=7000x(702.4-648.74) =375620 Kcals

% heat absorption in super heater=375620/4776800=0.07863=7.86%

A/4.5: Condenser & Vacuum related numerical :

Question -38 : Estimate the condenser cooling water flow rates for a 400MW power plant if the

water under goes 10*C temp rise. Assume plant overall efficiency as 40% and boiler efficiency as

80%, Cpw=4.187 MP BOE-2014

Solution :

Turbine efficiency=Overall efficiency/Boiler efficiency

0.4/.8=0.50=50%

400MWHper hr=400000Kwh/hr=400000X3600Kj/hr=1440000000Kj/hr

Total heat input into the turbine=1440000000/Turbine efficiency

=1440000000/0.5=2880000000Kj/hr

While efficiency of turbine is 50% hence out-off 2880000000kj/hr energy will distribute 50% into electric

power & 50% into Cooling tower loss as latent heat.

H=m X Cpw X delta T

Cooling water flow m=H/(Cpw X delta T)=1440000000/(4.187x10)=34392166.23Kg/hr

=34392.16623 Tonnes/hr

Question -39 : During a trial of a condenser following readings were taken :

Barometer reading - 766 mm of mercury

Actual vacuum in condenser -710mm of mercury

Temp of hot well - 29 deg c

Inlet temp. of cooling water - 18 deg c

Outlet temp. of cooling water - 27 deg c

Determine :

1 - Vacuum corrected to a saturated barometer of 760 mm of mercury

2 - Vacuum efficiency

3 - Under cooling of condensate

4 - Coefficient of performance

Solution : Absolute vacuum=766-710=56mm of Hg

Corrected vacuum=760-56=704mm of Hg

Ideal Vacuum =Barometer reading-Condensate temp corresponding pressure

(29*C saturation temp corresponding pressure is 0.04004bar)

=766-(0.04004x750)=766-30=736mm of Hg

Vacuum efficiency =[Actual vacuum/Ideal vacuum} =710/736=0.9647=96.47%

Under cooling of condensate

=Saturation temperature corresponding to Absolute pressure-Condensate temperature(Hot well temp)

(56mm of Hg pressure equal to 56/750=0.07bar corresponding temp is 39*C)

=39-29=10*C

Coefficient of performance i.e. condenser efficiency =(t2-t1)/(ts-t1)

=(27-18)/(29-18)=9/11

=0.8182=81.82%

Question -40 : The vacuum in the condenser shell is 710 mm of Hg and atmospheric pressure is

760 mm of Hg. The temp. at inlet and outlet of the air cooling section are 35 deg c and 30 deg c .

Calculate for a leakage of 0.50 kg of air per hour .

1 - The volume of air entering the cooling section per hour and

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 18

2 - The mass of steam condensed per hour in the section ,Take R of air as 0.294 KJ/Kg K

Solution : Total absolute pressure in condenser

=760-710=50 mm of hg=50/750=0.0667bar {1bar=750 mm of hg}

At 35*C Partial pressure of vapour=0.05622bar {from steam table}

Partial pressure of air=0.0667-0.05622=0.01048bar

P1.V1/T1=P2.V2/T2

Or V2 =[P1.V1/T1]x[T2/P2] {1bar=1.0133 Kg/cm2)

=[0.7734x1.0133/273]x[(35+273)/0.01048] {1kg of air occupies 0.7734 m3 at NTP(0*c)}

=0.00287x29389.31=84.35 m3

Therefore volume of air entering the cooling section per hour =0.5X84.35=42.175 m3

i.e. steam at partial pressure of 0.05622 bar and 35*C will occupy the same volume which is 42.175 m3

Mass of steam entering the cooling section per hour =42.175/25.245=1.67kg

{ Specific volume of dry saturated steam at 35*C=25.245m3/kg}

At 30 *C Partial pressure of vapour=0.04242bar {from steam table}

Partial pressure of vapour=0.0667-0.04242=0.02428 bar

Similarly volume of air at 30*C and 0.02428 bar pressure

=0.5x{(0.7734x1.0133)/273}x{(30+273)/0.02428}=0.5{0.00287x12479.41}

=17.91 m3 volume of vapour

Mass of vapour in air=17.91/32.929=0.544kg

{ Specific volume of dry saturated steam at 30*C=32.929m3/kg}

Mass of steam condensed/hr in the cooling section=1.67-0.544=1.126kg

Question -41 : A surface condenser operate at a vacuum of 699.2 mm of Hg , when the barometric

head is 760 mm of Hg . It receives steam at the rate of 10 tons per hour, which is 0.9 dry , calculate

1 – condenser efficiency

2 – cooling water flow rate

If cooling water inlet tem. = 33 deg c and outlet temp. = 40 deg c

Solution :

Absolute pressure in condenser=(760-699.2)/750

=0.08bar absolute pressure

At 0.08bar absolute pressure corresponding saturation temperature is 41.53*C

Condenser efficiency= (t2-t1)/(ts-t1)

=(40-33)/(41.53-33)

=7/8.53=0.8206=82.06%

Mw= Msx(hf+X.hfg-hc)/[Cpwx(t2-t1)]

=[10000x0.9X2403.2]/[4.186x(40-33)] {here value of hf=hc}

=21628800/29302=738839.926Kg/hr

=738.84 tonnes/hr

Question -42 : In a surface condensing plant the following data were obtained .

