Académique Documents

Professionnel Documents

Culture Documents

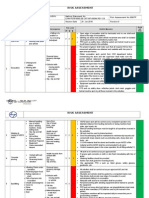

Risk Assessment For Installation of Drainage Pipes

Transféré par

Anandu Ashokan97%(34)97% ont trouvé ce document utile (34 votes)

14K vues17 pagesRisk Assessment for Installation of Drainage Pipes

Titre original

Risk Assessment for Installation of Drainage Pipes

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentRisk Assessment for Installation of Drainage Pipes

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

97%(34)97% ont trouvé ce document utile (34 votes)

14K vues17 pagesRisk Assessment For Installation of Drainage Pipes

Transféré par

Anandu AshokanRisk Assessment for Installation of Drainage Pipes

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 17

Document Reference

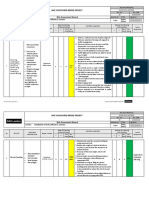

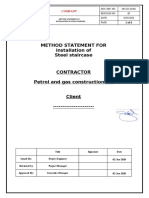

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to

traffic management.

Plant and Traffic 2. Ensure exclusion zone is set up around the

movement preparation work area and all plant

movement and checked by supervisor

Run over by 3. Always use the pedestrian access provided

vehicles/plants 4. Traffic light batons shall be provided for banks

Hit by reversing man at night

equipment 5. All plant to have a fully trained banks man

Delivering, Overhead present all times.

unloading and obstructions 6. No plant to reverse without banks man.

Operatives Site Eng.

storing of PVC Vehicle break 7. Ensure access route are sufficient and safe to

1 Staff/visitors Med Supervisor,

Pipe and fittings down 3 4 12 use. 1 4 4 Low

ium Foreman,

using pickup and Property damage 8. Do not take rest in or under vehicles

unloading by Collision with 9. Proper barricade and safety signboard

manual handling other vehicles provided on open excavation

Personal injury 10. All vehicles must be fitted with reverse alarm

Fatality / Flashing light.

Accident due to 11. The work place and all access to be well

poor lighting and illuminated.

visibility (operation 12. Enforce Speed limit

at night 13. Ensure all vehicles entering the site is properly

maintained and reported if found any defect

14. Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

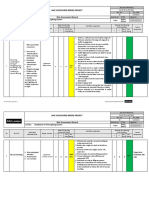

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Eliminate the need for manual handling by

using mechanical aid.

2. Reduce the weight of a load to limit force

exertion

3. If unsure of the load weight, check with

1. Musculoskeletal supervisor. Supervisor,

Operatives 4. Ensure proper manual handling procedure

Manual Handling disorders Med Foreman,

2 involved in 5. Ensure adherence with sufficient and Low

2. Hand injuries 3 4 12 ium 1 4 4 Site Eng.

work appropriate PPE.

3. cut & bruises

6. Limit load carrying to 20kg per person

7. Supervisor must make sure while manual

handling load individual task and environment

to be considered to reduce the risk of manual

handling.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure accesses are kept clear at all times.

2. Housekeeping to be carried out regularly

throughout the day when required

3. Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a

Operatives safe condition

Slips, Trips and fall Supervisor,

Staff/storekeepe 4. Provide adequate lighting especially during

Poor house Med Foreman,

3 Material storing r 3 4 12 night hours 1 4 4 Low

keeping ium Site Eng.

5. Appropriate space is allowed around storage

areas for employees to move around safely

without the risk being trapped between

stacked materials.

6. Maintain good housekeeping.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

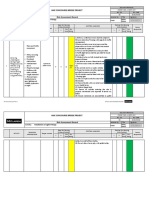

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. STARRT card briefing must before start the

activity

2. Ensure the PTW in place.

3. Ensure proper working platform with

complete fall protection

4. Ensure Full body harness and 100% Tie off

5. Ensure the scaffold platform is properly

erected with "Safe to use" tag.

Work at height 6. Ensure castor wheels are locked

7. Hand tools must be secured/tethered

8. Work materials strictly not allowed to be

Installation of Fall form height stored on platform except for working tools

Operatives/Staf

drainage Pipe 9. Ensure avoid over reaching and climb on

f/ Supervisors

(PVC) with Falling objects Med handrail.

