Académique Documents

Professionnel Documents

Culture Documents

CML2525 User Guide

Transféré par

lokelooksCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CML2525 User Guide

Transféré par

lokelooksDroits d'auteur :

Formats disponibles

USER GUIDE

Vetting Signature

Local engineer to vet for validity of the EQN, if not valid return to raiser, if valid ring the Manufacturing Engineering Business Team

(Tel.4018) for allocation of an EQN number. You will need to support your request for an EQN number with the Name and Department of

the raiser, send EQN to the EBT who will log and distribute query to be answered. Any eqns that do not have a vetting signature will be

returned to raiser.

Cost Model

Is a cost model required (Yes if the query changes tooling or changes part).

Signature 4th A/C or above.

This is to be signed by the H.O.M for the 4th or the above, or the EQN will be rejected.

TICK AS APPROPRIATE

Corrective Action Critical

This is only if manufacturing engineering input is required to close a customer raised corrective action. This category of EQN will only be

accepted with appropriate document number entered into the box. Document examples are: QA I 75, QPI I 10, RFQI, NRR, QFR, DIR or

concession.

Engineering Error

This is for any error with Manufacturing Engineering data or tooling. It is not to be used if the current method or tooling produces an

acceptable product.

Engineering Improvement

This is to be used to highlight improvements to the engineering method or tooling. When answered this improvement will be embodied at

the appropriate aircraft project build or refinement plan.

Tool Replace, Tool Refurb & Tool Mod

Self explanatory.

ALL FIELDS BELOW ARE MANDATORY IF THE EON IS TO BE ANSWERED!

Part No / Description, Process Issue / Op No, Tool No / Issue, Eng Build No, Stage No and Retro Stage No.

Nature of Query / Clarification

1. Provide a much detail about your query as is possible.

2. Identify how you have overcome the problem in the past.This field must be completed if not the I st aircraft.

3. Savings Details - Must be filled in by EQN raiser. This is to determine the break Even statement of the change.

4. STD Hours Reductions - See local Cost Engineer for this information.

5. Build Stage Improvements (Time Saved) - Information to be supplied by the team leader. Time Reduction x Charging Rate.

6. Qty Scrap Costs - Information supplied by Team Leader of items scrapped, local cost engineer to work out scrap value.

7. Cost of Concessions - Information from QA.

8. Tool Declared Lost Signature - This is for toolstores to confirm that the tool is lost.

9. Obtain supervision authorisation for the EQN.

Forward completed EQN Forms to: Local Manufacturing Support Engineer.

Please use black pen for questions and answers as it stands out when scanning on EDSRS

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Presentation On BEL Retired Employees Contributory Health Scheme (Berechs)Document9 pagesPresentation On BEL Retired Employees Contributory Health Scheme (Berechs)lokelooksPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Section - 4 General Damage Mechanisms - 475deg C EmbrittlementDocument3 pagesSection - 4 General Damage Mechanisms - 475deg C EmbrittlementlokelooksPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument1 pageImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

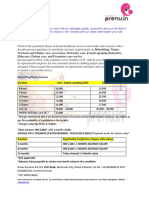

- Details of Prenu - in Charges - Bangalore - 2021Document3 pagesDetails of Prenu - in Charges - Bangalore - 2021lokelooksPas encore d'évaluation

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument2 pagesImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- Tool Rejection Report: Tata Lockheed Martin Aerostructures LimitedDocument2 pagesTool Rejection Report: Tata Lockheed Martin Aerostructures LimitedlokelooksPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Important Dates Notification For NET Results E-CertificateDocument1 pageImportant Dates Notification For NET Results E-CertificatelokelooksPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument1 pageImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument1 pageImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Ugc - National Eligibility Test June, 2014 Attendance Slip For Use at The Coordinating InstitutionDocument1 pageUgc - National Eligibility Test June, 2014 Attendance Slip For Use at The Coordinating InstitutionlokelooksPas encore d'évaluation

- Ugc - National Eligibility Test June, 2014 Print Copy of Application FormDocument1 pageUgc - National Eligibility Test June, 2014 Print Copy of Application FormlokelooksPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- World of Aviation: Aeronautical Society of IndiaDocument13 pagesWorld of Aviation: Aeronautical Society of IndialokelooksPas encore d'évaluation

- Chapter One: The Field of Organizational BehaviorDocument27 pagesChapter One: The Field of Organizational BehaviorlokelooksPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument2 pagesImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Important Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UsDocument1 pageImportant Dates Notification For NET Results E-Certificate: Home UGC About NET Contact UslokelooksPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- F2J3 - Basics 30 Oct 07Document28 pagesF2J3 - Basics 30 Oct 07lokelooksPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Presentation ON Quality Managementsystem Sae As 9100B Aerospace StandardDocument48 pagesPresentation ON Quality Managementsystem Sae As 9100B Aerospace StandardlokelooksPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Free Shipping On Time Service: Zoom EDIT-1.JPG)Document7 pagesFree Shipping On Time Service: Zoom EDIT-1.JPG)lokelooksPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hal BC: Tool Code ChartDocument11 pagesHal BC: Tool Code ChartlokelooksPas encore d'évaluation

