Académique Documents

Professionnel Documents

Culture Documents

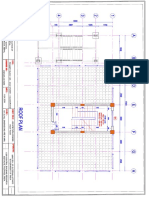

Sheet - Nirbhay - Baki 2

Transféré par

Nirbhay SinghTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sheet - Nirbhay - Baki 2

Transféré par

Nirbhay SinghDroits d'auteur :

Formats disponibles

PROTOTYPE FOR INDOOR FARMING

AGRICULTURE: URBAN WHOLESALE MARKETS

Okla Mandi is th one of the biggest vegetable wholesale

markets in Delhi. It was developed by DDA (Delhi Devel-

opment Authority) and is called the "fruits and vegetable

market sub yard•Okhla''.

Farmers from all adjacent villages come here to sell their

produce to the retailers and also to consumers. All the

areas around Delhi get their supply of vegetables and

fruits from Okhla Mandi, especially South Delhi, Ghasia-

bad, Noida and Gurgaon.

58% of Delhi’s waste directly dumped into river

Source : Food Systems (Re-Centering Delhi Research

elhi Rese Catalog) - The Yamuna River Project

B.Arch Thesis 2019-20

Site and its Nirbhay Singh

neighbourhood

AGRICULTURAL DISTRICT IN URBAN METROPOLIS OF DELHI 15110016

CULTURE ROOM

The following steps are taken by workers entering the

culture room:

(1) enter the changing/locker room

in the operation room,

(2) take off all clothing,

(3) take a hot water shower or air shower for the

whole body including hair/head washing,

(4) put on clean underwear, overalls, cap, mask, and

gloves,

(5) wash the hands while wearing the gloves using a

disinfectant for sterilization,

(6) put on clean

boots and sterilize the boot soles,

(7) take an air shower again, and

(8) enter the culture room.

“CLOSED-LOOP AGRICULTURAL” ECOSYSTEMS

Seeding for Trimming damaged weighing and pack- Shipping “Closed-loop agricultural” ecosystems intend to mimic

germination leaves aging natural ecosystems that treat waste as

a resource. Similar to aquaponics, the waste of one part

of the system becomes the nutrients for the other. The

closed-loop system recycles and reuses nearly every

element of the farming process—dirty water, sewage,

Growing germinated Harvesting/removing Labeling backs cooling and nutrients. Food waste can also be converted to

seedings in light roots compost. In a closed-loop system, everything remains

in the system, leading to a zero-waste outcome.

ANAEROBIC DIGESTER

“Closed-loop agricultural” ecosystems intend to mimic

2nd transplanting Packaging Labeling boxes natural ecosystems that treat waste as

1st transplanting

a resource. Similar to aquaponics, the waste of one part

of the system becomes the nutrients for the other. The

closed-loop system recycles and reuses nearly every

A typical flow of operations in the plant production process focusing on the movements of plants. element of the farming process—dirty water, sewage,

COMPONENTS OF A VERTICAL FARM

and nutrients. Food waste can also be converted to

Vertical Farms can be very diverse, both structurally and compost. In a closed-loop system, everything remains

technologically. Some farms rely solely on artificial light- in the system, leading to a zero-waste outcome.

ing for plant growth, whereas others grow plants verti-

cally, still utilizing some of the sun’s light. Also, plants can

either be grown in soil (potted) or using hydroponic

methods, which are much more common. Usually, a

commercial Vertical Farm relies on an artificial, ware-

house-like structure, thermally insulated, in which venti-

lation is kept at a minimum, and artificial light is used as

the sole light source for plant growth [9]. In such Vertical structure and

Farms, the environment for plant growth can be con- Air conditioning

growing system

trolled as precisely as desired, regardless of the outside

weather. In addition to the recirculating nutrient solution

in a hydroponic or aeroponic system, the water trans-

pired by plants can be condensed and collected at the

cooling panel of the air conditioners and then recycled

for irrigation.