4 Visitors 3 4 12 1 4 4 Low Foreman,

accessories ium 10. Ensure unauthorised person not allowed to

Others Site Eng.

fittings using Over loading modify the scaffolding and if needed to any

mobile Tower changes then must be modified by trained

Protruding objects and certified scaffolder.

11. Ensure safe access to the working platform

Access & egress 12. Scaffold access must be free from obstruction

13. Ensure sufficient illumination in work area

14. Ensure while fittings the GI clamp and

brackets operatives must safely use drill

machine to avoid finger injury.

15. Ensure that working near fragile surface

special care of body and eye protection with

necessary PPE.

16. Must clean the debris after completion the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

job and maintain good housekeeping.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Only light work, off short duration and work

in which the operative can maintain secure

hand and foot hold can be undertaken form

a ladder

2. Never try to overreach with any ladders

Falling from height

3. Check the ladder is of suitable quality for

industrial use and is in good condition

4. Maintain a minimum of 3 points of contact

with stepladders at all times

(feet/thighs/hands)

5. If possible avoid the use of stepladders at a

working height of 2 meters and more.

6. Check the ladder legs (and stays) are fully

Operatives/ Supervisor

Use of Ladder Med deployed or locked (depending on type) to

5 Staff/ 3 4 12 1 4 4 Low Site Eng.

ium maintain maximum base dimensions and the

Working on Uneven Foreman,

step ladder is orientated to provide

ground

maximum stability.

7. Stepladders/ladders has to be used on

leveled ground/firm base

8. Ensure that during using ladder from the top

2 step is blocked to avoid climb on that.

9. The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at

Falling objects

all times.

10. Person must hold the ladder while another

operative working on it

11. 8) Materials should not be placed above the

thread of ladders/step ladders

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

12. Do not carry any materials in one hand while

climbing or getting down from ladder

13. Ensure the area under the ladder is

barricaded especially if it is being used in a

public area.

14. Ensure the ladder is electrical insulated

podium type if working in live services

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure that all chemical substances have a

COSHH assessment

2. Refer SDS prior to any handling of hazardous

substances and ensure SDS is easily accessible

at site while working with chemicals.

3. Ensure chemicals are properly stacked.

4. Ensure all chemical containers are properly

labeled.

Spillage/ soil

5. Spill kits to be available at site.

contamination

6. Ensure operatives use the correct PPE

7. Competent person to oversee the storage,

Burns

use and disposal of hazardous materials.

Contact with skin

Use of Glue 8. Ensure that correct welfare/first aid facilities Supervisors

Operatives Med

6 Solvent, 3 4 12 are available in the area i.e. washing 1 4 4 Low Foreman,

Acute/Chronic using solvent ium

(Hazardous facility/eye wash. SiteEng.

adverse heath

Substance) 9. Proper and adequate PPE to be used always

effect.

10. Ensure all chemical containers are properly

Fire labeled.

11. Adjust work schedules so that workers are not

overexposed to a hazardous chemical.

12. Wear respiratory protection

13. Ensure proper and adequate PPE to be used

always.

14. Ensure smoking only in designated area

15. Ensure appropriate Firefighting equipment’s

are in place and easily accessible

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. All portable electrical equipment must be PAT

tested and color coded. Make sure the test

dates are visible on the equipment.

2. Ensure all disk shall be appropriate and expiry

date is over.

3. Ensure all power tools are in good condition

and appropriately maintained

Damaged

4. PTW to be obtained, prior to commencing the

Sockets & cable

task

insulation.

5. Damaged industrial sockets and power cables

Electrocution

Electric shock must be removed.

Short circuit & 6. Ensure the electrical cable is not damaged

Use of power and has not been repaired with insulating

Burns Supervisor

tools such as Operatives and Med

7 Trip/Fall 3 4 12 tape or unsuitable connectors. 1 4 4 Low Foreman

Grinder/Cutter & staff ium

Noise 7. Ensure cables from power tools shall be Site Eng.

Drill machine,

Hearing loss organized so as not to present a tripping

Vibration hazard

Dust 8. Only trained competent operatives to operate

the power tools.

9. Ensure proper and regular maintenance of

equipment that takes account of noise

10. Ensure proper hearing protection always.

11. Make sure people use the right tool for the

job and are trained to use it correctly

12. Ensure defective tools that require

maintenance is reported for repair or

replacement.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

13. Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly.

14. Ensuring proper job rotation and limiting time

operatives working with power tools and

hand tools.