- PLC and Arduino Based Boiler Automation Project Thesis Report DissertationDocument56 pagesPLC and Arduino Based Boiler Automation Project Thesis Report Dissertationfida13Pas encore d'évaluation

- IDfb45761d2-1994 Buick Park Avenue ManualDocument2 pagesIDfb45761d2-1994 Buick Park Avenue ManualHicks Saint Kilda0% (1)

- ITU - The Internet of Things 2005 PDFDocument212 pagesITU - The Internet of Things 2005 PDFjdanielrodriguezPas encore d'évaluation

- Everex Stepnote Va Series User ManualDocument140 pagesEverex Stepnote Va Series User ManualmrjqPas encore d'évaluation

- ICT Question Book PDFDocument19 pagesICT Question Book PDFRasanjaliPas encore d'évaluation

- Principles of ManagementDocument7 pagesPrinciples of ManagementHarshit Rajput100% (1)

- Fanuc Series 0I/0I Mate-Model D Maintenance Manual: HOW To Power Supply Fanuc Oi-Mf Plus ControllerDocument2 pagesFanuc Series 0I/0I Mate-Model D Maintenance Manual: HOW To Power Supply Fanuc Oi-Mf Plus ControllerNaveethshiek ShiekPas encore d'évaluation

- Insert Data in Database Using PHPDocument8 pagesInsert Data in Database Using PHPBlessie MercadoPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Draft RRL RrsDocument4 pagesDraft RRL RrscheesestickhahahaPas encore d'évaluation

- SRS For Signup PageDocument3 pagesSRS For Signup PageRohith RanganathPas encore d'évaluation

- GTMailPlusv2 PDFDocument103 pagesGTMailPlusv2 PDFAndrey100% (2)

- Sipovskij V V Iz Istorii Russkogo Romana I Povesti 01 XVIII Vek 1903Document370 pagesSipovskij V V Iz Istorii Russkogo Romana I Povesti 01 XVIII Vek 1903brankovranesPas encore d'évaluation

- Automatic Car Parking System Using RFID Ijariie4876Document7 pagesAutomatic Car Parking System Using RFID Ijariie4876Hưng Ngô GiaPas encore d'évaluation

- Microsoft OfficeDocument9 pagesMicrosoft OfficeKapilPas encore d'évaluation

- Stack and Queue: COMP171 Fall 2005Document44 pagesStack and Queue: COMP171 Fall 2005dasbhadarPas encore d'évaluation

- Spring Boot Interview Questions: 10 Step Reference CoursesDocument18 pagesSpring Boot Interview Questions: 10 Step Reference CoursesHanamant KalliguddiPas encore d'évaluation

- ACOS730 Flyer 201707 ENDocument5 pagesACOS730 Flyer 201707 ENSentaPas encore d'évaluation

- Ubuntu Unity PDFDocument1 pageUbuntu Unity PDFadam_tomasPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Case Study Report - Implementing Browser Backward and Forward ButtonDocument6 pagesCase Study Report - Implementing Browser Backward and Forward ButtonAnushkaPas encore d'évaluation

- Semantic Web Services For Various Govt. Initiated Projects: Abhishek Kumar PPD Csir - HQDocument36 pagesSemantic Web Services For Various Govt. Initiated Projects: Abhishek Kumar PPD Csir - HQitsme_theone4uPas encore d'évaluation

- Supports The Weatherlink Network Upgrade Which Allows Users To Purchased The " ". (Not Required For Weatherlinkip.)Document23 pagesSupports The Weatherlink Network Upgrade Which Allows Users To Purchased The " ". (Not Required For Weatherlinkip.)JavierQuevedoPas encore d'évaluation

- Datex-Ohmeda S5 PDFDocument6 pagesDatex-Ohmeda S5 PDFSERGIO PEREZPas encore d'évaluation

- The Idea Behind It. INDEX C100 and C200 With Handling SystemDocument2 pagesThe Idea Behind It. INDEX C100 and C200 With Handling SystembaumgconradoPas encore d'évaluation

- User Guide HSLC Online Form Fill Up PortalDocument4 pagesUser Guide HSLC Online Form Fill Up PortalVeijakim MisaoPas encore d'évaluation

- CPrime SAFewhitepaper 0829 125636Document48 pagesCPrime SAFewhitepaper 0829 125636dspwhizPas encore d'évaluation

- Fortiedr Mitre Att&Ck Evaluation Fact Sheet: Fortiedr Blocks All Attacks Accurate Analytic Rate of 94%Document2 pagesFortiedr Mitre Att&Ck Evaluation Fact Sheet: Fortiedr Blocks All Attacks Accurate Analytic Rate of 94%LuisPas encore d'évaluation

- Software Quality Assurance Plan PDFDocument35 pagesSoftware Quality Assurance Plan PDFanjas_tsPas encore d'évaluation

- ch02 Forouzanv2Document48 pagesch02 Forouzanv2Mohamad KhamizanPas encore d'évaluation

- MadheswaranDocument10 pagesMadheswaranMadhes WaranPas encore d'évaluation

- PHP Runner Manual 9.6Document795 pagesPHP Runner Manual 9.6DiegoKodner75% (4)