Académique Documents

Professionnel Documents

Culture Documents

Product Sheet 1 en PDF

Transféré par

nishant_dreamviewer0 évaluation0% ont trouvé ce document utile (0 vote)

48 vues4 pagesTitre original

product-sheet-1-en.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

48 vues4 pagesProduct Sheet 1 en PDF

Transféré par

nishant_dreamviewerDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

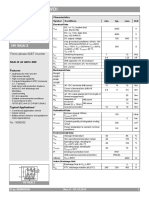

Technical Data Sheet

Dobeckot 605 + Hardener 758

Two-component epoxy based trickle impregnation resin

January 2018

ELANTAS Beck India Ltd.

Marketing Head Office,

147, Mumbai Pune road,

Pimpri,

Pune 411018

India

Tel +91 20 30610 800

Fax +91 20 30610 792

www.elantas.com/beck-india

Description shrinkage this combination also cures

Dobeckot 605 designates a solvent-free, without cracks in thick layers and can thus

low viscous, epoxy based trickle resin. also be used to protect the windings, e.g.

Furthermore, this combination is noted for from carbon brush abrasion or abrasive

its very good penetration, especially for dusts .

windings with thin wires. Application Method

Hardener 758 is a polyamine with a slightly Dobeckot 605 in combination with

yellow and transparent appearance and a hardener 758 can be processed in all

low physiological effectiveness. conventional trickling plants. For a better

penetration it is of advantage to reduce the

Curing of the resin compound is a viscosity of the resin by slightly raising the

polyaddition reaction, which occurs under heating temperature. In accordance with

the effect of heat until a duroplastic cured the trickle impregnation principle, a thin

material is produced. stream of the activated resin is applied to

Polymerisation is initiated by mixing the the rotating and heated winding. The resin

two components and under the effect of immediately adopts the temperature of the

heat proceeds as a rapid chain-reaction windings, becomes considerably more

until a three-dimensionally cross-linked, thin-fluid and distributes itself uniformly

duroplastic cured material is produced The throughout the winding as a result of

material does not contain by recipe rotation and capillary forces. The pre-

substances listed in Restriction of heating temperature of the objects should

Hazardous Substances (RoHS) Directive

range between 80°C and 120°C. Gelling

(2002/95/EC)

and curing usually occurs in a circulating air

Areas of Application

oven or by current heating under rotation.

Preferred applications for Dobeckot 605

The typical trickle process parameters are

trickle resin combined with hardener 758:

as follows :

Repair shops

Windings of machines with high Pre-heating to 100-110°C for 2-15

chemical requirements min.,

Armatures of hand tools, household rotation 20-30 rpm, inclination angle

machines, universal motors, etc. 8-10°

Properties of cured material Trickling and gelling at 90-100°C

After curing there is a hard cured material,

Curing at 120-130°C for 5-30 min

which is noted for its exceptional adhesion

to various materials. The cured material . Cleaning

also displays very good resistance to Uncured resin can be easily cleaned by

tropical influences, solvents, weak washing with hot detergent solution,

lyesalkalies as well as oil and allows acetone or Thinner 221. It is difficult to

impregnated objects to be used even remove cured resin and for this reason

under extreme conditions. tools and containers contaminated with

The high bonding strength of this resin + hardener mixture should be

combination imparts good mechanical cleaned immediately after use.

stability to the impregnated windings The

combination Dobeckot 605 plus Hardener

758 can be used for machines in thermal

class B (1300C). Owing to low volume

Dobeckot 605 + Hardener 758 Page 2 of 4 Rev 8, Jan 2018

Properties of Dobeckot 605 as supplied

Colour & appearance [*] DBI 1001[**] Colourless to

brownish yellow clear

Viscosity at 25oC[*] DBI 3005 [**] Brookfield mPa.s 1200-1400

Density at 23oC ISO 1675 g/ml 1.160- 1.163

Epoxy Equivalent[*] DBI 1041[**] 180-220

Flash point DBI 1005 [**] (closed cup) oC > 100

Storage stability [*] When stored in original sealed months 12

container at R.T

[*] These properties form our sales specification.

