Académique Documents

Professionnel Documents

Culture Documents

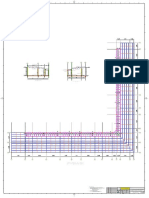

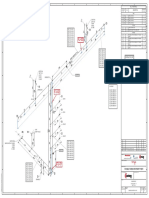

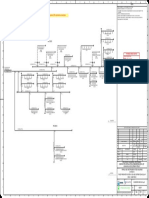

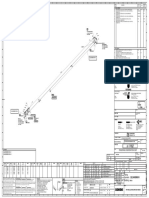

411111-4262-012 Rev - 0 - (Issued For Fabrication) (Design Drawing For Spray Nozzle Assembly For Spray Condenser (Finisher) (4262-s01-g01) )

Transféré par

Faisal BojongTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

411111-4262-012 Rev - 0 - (Issued For Fabrication) (Design Drawing For Spray Nozzle Assembly For Spray Condenser (Finisher) (4262-s01-g01) )

Transféré par

Faisal BojongDroits d'auteur :

Formats disponibles

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

L L

Nozzle on Vessel

BETE FOG NOZZLE, INC.

2", Sch 40S, SS304 ELBOW

Spray Nozzle, Model No.

2" TF 88 FCN (See Table 1)

- BY OTHERS

K K

S1 S1

J J

1.6 Gasket (typ.)

MOC: White Virgin Teflon (TEFE)

BY PIPING

(150

)

(229

)

555.58 (Ref.)

FINISHER PROBE ASSEMBLY

I I

741

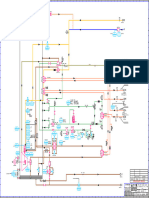

4" 150# Full Port

13 X 13 Thk

Split Body Ball-Valve

2" Schd 40S 304 SS Pipe

Nozzle on Vessel

See Pipe Detail

Use clean undamaged

(Bore Dia. 98mm as per Vendor Data)

3 sides

2-11.5 NPT

mill surface pipe

- BY OTHERS

3/8" Square Packing (4X)

25

No weld this side

Garlock Type 127 or Equiv.

Coupling

(See Detail)

Stuffing Box

(See Detail)

H H

(26.87)

790

Pipe Detail

SCALE 1 / 2.5

G D1

G

(147.5

220

M16 X 80 Bolt and Nut (16X)

M16 X 90 Bolt and Nut (8X)

267

(See Note 7)

(REF.)

(See Note 7)

Gland Cover

559.20

(See Detail)

(Ref.)

90

60

25

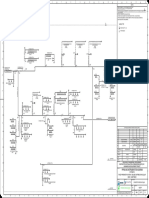

F SECTION S1-S1

TYP

S3

41

60

F

2X

SCALE 1 / 2.5

20

9.4

R48

Q78

120

2 X 88 OD X 78.2 X 2 THK.

SS 304 WASHER

69 Hex Flats

2X Smalley Snap Ring

Snap Ring Groove

Part #VSM-78 or Equiv.

3 X 99 OD X 64 ID X 3 THK

75.66 C0.15

Matl: SS 304

Q38.00

Soft Durometer (55 Recommended)

30

http://smalley.com/

Table 1: Spray Nozzle

66 C0.2

Viton Rubber

2 X

DETAIL D1

Tag Number

Part Number

Coupling Thread - (Depth - Ref)

4262-S01-G01 A-C 2" TF 88 FCN

2-11.5 MNPT - (17.7mm - Ref)

SCALE 1 : 1

Adjust to fit

(17.7)

E as rqd

Ref.

E

by Table 1

Table - 2

Tag Number Qty.

Ref. P & ID No.

Spray Condensor MDS No.