Temp of exhaust steam entering the condenser = 42.67 deg c .

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 19

Temp of condensate leaving the condenser = 35 deg c ,

Inlet temp of cooling water = 16.5 deg c & outlet temp = 30 deg c

Quantity of cooling water per hour 46250 kgs ,

Quantity of condensate per hour 1190 Kgs

Calculate the dryness fraction of Exhaust steam entering the condenser .

Solution : Suppose X is the dryness fraction of exhaust steam entering the condenser

At the saturation temp of 42.67*C corresponding hf=178.7 Kj/kg & hfg=2578.3

At the condensate temp of 35*C corresponding hf=146.6Kj/kg

As per law of energy conservation,

Heat gained by cooling water=Heat lost by exhaust steam

Or MwxCpwx(t2-t1)=Msx(hf+X.hfg-hc)

Or 46250x4.186x(30-16.5)=1190x(178.7+X.2578.3-146.6)

Or 1190(2578.3X+32.1)=2613633.75

Or 2578.3X+32.1=2613633.75/1190

Or 2578.3X+32.1=2196.33

Or 2578.3X=2196.33-32.1

Or X=2164.23/2578.3=0.84

Dryness fraction of exhaust steam =0.84

Question -43 : A surface condenser deals with 2100 kgs steam and the air leakage amounts to 0.8

kg/hr. The temp. of the air pump suction is 35*C & the vacuum is 580 mm of Hg when

barometer reads 760 m of Hg. Determine the capacity of the wet air pump which has a

volumetric efficiency of 75%.

Solution: Absolute pressure in Condenser = (760 – 580)/750 = 0.24 bar

At 35*C, the partial pressure of vapour = 0.05622 bar

Hence partial pressure of air = 0.24 – 0.05622 = 0.184 bar

Volume of air at this condition

= 0.8 x {(0.7734 x 1.0133) / 273} x {(35 + 273) / 0.184}

=0.8x[0.00287x(308/0.184)]=0.8x4.804

= 3.843 m3 per hour

At 0.24bar pressure of condensate corresponding specific volume is 0.001019m3/kg

Hence Volume of condensate = mass of condensate x specific volume

=2100 x 0.001019 = 2.1399 m3

Wet air to be handled by the pump = 3.843 + 2.1399= 5.9829 m3 per hour

Volumetric capacity of the pump required =Volume of wet air/Volumetric efficiency

= 5.9829/ 0.75 = 7.9772 m3/ hour

Question -44 : In a small capacity of Thermal Power plant, the condenser is provided with a

separate air-cooling section. The temp. of steam entering the condenser is 56*C and temp. at

the air pump section is 46*C. The barometer reads 76 cm of Hg, find

(1) Vacuum in Condenser

(2) If discharge of dry air-pump is 90 m3/min., find the air leakage in the condenser in kg/hr.

Solution: Considering no ingress of air at the inlet, the pressure in the condenser will be the same as the

pressure of the steam entering at that temperature.

From the steam table at 56*C, the corresponding pressure

= 0.1653 bar absolute = 0.1653 x 750 = 123.98 mm of Hg,

Vacuum in the condenser = 760 – 123.98 = 636.02 mm of Hg

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 20

Now at the outlet the partial pressure of the steam = 0.10101 bar abs. (from steam table at 46*C)

Therefore the partial pressure of air = 0.1653 – 0.10101 = 0.0643 bar

The discharge of air pump = 90 m3/ min = 5400m3/ hr.

Here T = 46*C + 273 = 319 *K,P = 0.0643 bar = 0.0643 x 102 kPa, V = 5400 m3, R of air =0.294 kJ/ kg* K

PV = mRT

Therefore mass of air leakage in the condenser per hour

m= (0.0643 x 102 x 5400)/ (0.294 x 319)=35416.44/93.786 = 377.63 kg/hr

Question -45 : A surface condenser condenses steam at the rate of 20t/hr which leaves the

condenser at the corresponding saturation temp. The condenser operates at a vacuum of 680mm

of hg. Determine (a) Condenser efficiency (b) Flow rate of cooling water (c) Number of condenser

tubes ,Where CW inlet temp=33*c,CW outlet temp=43*c, Mean velocity of cooling water =2.5m/s,

ID of condenser tubes=19.6mm,Barometer pressure=760mm of hg & steam is 0.95 dry

Solution:

Absolute pressure=Barometer pressure-vacuum in the condenser

=760-680=80mm of hg=80/750=0.10667bar

At 0.10667bar corresponding saturation temp will be 46.96*C

Condenser efficiency=( t2-t1)/(ts-t1)=(43-33)/(46.96-33)=10/13.96=0.7163=71.63%

As per law of energy conservation,

Heat gained by cooling water=Heat lost by steam

MwxCpwx(t2-t1)=Msx(hf+X.hfg-hc)

Flow rate of cooling water Mw={Msx(hf+X.hfg-hc)}/{Cpwx(t2-t1)}

={20000x(199.7+0.95x2388.4-199.7}/{4.186x(43-33)}

={20000x2268.98}/41.86=1084080.268 kg/hr

=301.13kg/sec=301.13/1000 m3/sec=0.3011m3/sec

Area of one tube A={3.14x(0.0196x0.0196)}/4=0.0003 m2

Volume of one tube=Area of one tube X velocity of cooling water =0.0003X2.5 =0.00075m3/sec

Nos. of tubes= Flow rate of cooling water/Flow rate of one tube = 0.3011/0.00075=401.47=401 tubes

Question -46 : The vacuum produced in a surface condenser is 685mm of hg when the barometer

reading is 760mm of hg. The condensing steam temp is 36*C. The net volume of steam space is

25m3. Determine

(a) The partial pressure of air

(b) The mass of air present in the condenser.

Solution:

Absolute pressure =760-685=75mm of hg=75/750=0.1bar

At 36*C condensing steam temp corresponding saturation pressure will be 0.0594bar

Partial pressure of air= Absolute pressure-Saturation pressure

=0.10bar-0.0594bar=0.0406bar=0.0406x1.0133=0.0411kgf/cm2

PV=mRT

Mass of air present in the condenser m =PV/RT

={0.0411x10000x25}/{0.294x(273+36)} {1Kg/m2=10,000Kg/cm2}

=10275/90.846

=113.48kg

Question : 47. - A surface condenser condenses 20 tons per hour of exhaust steam at 49 degree c

from a turbo - alternator. The dryness fraction of the steam is 0.85. Determine the flow rate of

cooling water if cooling water inlet temperature is 33 degree c , cooling water outlet temperature is

42 degree c .

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 21

Solution :

49*C corresponding pressure will be 0.11736bar

Corresponding Latent heat (hfg)of 0.11736bar pressure =2384.3kj/kg

As per law of energy conservation

Latent heat exhausted by turbine=Heat exchange to cooling water

Exhaust steam flow X dryness factorxLatent heat of exhaust steam=QX(Outlet –inlet temp)

Cooling water flow(Q) =[20x1000x0.85x(2384.3/41.86)]/(42-33)

=9683014.811/9

=1075890.535kg/hr

=1075.89TPH

Question -48 : Calculate the quantity of cooling water required in Kg/minute for a surface

condenser to condense 18 kg per steam per minute . The dryness fraction of steam is 0.9 and the

temperature of steam entering the condenser is 37c. The outlet and inlet temperature of cooling

water are 28*c &18*c respectively. The condensate temperature is 37c. The latent heat of steam

should be taken as 576 kcal/Kg.

Solution :

Given that latent heat of exhaust steam =576kcal/kg

As per law of energy conservation

Latent heat exhausted by turbine=Heat exchange to cooling water

Exhaust steam flow X dryness factorxLatent heat of exhaust steam=QX(Outlet –inlet temp)

Cooling water flow(Q) =[18x0.9x576/(28-18)

=9331.2/10

=933.12kg/min

A/4.6: Energy Saving/loss related numerical :

o

Question -49 : In a Boiler the exhaust flue gas temperature is 145 C and that of ambient air is

o

35 C .Calculate energy loss in dry exhaust gas per kg. if specific heat of flue gas is 0.23kcal/kg.

Solution; Energy loss = Mass of flue gas ×C P(TP-TA)

=1×0.23(145-35) =25.3kcal per kilogram of flue gas

Question -50 : A 60 MW turbine operating at 40% Load factor is fed from a boiler with 85%

efficiency. Burning coal of CV of 27900 Kj/kg. The Turbine steam consumption without feed

heating system is 4725Kg/kwh. The boiler feed temp is first case is 31*c and in the later case is

93*C. Calculate the coal saving per year if turbine is running with feed heating system. Specific

heat capacity of water is 4.19Kj/kg*C

MP BOE-1992 &1996

Solution :

Assume that steam generation by boiler will fully consumed by turbine (No leakage).

