Académique Documents

Professionnel Documents

Culture Documents

MS For Installation of Electrical Containment & Wiring, Cable Pulling

Transféré par

Anandu AshokanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MS For Installation of Electrical Containment & Wiring, Cable Pulling

Transféré par

Anandu AshokanDroits d'auteur :

Formats disponibles

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement and Risk Assessment for

Installation of Electrical Containment &

Wiring/Cable Pulling, at AMC Connectivity

Corridors & Concourse Bridge Project , Maryah

island,

ABUDHABI

Project No-M- 1467

Document Ref No: MCL-ME-A-MST-MSS-004

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 1 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Project name AMC Connectivity Corridors & Concourse Bridge Project Project No M1467

Main Contractor McLaren Construction Ltd. Document No MCL-ME-A-MST-MSS-004

Title/Task Installation of Electrical Containment & Wiring Revision No 00

Document

Date of issue 21/02/2019 Prepared By

Syed Faisal

Duration of

Proposed start date 03/03/2019 task 60 DAYS

Contents

Section A Register of Revisions

Section B Scope of Works to be undertaken:

Section C Location of the Project

Section D Location of the Works to be Undertaken with the Project

Section E Site Access/Egress and Access to the Work Zone

Section F Emergency Contacts Details and Procedures:

Section G McLaren Site Specific HSE Safety Induction:

Section H Welfare facilities:

Section I Personal Protective Equipment

Section J Plant/Equipment and tools to be Used

Section K Materials To be used.

Section L Communication/Toolbox Talks/Training Requirements:

Section M Works Permits

Section N Environmental and Waste Management:

Section O Programme for the Works:

Section P Housekeeping and Storage:

Section Q Hygiene and cleanliness

Section R Working at Height

Section S Occupational Health

Section T Sequence of Works/Activities

Appendices

Appendix A Site Logistic Plans and Other Design Information Relative to the Works

Appendix B Crisis/Emergency Plan

Appendix C COSHH Assessments and Material Data Sheets (to be provided by Subcontractor)

Appendix D Risk Assessments (to be provided by Subcontractor)

Appendix E Technical Information (to be provided by the Subcontractor)

Appendix F Risk Assessment

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 2 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section A - Register of Revisions

Revision Date Reason for Amendment Amended By Signature Has this amendment been briefed

No (Name) to the operatives involved and have

the operatives signed the register.

This method statement has been prepared in conjunction with the following documents;

1. OSHAD regulation and requirements

2. OHSAD- Code of Practices, HSE Regulations, Technical Guidelines, Mechanisms

3. GR HSE Guidelines and Requirements

4. Federal Environmental Authority Law No 24/1999 and its supplements.

5. Federal Labour Law No 8

6. Articles (3,4,5,7) Local Law No 21/2005 (Waste Management)

7. McLaren SHE Procedures

8. McLaren’s site specific SHEQ Plan (including TMMS, SWMP, EPP).

9. McLaren’s Integrated Management System Policy Statement (IMS).

Section B- Scope of Works to be undertaken:

The work Describes the installation activity of electrical containment system and laying of wires and armoured

cables through the containment system.

The following Critical Hazards have been identified during the preparation of the scope of works, please refer to

the Risk Assessments within Appendix D.

1. Manual Handling Injuries

2. Slip Trips and Falls

3. working at Height/ Ladders

4. Fall from Height

5. Electrical Hazard

6. Struck by Objects

7. Use of ladders

8. Falling objects

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 3 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section C- Location of the Project

Location of the Project;

Our project is located is located AMC CONCOURSE BRIDGE in between Almaryha and Galleria Mall as marked

below.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 4 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section D- Location of the Works to be Undertaken within the Project

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 5 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section E- Site Access/Egress and Access to the Work Zone

Entrance to the Site will be from Gate no 1 as per attached drawing.