Environmental

Vertical farm

control units CO2 supply unit

NUTRIENT FILM TECHNIQUE (NFT) DEEP FLOW TECHNIQUE (DFT) components

In the Nutrient Film Technique (NFT), a thin film of water Deep Flow Technique (or Deep Water Culture), as op-

continuously flows through the pipe/gutter, so it is posed to NFT, always has some amount of nutrient solu-

always in contact with the roots. This ensures constant tion at some depth. More nutrient is periodically pumped

availability of nutrients to the plants. NFT also supplies in and through the overflow pipe and the excess nutrient

ample oxygen to the plants, since the roots are exposed solution goes back to the reservoir and is recycled.

above the thin film. Even when there is a power outage, or other problem Nutrient supply &

This system requires the nutrient solution to be continu- preventing the pump operating properly, there is always Lighting

control

ously in circulation, which results in no stagnant water in some water to keep the plants alive. This system allows

any point of the system. more control over water temperature when compared to

N F T .

VERTICAL FARMING SPATIAL DESIGN

Schematic diagrams of DFT (left) and NFT (right) hydroponic systems

Source : GROWING POWER VERTICAL FARM - Building Systems Integration Structural Systems

B.Arch Thesis 2019-20

Components of Nirbhay Singh

vertical farming

AGRICULTURAL DISTRICT IN URBAN METROPOLIS OF DELHI 15110016

Vous aimerez peut-être aussi

- Aquaponics system, fish. Volume 1: Sistemas de acuaponíaD'EverandAquaponics system, fish. Volume 1: Sistemas de acuaponíaPas encore d'évaluation

- Aquaponics System, Plants. Volume 1: Sistemas de acuaponíaD'EverandAquaponics System, Plants. Volume 1: Sistemas de acuaponíaPas encore d'évaluation

- SRAC Publication No. 454 Recirculating Aquaculture Tank Production Systems Aquaponics Integrating Fish and Plant Culture PDFDocument16 pagesSRAC Publication No. 454 Recirculating Aquaculture Tank Production Systems Aquaponics Integrating Fish and Plant Culture PDFJeferson MorenoPas encore d'évaluation

- Sanitation For The BiogasDocument4 pagesSanitation For The BiogasChimmi DorjiPas encore d'évaluation

- Waste Stabilisation Ponds SSWM - Find Tools For Sustainable Sanitation and Wat 1Document19 pagesWaste Stabilisation Ponds SSWM - Find Tools For Sustainable Sanitation and Wat 1timeciciPas encore d'évaluation

- A Suspended Net-Pot, Non-Circulating Hydroponic Method For Commercial Production of Leafy, Romaine, and Semi-Head LettuceDocument19 pagesA Suspended Net-Pot, Non-Circulating Hydroponic Method For Commercial Production of Leafy, Romaine, and Semi-Head LettuceJose LuisPas encore d'évaluation

- 1st RDA/ARNOA International Conference "Development of Basic Standard For OrganicDocument6 pages1st RDA/ARNOA International Conference "Development of Basic Standard For OrganicMoch Rifki HartantoPas encore d'évaluation

- Course - 53 - Lesson 1INTRODUCTION To HYDROPONICSDocument8 pagesCourse - 53 - Lesson 1INTRODUCTION To HYDROPONICSBaigalmaa NyamtserenPas encore d'évaluation

- SRAC 454web PDFDocument16 pagesSRAC 454web PDFAldo Ivan Vargas PeñaPas encore d'évaluation

- Organica FCR BrochureDocument2 pagesOrganica FCR BrochureAhmed AsemPas encore d'évaluation

- DSDP 4 (SI1) 83-88oDocument6 pagesDSDP 4 (SI1) 83-88oDheiva YegappanPas encore d'évaluation

- Novel shrimp toilet for organic waste disposal in aquacultureDocument3 pagesNovel shrimp toilet for organic waste disposal in aquacultureHữu Công HuỳnhPas encore d'évaluation

- Valorisation of Biodegradable Wastes Using Worms' Cropping: June 2009Document7 pagesValorisation of Biodegradable Wastes Using Worms' Cropping: June 2009Loredana Veronica ZalischiPas encore d'évaluation

- Backyard Aquaponics 09Document2 pagesBackyard Aquaponics 09LucasPas encore d'évaluation