Total power generation per annum = 60x1000x365x24x0.40

=210240000Kwh/annum

11

Total steam consumption by turbine=210240000x4725=9.93384x10 Kg. of steam per annum

Saving of heat loss in a year due to the charging of feed heating system

= MxCpxΔt

14

=993384000000x4.19x(93-31) =2.5806x10 Kj/annum

Mass of Coal saving in a year

= Heat saving per annum/(GCV of coal x Efficiency of Boiler)

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 22

14

=[(2.5806x10 ) /(27900x0.85)]

10 7

=1.088172043x10 Kg. of coal ==1.088172043x10 Tons of coal

=10.88172043 million tons of coal per annum

Question :51 - It is proposed to replace an oil-fired boiler of 10 tons per hour with a coal fired

boiler of equivalent capacity . With the help of the data provided find out the following.

a - the annual oil consumption in tons per hour

b - the annual coal consumption in tons per hour

c - estimate annual fuel cost saving in crore rupees

d - simple pay back period of the project,

assuming the coal fired boiler costs Rs 1.5 crore and annual repair and maintenance costs of the

coal fired boiler are 25% of capital cost .

Operational data is :

heat content of steam 760 kcal/kg

Feed water inlet temp 70 degree c

Daily operating hours 24

Number of days / year 280

Efficiency of oil fired boiler 80%

Efficiency of coal fired 74%

Cost of oil Rs - 14/kg

Cost of coal Rs - 1.4/kg

GCV of oil 10,000 kcal/kg

GCV of coal 44,00 kcal/kg

Solution :

Total enthalpy of steam=10X1000X(760-70) =6900000 Kcals per hour =46368000000 Kcals per annum

(a) Annual oil consumption per annum =

=(Total heat of steam/oil fired boiler efficiency)/GCV of oil

=(46368000000/0.8)/10,000=5796000 kg per annum

=862.5kg/hr =0.8625 tons per hr

(b) Annual coal consumption per annum= =(46368000000/0.74)/4,400=14240786.2 kg per annum

=2119.16kg/hr =2.11916 tons per hr

(c) Total cost of oil per annum=5796000X14=Rs.8,11,44,000=8.1144 corers

Total cost of coal per annum=14240786.24X1.4=Rs. 1,99,37,101=1.9937crores

Annual fuel cost saving=8.1144-1.9937

=6.1207 corers

(d) Total cost of coal fired boiler installation=Project cost + Maintenance cost

=1.5+(1.5x0.25)=1.5+0.375=1.875 corers

Simple pay back period(Year)= Total cost of boiler installation/Annual fuel saving cost

=1.875/6.1207 =0.306 years =3.7 months

Question :52

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 23

Solution :

Annual cost savings by replacing the boiler = Rs. (360-321) lakh =Rs.39lakh

Investment for the new boiler = Rs. 30 lakh

Simple pay period = (Investment /Annual savings) =(30/39) =0.72years =9.2months

Question -53 : Calculate quantity of heat available without economizer and fuel oil saving by

providing an economizer for a boiler. The performance data of the boiler are given as below.

Average quantity of steam generated 5 T/hr

Average flue gas temperature 315*C (without economizer)

Average steam generation/kg of fuel oil 14kg

Ambient temperature 40*C

Fuel oil supply quantity 314kg/hr

Flue gas quantity 17.4 kg/kg of fuel

Specific heat of fuel 0.23 kcal/kg*C

GCV of fuel oil 10000Kcal/kg

Rise in feed water temperature by providing economizer 26*C

Annual operation hours 8600hrs. MH BOE-2013

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 24

Solution :

Total flue gas quantity =17.4X314=5463.6 Kg/hr

Quantity of heat available without economizer =Total flue gas quantity X specific heat X ∆T

=5463.6X0.23X(315-40)=345572.7Kcal/hr

Sensible heat gain after installation of economizer= Mass of steam flow X Rise in FW temperature

=5X1000X26=130000 Kcal/hr

Saving of fuel oil= Sensible heat gain after installation of economizer/GCV of fuel oil

=130000/10000=13 Kg/hr=13X8600 Kg/annum=111800kg/annum=111.8 tones/annum

Question. 54. Calculate the coal consumption in below mention boiler :

where S/H temp=440*C, Economizer temp=170*C,GCV of coal=4200Kcal/kg, Steam

generation=45TPH & steam pressure=58kg/cm2.

Solution=

Suppose Boiler efficiency is 80%=0.80

Total enthalpy of steam=

Steam flow in kgX(Specific enthaply of superheated steam-specific enthalpy of Economizer inlet temp)

=45X1000x(782.83-170) (Kindly note that for sensible heat 1*C=1 Kcal/Kg.)