4262-S01-G01 A-C 3 Nos 503416-4260-012 511048-4262-012

See

S3

Table 1

+

0.10

+

0.08

2 - 11.5 NPT

1.6

- 0.00

1.12

- 0.00

2 Places

2 Places

APPROVED FOR

COUPLING

FABRICATION

SCALE 1 / 1

D (Matl: SS 304)

SECTION S3-S3

D

4" 150# SORF

SCALE 1 / 1

General Notes-

(Matl: SA 182 F 304)

1) All dimensions are in mm unless otherwise specified.

(Q228.60)

2) Dimensions given in the drawing are finished dimensions. Vendor

4" Schd 40S

to ascertain the actual requirements based on the cutting/maching

304 SS Pipe

4" 150# Blind Flange

(Q19.05)

8X

allowance, before material procurement.

S2

(Matl: SA 182 F 304)

(Q19.05)

8X

(Q228.60)

4" 150# Blind Flange

3) Welding details given in the drawing are indicative. Fabricator may use

(MATL: SA 182 F 304)

equivalent welding details.

S4

4) Break all edges. Remove all burrs and weld splatters.

5

5) All gasket surfaces shall have spiral groove with 90 included angle,

0.4 pitch & 0.8 pitch, with 125 to 250 micro inch surface finish.

G

6) Forged SS Flanges can be subtiuted by Plate SS flanges.

7) MOC of nut/bolts : ASTM A 193 Gr B7 (BOLTS), ASTM A 194 Gr 2H (NUTS)

C

C

(REF.)

Reference Specification No.-

130

61.3

80.3

EIT012-44-17-16 - Specification for Spray nozzle assembly for spray

114.3

condenser (Finisher)

79.3

61.3

REVISION HISTORY

REV DESCRIPTION BY CHK APPROVED DATE

B 0 DWG ISSUED FOR FABRICATION SGB HKD KKP 11-09-2012

94

125

S2

511063-31262-11015

392

S4

95

THIS DOCUMENT IS PROPRIETARY AND CONFIDENTIAL INFORMATION OF CHEMTEX AND ITS LICENSER AND MAY BE

USED ONLY WITH PRIOR WRITTEN CONSENT

GLAND COVER

P.T. INDORAMA, POLYCHEM INDONESIA

STUFFING BOX

SECTION S2-S2

SCALE 1 / 2.5

SECTION S4-S4

ALL DIMENSIONS IN

SCALE 1 / 2.5

mm

DESIGN DRAWING FOR SPRAY NOZZLE ASSEMBLY

SCALE 1 / 2.5

(Matl: SS 304)

SCALE 1 / 2.5

TOLERANCE ON ALL

FOR SPRAY CONDENSER (FINISHER) (4262-S01-G01)

(Matl: SS 304)

NEXT ASSY LEVEL:

DWG COPIED FROM:

DIMENSIONS UNLESS

REF SPEC NO.:

OTHERWISE

SPECIFIED SHALL BE:

DWN:

SGB

10/08/12

SIZE

C1a

CHK:

HKD

10/08/12

A

ANGLES:

0 PLACE: C2mm

APP:

JWM

A0

A

1 PLACE: C0.5mm

APP:

REV

2 PLACE: C0.10mm

SCALE:

As noted

411111-4262-012

0

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Vous aimerez peut-être aussi

- Colegio Santa Isabel de Hungria Planta General de Cubierta MEGA-COL-SIH-003Document1 pageColegio Santa Isabel de Hungria Planta General de Cubierta MEGA-COL-SIH-003ANGEL VILORIA SANTIAGOPas encore d'évaluation

- Hidráulico 40 Linhas Fast RiserDocument1 pageHidráulico 40 Linhas Fast RiserOzias RamosPas encore d'évaluation

- Detail Parapet Samping A 301Document1 pageDetail Parapet Samping A 301Ferry AnggriawanPas encore d'évaluation

- Site Lay Out - NewDocument1 pageSite Lay Out - NewBeckiePas encore d'évaluation

- Ec1-02a Second Floor Fdas LayoutDocument1 pageEc1-02a Second Floor Fdas LayoutSEDFREY DELA CRUZPas encore d'évaluation

