Académique Documents

Professionnel Documents

Culture Documents

Plant Layouting LM

Transféré par

EruCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Plant Layouting LM

Transféré par

EruDroits d'auteur :

Formats disponibles

NATIONAL INSTITUTE OF FASHION TECHNOLOGY,

KANGRA

Lean Management

ASSIGNMENT - 2

SUBMITTED TO : SUBMITTED BY:

MR. SAURABH CHATURVEDI DRISHTI

(ASSISTANT PROFESSOR) HARSHITA KHATWANI

ANURAG VERMA

PRIYANKA KAPOOR

SHIVAM BHANDARI

SNIGDHA MAHAJAN

Acknowledgement

Any attempt at any level cannot be satisfactorily completed without the support of all those

who have directly or indirectly helped me in this assignment. We would like to express my

immense gratitude to Mr Saurabh Chaturvedi who provided us the opportunity to come up

with this assignment.

A special thanks to the all those who rendered their whole hearted support to all times for the

successful completion of this assignment.

OPERATIONAL BREAKDOWN

Output per

SAM MC operation Operators

Shoulder

Attaching 0.6 SNLS 100 1

Front Placket

Shirt 0.85 HELPER 70.58824 1.5

Front Placket

Attaching 1.05 SNLS 57.14286 2

Front Placket

Finishing 0.55 SNLS 109.0909 1

Pocket Hemming 0.4 SNLS 150 1

Pocket Pressing 0.3 HELPER 200 1

Pocket Attaching 0.6 SNLS 100 1

Check Point 0.35 HELPER 171.4286 1

Collar Attaching 0.7 SNLS 85.71429 1

Collar Tape

Attachment 0.45 SNLS 133.3333 1

Side Seam 0.59 4t O/L 101.6949 1

Sleeve

Attachment 1 4t O/L 60 2

Sleeve Hem 0.8 F/L 75 1.5

Bottom Hem 0.95 F/L 63.15789 1.5

Check Point 0.35 HELPER 171.4286 1

SAM 9.54 18.5

SAM = 9.54 == 10 min

No. of Operations = 16 (including 2 checkpoints)

Output per operations = 60/Sam of Operation

Total workers = 18.5

Pitch time = 88 (i.e. 88 pieces per operation should be made)

Man : Machines = 1.6 : 1

Machines= 100

Therefore man= 160

Longest process time = 0.95 min

Line balancing rate (LBR) = (SAM/ (Longest process time X no. of workers)) X 100

LBR =63%

Output per line per day= (480 X 18 X 70)/ (100 X 10) == 600

No. of lines 5 (since capacity of 99 m/c)

Output per day = 600 X 5 = 30,000 pcs

Button attaching machine= 200 buttons per Hr.

Therefore, for a day = 200 X 8 =1600

CALCULATED OUTPUT BASED ON LINE BALANCING

OPERATION MACHINE NO. OF EXPECTED CALCULATED

WORKERS OUTPUT PER OUTPUT

HOUR

Shoulder Attaching SNLS 1 88 100

Front Placket Shirt HELPER 1.5 88 105

Front Placket

Attaching SNLS 2 88 110

Front Placket

Finishing SNLS 1 88 109

Pocket Hemming SNLS 1 88 150

Pocket Pressing HELPER 1 88 200

Pocket Attaching SNLS 1 88 100

Check Point HELPER 1 88 171

Collar Attaching SNLS 1 88 85

Collar Tape

Attachment SNLS 1 88 133

Side Seam 4t O/L 1 88 101

Sleeve Attachment 4t O/L 2 88 120

Sleeve Hem F/L 1.5 88 120

Bottom Hem F/L 1.5 88 94

Check Point HELPER 1 88 171

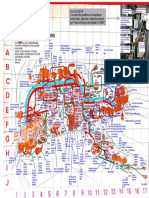

PLANT LAYOUT

Fig 1.1 : Plant Layout

CUTTING DEPARTMENT LAYOUT

Fig 2.1 : Layout made using AutoCad

Fig 2.2: Cutting Department layout

SEWING AND FINISHING DEPARTMENT LAYOUT

Fig 3.1 : Sewing Department Layout

Fig 3.2 : Finishing Department Layout

Note :

In the pictures given above :

1. Yellow box denotes a helper.

2. 4 boxes are button hole and button attaching machine.