15. Use dust mask

16. Ensure proper earth leakage protection is

provided.

17. All power tools must be 110V to be ensured.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Arrange adequate drinking water and rest

shelter

2. Drink plenty of water with electrolyte

Heat exhaustion.

3. If feel something unusual immediately inform

Working under Heat stroke

supervisor and report to site clinic.

High Dehydration

4. Make shift to operate the routine work Site Eng.

temperature Personal injuries Workers

8 4 4 16 High 5. Do not allowed alone work 1 4 4 Low Supervisors,

Direct sun light due to high

6. Frequent breaks Foreman

Dusty temperature,

7. Proper supervision available

High wind Sunstroke &

8. Correct PPE must use

Tiredness

9. Provide heat stress training

10. Conduct tool box talk

11. Proper signage for drinking water

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

4. Industrial safe torches to be available for

Poor visibility emergency situations Site Engr

Working at night due to darkness / Operatives/staff 5. High visibility Traffic Vest for personnel’s in

Med Supervisor

9 time poor illumination 3 4 12 night shift 1 4 4 Low

ium Foreman

Lone worker 6. Avoid lone working and always ensure buddy

system while working at night

7. Employees to be trained and understand

McLaren Crises plan.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Risk assessment must brief to the

operatives.

2. Ensure permit obtained for pressure

test.

3. All pressure tests must be conducted

with due regard for the safety of life and

property.

4. Precautions should be taken to see that

people not directly engaged in the

testing operations remain out of the test

area during the test period.

Hydro test

High-pressure leak

5. During pressure testing events, distinct

of water All operatives Site eng

warning signs, such as DANGER – HIGH

10 Failure of hydraulic involved in 4 4 16 High 1 4 4 Low Supervisor

Pressure Testing PRESSURE TESTING IN PROGRESS must

test pump work Foreman

be posted at the test work area with

Electric shock

exclusion zone .

Electrocution

6. Check that all high points have a tap or

vent to facilitate removal of air during

filling and that these are all closed.

7. Blank, plug or seal any open ends and

close all valves at the limits of the test

section of the piping.

8. Start to fill the piping and then ‘walk’ the

route of the piping under test,

continuously visually checking for leaks

and by listening for the sound of

escaping air

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

9. Release air from all the high points

systematically through the system to

completely fill it with water

10. Check that the test gauge is functioning

correctly has been calibrated and has the

correct range of the test pump.

11. Check that a suitable hose is available for

draining the system

12. Before attempting test, Supervisor will

review the test specifications and

procedures with the Test Inspector and

any other relevant personnel to be

certain that all equipment is adequate,

and duties are organized and understood

13. All the electric live service must be

temporary isolate to avoid electric shock

and electrocution

14. STARRT talk must conduct by supervisor

15. PPE must in use with face shield

16. Ensure proper grounding and earthling.

17. After completion of the pressure test,

release the water and disconnect all the

temporary connections and close both

ends

18. Exclusion zone must be removing and

remove the danger signage after

completion of pressure test.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0015

Rev. No. Rev. Date

00 14/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Drainage Pipe Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Hand tools should be visually inspected for

Improper defects, prior to use.

selection of hand 2. Never use damaged, blunt or broken tools to

tools. avoid injury.

Damaged and 3. Select right tools for right Job Site engg

Defective Hand 4. Ensure no Homemade or makeshift tools to Supervisor

Use of Hand

tools. be used at site Foreman

Operatives/Staff Med

11 tools Hand injuries 3 3 9 5. Remove from service any tool that shows 1 3 3 Low

ium

Pinch point signs of damage or defect

Ergonomics 6. Ensure Hand tools are Stored in accordance

Repetitive strain with the manufacturer’s instructions.

injury 7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

Approved By: Name Position __________ Signature _________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

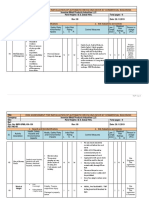

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that

risks have well established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

potential high risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

the table below.

