Académique Documents

Professionnel Documents

Culture Documents

Technical Information For Drilling Jigs DIN 6348 en

Transféré par

Atthapol YuyaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Information For Drilling Jigs DIN 6348 en

Transféré par

Atthapol YuyaDroits d'auteur :

Formats disponibles

01000

Technical information for DIN 6348 drilling jigs

Using norelem drilling jigs, down times and machine

02000

costs can be saved by significantly reducing the clamping

times. The stress is removed from the design department

and toolmaking through the universal ability to use the

drilling jigs, even for small-scale production runs.

The drill and support plates are prepared dependent on

the bore spacing of the part to be machined. While the

03000

corresponding drill bushes are placed in the drill plate,

fixing pins are attached to the support plate to enable

quick and easy positioning of the part for machining.

Since the drill and supporting plates can be changed

quickly, the drilling jig is immediately available for another

part to be machined.

04000

Version:

The drilling jigs are supplied in 9 sizes. They differ in

terms of the position of the working area relative to the worm gear column

columns. In the case of sizes 0 to 3 the working area is

in front of the columns, in sizes 3 to 5 the working area is

05000

between the columns.

locating-

cone bolts cone

Operating method:

The spiral-geared pinion shaft has cones at both ends.

The axial force of the helical gear drive pulls the cone of

06000

the pinion shaft into a taper bore which is worked into

the casing. The pair of cones at the ends of the pinion

shaft work in opposition to the powerful and consistent adjustable

clamping top and bottom; as a result, the drill plate cannot clamping lever

fall onto hands when the part to be machined is changed.

The clamp holds perfectly and safely, even in case of

07000

vibration. The clamping element can be taken apart and

put together by anyone with no professional knowledge.

housing spiral-geared pinion shaft handgrip

The clamping lever can be changed from left to right-

hand use by loosening the hexagonal bolt on the face of

the right-hand cone. The pinion shaft can now be used

so that the adjustable clamping lever is on the right-hand

08000

side.

The clamp is activated by pressing the lever down and

released by lifting the lever up. The best working position

can be engaged using the adjustable clamping lever, so

the operator can work in a standing or seated position.

09000

20000

21000

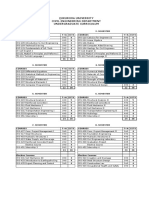

Force tables

Hand force Size

N

0 1 2 2S 3S 3 4 5

22000

Clamping force N

100 600 1200 1250 1250 1300 2800 2900 3800

200 1100 2100 2150 2150 2200 5500 5600 7500

23000

781

Vous aimerez peut-être aussi

- Cardan Shafts: Mounting and Maintenance: Universal Joints: Movement ProgressionDocument1 pageCardan Shafts: Mounting and Maintenance: Universal Joints: Movement ProgressionmesinPas encore d'évaluation

- Hovmand - Handling of ReelsDocument6 pagesHovmand - Handling of ReelsIker BasqueAdventurePas encore d'évaluation

- Module 4.1 Angle MeasurementDocument29 pagesModule 4.1 Angle MeasurementonemillionsubinPas encore d'évaluation

- VRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorDocument8 pagesVRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorAlexandrFedyukPas encore d'évaluation

- VRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorDocument4 pagesVRM KL RDM: Hydraulic Casing Oscillator Hydraulic Casing RotatorАнтонPas encore d'évaluation

- IMG - 1801301 Chumacera Tunel PDFDocument31 pagesIMG - 1801301 Chumacera Tunel PDFJuan Isaac PerezPas encore d'évaluation

- First For Professionals: Torque WrenchesDocument9 pagesFirst For Professionals: Torque WrenchesAnonymous as5qbwfePas encore d'évaluation

- Shock Sub Tool: Impact and Vibration Reduction ToolDocument4 pagesShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Euronorm Slewing Rings Manual (ENG)Document8 pagesEuronorm Slewing Rings Manual (ENG)Gladwin JesPas encore d'évaluation

- Shock Sub BRDocument4 pagesShock Sub BRJose Manuel Lezama SantaellaPas encore d'évaluation

- 2 Burners Gas Boiling Tops: Range CompositionDocument2 pages2 Burners Gas Boiling Tops: Range CompositionAnuta CosminPas encore d'évaluation

- Vertical Clamp CouplingDocument2 pagesVertical Clamp Couplingali tabePas encore d'évaluation

- Sf6 Insulated Metal-Enclosed Switchgears Type Cbgs-0 51083900MO-IDocument6 pagesSf6 Insulated Metal-Enclosed Switchgears Type Cbgs-0 51083900MO-IGANIMPas encore d'évaluation

- Sandvik DL430Document2 pagesSandvik DL430Nelson MezaPas encore d'évaluation

- Only!: Liftcrane Boom Capacities MLC650 Series 3Document7 pagesOnly!: Liftcrane Boom Capacities MLC650 Series 3Felipe Schönffeldt Torres100% (1)