[**] DBI are internal test methods and are available on request

Properties of Hardener 758 as supplied

Chemical base Polyamine

Colour & Appearance [*] DBI 1001[**] Pale yellow, pale

brown clear liquid

Viscosity at 250C[*] DBI 3005[**] mPa.s 15-35

Density at 250C DBI 1002[**] 0.972-0.982

Flash point DBI 1005[**] (open cup) 0C > 100

Amine Value[*] DBI 1012 [**] 1290-1410

Storage Stability [*] When stored in sealed in months 12

original container at R.T.

Mixing Proportions & Pot life

Mixing proportion Dobeckot 605 + Hardener 758 pbw 100 : 10

Gelling & recommended Curing Cycle :

Gelling time at 80oC ISO 2535 min 2 (typical)

2 to 5 minutes at 80 -100°C (for trickle impregnation). For windings with higher mechanical

stresses such as angle grinder armatures; post curing of 1 at 120°C is suggested in addition

to 5 minutes curing at 120°C on trickle machines.

Cured Film Properties :

at RT 350N

Bond Strength IEC 61033

at 130° 55N

Hardness Shore D 75

Temperature Index

Temperature index IEC 60216 30% wt. loss criteria °C 130

Dobeckot 605 + Hardener 758 Page 3 of 4 Rev 8, Jan 2018

o

Dielectric Properties Specimen Curing – 16 h at R.T + 4h at 80 C

Dielectric strength as per 20

at RT kV/mm

IEC 60455-2

15

Volume resistivity at 500 V at RT 10

ohm.cm 14

DC as per IEC 60455-2 after 168 h water immersion at R.T. 10

Dielectric constant at 30 V/1 at RT

0 - NT

kHz as per IEC 60455-2 at 155 C

Tracking Index IEC 60112 At 200V,no. of > 300

drops

Adhesive strength at R.T. N/mm2 15

4 sq.cm M.S to M.S Joint at 1300C 1.3

Resistance against solvents & chemicals

Solvent resistance as per IEC 10% H2SO4 No Change in colour -

60455-2 2% NaOH -

No Change in colour

Packaging

Dobeckot 605 : 1,5, 30& 210 kg containers

Hardener 758 : 0.05,0.25,1,5 & 30 kg in polyethyle containers.

Hardener 758 on long storage has tendency to crystallize. Whitish particles formed due to

this can be mixed by slight warming Hardener 758 in the original bottle in warm water. Such

crystallization does not affect the curing performance.

.

Safe Handling

Dobeckot 605 + Hardener 758 is a flammable liquid. Use foam, CO2 or dry chemical powder

for fire fighting. Inhalation and direct contact with the skin should be avoided. In case of

contact, the affected area should be washed with soap and plenty of water. For further

details refer respective material safety data sheet.

Desclaimer

This information is intended only for general guidance in the application of our product. It

has been obtained by careful investigation and represents the present state of our

knowledge and experience. Because of the large number of possible methods of application

and processing we are not able to assume responsibility in any one particular case for either

the technical results or the patent rights situation applicable to the country under

consideration

Technical Services Department Regional Offices:

147, Mumbai-Pune Road, • Bengaluru: Tel: (080) 6792 0871, 6792 0872

Pimpri, • New Delhi: Tel: (011) 2341 1664, 2341 2940

Pune 411018 Fax: 2341 3408

India • Pune: Tel: (020) 30610673

Tel +91 20 30610 721/722 Fax: 30610792

Fax +91 20 30610 880 • Kolkata: : Ph:033-44000500

Dobeckot 605 + Hardener 758 Page 4 of 4 Rev 8, Jan 2018

Vous aimerez peut-être aussi

- Elantas Gel Coat Redproduct-Sheet-1-EnDocument4 pagesElantas Gel Coat Redproduct-Sheet-1-EnAjay AbrahamPas encore d'évaluation