3. 10 boxes are Iron tables.

4.8 boxes are inspection table.

5. 6 boxes in placed horizontally are for rework.

6. 1 big box is dispatch.

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Mass Effect 5e - The HomebreweryDocument253 pagesMass Effect 5e - The HomebreweryRony Do CarmoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Seams and Stitching Problems and CausesDocument53 pagesSeams and Stitching Problems and CausesYetana WubnehPas encore d'évaluation

- Beer Distribution Game - Wikipedia, The Free EncyclopediaDocument3 pagesBeer Distribution Game - Wikipedia, The Free EncyclopediaSana BhittaniPas encore d'évaluation

- HRSGDocument21 pagesHRSGrabia2090Pas encore d'évaluation

- Color Management Handbook Vol2Document28 pagesColor Management Handbook Vol2ianjpr100% (2)

- Freelance Contract AgreementDocument10 pagesFreelance Contract AgreementGayathri Prajit100% (1)

- Introduction To Linear Programming SauDocument42 pagesIntroduction To Linear Programming SauEruPas encore d'évaluation

- Strategic PlanningDocument24 pagesStrategic PlanningSara Sharma0% (1)

- Internship ReportDocument64 pagesInternship ReportThushara MKPas encore d'évaluation

- Vikash Kumar Sinha GP DocumentDocument57 pagesVikash Kumar Sinha GP DocumentEru100% (3)

- Outsourced New Product DevelopmentDocument5 pagesOutsourced New Product Developmentvinnakota5Pas encore d'évaluation

- Debt RestructuringDocument4 pagesDebt Restructuringjano_art21Pas encore d'évaluation

- LP As A Tool of OptimizationDocument5 pagesLP As A Tool of OptimizationEruPas encore d'évaluation

- CHAPTER3-RESEARCHMETHODOLOGY DatacollectionmethodandResearchtoolsDocument10 pagesCHAPTER3-RESEARCHMETHODOLOGY DatacollectionmethodandResearchtoolscmwainainaPas encore d'évaluation

- MMPP001 Project GuidelinesDocument11 pagesMMPP001 Project GuidelinesTapaswini Web100% (1)

- StepDocument1 pageStepEruPas encore d'évaluation

- Reference PaperDocument69 pagesReference PaperEruPas encore d'évaluation

- Mr. Chinnaraja G Naidu ProfileDocument1 pageMr. Chinnaraja G Naidu ProfileEruPas encore d'évaluation

- Reference PaperDocument69 pagesReference PaperEruPas encore d'évaluation

- Khadi and Village Industries CommissionDocument9 pagesKhadi and Village Industries CommissionEruPas encore d'évaluation

- Price Optimization To Improve Store Profitability: Project DetailsDocument4 pagesPrice Optimization To Improve Store Profitability: Project DetailsEruPas encore d'évaluation

- Questionnaire Retail OutletDocument3 pagesQuestionnaire Retail Outletsandy90% (10)

- Senior IP Counsel-India & South Asia United States Patent and Trademark Office (USPTO)Document1 pageSenior IP Counsel-India & South Asia United States Patent and Trademark Office (USPTO)EruPas encore d'évaluation

- Our Business Heads: Reliance Brands LimitedDocument4 pagesOur Business Heads: Reliance Brands LimitedEruPas encore d'évaluation

- Production DepartmentDocument6 pagesProduction DepartmentEruPas encore d'évaluation

- SleeveDocument3 pagesSleeveEruPas encore d'évaluation

- John Cabeca United States Intellectual Property Attaché For South AsiaDocument1 pageJohn Cabeca United States Intellectual Property Attaché For South AsiaEruPas encore d'évaluation

- What Is An ERP ImplementationDocument10 pagesWhat Is An ERP ImplementationEruPas encore d'évaluation

- Forecasting For ProductionDocument51 pagesForecasting For ProductionEruPas encore d'évaluation

- Fab IndiaDocument10 pagesFab IndiaEruPas encore d'évaluation

- Canadian Tire - Inventory Control in The RetailDocument153 pagesCanadian Tire - Inventory Control in The RetailAriel Kozakevich100% (1)