- Bozza Catalogo Pubblicitario 07-02-2019Document10 pagesBozza Catalogo Pubblicitario 07-02-2019МаксимPas encore d'évaluation

- Induction Tops: Range CompositionDocument5 pagesInduction Tops: Range CompositionAnuta CosminPas encore d'évaluation

- Masson Selection-Guide-2021-Light PDFDocument76 pagesMasson Selection-Guide-2021-Light PDFchgm.ts.udpPas encore d'évaluation

- LICO Light Weight Column FormworkDocument8 pagesLICO Light Weight Column FormworkSarinPas encore d'évaluation

- Katalog en SDocument24 pagesKatalog en SmadhavikPas encore d'évaluation

- Pile Pull Out Rehmat Floor MillDocument12 pagesPile Pull Out Rehmat Floor MillMuzammil MustafaPas encore d'évaluation

- All Gear Lathe MachineDocument2 pagesAll Gear Lathe MachineMihir Machine Tools Gujarat Pvt LtdPas encore d'évaluation

- Experimentation & Instrumentation MECH 212: Experiment 5: Universal CouplingDocument16 pagesExperimentation & Instrumentation MECH 212: Experiment 5: Universal CouplingTanya DeebPas encore d'évaluation

- Rohm PuntaDocument3 pagesRohm PuntamikadoturkPas encore d'évaluation

- AMAWELD Catalogue NEWDocument8 pagesAMAWELD Catalogue NEWJoshita YoPas encore d'évaluation

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaPas encore d'évaluation

- SS & SC All Gear Lathe MachineDocument2 pagesSS & SC All Gear Lathe MachineMihir Machine Tools Gujarat Pvt LtdPas encore d'évaluation

- Ballscrew Product Specifications 13 14Document2 pagesBallscrew Product Specifications 13 14harryPas encore d'évaluation

- Manual Wedge Action GripsDocument3 pagesManual Wedge Action GripsAnilPas encore d'évaluation

- LICODocument16 pagesLICOAmrPas encore d'évaluation

- Uwf 12Document1 pageUwf 12Frederik HenderwanzaPas encore d'évaluation

- D1 D19 (Vertex 33)Document19 pagesD1 D19 (Vertex 33)Giane NavasPas encore d'évaluation

- Untitled 4Document1 pageUntitled 4chinsy83Pas encore d'évaluation

- Positioner Technical Specification: Welding/Cutting Expert For Over 20 YearsDocument3 pagesPositioner Technical Specification: Welding/Cutting Expert For Over 20 YearsdinescPas encore d'évaluation

- Safety Regulations For The Use of Lifting Eye Bolts and Lifting Eye NutsDocument2 pagesSafety Regulations For The Use of Lifting Eye Bolts and Lifting Eye NutsGorkaPas encore d'évaluation

- MD 0431 RevNR (Understanding Torque Angle Signatures of Bolted Joints White Paper)Document15 pagesMD 0431 RevNR (Understanding Torque Angle Signatures of Bolted Joints White Paper)سید حسین عارفیPas encore d'évaluation

- Selection Guide VF 2020Document73 pagesSelection Guide VF 2020Nurburgringo BZHPas encore d'évaluation

- 2015-EMUGE SOFTSYNCHRO CATALOG Web Rev04-18Document20 pages2015-EMUGE SOFTSYNCHRO CATALOG Web Rev04-18Umesh LahorkarPas encore d'évaluation

- Britool TORQUE WRENCH PDFDocument2 pagesBritool TORQUE WRENCH PDFfarooq929Pas encore d'évaluation

- Laser Cutting Machine Infinity f1Document6 pagesLaser Cutting Machine Infinity f1Divyaba DodiyaPas encore d'évaluation

- sqm5 SiemensDocument6 pagessqm5 SiemensEdgar ChavezPas encore d'évaluation

- Shaft Alignment Excel SheetDocument5 pagesShaft Alignment Excel Sheetpollekeshooter100% (1)

- Bost VTCDocument13 pagesBost VTCPrasannaPas encore d'évaluation

- Only!: Liftcrane Boom Capacities MLC650 Series 1Document5 pagesOnly!: Liftcrane Boom Capacities MLC650 Series 1Felipe Schönffeldt TorresPas encore d'évaluation

- Technical Information For Toggle Clamps enDocument1 pageTechnical Information For Toggle Clamps enIvkraPas encore d'évaluation

- HF DiemasterDocument18 pagesHF DiemasteralphatoolsPas encore d'évaluation

- Soil Mixing Wall System: Product InformationDocument8 pagesSoil Mixing Wall System: Product Informationnoto.sugiartoPas encore d'évaluation