- Elantas 50VTDocument4 pagesElantas 50VTAjay AbrahamPas encore d'évaluation

- Elantas B-6-665product-Sheet-1-EnDocument4 pagesElantas B-6-665product-Sheet-1-EnAjay AbrahamPas encore d'évaluation

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- Elantas 51JDocument4 pagesElantas 51JAjay AbrahamPas encore d'évaluation

- Jyoti Resin 1520F and Hardener 1758 - E Potting CompoundDocument5 pagesJyoti Resin 1520F and Hardener 1758 - E Potting CompoundBabyboy2010Pas encore d'évaluation

- Jyoti H171 A - H Impregnating VarnishDocument3 pagesJyoti H171 A - H Impregnating VarnishBabyboy2010Pas encore d'évaluation

- Dobeckot EH-411 & 505CDocument2 pagesDobeckot EH-411 & 505CDeependraPas encore d'évaluation

- Shimocast 101 H Is 32Document4 pagesShimocast 101 H Is 32HenriquecardososPas encore d'évaluation

- Ancamine 2739 TdsDocument8 pagesAncamine 2739 Tdsnc5r8fkp6zPas encore d'évaluation

- F F o P L: Aquapoxy - 3800Document3 pagesF F o P L: Aquapoxy - 3800Karishma PrabhuPas encore d'évaluation

- 8936 - Crestapol 1080 Crestapol en Mar16Document4 pages8936 - Crestapol 1080 Crestapol en Mar16Marjan ArhPas encore d'évaluation

- VA42Document4 pagesVA42Ike EvelynePas encore d'évaluation

- Jyoti 151J - H Impregnating VarnishDocument3 pagesJyoti 151J - H Impregnating VarnishBabyboy2010Pas encore d'évaluation

- Sikalastic®-851: Product Data SheetDocument3 pagesSikalastic®-851: Product Data Sheetprem prakash mishraPas encore d'évaluation

- Sikalastic®-851: Product Data SheetDocument3 pagesSikalastic®-851: Product Data SheetHo Sy ToanPas encore d'évaluation

- TDS LF-361Document2 pagesTDS LF-361ofershochetPas encore d'évaluation

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetPas encore d'évaluation

- 745Document2 pages745idrees.theheroPas encore d'évaluation

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliPas encore d'évaluation

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtPas encore d'évaluation

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosPas encore d'évaluation

- Bel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1Document2 pagesBel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1xxx yyyPas encore d'évaluation

- Araldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFDocument8 pagesAraldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFneerajaPas encore d'évaluation

- HQ 800 AF 45-gb Rev 10Document1 pageHQ 800 AF 45-gb Rev 10Marjan ArhPas encore d'évaluation

- Vitralit 1650 English Tds Panacol AdhesiveDocument4 pagesVitralit 1650 English Tds Panacol Adhesivetito3007Pas encore d'évaluation

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroPas encore d'évaluation

- Product Description: Properties Unit Value ASTM MethodDocument2 pagesProduct Description: Properties Unit Value ASTM Methodkhaled aymanPas encore d'évaluation

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmPas encore d'évaluation

- Ancamine 2740 TdsDocument5 pagesAncamine 2740 Tdsnc5r8fkp6zPas encore d'évaluation

- Stycas 2850Document2 pagesStycas 2850die6o_brPas encore d'évaluation

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuPas encore d'évaluation

- 2.slide 1Document52 pages2.slide 1Radhashyam GiriPas encore d'évaluation

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriPas encore d'évaluation

- Shell Gadus S2 U1000: High Performance Heavy Duty GreaseDocument2 pagesShell Gadus S2 U1000: High Performance Heavy Duty Greasenutchai2538Pas encore d'évaluation

- TDS of Metlok 703Document2 pagesTDS of Metlok 703idrees.theheroPas encore d'évaluation

- Loctite PC 7227™: Technical Data SheetDocument3 pagesLoctite PC 7227™: Technical Data SheetMohsin ModiPas encore d'évaluation