=45000X612.83 =27577350 Kcals/hr

Total equivalent heat input in the boiler

=27577350/0.8 =34471687.5 Kcals/hr

Coal consumption=Total equivalent heat input in the boiler/GCV of coal

=34471687.5/4200 =8207.54Kg/hr =8.20754TPH

Question-55: A 5000 kg/hr boiler operates at 10.5kg/cm2(g) and has a maximum allowable boiler

TDS of 3500ppm. Calculate blow down rate in kg/hr. If the boiler is operated with manual blow

down and assuming that boiler water TDS is maintained at 2500ppm. Assume boiler feed water

TDS is 300ppm and feed water temperature is 30*C. Calculate energy loss due to excess blow

down. <MH BOE-2014>

Solution :

% Blowdown =[TDS of FWx100]/[Max permissible TDS-TDS of FW]

% Blow down at Max permissible limit(3500ppm) =[300x100]/[3500-300]

=30000/3200=9.375%

Blow down rate at Max permissible limit=5000x9.375%=468.75 kg/hr

% Blow down at manual operated(2500ppm) = [300x100]/[2500-300]

=30000/2200=13.64%

Blow down rate at manual operated=5000x13.64%=682.00 kg/hr

Loss of water due to manual blow down= 682-468.75=213.25 kg/hr

Energy loss due to excess blow down due to manual operation

=213.25x30 =6397.5 kCal/hr

Question-56 : Specific fuel consumption of a 300 TPH boiler is 0.2 kg of fuel per kg of steam.

Calculate yearly net financial burden to the company if cost of fuel increased by 50 rupees per

ton. Consider average 90% loading of the boiler and 300 running days in a year.

<MH BOE-2015>

Solution : 90% Loading of boiler is 300x0.9 =270TPH

=6480 tons per day

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 25

=1944000 tons per annum

Specific fuel =0.2 kg of fuel per kg of steam

Quantity of fuel per annum = 194400x0.2=388800 tons of fuel per annum

Net financial burden=388800x50=Rs. 19440000=1.944 Crores

A/4.7: Miscellaneous important numerical :

Question -57 : The following is the typical data of APH in a power plant

O2 in flue gas inlet -2.8% O2 in flue flue gas outlet-5.7%

Flue gas inlet temp-333.5*C Flue gas outlet temp-133.8*C

Air inlet temp-36.1*C Air outlet temp-288*C

Assume mean specific heat of Air and gas as same. Calculate the following

(a) Leakage of APH in %

(b) Flue gas outlet temp at no leakage

(c) Gas side efficiency of APH

(d) X-ratio of APH

CG BOE-2014

Solution :

(a) Air heater leakage is determined by an empirical approximation as following.

AL = (O2 gl – O2 ge) x 0.9 x 100

(21 - O2 gl)

Where AL = air heater leakage (%)

O2ge = percent O 2 in gas entering air heater (2.8 %)

O2gl = percent O 2 in gas leaving air heater (5.7 %)

= 5.7 – 2.8 * 90/ (21-5.7) = 17.1 %

(b) The numerical average of the air heater’s gas inlet, gas outlet and air inlet temperatures is

calculated. Then the corrected air heater gas outlet temperature is calculated using the following

formula.

Tgnl = AL x Cpa x (Tgl – Tae) + Tgl

100 x Cpg

Where Tgnl = gas outlet temperature corrected for no leakage

Cpa = the mean specific heat between Tae and Tgl

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 26

Tae = temperature of air entering air heater (36.1 C)

Tgl = temp of gas leaving air heater (133.8 C)

Cpg = mean specific heat between Tgl and Tgnl

Tgnl = 17.1 * (133.8 – 36.1) + 133.8 = 150.5*C

100

(c) The gas side efficiency is defined as the ratio of the temperature drop, corrected for leakage, to

the temperature head, expressed as a percentage. Temperature drop is obtained by subtracting

the corrected gas outlet temperature from the gas inlet temperature. Temperature head is

obtained by subtracting air inlet temperature from the gas inlet temperature. The corrected gas

outlet temperature is defined as the outlet gas temperature calculated for ‘no air heater leakage’.

Gas Side Efficiency (GSE) = (Temp drop / Temperature head) * 100

GSE = (Tge – Tgnl) x 100

(Tge – Tae)

Where Tae = Temperature of air entering air heater (36.1 C)

Tgnl = gas out temp corrected for no leakage (150.5 C)

GSE = (333.5-150.5) / (333.5-36.1) X100 = 61.5 %

X ratio is the ratio of heat capacity of air passing through the air heater to the heat capacity of flue gas

passing through the air heater and is calculated using the following formulae

= Wair out * Cpa

Wgas in * Cpg

= Tgas in - Tgas out (at no leakage)

Tair out - Tair in

= (333.5 – 150.5) / (288 –36.1) = 0.73

Question -58 : During an engine trial , the gas as used was tested in a calorimeter and gave the

following results :

3

20 Liter(0.02M ) of Gas at pressure 50mmhg above atmospheric pressure of 740mmhg and

temperature 18*C was burned, which raised the temperature of 10.2 kg of water from 16*C to

24.5*C and the steam formed was condensed to 20gm of water. Calculate the higher & lower

calorific values per cubic meter of the gas at a temperature of 0*c an pressure of 760mmhg(NTP).