- 9361BM (MB-S2 Blocked)Document7 pages9361BM (MB-S2 Blocked)Felipe Schönffeldt TorresPas encore d'évaluation

- Wittur Range of Systems: Machine Roomless EfficiencyDocument16 pagesWittur Range of Systems: Machine Roomless EfficiencyLe Huynh LongPas encore d'évaluation

- Data-Sheet Slip JointDocument4 pagesData-Sheet Slip Jointamit02mechPas encore d'évaluation

- Defender-S: NJZ-FEL-C SeriesDocument6 pagesDefender-S: NJZ-FEL-C SeriesjeorginagPas encore d'évaluation

- Interaction DiagramDocument8 pagesInteraction DiagramGregory BrownPas encore d'évaluation

- Mahr CaliperDocument45 pagesMahr CalipercengkunetPas encore d'évaluation

- HNK - H BorerDocument26 pagesHNK - H Boreragri.mariadasPas encore d'évaluation

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheD'EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Mech 211 - Lecture 1Document90 pagesMech 211 - Lecture 1Nancy PierrePas encore d'évaluation

- Mujiarto 2018 IOP Conf. Ser. Mater. Sci. Eng. 306 012090Document7 pagesMujiarto 2018 IOP Conf. Ser. Mater. Sci. Eng. 306 012090Atthapol YuyaPas encore d'évaluation

- Mechanical Engineering Drawing WorkshopDocument158 pagesMechanical Engineering Drawing Workshopjeswin johnsonPas encore d'évaluation

- ME170 Term Design Project - Details-Fa2019Document6 pagesME170 Term Design Project - Details-Fa2019Atthapol YuyaPas encore d'évaluation

- Mech 211 - Lecture 1Document90 pagesMech 211 - Lecture 1Nancy PierrePas encore d'évaluation

- Mechanical Engineering Architecture and Building Printing and BDocument43 pagesMechanical Engineering Architecture and Building Printing and BAtthapol YuyaPas encore d'évaluation

- Drafting 9-12 BibDocument33 pagesDrafting 9-12 BibAtthapol YuyaPas encore d'évaluation

- Engineering DrawingDocument240 pagesEngineering DrawingKhelly Shan C. Sta. RitaPas encore d'évaluation

- Engineering Drawing PracticesDocument32 pagesEngineering Drawing Practicestrungkien1100% (1)

- Engineering Drawing 1st Sem FinalDocument122 pagesEngineering Drawing 1st Sem FinalGopal LoharPas encore d'évaluation

- Engineering Working Drawing BasicsDocument22 pagesEngineering Working Drawing BasicssathishjeyPas encore d'évaluation

- TechDraw IUG 2012-2013 PDFDocument153 pagesTechDraw IUG 2012-2013 PDFvcock6109Pas encore d'évaluation

- Engineering DrawingDocument30 pagesEngineering DrawingDeepak MmechPas encore d'évaluation

- Drawing and EstimatesDocument359 pagesDrawing and EstimatesceanilPas encore d'évaluation

- 2019 Tech Support Price BookDocument18 pages2019 Tech Support Price BookAtthapol YuyaPas encore d'évaluation

- Civil Engineers DrawingDocument67 pagesCivil Engineers Drawingthusharajcl100% (9)

- Çukurova University Civil Engineering Department Undergraduate CurriculumDocument9 pagesÇukurova University Civil Engineering Department Undergraduate CurriculumAtthapol YuyaPas encore d'évaluation

- Chemical Engineering DrawingDocument3 pagesChemical Engineering DrawingNasrul ZA ST MT0% (1)

- Linking Design, Analysis, Manufacture and Test in The Engineering Student ExperienceDocument6 pagesLinking Design, Analysis, Manufacture and Test in The Engineering Student ExperienceAtthapol YuyaPas encore d'évaluation

- Am09 PDFDocument10 pagesAm09 PDFnavneetkpatil8409Pas encore d'évaluation

- Drafting 9-12 BibDocument33 pagesDrafting 9-12 BibAtthapol YuyaPas encore d'évaluation

- UG NX DraftingDocument17 pagesUG NX DraftingAhmed BdairPas encore d'évaluation

- Technical Drawing - Grade-12 PDFDocument132 pagesTechnical Drawing - Grade-12 PDFGanesh Kumar86% (21)

- Kadi Sarva Vishwavidyalaya: Faculty of Engineering & TechnologyDocument5 pagesKadi Sarva Vishwavidyalaya: Faculty of Engineering & TechnologyLiyanshu patelPas encore d'évaluation

- FD DL1207 Descr Geometry and Tech Drawing TCM EngDocument4 pagesFD DL1207 Descr Geometry and Tech Drawing TCM EngAtthapol YuyaPas encore d'évaluation