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliPas encore d'évaluation

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Besoflex- TX 000 (2) (3) (1) (8)Document2 pagesBesoflex- TX 000 (2) (3) (1) (8)TRIFLOW INDIAPas encore d'évaluation

- 4x-Datasheet BONDiT B-481Document4 pages4x-Datasheet BONDiT B-481Marco BrolloPas encore d'évaluation

- Exact 8201Document2 pagesExact 8201Kashif MuhammadPas encore d'évaluation

- Brochure TDS RedisetLQ 1106Document1 pageBrochure TDS RedisetLQ 1106Iwan ShofyanPas encore d'évaluation

- Techn I Cured 10Document1 pageTechn I Cured 10Vicky MishraPas encore d'évaluation

- Shell Alvania Grease CG: For Couplings Used in Industrial EquipmentDocument3 pagesShell Alvania Grease CG: For Couplings Used in Industrial EquipmentOrlando MantillaPas encore d'évaluation

- Epofine 404 - Finehard 2404Document3 pagesEpofine 404 - Finehard 2404Karishma PrabhuPas encore d'évaluation

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaPas encore d'évaluation

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonPas encore d'évaluation

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthPas encore d'évaluation

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezPas encore d'évaluation

- POLYGLASS TapeDocument3 pagesPOLYGLASS Tapetesting eiplPas encore d'évaluation

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziPas encore d'évaluation

- Corocrete Eng A4 20090807Document3 pagesCorocrete Eng A4 20090807andriPas encore d'évaluation

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahPas encore d'évaluation

- Documents-639 - Albida Grease EP2 (PDS)Document2 pagesDocuments-639 - Albida Grease EP2 (PDS)aryawigiPas encore d'évaluation

- TDS LF-350Document1 pageTDS LF-350Ofer ShochetPas encore d'évaluation

- Epoxylite® E478Document4 pagesEpoxylite® E478pedro maiaPas encore d'évaluation

- EP 520 EPC 520 Rev. 3Document2 pagesEP 520 EPC 520 Rev. 3yoniPas encore d'évaluation

- Loctite 7232 High Temperature Wear Resistant Putty: Product Description SheetDocument1 pageLoctite 7232 High Temperature Wear Resistant Putty: Product Description SheetjohnPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- DRM127 PDFDocument77 pagesDRM127 PDFKhalid KhassawnehPas encore d'évaluation

- Skai 45 A2 Gd12-WdiDocument9 pagesSkai 45 A2 Gd12-Wdinishant_dreamviewerPas encore d'évaluation

- M8 (5x) 10-Polig Pin 1 14-Polig Pin 1: Innovation + ServiceDocument1 pageM8 (5x) 10-Polig Pin 1 14-Polig Pin 1: Innovation + Servicenishant_dreamviewerPas encore d'évaluation

- Skai 90 A2 Gd06-Wci 14282034Document12 pagesSkai 90 A2 Gd06-Wci 14282034nishant_dreamviewerPas encore d'évaluation

- SKAI 48 B3 MD 15 P (Target)Document4 pagesSKAI 48 B3 MD 15 P (Target)nishant_dreamviewerPas encore d'évaluation

- A123 PRODUCT SPEC FOR 8ah LFP CELLDocument9 pagesA123 PRODUCT SPEC FOR 8ah LFP CELLnishant_dreamviewerPas encore d'évaluation

- Product Sheet 1 en PDFDocument4 pagesProduct Sheet 1 en PDFnishant_dreamviewerPas encore d'évaluation

- PHMSA Form 10 Standard Breakout Tank Insp 2008Document21 pagesPHMSA Form 10 Standard Breakout Tank Insp 2008Irvansyah RazadinPas encore d'évaluation

- Origins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsDocument11 pagesOrigins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsEstefania GrisalesPas encore d'évaluation

- Phase I document covers states of matter basicsDocument41 pagesPhase I document covers states of matter basicsdivakarsPas encore d'évaluation