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHPas encore d'évaluation

- Dry Street Lighting Network Layout Ci SL LP 104Document1 pageDry Street Lighting Network Layout Ci SL LP 104Ahmed BoraeyPas encore d'évaluation

- SS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRDocument1 pageSS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRtukaram.pawarPas encore d'évaluation

- Energy: Integrated System and Support ServicesDocument1 pageEnergy: Integrated System and Support ServicesLucky Cham AguilaPas encore d'évaluation

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserPas encore d'évaluation

- 06-09-2023 Bridge Layout Plan & Section at Ds Coffer DamDocument1 page06-09-2023 Bridge Layout Plan & Section at Ds Coffer Damekta guptaPas encore d'évaluation

- Cable Trenc Layout Jmaui R0-ModelDocument1 pageCable Trenc Layout Jmaui R0-ModelManas MondalPas encore d'évaluation

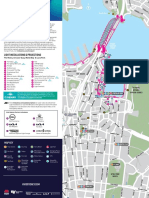

- DNSW Vivid Sydney Lightwalk Map FinalDocument2 pagesDNSW Vivid Sydney Lightwalk Map FinalShuba SundaramPas encore d'évaluation

- SCSEI - TED.0004 Road LayoutDocument1 pageSCSEI - TED.0004 Road LayoutRochelle GuitguitenPas encore d'évaluation

- Top Flanges Which Are To Be Studwelded Must Not Be Primed or PaintedDocument1 pageTop Flanges Which Are To Be Studwelded Must Not Be Primed or PaintedPANDU RANGARAO A N VPas encore d'évaluation

- HW Nic Allam DD Ge 002Document1 pageHW Nic Allam DD Ge 002ehab.m.saad88Pas encore d'évaluation

- B01 TL101P2Document1 pageB01 TL101P2alysamir.eetdPas encore d'évaluation

- Fsa 1210 F2Document1 pageFsa 1210 F2Nagamani ManiPas encore d'évaluation

- Ellectric Office - 1Document1 pageEllectric Office - 1kom1984Pas encore d'évaluation

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirPas encore d'évaluation

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserPas encore d'évaluation

- FuenteDocument1 pageFuenteAlejandro FernandezPas encore d'évaluation

- 018409-Jingold M&e Bole Me FC SH 01 08Document1 page018409-Jingold M&e Bole Me FC SH 01 08Getahun AbebePas encore d'évaluation

- Plumbing Iso SampleDocument1 pagePlumbing Iso SampleJemmylyn LeonardoPas encore d'évaluation

- 19011-U-100-Pro-Pid-110-A1 NodeDocument1 page19011-U-100-Pro-Pid-110-A1 NodeAjay TulpulePas encore d'évaluation

- MR-KCP-1 & 4-026 - Birco Drain ChannelDocument1 pageMR-KCP-1 & 4-026 - Birco Drain ChannelUsman SandhuPas encore d'évaluation

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkPas encore d'évaluation

- Wingspan Transition Section Charts V2.0Document2 pagesWingspan Transition Section Charts V2.0constantinescuana200Pas encore d'évaluation

- Claudare Stree T: Not For ConstructionDocument1 pageClaudare Stree T: Not For Constructionfehmeen zehraPas encore d'évaluation

- 5030-Elomp-Int-Dwg-5853-Fire Alarm Layout PDFDocument1 page5030-Elomp-Int-Dwg-5853-Fire Alarm Layout PDFEmmanuel ToretaPas encore d'évaluation

- Mz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1Document1 pageMz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1AMR ABDALHPas encore d'évaluation

- Global - Shop Drawing Dry Wall 1st Floor - 2023.11.03Document11 pagesGlobal - Shop Drawing Dry Wall 1st Floor - 2023.11.03PasyaHumendruPas encore d'évaluation