- RASpublishedpaperDocument7 pagesRASpublishedpaperVijay SharmaPas encore d'évaluation

- Ijser: Fabrication of Agricultural Waste Shredder MachineDocument5 pagesIjser: Fabrication of Agricultural Waste Shredder MachineSharan AnnapuraPas encore d'évaluation

- Small Community Wastewater Issues ExplainedDocument8 pagesSmall Community Wastewater Issues Explaineddinar restiPas encore d'évaluation

- Lecture 5 + 6Document15 pagesLecture 5 + 6nienke.geerts.96Pas encore d'évaluation

- Ecology II - Community ConnectionsDocument5 pagesEcology II - Community ConnectionsHelenPas encore d'évaluation

- Membrane Filtration of ManureDocument38 pagesMembrane Filtration of ManureIndustria ProyectosPas encore d'évaluation

- Water Usage in Recirculating Aquaculture/Aquaponic SystemsDocument2 pagesWater Usage in Recirculating Aquaculture/Aquaponic SystemsFood and Water WatchPas encore d'évaluation

- Revue Des Sciences de L'eau Journal of Water ScienceDocument10 pagesRevue Des Sciences de L'eau Journal of Water ScienceSabrina GrouchyPas encore d'évaluation

- EcosystemDocument43 pagesEcosystemPhantom DeluxPas encore d'évaluation

- Vermicomposting of Agriculture Waste and Its Importance in Improvement of Soil Nourishments and Agricultural CropsDocument7 pagesVermicomposting of Agriculture Waste and Its Importance in Improvement of Soil Nourishments and Agricultural CropsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- ESR Factsheet 02Document2 pagesESR Factsheet 02sthrandomPas encore d'évaluation

- Lecturer: James Reeler: BCB 341: Principles of Conservation BiologyDocument18 pagesLecturer: James Reeler: BCB 341: Principles of Conservation BiologyEmilia DuncaPas encore d'évaluation

- Natural Farm PigDocument7 pagesNatural Farm PigmariekarduenasPas encore d'évaluation

- New Trends in Agriculture - Crop Systems Without Soil: Ioan GRAD, Camelia MĂNESCU, Teodor MATEOC, Nicoleta MATEOC-SÎRBDocument4 pagesNew Trends in Agriculture - Crop Systems Without Soil: Ioan GRAD, Camelia MĂNESCU, Teodor MATEOC, Nicoleta MATEOC-SÎRBichrak ouririPas encore d'évaluation

- Finishing - BenningerDocument3 pagesFinishing - Benninger呂仲書Pas encore d'évaluation

- Plants That Remove Contaminants From The EnvironmentDocument5 pagesPlants That Remove Contaminants From The EnvironmentfesooPas encore d'évaluation

- The Rhino & Dedko Digester Systems: Environmental & Societal ImpactDocument4 pagesThe Rhino & Dedko Digester Systems: Environmental & Societal ImpactKabir UdeshiPas encore d'évaluation

- Aquaponics-Integrating Hydroponics With AquacultureDocument20 pagesAquaponics-Integrating Hydroponics With Aquaculturekriskee13Pas encore d'évaluation

- Chetty C 218055220 Babe IB 218002346 Chauke ML 218033549 Chayke BF 217025411Document19 pagesChetty C 218055220 Babe IB 218002346 Chauke ML 218033549 Chayke BF 217025411ThabangPas encore d'évaluation

- Chapter 1Document7 pagesChapter 1shahidlatif_mughalPas encore d'évaluation

- Adlerand Sikora 2005 Compost Science UtilizationDocument10 pagesAdlerand Sikora 2005 Compost Science UtilizationBinh NguyenPas encore d'évaluation

- Study of Automated and Controlled Aquaponics System An Innovative and Integrated Way of FarmingDocument5 pagesStudy of Automated and Controlled Aquaponics System An Innovative and Integrated Way of FarmingEditor IJTSRDPas encore d'évaluation

- A Survey of Solid Waste Management in Chennai (A Case Study of Around Koyambedu Market and Madhavaram Poultry Farms)Document4 pagesA Survey of Solid Waste Management in Chennai (A Case Study of Around Koyambedu Market and Madhavaram Poultry Farms)Peertechz Publications Inc.100% (1)