- APPM Paper StructureDocument5 pagesAPPM Paper StructureEruPas encore d'évaluation

- Session-4 SNLSDocument26 pagesSession-4 SNLSEruPas encore d'évaluation

- Folders Used IN Sewing MachinesDocument24 pagesFolders Used IN Sewing MachinesrajasekaranvgPas encore d'évaluation

- Session-6Threads and Stitches - PpsDocument49 pagesSession-6Threads and Stitches - PpsEruPas encore d'évaluation

- Session-8 Machine Bed TypesDocument16 pagesSession-8 Machine Bed TypesEruPas encore d'évaluation

- StitchtypeclassificationDocument8 pagesStitchtypeclassificationRishikesh RaiPas encore d'évaluation

- Session-11Presser FootDocument20 pagesSession-11Presser FootEruPas encore d'évaluation

- 010 Informed Search 2 - A StarDocument20 pages010 Informed Search 2 - A StarRashdeep SinghPas encore d'évaluation

- Roger Rabbit:, Forest Town, CA 90020Document3 pagesRoger Rabbit:, Forest Town, CA 90020Marc TPas encore d'évaluation

- BOOK2Document201 pagesBOOK2Chetan Satish PadolePas encore d'évaluation

- Nigeria Country Profile - 0Document4 pagesNigeria Country Profile - 0Nden SohbutPas encore d'évaluation

- Box MCB Hager BrochureDocument5 pagesBox MCB Hager BrochureTOLLAUT DESIGNPas encore d'évaluation

- Glass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Document80 pagesGlass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Sam OrlandoPas encore d'évaluation

- XJ600SJ 1997Document65 pagesXJ600SJ 1997astracatPas encore d'évaluation

- Introduction To Risk Management and Insurance 10th Edition Dorfman Test BankDocument26 pagesIntroduction To Risk Management and Insurance 10th Edition Dorfman Test BankMichelleBellsgkb100% (50)

- Desktop Window Manager: DWM Overviews DWM Reference DWM Sample CodeDocument3 pagesDesktop Window Manager: DWM Overviews DWM Reference DWM Sample Codekris_onlinePas encore d'évaluation

- Chem 111a - Activity No. 2Document5 pagesChem 111a - Activity No. 2MARY KATE FATIMA BAUTISTAPas encore d'évaluation

- Q1 LAS 4 FABM2 12 Week 2 3Document7 pagesQ1 LAS 4 FABM2 12 Week 2 3Flare ColterizoPas encore d'évaluation

- Relative Clauses (Who, Which, That) For B LevelDocument16 pagesRelative Clauses (Who, Which, That) For B LevelOğuzhan KarabayPas encore d'évaluation

- Polymer AbbreviationsDocument9 pagesPolymer AbbreviationsFernando GuerreroPas encore d'évaluation

- 164 Dashboard Annotated Ver 2a W-InsertDocument1 page164 Dashboard Annotated Ver 2a W-Insertoleg164Pas encore d'évaluation

- DSP QBDocument8 pagesDSP QBNithya VijayaPas encore d'évaluation

- Sharp AR-C172M ServiceM EN PDFDocument308 pagesSharp AR-C172M ServiceM EN PDFpiaggio_nrgPas encore d'évaluation

- Topic 7Document18 pagesTopic 7Anonymous 0fCNL9T0Pas encore d'évaluation

- Programa de Formacion: English Dot Works 2Document4 pagesPrograma de Formacion: English Dot Works 2Juan GuerreroPas encore d'évaluation

- Incorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)Document9 pagesIncorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)juan diazPas encore d'évaluation

- M6 FORMATIVE3 VHDL Behavioral Programming 1Document14 pagesM6 FORMATIVE3 VHDL Behavioral Programming 1Allen Ray LedesmaPas encore d'évaluation

- Books Confirmation - Sem VII - 2020-2021 PDFDocument17 pagesBooks Confirmation - Sem VII - 2020-2021 PDFRaj Kothari MPas encore d'évaluation

- Designing A 3D Jewelry ModelDocument4 pagesDesigning A 3D Jewelry ModelAbdulrahman JradiPas encore d'évaluation