Take the heat liberated in condensing the water vapour(steam) an cooling the condensate as

2520KJ/Kg an specific heat of water as 4.187Kj/kg*K. CG BOE-2014

Solution : Higher calorific value

H.C.V. = (Weight of water collected in kg x temperature rise in *C)

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 27

Volume of gas burnt in cu M at STP

=10.2x(24.5-16)/0.02

HCV=4335 Kcal/Kg

Lower Calorific value

L.C.V = H.C.V.- (Wt. of condensate in kg x(Total heat recovered from condensate)

Volume of gas burnt in m3 at STP

=4335-{0.02x(2520/4.187)/0.02} =4335-601.86 LCV=3733.14 Kcal/kg

2

Question -59 : A process requires 6TPH of dry saturated steam at 7 kg/cm (g). Determine the

2 3

size of pipe line specific volume of steam at 7 kg/cm (g) is 0.24 m /kg.(Take velocity of steam as

30m/sec). UP BOE-2014

Solution : Total volume of the steam =Flow rate of steam per second x specific volume of steam

=(6x1000/3600)x0.24 =0.399 m3/sec

Total volume of the steam =Area of the pipe line x velocity of the steam

or Area= Volume/velocity

Area=0.399/30=0.0133m2

2

πxr =0.0133

2

r =0.0133/π

=0.0133/3.14=0.00424

r=√0.00424

r=0.065 meter

diameter of the pipe line =2xr=2x0.065 =0.13 meter Answer

3 2

Question -60 : A pump is delivering 50m /hr of water with a discharge pressure of 3.5kg/cm .

The water is drawn from a sump where water level is 5 meter below the pump centre line. The

power drawn by the motor is 9.5KW at 90% motor efficiency. Find out the efficiency of the pump.

UP BOE-2014

Solution :

Hydraulic power Ph = Q (m3/s) x Total head, hd - hs (m) x δ (kg/m3) x g (m/s2) / 1000

Where hd – discharge head, hs – suction head, δ – density of the fluid, g – acceleration due to gravity

Ph =(50/3600)x(35-5)x1000x9.81/1000

=4.09KW

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 28

Efficiency of the pump= Hydraulic power Ph/ Pump shaft power Ps

=4.09/(9.5x0.9)

=4.09/8.55

=47.84%(Answer)

Question -61 : Calculate the available NPSH for the system where

Atmospheric pressure at installation is =0.9kg/cm2

Friction loss is 1.5 mtrs

Vapor pressure of liquid is =0.45kg/cm2

Specific gravity of liquid=0.8

Pressure inside the tank is 0.5kg/cm2

Height of the liquid level from pump center line is 0.2 mtrs UP BOE-2014

Solution :

Absolute pressure over liquid=0.9+0.5=1.4 kg/cm2

Effective available NPSH available of pump=

= Absolute pressure over liquid + Height pr of liquid -Vapour pressure-friction loss

=1.4+(0.2x0.8/10.8)-0.45-(1.5x0.8/10.8)

=1.4+0.0148-0.45-0.1111

=0.8569 kg/cm2 (Answer)

Question -62: A fan is operating at 900rpm, develops a flow of 3000 Nm3/hr at a static pressure

of 600 mmWC. What will be the flow and static pressure if the speed is reduced to 600rpm?

UP BOE-2014

Solution : As per fan’s affinity law :

(i) Flow α Speed i.e. F1/F2=N1/N2

3000/ F2=900/600

F2=(3000x600)/900

Flow =2000 Nm3/hr Answer

2 2

(ii) Pressure α Speed i.e. P1/P2=(N1/N2)

2

600/P2=(900/600)

P2=600x4/9 Static pressure=267 mmWC Answer

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 29

2 o

Question -63 : In a 200NB Pipe line, steam at 20kg/cm and 380 C flows. The velocity measured

3

and found 20m/sec. Calculate steam flow in M /Hr and Ton/Hr.

Solution; Diameter(D) of the pipe is 200mm= 0.2meter

Velocity is given as 20m/sec.

Volumetric flow= Area of pipe × Velocity

2 3 3

= π 0.2 /4×20=0.628 m /sec =2261m /Hr

2 o 3

From the steam table specific volume of steam at 20 kg/cm and 380 C = 0.149m /kg

Weight of steam flow per hour=Volumetric flow/ specific volume

=2261/0.149=15174.5kg/Hr=15.1745 ton/Hr

Question -64 : Calculate pressure drop in a 100 NB, 150meter long horizontal steam pipe line.

Velocity of steam in the pipe line is 3 m/sec. Consider friction factor 0.005.