- Assignment No. 5: in Partial Fulfillment of The Requirements For The SubjectDocument6 pagesAssignment No. 5: in Partial Fulfillment of The Requirements For The SubjectJasper Kenneth PeraltaPas encore d'évaluation

- AGRICULTURAL WASTE MANAGEMENT ENGINEERING - ReviewerDocument9 pagesAGRICULTURAL WASTE MANAGEMENT ENGINEERING - Reviewerxandermacawile09Pas encore d'évaluation

- BNR Process and Nutrient Removal Using Bardenpho MethodDocument4 pagesBNR Process and Nutrient Removal Using Bardenpho MethodFraz AliPas encore d'évaluation

- Evaluation of Vermifiltration of Cassava Effluent Using EarthwormDocument19 pagesEvaluation of Vermifiltration of Cassava Effluent Using EarthwormTania MarisolPas encore d'évaluation

- 2015 Fiche13 Agroforestry GB WebDocument2 pages2015 Fiche13 Agroforestry GB WebGabriel R.Pas encore d'évaluation

- Vermicomposting Process of Organic Waste and Paper Mill SludgeDocument7 pagesVermicomposting Process of Organic Waste and Paper Mill SludgeInternational Journal of Innovative Science and Research Technology100% (1)

- CH 14 EnvDocument17 pagesCH 14 EnvHimanshu KesarwaniPas encore d'évaluation

- Permaculture Design Fundamentals: Smart Regenerative Design Will Save the WorldDocument95 pagesPermaculture Design Fundamentals: Smart Regenerative Design Will Save the WorldfaroeldrPas encore d'évaluation

- Ecosystem MinDocument23 pagesEcosystem Minkajolkajol71211Pas encore d'évaluation

- Pineapple Vermicomposting - 1-S2.0-S0301479720317096-MainDocument11 pagesPineapple Vermicomposting - 1-S2.0-S0301479720317096-MainVania Cruz RíosPas encore d'évaluation

- Anaerobic Digestion of Peel Waste and Wastewater For On Site EnergyDocument7 pagesAnaerobic Digestion of Peel Waste and Wastewater For On Site EnergyEFF FerreiraPas encore d'évaluation

- A Practical Guide For Aquaponics As An ADocument10 pagesA Practical Guide For Aquaponics As An AMathy MpassyPas encore d'évaluation

- Ecology & Environment - 1st - Chapter - 21Document9 pagesEcology & Environment - 1st - Chapter - 21udhayprakash111Pas encore d'évaluation

- CIS1175 Compost PDFDocument8 pagesCIS1175 Compost PDFJoselyn Vanessa Seminario PeñaPas encore d'évaluation

- Waste & Waste Water Recycling: C2.2 Ecology & Sustainable HabitatDocument50 pagesWaste & Waste Water Recycling: C2.2 Ecology & Sustainable HabitatTarakesh BnPas encore d'évaluation

- Understanding The Composting Process: Agriculture and Natural ResourcesDocument4 pagesUnderstanding The Composting Process: Agriculture and Natural ResourcesDedy LesmanaPas encore d'évaluation

- Assesment of Biofertilizer Quality and Health Implications of Anaerobic Digestion Effluent of Cow Dung and Chicken Droppings PDFDocument6 pagesAssesment of Biofertilizer Quality and Health Implications of Anaerobic Digestion Effluent of Cow Dung and Chicken Droppings PDFSergio ArangoPas encore d'évaluation

- The "Tesla of Ecovillages": Tech-Integrated and Regenerative Neighborhood DevelopmentDocument22 pagesThe "Tesla of Ecovillages": Tech-Integrated and Regenerative Neighborhood DevelopmentSuriyah SivakumarPas encore d'évaluation

- Poster - MITAOE - EIA CCDocument1 pagePoster - MITAOE - EIA CCChetan BalRajePas encore d'évaluation

- The Importance and Science of Hydroponics: Presentation By: Sherry Anne Pancho and Kamele SanchezDocument11 pagesThe Importance and Science of Hydroponics: Presentation By: Sherry Anne Pancho and Kamele SanchezTolulope 'Segun AdekoyaPas encore d'évaluation