Section F- Emergency Contacts Details and Procedures:

The following staff from both McLaren and Genfocus will be on site during the execution of the works and will be

responsible for managing the works;

Name Position Company Contact Details

Paul Carlin Operations Director McLaren 056-1054691

Luke Watson Project manager McLaren 052-1022402

Prabhu Srinivasulu Construction Manager McLaren 050-9709963

Joby John HSE Manager (First Aider) McLaren 050-6372060

Evangeline Huerto First Aider McLaren 056-1852727

Jijo Mathew Safety Advisor/First Aider McLaren 055-2152903

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 6 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Ramil Magano QA/QC Engineer (Fire marshal) McLaren 050-2923058

Biju MEP Engineer McLaren 056-8059139

Syed Faisal Ahmed Project Manager Genfocus 056-5465814

Anu Baby Project Engineer Genfocus 0565465807

Prabir Kumar Chattarjee Safety Officer Genfocus 0547937312

Prabir Kumar Chattarjee First Aider Genfocus 0547937312

In case of an Emergency/fire Alarm, all operatives, Staff and Visitors are required to report to the Assembly Point,

which is indicated on the site logistics drawing, as indicated by the symbol below. Where the registers will be

checked to ensure that no one is un-accounted. No one will be allowed to leave the assembly point until the

Emergency response Controller confirms that it is safe to do so.

1 Assembly Point No-01 (TBA)

2 Assembly Point No-02 (TBA)

Please refer to the attached Crisis/Emergency Plan, (Appendix B) which is to be implemented where the need

arises.

The Qualified First Aiders for the Project are listed below, and the first Aid Boxes will be available either in the

Induction/First Aid Room or in the Main Office.

McLaren: (details of First Aiders) Subcontractors(Details of First Aiders )

Joby John- 050-6372060 Syed Faisal Ahmed 056-5465814

Jijo Mathew 055-2152903

Please see below the Emergency contact details

Authority/Company Contact Telephone No.

McLaren Construction Ltd 04-3417964

Police 999

Ambulance 997

GR Emergency No 058-2864950

AMC Emergency No 056-7459621

Section G- McLaren Site Specific HSE Safety Induction:

Prior to any works taking place, all Operatives arriving at AMC project will be required to undergo a

Multiplex/Gulf Related safety induction followed by McLaren Site Safety induction, which will be held in the

induction room, by McLaren’s HSE Representative or other designated person. Once the operatives have received

the site specific safety induction, they then will be briefed on the contents of this RAMS, by their respective Site

Supervisor, from which they will then be required a sign a RAMS Briefing Register (SAF019 UAE) confirming that

they have been briefed and that they fully understand the RAMS and what is expected from them during the

execution of the site works. The Operatives will also be briefed on the Emergency and Security Procedures for the

project, which is also a part of site safety induction programme.

Any operative who will be operating any plant and equipment will be required to produce a copy of their

competency certificate/card carried out by an OSHAD approved third party training provider, to enable McLaren

to issue them with the Plant Operators Authorisation (SAF023 UAE).

Section H- Welfare facilities:

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 7 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Drinking Water-

Clean drinking water will be provided on site (as per approved Logistics plan) and all operatives are to ensure they

take on enough fluids throughout the day.

Comply with Summer Working Requirements .

Rest areas and toilet-

Rest area and toilets are being provided at site and located as per AMC logistics layout plan

Section I- Personal Protective Equipment (PPE)

The Following Personal Protective Equipment must be worn/be available during the execution of the works

activities

Type of PPE Required Yes No

Safety Helmet (as per standards) Yes

Safety Footwear (as per standards) Yes

Eye protection (as per standards) Yes

Gloves (as per standards) Yes

Hi- viz Vests Yes

Overalls (for operatives only) Yes

Ear protection Yes

Face Respirator No

Body Harness Yes

Respiratory masks Yes

Others (other specific requirements)

Please ensure that any specific precautions for PPE as identified within MSDS/COSHH assessment or any

specific requirements by supplier/manufacturer are to be complied and adhered to.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 8 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section J- Plant and Equipment to be Used

It is anticipated that the following hand tool will be used during the execution of the works; other items will also

be identified on the schedule below;

Various hand tools

Tools (Drilling machines, hammer,etc)

Grinders

Manual Lifting Jacks and spindle for placing cable drums

Multi-meter. (valid calibration certificate will be provided before use)

Rubber Padded Ladders

Cable Pulling Rollers

*Note: All relevant competency certificates (as per OHSAD /GR requirements) to be submitted to HSE

Manager/Eng./Advisor prior to start of any activity.