- Uvls.2 Uqair-A.12 PDFDocument1 pageUvls.2 Uqair-A.12 PDFAnonymous BZQOJwWIh6Pas encore d'évaluation

- Naffco: Verified By: Mohammad Jaber AlmajediDocument1 pageNaffco: Verified By: Mohammad Jaber AlmajediArun UdayabhanuPas encore d'évaluation

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarPas encore d'évaluation

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserPas encore d'évaluation

- Map BCWCZones Transit LinesDocument1 pageMap BCWCZones Transit Lineshen434Pas encore d'évaluation

- SAP16P: Absolute Maximum Ratings Electrical CharacteristicsDocument6 pagesSAP16P: Absolute Maximum Ratings Electrical Characteristicsr_cristiPas encore d'évaluation

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZPas encore d'évaluation

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserPas encore d'évaluation

- R2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelDocument1 pageR2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelNachiketa MithaiwalaPas encore d'évaluation

- Epcc05 MDR 421 STR DWG 000 0072 14Document1 pageEpcc05 MDR 421 STR DWG 000 0072 14RANJEET PRATAP SINGHPas encore d'évaluation

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirPas encore d'évaluation

- Lor 03127Document1 pageLor 03127HighSpeedRailPas encore d'évaluation

- CR101P2Document1 pageCR101P2Mina AzmiPas encore d'évaluation

- Colour Coded Zoning Map of Bangalore: WGS-1984 DATUMDocument1 pageColour Coded Zoning Map of Bangalore: WGS-1984 DATUMLIKITH DPas encore d'évaluation

- B01 TJ101MDocument1 pageB01 TJ101Malysamir.eetdPas encore d'évaluation

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirPas encore d'évaluation

- Delta+DPS-205CP TIVIDocument3 pagesDelta+DPS-205CP TIVINgoc Tuy NguyenPas encore d'évaluation

- Key plan layout of fire protection systemsDocument1 pageKey plan layout of fire protection systemsAbdul basithPas encore d'évaluation

- Vu 1108 070822Document1 pageVu 1108 070822api-3698996Pas encore d'évaluation

- A2 Km. 186+580 ST PDFDocument1 pageA2 Km. 186+580 ST PDFciciPas encore d'évaluation

- Pid-So59117 BR15 01Document1 pagePid-So59117 BR15 01Oscar RoblesPas encore d'évaluation

- Elm 03 JGC CV Gas 0010Document1 pageElm 03 JGC CV Gas 0010Amin GPas encore d'évaluation

- G Board Schematic Diagram For 40" ModelDocument2 pagesG Board Schematic Diagram For 40" Modelroto44Pas encore d'évaluation

- Sony 1-876-467-11 A1556720a Ip5-Board PsuDocument3 pagesSony 1-876-467-11 A1556720a Ip5-Board PsuJohnny MarquesPas encore d'évaluation

- JSWCF-C-MFB-012 - Boundary Fence Arrangement & Details-Sh-4 - (Rev 01)Document1 pageJSWCF-C-MFB-012 - Boundary Fence Arrangement & Details-Sh-4 - (Rev 01)Mohammed JamsheedPas encore d'évaluation

- Lor 03108Document1 pageLor 03108HighSpeedRailPas encore d'évaluation

- Design Data: Saudi Arabian Oil CompanyDocument15 pagesDesign Data: Saudi Arabian Oil Companysuria qaqcPas encore d'évaluation

- BRT vs Light Rail Costs: Which is Cheaper to OperateDocument11 pagesBRT vs Light Rail Costs: Which is Cheaper to Operatejas rovelo50% (2)

- Case Study 1Document2 pagesCase Study 1Diana Therese CuadraPas encore d'évaluation

- Marketing Strategy of Singapore AirlinesDocument48 pagesMarketing Strategy of Singapore Airlinesi_sonet96% (49)

- Journal Entry DiscussionDocument8 pagesJournal Entry DiscussionAyesha Eunice SalvaleonPas encore d'évaluation

