Académique Documents

Professionnel Documents

Culture Documents

Hydrocracking Processes 39

Transféré par

Annu RawatCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hydrocracking Processes 39

Transféré par

Annu RawatDroits d'auteur :

Formats disponibles

The ebullating oil flow is controlled by varying the speed of the

ebullating pump. Within the reactor, the ebullating liquid is drawn into

a conical collecting pan, located several feet above the catalyst bed

interface to ensure catalyst-free liquid circulation down the internal stand

pipe and into external ebullating pump. The ebullating liquid is distrib-

uted through the reactor bottom by its individual sparger.

The height of the fluidized bed of the catalyst in the reactor is related to

the gas flow rate, the liquid flow rate, and the physical properties of the

fluid, which in turn are affected by the operating temperature and pres-

sure, conversion, size, density, and shape of the catalyst particles. All

these parameters are maintained within the constraints imposed by these

correlations.

RESID HYDROCRACKER UNITS

The feed to resid hydrocracker is crude unit vacuum bottoms. Fresh

feed is mixed with a heavy vacuum gas oil diluent. The combined feed

enters surge drum V-33, is pumped to feed heater H-Ol then mixed with

high-pressure recycled hydrogen gas, is preheated in H-02 in mixers, then

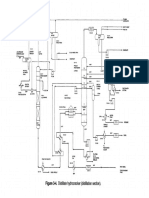

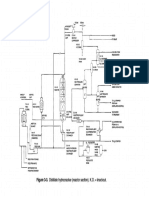

fed to the reactor V-Ol at about 7500F and 2450psig (see Figure 3-13).

Ebullation pump P-02 maintains circulation to keep catalyst particles

in suspension. The catalyst bed level is monitored by a radioactive source.

Fresh catalyst is added to the reactor and spent catalyst is withdrawn from

the reactor periodically to maintain the catalyst level.

The reactor effluent flows as a vapor/liquid mixture into vapor/liquid

separator V-02. The vapor from separator drum is a hydrogen-rich stream

containing equilibrium quantities of hydrocarbon reaction products. The

liquid is composed essentially of heavier hydrocarbon products from

resid hydrocracking reactions and unconverted feed. The hot flash liquid

contains an appreciable amount of dissolved hydrogen and light ends. The

flash vapor leaving V-02 is cooled with light distillate in exchanger E-02.

The cooled vapor effluent is then fed to primary distillate knockout drum

V-03 for removal of condensed liquid. Vapor from V-03 is further cooled

to about 1400F in air cooler E-03 and then enters distillate separator drum

V-04. On leaving separator V-04, the hydrogen-rich gas is split into two

streams. The larger stream is compressed to approximately 2700 psig in

a recycle gas compressor and returned to the reactor V-Ol as recycled

gas. The smaller purge gas stream is withdrawn as purge to maintain the

purity of the recycled gas.

Vous aimerez peut-être aussi

- Hydrocracking Processes 21Document1 pageHydrocracking Processes 21Annu RawatPas encore d'évaluation

- Hydrocracking Processes 25Document1 pageHydrocracking Processes 25Annu RawatPas encore d'évaluation

- Hydrocracking Processes 22Document1 pageHydrocracking Processes 22Annu RawatPas encore d'évaluation

- Hydrocracking Processes 27Document1 pageHydrocracking Processes 27SameerPas encore d'évaluation

- Hydrocracking Processes 18Document1 pageHydrocracking Processes 18Annu RawatPas encore d'évaluation

- Hydrocracking Processes 17Document1 pageHydrocracking Processes 17Annu RawatPas encore d'évaluation

- Hydrocracking Processes 16Document1 pageHydrocracking Processes 16Annu RawatPas encore d'évaluation

- Hydrocracking Processes 20Document1 pageHydrocracking Processes 20Annu RawatPas encore d'évaluation

- Hydrocracking Processes 19Document1 pageHydrocracking Processes 19Annu RawatPas encore d'évaluation

- Hydrocracking Processes 24Document1 pageHydrocracking Processes 24Annu RawatPas encore d'évaluation

- Hydrocracking Processes 8Document1 pageHydrocracking Processes 8Annu RawatPas encore d'évaluation

- Hydrocracking Processes 33Document1 pageHydrocracking Processes 33SameerPas encore d'évaluation

- Hydrocracking Processes 7Document1 pageHydrocracking Processes 7Annu RawatPas encore d'évaluation

- Hydrocracking Processes 32Document1 pageHydrocracking Processes 32SameerPas encore d'évaluation

- Hydrocracking Processes 14Document1 pageHydrocracking Processes 14Annu RawatPas encore d'évaluation

- Hydrocracking Processes 26Document1 pageHydrocracking Processes 26SameerPas encore d'évaluation

- Hydrocracking Processes 23Document1 pageHydrocracking Processes 23Annu RawatPas encore d'évaluation

- Hydrocracking Processes 34Document1 pageHydrocracking Processes 34SameerPas encore d'évaluation

- Hydrocracking Processes 11Document1 pageHydrocracking Processes 11Annu RawatPas encore d'évaluation

- Hydrocracking Processes 12Document1 pageHydrocracking Processes 12Annu RawatPas encore d'évaluation

- Hydrocracking Processes 15Document1 pageHydrocracking Processes 15Annu RawatPas encore d'évaluation