- Ecosystem Structure and Energy FlowDocument11 pagesEcosystem Structure and Energy FlowSunil 2doPas encore d'évaluation

- The Ultimate Permaculture Gardening for Beginners: Profitable gardening, #3D'EverandThe Ultimate Permaculture Gardening for Beginners: Profitable gardening, #3Pas encore d'évaluation

- The EZ Guide to Aeroponics, Hydroponics and AquaponicsD'EverandThe EZ Guide to Aeroponics, Hydroponics and AquaponicsÉvaluation : 4 sur 5 étoiles4/5 (4)

- Living RoomDocument1 pageLiving RoomNirbhay SinghPas encore d'évaluation

- Wiley English BankingDocument305 pagesWiley English BankingNirbhay Singh100% (1)

- 2 1Document1 page2 1Nirbhay SinghPas encore d'évaluation

- Summarising The Factors, Part-3Document11 pagesSummarising The Factors, Part-3Nirbhay SinghPas encore d'évaluation

- Roof Garden Construction - Step by Step Details PDFDocument3 pagesRoof Garden Construction - Step by Step Details PDFNirbhay SinghPas encore d'évaluation

- RV Prob Distributions PDFDocument44 pagesRV Prob Distributions PDFMrigendra MishraPas encore d'évaluation

- Data For 1st SeminargDocument3 pagesData For 1st SeminargNirbhay SinghPas encore d'évaluation

- Wall Lights: My SuggestionDocument6 pagesWall Lights: My SuggestionNirbhay SinghPas encore d'évaluation

- LIST OF L-6 VENDS OF DSIIDCDocument8 pagesLIST OF L-6 VENDS OF DSIIDCAditya TripathiPas encore d'évaluation

- 2 2Document1 page2 2Nirbhay SinghPas encore d'évaluation

- Structured Query Language Tutorial PDFDocument30 pagesStructured Query Language Tutorial PDFharhahPas encore d'évaluation

- 2 1Document1 page2 1Nirbhay SinghPas encore d'évaluation

- Efficient Multi-Purpose Cycle Stand DesignDocument8 pagesEfficient Multi-Purpose Cycle Stand DesignNirbhay SinghPas encore d'évaluation

- Data Science Interview Questions - 365 QuestionsDocument48 pagesData Science Interview Questions - 365 QuestionsAbhay KumarPas encore d'évaluation

- Roof PlanDocument1 pageRoof PlanNirbhay SinghPas encore d'évaluation

- Hotel PDFDocument1 pageHotel PDFNirbhay SinghPas encore d'évaluation

- Living Standard in Delhi Slums Occupation, Income and Expenditure Pattern of Migrants (A Study of Delhi Slum Migrants)Document13 pagesLiving Standard in Delhi Slums Occupation, Income and Expenditure Pattern of Migrants (A Study of Delhi Slum Migrants)Nirbhay SinghPas encore d'évaluation

- Hotel PDFDocument1 pageHotel PDFNirbhay SinghPas encore d'évaluation

- The Role of Water in Sustainable Architecture: Sposito, CesareDocument7 pagesThe Role of Water in Sustainable Architecture: Sposito, CesareNirbhay SinghPas encore d'évaluation

- Graduation Plan Osama NajiDocument7 pagesGraduation Plan Osama NajiPeter Hilario Nadal PinedaPas encore d'évaluation

- History of Indian ArchitectureDocument2 pagesHistory of Indian ArchitectureNirbhay SinghPas encore d'évaluation

- The Vedic Culture: The Rigvedic AgeDocument50 pagesThe Vedic Culture: The Rigvedic Ageb.sreevatsavaPas encore d'évaluation

- Sociology PresentationDocument31 pagesSociology PresentationNirbhay SinghPas encore d'évaluation

- Hindu Art and Architecture OverviewDocument31 pagesHindu Art and Architecture OverviewAdarsh AgarwalPas encore d'évaluation