Solution;

Given that, F = friction factor(0.005), L = Length of pipe 150 meter ,U = flow velocity 3m/sec

2

g (gravitational constant)= 9.81 m/sec D = diameter of the pipe 100mm=0.1meter

2

Pressure drop(meter) in horizontal pipe line is calculated by =(4fLU )/(2gD)

2

Pressure drop =(4x0.005x150x3x3)/(2x9.81x0.1) =27/1.962= 13.76 meter = 1.376 Kg/cm

Question -65 : The safety valve of a boiler is set at 42 Kg/cm2.during testing it is found valve lifts

at 45 kg/cm2 and reset at 39.5kg/cm2. calculate

i ) Over pressure

ii) % Blowdown

Solution; i) Over pressure = lifting pressure – set pressure = 45-42=3 kg/cm2

Over pressure percentage=Overpressurex100/Set Pressure=3x100/42=7.14%

ii) Blow down percentage={(Set pressure-Reset pressure)x100}/Set Pressure

= {(42-39.5)x100}/42 =5.95%

Question -66 : Following readings are noted from a power plant cooling tower

Cooling water flow 1500m3/hr

Cooling water inlet temperature 38*C

Cooling water outlet temperature 30*c

Wet bulb temperature 27*c

Dry bulb temperature 45*c

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 30

TDS of cooling water 1500ppm

TDS of makeup water 250ppm

Evaporation loss 2%

Windage loss negligible

Calculate;

ii) Approach

iii) Range

iv) Heat load of the cooling tower

v) COC

vi) Blow down

vii) Makeup water required

Solution;

*

(i) Approach = Out let Cold water temperature-wet bulb temperature = 30-27 = 3 c

(ii) Range = Inlet hot water temperature-Outlet let cold water temperature =38-30 =8*c

(iii) Heat Load =Flow rate(kg)×Specific heatx(inlet temp.- Outlet Temp.)

=1500×1000×1(38-30) =12000000kcal/hr

(iv) COC=TDS of cooling water/TDS of makeup water =1500/250=6

(v) %Blow down=% Evaporation/(COC-1)2/(6-1)=0.4%

3

Blow down quantity = Flow rate x %blow down =1500x0.4%=1500x0.004= 6M /hr

(vi) Make up water required =Evaporation losses + Blow down

=1500×0.02+6 =30+6

3

=36 M /hour

Question -67 : A forced draught fan discharge 1200 cubic meter of air per minute through the

outlet of 2.1 square meter and maintains a static pressure of 10 cm of water . The temperature of

air is 27c . Calculate the BHP of the motor to drive the forced draught fan if the efficiency of fan is

80%. Assume the weight of 1 cubic meter of air at NTP is 1.293 Kg .

Solution :

Here

Discharge volume of air V=1200m3/min

Pressure P=10cmwc=100mmwc=100kg/m2

Efficiency of the fan= 80%

BHP of motor= PV/4500xη

=100x1200/4500x0.8 =33.33

Question : 68 - Calculate the blow down rate for a boiler with an evaporation rate of 5 Ton / hr , if

the maximum permissible TDS in boiler water is 3500 ppm & with 17% make up water addition .

The feed water TDS is around 350 ppm.

Solution :

% Blow down =

=TDS of feed water X%DM water makeup /(Max permissible TDS limit of Boiler water)

=(350X17)/3500 = 5950/3500 =1.7%

Blow down rate = Blowdown %ageX(Evaporation rate of Boiler)

=0.017X5 =0.085TPH

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 31

Question :69- During an air pollution monitoring study, the inlet gas stream to a bag filter was

150000 m3/hr. The outlet stream from the bag filter was a little bit higher at 160000 m3/hr . Dust

load at the inlet was 7gm/m3 and at the outlet 0.2gm/m3. How much dust in Kg/hr was collected in

the bag filter bin. MH BOE-2013

Solution :

Dust collection in bag filter bin =Inlet gas stream dust -outlet gas stream dust

=(150000x7)-(160000x0.2)

=1050000-32000

=1018000gm/hr

=1018 kg/hr

Question -70 : Calculate the weight of coal in tones which is stored in a conical shape in the yard

if the diameter at base and height are 100 mts and 75 mts respectively. Assume density of coal is

0.9kg/M3. AP BOE-2013

Solution :

Volume of conical shape V=base area × perpendicular height/3

=(πr2)xh/3 =(3.14X50X50)X75/3 =196250m3

Weight of coal

=Volume of conical shape X density of coal

=196250X0.9 =176625kg

=176.625 tonnes.

Question-71: A close circular tank is to be installed in a boiler house as a feed water tank.

Diameter and height of tank are 2.1m and 6m respectively. Find water holding capacity of the tank.

Also find the cost for insulating the tank including top with insulation thickness of 50mm. Assume

insulation cost Rs. 145/m2. MH BOE-2014

Solution :

2

Volume of the circular tank =π.r .L

=3.14x1.05x1.05x6

3

=20.7711m (Holding capacity of tank)

Tank insulation area =Tank vertical face area+ Tank top face area.