- HDFC Bank's Organizational Profile and BackgroundDocument72 pagesHDFC Bank's Organizational Profile and Backgroundrohitkh28Pas encore d'évaluation

- ESS 4104 AssignmentDocument9 pagesESS 4104 AssignmentSamlall RabindranauthPas encore d'évaluation

- Relation of Sociology with other social sciencesDocument4 pagesRelation of Sociology with other social sciencesBheeya BhatiPas encore d'évaluation

- Dance Manual W. Learning Outcomes PDFDocument8 pagesDance Manual W. Learning Outcomes PDFJoshua Quijano LamzonPas encore d'évaluation

- Unit 3 Test A Test (Z Widoczną Punktacją)Document4 pagesUnit 3 Test A Test (Z Widoczną Punktacją)Kinga WojtasPas encore d'évaluation

- Ko vs. Atty. Uy-LampasaDocument1 pageKo vs. Atty. Uy-LampasaMaria Janelle RosarioPas encore d'évaluation

- Vdoc - Pub Parrys Valuation and Investment TablesDocument551 pagesVdoc - Pub Parrys Valuation and Investment TablesWan Rosman100% (1)

- Masters of Death: The Assassin ClassDocument5 pagesMasters of Death: The Assassin Classjbt_1234Pas encore d'évaluation

- Endoplasmic ReticulumDocument4 pagesEndoplasmic Reticulumnikki_fuentes_1100% (1)

- Cub Cadet 1650 PDFDocument46 pagesCub Cadet 1650 PDFkbrckac33% (3)

- Chapter 018Document12 pagesChapter 018api-281340024Pas encore d'évaluation

- Motivate! 2 End-Of-Term Test Standard: Units 1-3Document6 pagesMotivate! 2 End-Of-Term Test Standard: Units 1-3Oum Vibol SatyaPas encore d'évaluation

- Fluid MechanicsDocument46 pagesFluid MechanicsEr Suraj Hulke100% (1)

- MASM Tutorial PDFDocument10 pagesMASM Tutorial PDFShashankDwivediPas encore d'évaluation

- Global Finance - Introduction ADocument268 pagesGlobal Finance - Introduction AfirebirdshockwavePas encore d'évaluation

- SOG 5 Topics With SOPDocument2 pagesSOG 5 Topics With SOPMae Ann VillasPas encore d'évaluation

- Alberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016Document35 pagesAlberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016LucasPas encore d'évaluation

- Recommendation Letter - One Young WorldDocument2 pagesRecommendation Letter - One Young WorldNabeel K. AdeniPas encore d'évaluation

- Kasapreko PLC Prospectus November 2023Document189 pagesKasapreko PLC Prospectus November 2023kofiatisu0000Pas encore d'évaluation

- GRADE 8 English Lesson on Indian LiteratureDocument3 pagesGRADE 8 English Lesson on Indian LiteratureErold TarvinaPas encore d'évaluation

- Write The Missing Words of The Verb To Be (Affirmative Form)Document1 pageWrite The Missing Words of The Verb To Be (Affirmative Form)Daa NnaPas encore d'évaluation

- Ra 1425 Rizal LawDocument7 pagesRa 1425 Rizal LawJulie-Mar Valleramos LabacladoPas encore d'évaluation

- Full Download Test Bank For Macroeconomics 11th Edition Arnold PDF Full ChapterDocument36 pagesFull Download Test Bank For Macroeconomics 11th Edition Arnold PDF Full Chaptervitalizefoothook.x05r100% (17)

- Something About UsDocument18 pagesSomething About UsFercho CarrascoPas encore d'évaluation

- CH1 Ncert 11th BiologyDocument18 pagesCH1 Ncert 11th Biologysomnathsharma777Pas encore d'évaluation

- Enneagram Type-2Document18 pagesEnneagram Type-2pundirPas encore d'évaluation