(Below schedule to be completed by subcontractor)

Type of Plant/Equipment to be Used Yes No Type of Plant/Equipment to be Used Yes No

Lifting No Cradle No

Mechanical hoist No Excavation shoring No

Mobile elevating working platform No Hand tools Yes

Ladder Yes Electrical tools Yes

Hoist No CAT & Gen Set No

Test Equipment No Ventilation/Extraction Equip No

Task Lighting Yes Pump No

Tubular Scaffolding Yes Lifting slings/chains No

Mobile scaffolds Yes Mechanical plant No

Podium Scaffold No Others:

Section K- Materials To be used.

The following Materials will be utilised during the execution of the works, the Material Data sheets being

provided, which will allow the relevant COSHH assessments to be carried out; (See Appendix C)

Item Material Description Has MSDS been Has the COSHH

provided and Assessment sheet been

attached? completed and attached?

1 Cable Tray/Trunking N/A N/A

2 GI/PVC Conduits N/A N/A

3 Wires and Armoured cables N/A N/A

Section L- Communication/Tool Box Talks/Training Requirements:

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 9 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Once the RAMS has been briefed to the workforce, we will also hold Tool Box Talk relative to the work activities

being carried out, these will be conducted by the HSE team, in conjunction with the relevant site supervisors, this

will ensure that the message gets across to the workforce, in their own language, thus avoiding any

misinterpretation of the RAMS/Toolbox Talk.

During the Preparation of this RAMS the following training for the staff and operatives has been identified;

Item Description of Training Has the Training been If not, when will be

completed? (Yes/No) completed(Date)

1 3rd party training for operative of plant and N/A

equipment

2 3rd party competency card for operators N/A

3 Riggers, Banksman N/A

4 First aid training Yes

5 Scaffolding inspection and erection Yes

*Note: All relevant certificates will be submitted prior to works commencing or during induction. Where the

training has not been carried out, it must do so prior to the works/activities commencing.

Section M- Works Permits

The following works permits will be required during the execution of the Works;

Item Description of the Work Permit Permit Issued By Tick only applicable

1 Permit to Enter Confined Space McLaren

2 Permit for Lifting Operations. McLaren

3 Permit to Dig McLaren

4 Permit to work Hot cutting or Welding McLaren

5 Permit to Work in Ceiling Void McLaren

6 Permit for Roof Access McLaren

7 Permit to Work with Ladders, steps McLaren

8 Permit to Work at Height McLaren

9 Permit to Work – Electrical above 110V McLaren

10 Permit to Work with COSHH Items McLaren

11 Permit to Work at External Face of The Building McLaren

12 Permit for Removal of Existing Fall Protections McLaren

13 Permit for Existing MEP Service Isolation McLaren

Any other permits if required to be added

Section N- Environmental and Waste Management:

During the execution of the project, waste will accumulate. Skips will be provided by McLaren and will be

required to put all waste in the skips provided. All waste will be segregated for recycling as per below sequence

1. Metal

2. Plastic

3. General waste

4. Concrete waste

5. Food waste

6. Hazardous waste

7. Wood Waste

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 10 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Due to the nature of the works and the actual conditions of the present site, airborne dust will be minimal,

however where necessary the area affected by the installation of the temporary works, the dust will be

suppressed by spraying water.

Drip trays to be placed under plant and generator to catch any excess oil. Approved Waste Collection Contractor

will then remove excess oil from site in oil containers and sent back to store for collection.

Section O- Programme for the Works.

The works will commence on 03/03/2019 For a duration of 4 weeks, as the works are scheduled, there will be

requirement for additional lighting in the working area.

However if Night shift starts, adequate task lighting will be required.

Section P- Housekeeping and Storage:

Housekeeping will be carried out as and when required and storage of materials will be in an agreed location (as

per approved site logistics plan) within the segregated area and as agreed in subcontractor prestart meeting. The

subcontractor will remove from site.