No Injury Minor Moderate Major Catastrophic

(1) Injury (2) Injury (3) Injury (4) (5)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD

Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

Almost

5 10 15 20 25

Certain (5)

RISK LEVEL:

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

Vous aimerez peut-être aussi

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For CABLE TRAYDocument11 pagesRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- Risk Assessment For Installation of SMDB&DBDocument15 pagesRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan82% (11)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Installation of Air Handling UnitsDocument19 pagesRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of SMDB DBDocument12 pagesRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanPas encore d'évaluation

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasPas encore d'évaluation

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Installation of Fire Fighting Pipes Risk AssessmentDocument15 pagesInstallation of Fire Fighting Pipes Risk AssessmentAnandu Ashokan75% (4)

- Risk Assessment For Structured CablingDocument7 pagesRisk Assessment For Structured CablingAnandu Ashokan67% (6)

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 pagesRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Temporary ServicesDocument15 pagesRisk Assessment For Temporary Servicesfaizan khan100% (2)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Sanitary Fixtures Risk AssessmentDocument12 pagesSanitary Fixtures Risk AssessmentAnandu Ashokan100% (1)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Project:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONDocument20 pagesProject:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONghaleb alhourani100% (1)

- Welding and Radiography Risk AssessmentDocument11 pagesWelding and Radiography Risk AssessmentAldrin75% (8)

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Task Specific Risk AssessmentDocument22 pagesTask Specific Risk Assessmentsimone92% (12)

- Risk Assessment For Cable InstallationDocument15 pagesRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- Risk Assessment ConstructionDocument70 pagesRisk Assessment ConstructionArun Celestin93% (42)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk assessment for excavation worksDocument3 pagesRisk assessment for excavation worksYaser A. Al-Bustanji72% (18)

- Risk Assessment HVAC DuctingDocument5 pagesRisk Assessment HVAC DuctingAsad Zakria100% (5)

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Risk assessment for conduit pipe installationDocument17 pagesRisk assessment for conduit pipe installationJayson Escamillan75% (4)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Risk assessment for automatic revolving doorsDocument8 pagesRisk assessment for automatic revolving doorssabirbdk100% (1)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Risk Assessment for Painting WorkDocument5 pagesRisk Assessment for Painting WorkVipul Shankar89% (9)

- RA For Hvac Duct InstallationDocument10 pagesRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetMuhammad Ibrahim93% (45)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Water Tank Base Construction Hazard Identification and Risk ControlDocument5 pagesWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- HEALTH & SAFETY RISK ASSESSMENTDocument52 pagesHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- Electrical Risk AssessmentDocument6 pagesElectrical Risk AssessmentRaul Moyo100% (2)

- Risk Assessment For Installation of Fire Fighting SystemDocument12 pagesRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- Building System Risk AssessmentDocument42 pagesBuilding System Risk Assessmentمحمد عمر حسين100% (4)

- Installation of Chilled Water PipesDocument6 pagesInstallation of Chilled Water PipesAnandu AshokanPas encore d'évaluation

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Risk Assessment For Block & Plastering WorksDocument43 pagesRisk Assessment For Block & Plastering WorksAndres Corsino Kristoffer AL100% (1)

- Risk Assessment For Installation of Cooling TowersDocument19 pagesRisk Assessment For Installation of Cooling TowersVlad Karo100% (1)

- Risk Assessment of Installation of Chilled Water PipesDocument20 pagesRisk Assessment of Installation of Chilled Water PipesJomy JohnyPas encore d'évaluation

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Method Statement For Water Heaters InstallationDocument9 pagesMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For Earthing and Lightning ProtectionDocument12 pagesMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan82% (11)

- RAMS EvaluationDocument3 pagesRAMS EvaluationAnandu AshokanPas encore d'évaluation

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanPas encore d'évaluation

- MS Cover SheetDocument1 pageMS Cover SheetAnandu AshokanPas encore d'évaluation

- MS Comments SheetDocument1 pageMS Comments SheetAnandu AshokanPas encore d'évaluation

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanPas encore d'évaluation

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanPas encore d'évaluation

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanPas encore d'évaluation

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Safety Data Sheet Petroleum, Crude Oil: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument12 pagesSafety Data Sheet Petroleum, Crude Oil: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingnivasmarinePas encore d'évaluation

- Appendix 2 - Fire Risk Assessment ChecklistDocument6 pagesAppendix 2 - Fire Risk Assessment Checklistnosula87100% (1)

- Contruction Safety and Health Program - AmdocsDocument21 pagesContruction Safety and Health Program - AmdocsRonald DolorPas encore d'évaluation