2

=π.r.L + π.r

2

=(3.14x1.10x6.05)+(3.14x1.10x1.10) =20.8967+3.7994 =24.6961m

Insulation Cost=24.6961x145 = Rs. 3581/-

2

Question-72: Estimate the pipe size required to carry dry saturated steam at 65 kg/cm (g) pressure

from boiler giving steam flow 68750 kg/hr. Assume steam velocity 38m/sec. MH BOE-2014

Solution :

Steam pressure =65kg/cm2(g)=66kg/cm2(abs)

3

Specific volume at 66kg/cm2(abs) pressure of steam =0.029218 m /kg

Steam flow at 66kg/cm2(abs) =68750kg/hr=19.097kg/sec

Volume of steam =steam flow x specific volume

=19.097x0.029218=0.56m3/sec

Steam pipe Area =Volume of steam/velocity of steam

=0.56/38=0.0147m2

2

Area=π.r

2

0.0147=3.14xr

2

(r ) =0.0147/3.14=0.047

Radius of pipe ‘r’=√0.047=0.217meter

Diameter of pipe=2xr=2x0.217=0.434meter=434mm

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 32

A/4.8: SOM(Strength of Material) related numerical :

Question -73 : A steel rod 25mm in diameter and 2 meter long is subjected to an axial pull of

15kN. Find

(a) Intensity of stress

(b) The strain

5 2

© Elongation, Take E=2x10 N/mm UP BOE-2014

Solution : Intensity of stress δ

=Load/Area=P/A

=(15x1000)(π/4x25x25)

=15000/490.625

=30.57 N/mm2 (Answer)

(a) Strain(e) =Intensity of stress/Modulas of Elasticity= δ/E

5

=30.57/2x10

=0.000153 (No unit) (Answer)

© Elongation =(Pxl)/(AxE)

5

=(15000x2000)/( π/4x25x25x2x10 )

=30000000/(490.625x200000)

=0.3057mm (Answer)

Question -74 : The temperature of a 2 meter long rod is raised from 10*C to 80*C. Find the

expansion of the rod. If the expansion of the rod is prevented, find stress developed in the

5 2

material. Take E=1x10 N/mm , α=0.000012/*C UP BOE-2014

Solution :

Given that , Length of rod L=2meter=2000mm

Initial temperature T1=10*C

Final temperature T2=80*C

5 2

Youngs modulus E=1x10 N/mm

Co-efficient of linear expansion α=0.000012/*C

Rise in temperature T= T2-T1=80-10=70*C

(i) Expansion in rod is given by = αxTxL

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 33

=0.000012x70x2000

=1.68mm (Answer)

(ii) Thermal stress δ = αxTxE

5

=0.000012x70x1x10

=84 N/mm2 (Answer)

Question -75 : Find the power that can be transmitted by a shaft 60mm diameter at 180rpm. The

2

permissible shear stress is 85 N/mm . UP BOE-2014

2

Solution : Given that, d=60mm ,N=180rpm ,fs= 85 N/mm

Power is given by.P=2*3.14*N*T/60000

Where T=fs*0.196*d*d*d

=85*0.196*60*60*60

= 3598560 Nmm

Power transmitted by shaft “P”=2*3.14*180*3598560/60000

=67796.8704 watt P=67.797KW (Answer)

Question -76 : A Circular Shaft Of 60mm diameter is running at 150 rpm. If the shear stress is not

to exceed 50 MPa, find the Power which can be transmitted by the shaft.

CG BOE-2013

Solution :

given::; d=60mm

N=150rpm

fs=50mpa

to find::: power=??

solution::;

power is given by.P=2*3.14*N*T/60000

Where T=fs*0.196*d*d*d

=50*0.196*60*60*60

=2119500Nmm

so power if finally,P=2*3.14*150*2119500/60000

P=33276.15Watt

Question-77: A Gas of certain mass is expanded from an initial state of 400KPa and 0.04m³ to

another condition of 120KPa and 0.1m³. The temperature fall was observed to be 146°C. If the

values of Cp and Cv are 1.0216 kJ/kgK respectively, calculate the change in the internal energy of

the gas.

CG BOE-2013

Solution :

change in internal energy is given by...U2-U1=MCv(T2-T1)

We know that p1v1=mrt1

therefore,,m=p1vi/RT1

=400*0.04*10^6/286*419.............................(R=UNIVERSAL GAS

Indian BOE Exam Guide Book (Edition-2)

Author : MITHILESH SINGH, mobile: +91-9827482029, Email : mithileshkhudawal@gmail.com

PART-A [Syllabus ,Guideline, Formulae& Numerical Exercise] 34

CONSTANT,..Temp converted into kelvin))

m=1.3kg.......

now,,p1v1/T1=p2v2/T2

400*0.04/419 =120*0.1/T2

T2=316K

Therefore,, Change in internal energy =Mcv(T2-T1)

=1.3*1.0216(419-316)

U2-U1=139.44KJ

Question-78: If a shaft has a diameter of 50 mm & the maximum shearing stress is 425 kg/cm².

What will be the moment of resistance of shaft to twist. MH BOE-11/2/2012

Solution :

given:; d=50mm

fs=425kg/cm^2

to find:::: Moment of resistanceof shaft....

solution::;;;;;

Moment of resistance of solid shaft is given by MR=0.1962*fs*d*d*d

Mr=0.1962*425*5*5*5