Section Q- Hygiene and cleanliness:

Hygiene and cleanliness are the upmost requirements for the project. All works carried out with AMC Projects

Procedures and requirements.

Section R- Working at Height

During the preparation of the RAMS, the following activities for working at height have been identified and have

been addressed within the risk assessments within Appendix D. (to be filled if applicable to your works)

Item Activity Risk Assessment Reference

1 Installation of GI/PVC Conduits Refer attached risk assessment

2 Installation of Cable Tray/Trunking Refer attached risk assessment

Pulling of wires and Cables over Refer attached risk assessment

3

containment

Section S- Occupational Health

During the preparation of the RAMS, the following Occupational Health items have been reviewed and addressed

within this Method Statement.

Item Description of OH Item Preventative Measures, (see also within the Risk Assessments)

1 Manual handling As much as possible Eliminate the need for manual handling by

using mechanical aid

2 Respiratory diseases Area will be watered to minimise dust and dust mask will be

provided

3 Falling from height Safety harness must be worn and hooked at secured place.

injuries/Fatalities Working at height training to be conducted by supervisor.

4 Cut and laceration injuries Wearing loose cloths shall be avoided and wearing proper

PPEs .

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 11 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section T- Sequence of Works/Activities

The works will be carried out in the following sequences;

1 RAMS to be briefed to all the operatives involved in the work.

2 STARRT card to be prepared by assessing the area of work prior starting the work.

3 Supervisor to ensure all operatives have received a McLaren and Multiplex site basic induction

4 Supervisor to ensure all operatives have adequate PPE for the job including Full body harness.

5 Supervisor to ensure that the site is clean and ready to start the work.

6 Supervisor to ensure adequate tools are provided and advise Site manager if more tools are needed.

7 Works will be carried out in such a way as to minimize the impact of the work.

INSTALLATION OF CABLE TRAY/ TRUNKING:

Tray/trunking sizes are based on the local authority requirements and as per the shop drawings approval

1

by consultant.

Electrical Supervisors shall use consultant approved shop drawings for marking the route of the

2

tray/trunking.

Ladders and scaffoldings shall be placed along the tray/trunking route at required heights, as per the

3 requirements/locations. The same shall be checked by the safety officer before starting the installation

works.

Technicians shall perform drilling operations for fixing 10mm unifix bolts at wall/ceiling for the purpose of

4 hanging the 10mm thread rods. A pair of thread rods and a 41x41mm unistrut channel forms a support for

cable trunking/tray hung from ceiling or from beam clamps.

5 Approximately 1.50M uniform distance shall be maintained between supports.

6 Thread rods shall be placed at a distance of 50mm on both sides of tray/trunking.

Tray/Trunking shall be cut and grinded as per the site requirements using cutting wheels or hacksaw

7

blades and grinders.

The bottom support of tray/trunking shall be of 41x41mm unistrut channel and is hanged using thread

8 rods using Hex nuts and washers. The length of this unistrut shall be 150mm greater than the size of

trunking so as to maintain 75mm distance on both sides.

Tray/trunking is fixed permanently to the 41x 41mm unistrut using spring nuts of suitable sizes as per the

9

requirements.

10 Typical supporting details with sections shall be provided in the Shop Drawings.

The location of the supports shall be marked on ceiling, walls and if the supports are to be installed on

11

the structural beams, suitable clamps shall be used to clamp the tread rods, as per the site conditions.

12 Earth tags shall be provided at the joints of two tray/trunkings.

Proper labelling shall be done after installation of tray/trunking, indicating the service which it has been

13

provided for.

The ends and other finished ends of tray/trunking shall be provided with bushes such that cables/wires

14 do not sustain damage at the time of installation.

INSTALLATION OF GI /PVC CONDUITS:

Electrical supervisor shall identify the start and end points of each circuits by seeing the approved shop

1

drawings, in order to lay the GI/PVC conduits.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 12 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

2 Supervisor shall mark the electrical points on the slab/wall by using approved shop drawings.

The route of GI/PVC conduits shall be checked to make sure that it is free from debris and any other

3

services.