- Safety Engineering and Disaster Risk ManagementDocument3 pagesSafety Engineering and Disaster Risk ManagementAnil MarsaniPas encore d'évaluation

- Curriculum Vitae: Muhammad AmmarDocument5 pagesCurriculum Vitae: Muhammad Ammarammar mughalPas encore d'évaluation

- Chain Washing System Mod.635 18/16 ALUPRESSDocument88 pagesChain Washing System Mod.635 18/16 ALUPRESSAlamin SiddiquePas encore d'évaluation

- 103 Solution EC Msds 5-08Document3 pages103 Solution EC Msds 5-08Brian HernandezPas encore d'évaluation

- Msds For Rp-1616-p Type Oil - Dos OilDocument4 pagesMsds For Rp-1616-p Type Oil - Dos OiltagashiiPas encore d'évaluation

- Operating Instruction: MAN Marine Diesel Engines D2868 LE4XX / D2862 LE4XXDocument112 pagesOperating Instruction: MAN Marine Diesel Engines D2868 LE4XX / D2862 LE4XXOveis DarvishiPas encore d'évaluation

- Permit to Work ElectricalDocument3 pagesPermit to Work ElectricalHans SalenussaPas encore d'évaluation

- Marine Yard Supervisor ResponsibilitiesDocument2 pagesMarine Yard Supervisor ResponsibilitiesJethro StanlyPas encore d'évaluation

- Petroleum Development Oman L.L.C.: Document Title: Road Safety StandardDocument244 pagesPetroleum Development Oman L.L.C.: Document Title: Road Safety Standardviju1982Pas encore d'évaluation

- Gwo Criteria For Training Providers Version 5 September 2016pdfDocument14 pagesGwo Criteria For Training Providers Version 5 September 2016pdfMauricio SosaPas encore d'évaluation

- Physical security system essentialsDocument5 pagesPhysical security system essentialsLindo Gondales Jr.Pas encore d'évaluation

- 5S Color Chart: Equipment SafetyDocument1 page5S Color Chart: Equipment SafetyOP AryaPas encore d'évaluation

- Basic Modules of Instruction Agriculture NC IIDocument13 pagesBasic Modules of Instruction Agriculture NC IIMEAMALLORCAPas encore d'évaluation

- BP Code of ConductDocument112 pagesBP Code of ConductLuis ZequeraPas encore d'évaluation

- Pany ProfileDocument24 pagesPany ProfileDebye101Pas encore d'évaluation

- Training Activity Matrix: Lecture in Occupational Safety and Health in The Construction IndustryDocument3 pagesTraining Activity Matrix: Lecture in Occupational Safety and Health in The Construction IndustryOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCPas encore d'évaluation

- GMP b2 - en 20160401Document45 pagesGMP b2 - en 20160401Morty KobusPas encore d'évaluation

- Contingency and Emergency PlanDocument17 pagesContingency and Emergency PlanVIVO AGGREGATES RESOURCES CORPORATIONPas encore d'évaluation

- "Our Aim - Zero Harm": 51St National Safety Day Quiz QuestionaireDocument2 pages"Our Aim - Zero Harm": 51St National Safety Day Quiz QuestionaireAmit WaghPas encore d'évaluation

- Install Steel Staircase Method StatementDocument6 pagesInstall Steel Staircase Method Statementdadz mingi88% (8)

- Schneider Electric Earth Leakage ProtectionDocument3 pagesSchneider Electric Earth Leakage ProtectionNelyana UnoPas encore d'évaluation

- InglesDocument7 pagesInglesSALUD OCUPACIONAL HHUT0% (1)

- Tire Curing With Nitrogen.: GeneralDocument2 pagesTire Curing With Nitrogen.: GeneralRohmat HusinPas encore d'évaluation

- Mega Water Tank Insp RSP 5Document27 pagesMega Water Tank Insp RSP 5Vicente SosaPas encore d'évaluation

- Libro Fire Engineering Crew Resource Managemnet For The Fire ServiceDocument308 pagesLibro Fire Engineering Crew Resource Managemnet For The Fire ServiceYorman J. Mari PerazaPas encore d'évaluation

- SERVO 954-ManualDocument304 pagesSERVO 954-ManualCESARPas encore d'évaluation

- Bomag BMP 8500 Operating and Maintenance ManualDocument128 pagesBomag BMP 8500 Operating and Maintenance ManualIslam AttiaPas encore d'évaluation