- Hydrocracking Processes 10Document1 pageHydrocracking Processes 10Annu RawatPas encore d'évaluation

- Hydrocracking Processes 13Document1 pageHydrocracking Processes 13Annu RawatPas encore d'évaluation

- Hydrocracking Processes 31Document1 pageHydrocracking Processes 31SameerPas encore d'évaluation

- Hydrocracking Processes 28Document1 pageHydrocracking Processes 28SameerPas encore d'évaluation

- Hydrocracking Processes 9Document1 pageHydrocracking Processes 9Annu RawatPas encore d'évaluation

- Hydrocracking Processes 30 PDFDocument1 pageHydrocracking Processes 30 PDFAnnu RawatPas encore d'évaluation

- Hydrocracking Processes 16 PDFDocument1 pageHydrocracking Processes 16 PDFAnnu RawatPas encore d'évaluation

- Hydrocracking Processes 6Document1 pageHydrocracking Processes 6Annu RawatPas encore d'évaluation

- Hydrocracking Processes 17Document1 pageHydrocracking Processes 17Annu RawatPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Seismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2Document35 pagesSeismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2jakeer7100% (2)

- Daikin Split System BrochureDocument11 pagesDaikin Split System BrochureLasitha WiPas encore d'évaluation

- Weiss ITC Manual 13 Web Engl 201307Document123 pagesWeiss ITC Manual 13 Web Engl 201307Ciprian BalcanPas encore d'évaluation

- Connecting Rod Force Analysis and Weight OptimizationDocument18 pagesConnecting Rod Force Analysis and Weight OptimizationSukhamMichaelPas encore d'évaluation

- Catalogo Crox125 WBDocument45 pagesCatalogo Crox125 WBJeisson Beltrán ValderramaPas encore d'évaluation

- Sl20 Cg20 Parts Manual Ph7 Opl Pn-450222 (Rev-2) 042803Document29 pagesSl20 Cg20 Parts Manual Ph7 Opl Pn-450222 (Rev-2) 042803naokito AkemiPas encore d'évaluation

- Ultimate Behaviour and Design of Post-TensionedDocument8 pagesUltimate Behaviour and Design of Post-TensionedManuel RochaPas encore d'évaluation

- 1 Hcpl-Eot 7.5 MTDocument7 pages1 Hcpl-Eot 7.5 MTavashborahPas encore d'évaluation

- Stack Damper FATDocument13 pagesStack Damper FATSureandran SabadiPas encore d'évaluation

- I Unit PDFDocument5 pagesI Unit PDFgobardhan singhPas encore d'évaluation

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them100% (6)

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Document14 pagesProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhPas encore d'évaluation

- Duplomatic Inline Filter CatalogueDocument4 pagesDuplomatic Inline Filter Cataloguejulia bordenPas encore d'évaluation

- Latestrage CatalogDocument120 pagesLatestrage CatalogRWBalmeloPas encore d'évaluation

- Diagnostic Trouble Codes: TroubleshootingDocument9 pagesDiagnostic Trouble Codes: TroubleshootingEva AprianaPas encore d'évaluation

- JR - Fluid Controls Brochure - SPM0838-FOR-WEBDocument16 pagesJR - Fluid Controls Brochure - SPM0838-FOR-WEBMai Tuan AnhPas encore d'évaluation

- Parts Catalog: Revision 1Document269 pagesParts Catalog: Revision 1Yesenia GonzalezPas encore d'évaluation

- Design of Composite Slabs With Profiled Steel Deck PDFDocument16 pagesDesign of Composite Slabs With Profiled Steel Deck PDFPanha MenhPas encore d'évaluation

- CAT Engine Specifications 2.0% O Rating: G3304 Gas Petroleum EngineDocument4 pagesCAT Engine Specifications 2.0% O Rating: G3304 Gas Petroleum EngineDiogo Purizaca PeñaPas encore d'évaluation

- D7918-En (LHT)Document15 pagesD7918-En (LHT)Asa ReidPas encore d'évaluation

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanPas encore d'évaluation

- Ada 028794Document220 pagesAda 028794MOFEEZALAMPas encore d'évaluation

- Mech 32-Strength of Materials: Fundamental Concepts 1Document34 pagesMech 32-Strength of Materials: Fundamental Concepts 1Alyssa MadelPas encore d'évaluation

- Services Product CatalogueDocument132 pagesServices Product CatalogueAhmed Ben OthmanPas encore d'évaluation

- Polytropic Process1Document4 pagesPolytropic Process1Manash SinghaPas encore d'évaluation

- CFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageDocument7 pagesCFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageAlireza Ab100% (1)

- GE Codigos Error Estufas, Lavavajillas, Microondas PDFDocument5 pagesGE Codigos Error Estufas, Lavavajillas, Microondas PDFElvis Jesus Landa ReyesPas encore d'évaluation

- Marine Propulsion English Status January 2011Document20 pagesMarine Propulsion English Status January 2011Jodiel CoelhoPas encore d'évaluation

- Alfa Laval S927 FO PurifierDocument209 pagesAlfa Laval S927 FO Purifieriacovosf836100% (3)

- WRC Loadings and Sign ConventionDocument9 pagesWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamPas encore d'évaluation