4 Solvents shall be used for joining PVC conduits and couplers while installing PVC conduits.

Size of electrical conduits shall be minimum 20mm dia for lighting circuits and 25mm for other electrical

5

power circuits.

6 Conduit shall be installed with a maximum of two 90º bends or three 120º bends

The minimum internal radius of any bend or elbow fitting in a conduit shall be 2.5 times the diameter of

7

the conduit.

Technicians shall make holes on wall/ceiling using drilling machines for fixing rawal plugs inside these

8 holes. Saddles of appropriate sizes shall be fixed to the rawal plugs using screws. Saddles shall be fixed at

every one meter span.

GI/PVC conduits shall not be laid below water services, crossing vents and disturbing any wall/slab

9

openings.

Where a PVC conduit is installed within a wall, floor or ceiling it must be at a minimum depth of 50 mm

10

from the surface.

11 Couplers and circular boxes of suitable sizes shall be used to join the conduits.

Where conduits are connected to GI trunking or Distribution Boards conduits shall be connected using

12

threaded adaptors.

GI conduits to be used for all external/exposed locations. Earthing to be done for GI conduits and

13

checked for continuity.

Conduits shall be run neatly either horizontal or vertical. Overlapping of conduits shall be avoided as

14

much as possible.

In case of concrete pouring, the installation of PVC conduits shall be inspected by consultant and

15

approval to be obtained for the same.

At the time of concrete pouring, electricians shall be provided for taking care of conduits to avoid any

16

damage or dislocation.

WIRING:

All the materials intended for wiring shall be obtained approval from consultant prior to the starting if

1

activity.

Prior to the installation of wires/cables in trunking or conduits the entire containment system shall be

2 checked to ensure that it is free from any sharp edges which may damage the wires at the time of

pulling.

Before pulling the wires/cables, additional care to be taken to make sure that the wires/ cables are not

3

damaged.

Electrical supervisors shall refer to the approved load schedules and Lighting/Power layouts for

4

identifying the colour/size of wires to be pulled for any particular circuits.

Light switches shall be installed at a height of 1.30M from FFL and sockets at 300MM or 450MM from

5

FFL.

6 Rating of switches and sockets shall be as per the authority requirements and approved shop drawings.

Before Cable pulling commences, the actual length of the route will be measured and checked to ensure

7

adequacy of provided cable length.

Cable/Wire rolls or drums to be placed in a safe position, such that they are free to rotate at the time of

8

pulling.

Where wires are to be pulled in trunking, each circuits shall be segregated by using cable ties at every 2m

9

span.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 13 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

10 At expansion joints, adequate slack shall be left for cables/wires.

Where conduits are installed for pulling wires, a draw wire/pulling wire shall be provided between each

11

draw in points.

Maximum number of wires/cables that can be pulled through a conduit of particular diameters, shall be

12

as per ADDC requirements.

A slack of at least 200mm of wire will be left at each electrical outlet, and at the DBs side 800mm for

13

termination purpose.

About a length of 1 meter in DB’s and 2 meters in SMDB’s shall be left for cables for glanding and

14

termination purposes.

The ends of the wires and cables shall be marked with proper identification for testing and connection

15

purposes.

After completion of the activity, all the waste materials and debris shall be removed and materials shall

16 be shifted back to store.

ARMOURED CABLE PULLING OVER CABLE TRAY:

1 Suitable place shall be identified to place the cable drums, jack and spindle.

2 Cable drum shall be placed on jack and spindle arrangement to ensure free rotation of the drum.

Cable rollers shall be placed below cables for pulling over long distances. Standoff rollers to be used at

3

acute bends such that cable are pulled with minimum effort.

Cables shall be pulled by using rope at an end and care to be taken to prevent the damage for cables as

4

well as containment system.

Supervisors shall check the size of the cables on approved Electrical schematic diagrams /Load schedules,

5

prior to the commencement of the work.

Relevant earth cables also to be pulled along with the main cables and shall be run adjacent to the main

6

cables throughout the length. (Sizes as mentioned in approved shop drawings).

Care shall be taken at bending locations that minimum bending radius for cables shall be maintained as

7

per the manufacturer recommendations.