- Fisher Paykel Cosycot - Manual de Funcionamiento PDFDocument133 pagesFisher Paykel Cosycot - Manual de Funcionamiento PDFpirihuey1234Pas encore d'évaluation

- Bbe ProductDocument9 pagesBbe Productbackkomster6439Pas encore d'évaluation

- Air Pollution Control Technology Fact Sheet: EPA-452/F-03-017Document0 pageAir Pollution Control Technology Fact Sheet: EPA-452/F-03-017widhisaputrawijayaPas encore d'évaluation

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocument9 pagesRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Formohammed karasnehPas encore d'évaluation

- Laboratory Manual Machine Shop 1 PDFDocument59 pagesLaboratory Manual Machine Shop 1 PDFVinz Bryan AlmacenPas encore d'évaluation

- Protective Paints For Heat Treatment of SteelsDocument4 pagesProtective Paints For Heat Treatment of SteelsMauricio Cesar DalzochioPas encore d'évaluation

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument4 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton miranda100% (1)

- Synthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDocument3 pagesSynthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDabasish DekaPas encore d'évaluation

- Presentation On Forged Mill Balls Production in South AfricaDocument23 pagesPresentation On Forged Mill Balls Production in South AfricaRamoutar (Ken) SeecharranPas encore d'évaluation

- Project Content ChemistryDocument6 pagesProject Content ChemistryPrathmesh MorePas encore d'évaluation

- Congreso Ccps 2013Document116 pagesCongreso Ccps 2013gustav agudeloPas encore d'évaluation

- RocksDocument5 pagesRocksangelic dailyPas encore d'évaluation

- Common polyatomic ions and their formulasDocument16 pagesCommon polyatomic ions and their formulasskyline aviationPas encore d'évaluation

- Screw Gluing Pressure Distribution and Bond StrengthDocument10 pagesScrew Gluing Pressure Distribution and Bond Strengthm2auPas encore d'évaluation

- ASTM C-1196-09 Standard Test Method For in Sity Compressive Stress Within Solid Unit Masonry Estimated Using Flatjack Measurements PDFDocument6 pagesASTM C-1196-09 Standard Test Method For in Sity Compressive Stress Within Solid Unit Masonry Estimated Using Flatjack Measurements PDFAlejandro JiménezPas encore d'évaluation

- The Chemicals of LifeDocument12 pagesThe Chemicals of LifeGabriel XuerebPas encore d'évaluation

- CIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Document11 pagesCIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Edgar Barrios JPas encore d'évaluation

- BHCN 2700 TS 20249C 1020 EnglishDocument40 pagesBHCN 2700 TS 20249C 1020 EnglishandersonPas encore d'évaluation

- Experiment No. 4: Standardization of Sodium Thiosulphate Solution With A Standard Potassium Dichromate SolutionDocument20 pagesExperiment No. 4: Standardization of Sodium Thiosulphate Solution With A Standard Potassium Dichromate Solutionshiam50% (2)

- DPP 10th CBSE Week 1 of JulyDocument6 pagesDPP 10th CBSE Week 1 of JulyYash KapoorPas encore d'évaluation

- Nu 5100 5100eg HalfDocument19 pagesNu 5100 5100eg HalfCristian AedoPas encore d'évaluation

- COMPACT 99B Inlet Valve ManualDocument4 pagesCOMPACT 99B Inlet Valve Manualalwill09Pas encore d'évaluation

- Internship ReportDocument31 pagesInternship ReportShashidhara AEPas encore d'évaluation

- NORD-Painting CodeDocument3 pagesNORD-Painting CodeubabPas encore d'évaluation

- ReasoningDocument43 pagesReasoningrajkh0786Pas encore d'évaluation

- Acid BassDocument41 pagesAcid BassRobert Edwards100% (1)

- Latitude Travel Iron: Instructions For UseDocument9 pagesLatitude Travel Iron: Instructions For UseNickPas encore d'évaluation