- This Paper Explores The Possibility of Making Urban Spaces Delivering Its Potential in Terms of Several FactorsDocument2 pagesThis Paper Explores The Possibility of Making Urban Spaces Delivering Its Potential in Terms of Several FactorsNirbhay SinghPas encore d'évaluation

- For Model To Nirbhay PDFDocument1 pageFor Model To Nirbhay PDFNirbhay SinghPas encore d'évaluation

- Vedic CivilizationDocument12 pagesVedic Civilizationbudimah50% (2)

- Architecture Is The Art of Building Structures of EnclosedDocument11 pagesArchitecture Is The Art of Building Structures of EnclosedNirbhay SinghPas encore d'évaluation

- Importance of Discipline in LifeDocument8 pagesImportance of Discipline in LifeNirbhay Singh75% (4)

- A Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastDocument82 pagesA Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastJacques LeBlanc100% (18)

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDocument7 pagesEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersPas encore d'évaluation

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Document39 pagesPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- India - Wikipedia, The Free EncyclopediaDocument40 pagesIndia - Wikipedia, The Free EncyclopediaPrashanth KrishPas encore d'évaluation

- A6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Document12 pagesA6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Oula HatahetPas encore d'évaluation

- g4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDocument144 pagesg4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDevin DickenPas encore d'évaluation

- IS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableDocument1 pageIS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableReniePas encore d'évaluation

- Discuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?Document4 pagesDiscuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?harryPas encore d'évaluation

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqPas encore d'évaluation

- Baseline Program Rev 3A Presentation 25 July 2020Document24 pagesBaseline Program Rev 3A Presentation 25 July 2020Shakti Sourava RautrayaPas encore d'évaluation

- HSC 405 Grant ProposalDocument23 pagesHSC 405 Grant Proposalapi-355220460100% (2)

- Apollo TyresDocument78 pagesApollo TyresADITYA33% (3)

- Gauss Contest: Grade 8Document4 pagesGauss Contest: Grade 8peter100% (1)

- Datasheet PDFDocument6 pagesDatasheet PDFAhmed ElShoraPas encore d'évaluation

- Embankment PDFDocument5 pagesEmbankment PDFTin Win HtutPas encore d'évaluation

- Revolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationDocument14 pagesRevolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationKIU PUBLICATION AND EXTENSIONPas encore d'évaluation

- ROMUS 2012 Flooring CatalogueDocument20 pagesROMUS 2012 Flooring CatalogueDan George IIIPas encore d'évaluation

- Monster of The Week Tome of Mysteries PlaybooksDocument10 pagesMonster of The Week Tome of Mysteries PlaybooksHyperLanceite XPas encore d'évaluation

- DR-M260 User Manual ENDocument87 pagesDR-M260 User Manual ENMasa NourPas encore d'évaluation

- JY Series Single-Phase Capacitor Induction MotorsDocument1 pageJY Series Single-Phase Capacitor Induction MotorsAditya PrasetyoPas encore d'évaluation

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDocument26 pagesCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikPas encore d'évaluation

- 07.03.09 Chest Physiotherapy PDFDocument9 pages07.03.09 Chest Physiotherapy PDFRakesh KumarPas encore d'évaluation

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 pagesLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- De Thi HSG Tinh Binh PhuocDocument9 pagesDe Thi HSG Tinh Binh PhuocDat Do TienPas encore d'évaluation

- Handout Tematik MukhidDocument72 pagesHandout Tematik MukhidJaya ExpressPas encore d'évaluation

- Thermal BurnsDocument50 pagesThermal BurnsPooya WindyPas encore d'évaluation

- Transport of OxygenDocument13 pagesTransport of OxygenSiti Nurkhaulah JamaluddinPas encore d'évaluation

- Canon imageFORMULA DR-X10CDocument208 pagesCanon imageFORMULA DR-X10CYury KobzarPas encore d'évaluation

- Gotham City: A Study into the Darkness Reveals Dangers WithinDocument13 pagesGotham City: A Study into the Darkness Reveals Dangers WithinajPas encore d'évaluation

- Direct From: 1St Quarter 2020Document23 pagesDirect From: 1St Quarter 2020JeanPas encore d'évaluation