8 A slack of 800mm shall be kept at the distribution board side for the purpose of termination.

9 Cables shall be secured to the containment system by using cable ties at regular intervals.

10 Cables shall be caped and sealed at both ends after pulling until glanding and termination is done.

Glanding and termination shall be carried out with approved materials – glands, lugs, cable ties(for

11

dressing of cables inside DBs) and proper crimping tools.

Cables shall be identified at both ends mentioning size, type and where it is fed, using appropriate labels

12

as per the specifications at 50mm below the gland.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 14 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX A

Site Logistics Plan

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 15 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX B

CRISIS PLAN

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 16 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

CRISIS PLAN

1. Upon an incident, being discovered the first member of McLaren’s staff or the site operative

discovering the incident shall inform the Project Manager and Site HSE team through AMC Project

emergency Contact No-056-7459621.

2. Both the HSE Engineer/advisor and the First Aider are to attend the scene with their mobile. The

project Manager or authorised person waits in office ready to contact relevant emergency

services.

3. Both the HSE Engineer/advisor and the first Aider are to assess the situation and put in place the

relevant systems to end/deal with the emergency.

4. Both the HSE Engineer/advisor and the first Aider are to ensure all trades are gathered at the

assembly point and liaise with supervisor to account for all operatives - no person should leave

site.

5. Either the HSE Engineer/advisor or the first Aider phones the project Manager or site receptionist

and informs him/her of which emergency services are required.

6. The Project Manager calls all relevant McLaren staff.

7. Both the HSE Engineer/advisor and the first Aider waits for the emergency services at scene.

8. Once emergency services arrive, The Project Manager will telephone the relevant authorities, i.e.

the HSE/Client’s Safety Advisor/QHSE Manager/McLaren’s operations Director.

9. Both the HSE Engineer/advisor and the first Aider keep trades informed of the situation and

releases trades to return to work or leave site only when emergency services or The Project

Manager instruct that it is safe to do so, and all names of witnesses are recorded.

10. Project Manager or Construction Manager are to arrange for photographs of the scene to be

taken, and if necessary the area to be cordoned.

A full investigation of the Incident is to be carried out, with a written report being submitted the

SHEQ Director, as soon as practicably possible after the incident, including all witness statements,

11. photos of the scene, induction and method statement records, recommendation to prevent a re-

occurrence and what action has been taken since the incident taking place.

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 17 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX C

COSHH ASSESSMENTS AND MSDS

(Not Applicable)

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 18 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

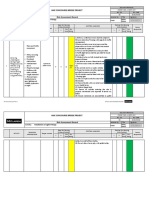

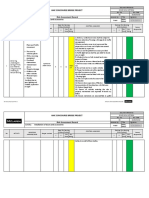

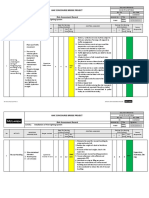

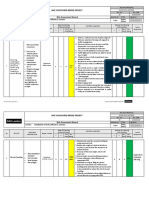

APPENDIX- D

RISK ASSESSMENTS

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 19 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX-E

TECHNICAL INFORMATION

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 20 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement Title Installation of Electrical Containment &Wiring/Cable Pullling Doc Ref No: MCL-ME-A-MST-MSS-004

Project Location: AMC Connectivity Corridors & Concourse Bridge Project Revision No: 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 21 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Vous aimerez peut-être aussi

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanPas encore d'évaluation

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanPas encore d'évaluation

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanPas encore d'évaluation

- MS For Installation of Electrical Wiring & Cable PullingDocument20 pagesMS For Installation of Electrical Wiring & Cable PullingAnandu Ashokan100% (1)

- Installation of Light Fitting.Document68 pagesInstallation of Light Fitting.Anandu AshokanPas encore d'évaluation

- RAMS For Testing & Commissioning of HVACDocument42 pagesRAMS For Testing & Commissioning of HVACAnandu AshokanPas encore d'évaluation

- MS - Installation of MEP ServicesDocument28 pagesMS - Installation of MEP ServicesAnandu Ashokan100% (3)