- Orthographic 1Document27 pagesOrthographic 1Atthapol YuyaPas encore d'évaluation

- Plumbing Engineering Design Handbook - A Plumbing Engineer's Guide To System Design and Specifications, Volume 1 - Fundamentals of Plumbing EngineeringDocument396 pagesPlumbing Engineering Design Handbook - A Plumbing Engineer's Guide To System Design and Specifications, Volume 1 - Fundamentals of Plumbing EngineeringMUBASHIRPas encore d'évaluation

- Engineering Drawing - N. D. BhattDocument129 pagesEngineering Drawing - N. D. BhattAsh71% (17)

- Mechanical Engineering Drawing WorkshopDocument158 pagesMechanical Engineering Drawing Workshopjeswin johnsonPas encore d'évaluation

- ME113 Wk10&11 Ch08Document128 pagesME113 Wk10&11 Ch08Atthapol YuyaPas encore d'évaluation

- PythagorasDocument109 pagesPythagorasaditya00012Pas encore d'évaluation

- EConsole1 Quick Start Guide ENGDocument21 pagesEConsole1 Quick Start Guide ENGManuel Casais TajesPas encore d'évaluation

- Anue 3500 Qrs - 0Document2 pagesAnue 3500 Qrs - 0ullascsPas encore d'évaluation

- فيزياء لغات ثانوية عامة أنجليزى-webDocument462 pagesفيزياء لغات ثانوية عامة أنجليزى-webMohamed RayanyPas encore d'évaluation

- Drop ForgingDocument18 pagesDrop ForgingpunkhunkPas encore d'évaluation

- Tribology Module 01 NotesDocument19 pagesTribology Module 01 NotesVinayaka G P89% (9)

- A Comparative Study On The Academic Performance ofDocument18 pagesA Comparative Study On The Academic Performance ofDiether Allen L. YnionPas encore d'évaluation

- Reverse Circulation Cementing: The Complete PictureDocument104 pagesReverse Circulation Cementing: The Complete PictureJoan Corso100% (1)

- Pneumatic Conveying of Bulk Solids PDFDocument231 pagesPneumatic Conveying of Bulk Solids PDFCarloLopez100% (2)

- Checklist For Conreting WorkDocument13 pagesChecklist For Conreting WorkMin Khant AungPas encore d'évaluation

- Symmetries and Conservation Laws-Consequences of Noether TheoremDocument8 pagesSymmetries and Conservation Laws-Consequences of Noether TheoremmastinaropuruPas encore d'évaluation

- Biomechanic of Foot PDFDocument8 pagesBiomechanic of Foot PDFMichealowen BabygoalPas encore d'évaluation

- Three - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureDocument6 pagesThree - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureWenjun ZhangPas encore d'évaluation

- Business Analytics Data Analysis and Decision Making 6th Edition Albright Solutions ManualDocument24 pagesBusiness Analytics Data Analysis and Decision Making 6th Edition Albright Solutions ManualAngelaLewisyqza100% (26)

- Chapter 1 IntroductionDocument49 pagesChapter 1 IntroductionGemex4fshPas encore d'évaluation

- North Sails Brochure 2007 enDocument24 pagesNorth Sails Brochure 2007 ennorthsailsPas encore d'évaluation

- Steam Turbine ProtectionDocument5 pagesSteam Turbine ProtectionRajesh P100% (1)

- TitleDocument142 pagesTitleAmar PašićPas encore d'évaluation

- How Convert A Document PDF To JpegDocument1 pageHow Convert A Document PDF To Jpegblasssm7Pas encore d'évaluation

- VT300 User ManualDocument21 pagesVT300 User ManualLuvPas encore d'évaluation

- RomerDocument20 pagesRomerAkistaaPas encore d'évaluation

- SpaceClaim - Developers Guide-5-6Document2 pagesSpaceClaim - Developers Guide-5-6Alexgh1993Pas encore d'évaluation

- Lab 6Document12 pagesLab 6Sujan HeujuPas encore d'évaluation

- Unit Exam 5Document3 pagesUnit Exam 5Rose AstoPas encore d'évaluation

- CSIE Fisa Disciplina - Baze de DateDocument4 pagesCSIE Fisa Disciplina - Baze de DateCostin CheluPas encore d'évaluation

- Synthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesDocument6 pagesSynthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesAnonymous yNMZplPbVPas encore d'évaluation

- Introduction To PercolationDocument25 pagesIntroduction To Percolationpasomaga100% (1)

- ATR4518R2Document2 pagesATR4518R2estebanarca50% (4)

- Various Image Enhancement Techniques-A Critical Review: S.S. Bedi, Rati KhandelwalDocument5 pagesVarious Image Enhancement Techniques-A Critical Review: S.S. Bedi, Rati KhandelwalArina AndriesPas encore d'évaluation