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Testing and Commissioning of Electrical SystemDocument21 pagesMS For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (2)

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Document6 pagesp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanPas encore d'évaluation

- Method Statement & Risk Assessment - Installation of Electrical WorksDocument31 pagesMethod Statement & Risk Assessment - Installation of Electrical WorksAbu Muhammed Khwaja67% (3)

- Risk Assesment For Electrical Testing and Commissioning.Document6 pagesRisk Assesment For Electrical Testing and Commissioning.Francis Enriquez Tan83% (12)

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanPas encore d'évaluation

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureDocument5 pagesp103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanPas encore d'évaluation

- Method Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQDocument13 pagesMethod Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQAzree Mohd Noor100% (2)

- Risk Assessment For .Testing and Commissioning of Fire Rated Bus DuctDocument13 pagesRisk Assessment For .Testing and Commissioning of Fire Rated Bus Ductarun kurlanPas encore d'évaluation

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocument7 pagesp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanPas encore d'évaluation

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesDocument6 pagesp103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanPas encore d'évaluation

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanPas encore d'évaluation

- Risk Assessment of Testing and Commissioning of Fire Alarm SystemDocument4 pagesRisk Assessment of Testing and Commissioning of Fire Alarm Systemfidgety67% (3)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- 1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15Document8 pages1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15NirmalKumarSelvarajPas encore d'évaluation

- Method Statement For Lightning Protection SystemDocument14 pagesMethod Statement For Lightning Protection Systemshareyhou75% (4)

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanPas encore d'évaluation

- Power Block Cable InstallationDocument20 pagesPower Block Cable InstallationAnandu AshokanPas encore d'évaluation

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 pagesRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEDocument18 pagesRisk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEarun kurlan89% (9)

- Installation of Spiral DuctsDocument15 pagesInstallation of Spiral DuctsAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- p103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemDocument10 pagesp103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemAnandu AshokanPas encore d'évaluation

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For .Testing and Commissioning of Fire DamperDocument9 pagesRisk Assessment For .Testing and Commissioning of Fire Damperarun kurlanPas encore d'évaluation

- Installation of Air Handling UnitDocument15 pagesInstallation of Air Handling UnitAnandu Ashokan100% (2)

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Electrical Risk AssessmentDocument6 pagesElectrical Risk AssessmentEman Fawzy100% (1)

- 00 - MS - Wires and Cables InstallationDocument9 pages00 - MS - Wires and Cables InstallationEslam TahaPas encore d'évaluation

- Testing and Commissioning of BMS Rev ADocument8 pagesTesting and Commissioning of BMS Rev Aanish7785100% (3)

- Method Statement For UPSDocument12 pagesMethod Statement For UPSshareyhou100% (2)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment For .TESTING AND COMMISSIONING OF LV CABLEDocument19 pagesRisk Assessment For .TESTING AND COMMISSIONING OF LV CABLEarun kurlan100% (3)

- Method of StatementDocument14 pagesMethod of Statementharigopalk12Pas encore d'évaluation

- Method Statement For Laying of Low Voltage Cables and WiresDocument5 pagesMethod Statement For Laying of Low Voltage Cables and WiresMark Anthony AlanoPas encore d'évaluation

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar50% (4)

- p103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingDocument5 pagesp103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingAnandu AshokanPas encore d'évaluation

- DWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingDocument22 pagesDWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingAnandu AshokanPas encore d'évaluation

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

- RA For Flushing of Chilled Water PipesDocument8 pagesRA For Flushing of Chilled Water PipesAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of Chilled Water Pipes & FittingsDocument21 pagesMS For Installation of Chilled Water Pipes & FittingsAnandu AshokanPas encore d'évaluation

- MS For Installation of FCUDocument20 pagesMS For Installation of FCUAnandu AshokanPas encore d'évaluation

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanPas encore d'évaluation

- Method Statement For Water Heaters InstallationDocument9 pagesMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Method Statement For Earthing and Lightning ProtectionDocument12 pagesMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanPas encore d'évaluation

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- RAMS EvaluationDocument3 pagesRAMS EvaluationAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation of Drainage PipesDocument17 pagesRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- MS Cover SheetDocument1 pageMS Cover SheetAnandu AshokanPas encore d'évaluation

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- MS Comments SheetDocument1 pageMS Comments SheetAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan90% (31)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Matrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014Document19 pagesMatrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014navigareePas encore d'évaluation

- 1 s2.0 S2238785423001345 MainDocument10 pages1 s2.0 S2238785423001345 MainHamada Shoukry MohammedPas encore d'évaluation

- MikoritkDocument6 pagesMikoritkChris Jonathan Showip RoutePas encore d'évaluation

- Nuttall Gear CatalogDocument275 pagesNuttall Gear Catalogjose huertasPas encore d'évaluation

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocument8 pagesTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaPas encore d'évaluation

- Volcano Lesson PlanDocument5 pagesVolcano Lesson Planapi-294963286Pas encore d'évaluation

- Model No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionDocument53 pagesModel No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionRavi ChandranPas encore d'évaluation

- Adsorption ExperimentDocument5 pagesAdsorption ExperimentNauman KhalidPas encore d'évaluation

- Previous Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDocument18 pagesPrevious Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDrRameem Bloch100% (1)

- Most Probable Number (MPN) Test: Principle, Procedure, ResultsDocument4 pagesMost Probable Number (MPN) Test: Principle, Procedure, ResultsHammad KingPas encore d'évaluation

- Annex A - Scope of WorkDocument4 pagesAnnex A - Scope of Workمهيب سعيد الشميريPas encore d'évaluation

- Transformational LeadershipDocument75 pagesTransformational LeadershipvincentpalaniPas encore d'évaluation

- 1 - DIASS Trisha Ma-WPS OfficeDocument2 pages1 - DIASS Trisha Ma-WPS OfficeMae ZelPas encore d'évaluation

- Edtpa Lesson 3Document3 pagesEdtpa Lesson 3api-299319227Pas encore d'évaluation

- Chapter 10 OutlineDocument3 pagesChapter 10 OutlineFerrari75% (4)

- CNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortDocument3 pagesCNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortKession HouPas encore d'évaluation

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocument13 pagesUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanPas encore d'évaluation

- 50 Law-Firms Details by Vaibhav SharmaDocument17 pages50 Law-Firms Details by Vaibhav SharmaApoorva NandiniPas encore d'évaluation

- Ace 2Document184 pagesAce 2Raju LaxmipathiPas encore d'évaluation

- Iit-Jam Mathematics Test: Modern Algebra Time: 60 Minutes Date: 08-10-2017 M.M.: 45Document6 pagesIit-Jam Mathematics Test: Modern Algebra Time: 60 Minutes Date: 08-10-2017 M.M.: 45Lappy TopPas encore d'évaluation

- Net Pert: Cable QualifierDocument4 pagesNet Pert: Cable QualifierAndrés Felipe Fandiño MPas encore d'évaluation

- U2 KeyDocument2 pagesU2 KeyHằng ĐặngPas encore d'évaluation

- Geopolymer Book Chapter1 PDFDocument37 pagesGeopolymer Book Chapter1 PDFDick ManPas encore d'évaluation

- Technical DescriptionDocument2 pagesTechnical Descriptioncocis_alexandru04995Pas encore d'évaluation

- Course Outline Cbmec StratmgtDocument2 pagesCourse Outline Cbmec StratmgtskyiePas encore d'évaluation

- Altos Easystore Users ManualDocument169 pagesAltos Easystore Users ManualSebPas encore d'évaluation

- 5 24077 Rev2 PDFDocument3 pages5 24077 Rev2 PDFJavier GarcíaPas encore d'évaluation

- D.O. 221-A - Application Form (Renewal)Document1 pageD.O. 221-A - Application Form (Renewal)Karl PagzPas encore d'évaluation

- Preblending of Raw Materia1Document26 pagesPreblending of Raw Materia1Mohammed Abdo100% (1)

- Investing in Granada's Property Market - Gaspar LinoDocument1 pageInvesting in Granada's Property Market - Gaspar LinoGaspar LinoPas encore d'évaluation