Académique Documents

Professionnel Documents

Culture Documents

Building - Design Calculation Report - Rev0

Transféré par

Behçet Serdal CanbazDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Building - Design Calculation Report - Rev0

Transféré par

Behçet Serdal CanbazDroits d'auteur :

Formats disponibles

KINGDOM OF SAUDI ARABIA Page: 2 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

TABLE OF CONTENTS

1.0. GENERAL ....................................................................................................................... 3

1.1. Introduction ................................................................................................................... 3

1.2. Scope of this document ............................................................................................... 3

1.3. Purpose of this document............................................................................................ 3

1.4. Definitions...................................................................................................................... 3

1.5. Abbreviations ................................................................................................................ 5

1.5.1. Parties ............................................................................................................................ 5

1.5.2. Institutes for Standardization ...................................................................................... 6

1.5.3. Systems / Locations / Stations .................................................................................... 6

1.5.4. Equipment, Hydraulic Indications ............................................................................... 7

1.6. Units ............................................................................................................................... 9

2.0. REFERENCES................................................................................................................ 9

3.0. DESIGN PARAMETER: ............................................................................................... 10

4.0. U VALUE FOR WALL, ROOF, DOOR & GLASS: ....................................................... 11

4.1. Coefficient of Transmission (U) for Roof: ................................................................ 11

4.2. Coefficient of Transmission (U) for External Wall: .................................................. 11

4.3. Coefficient of Transmission (U) for Door: ................................................................ 12

4.4. Coefficient of Transmission (U) for Glass: ............................................................... 12

5.0. EQUIPMENT HEAT DISSIPATION:............................................................................. 13

6.0. LIGHTING HEAT DISSIPATION: ................................................................................. 13

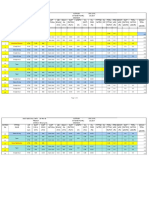

7.0. OVERALL LOAD SUMMARY OF VSD BUILDING: .................................................... 13

8.0. SAND TRAP LOUVER CALCULATION & SELECTION: ........................................... 14

9.0. VENTILATION CALCULATION ................................................................................... 14

9.1. AS PER AIR CHANGES PER HOUR (ACPH): ........................................................... 14

9.1.1. As per Air Changes per Hour for VSD ROOM-1:...................................................... 14

9.1.2. As per Air Changes per Hour for VSD ROOM-2:...................................................... 14

9.1.3. As per Air Changes per Hour for VSD ROOM-3:...................................................... 15

9.1.4. As per Air Changes per Hour for Cooling Pump Room: ......................................... 15

9.2. AS PER HEAT DISSIPATION:..................................................................................... 15

9.2.1. As per Heat Dissipation for VSD ROOM-1:............................................................... 15

9.2.2. As per Heat Dissipation for VSD ROOM-2:............................................................... 16

9.2.3. As per Heat Dissipation for VSD ROOM-3:............................................................... 17

9.2.4. As per Heat Dissipation for Cooling Pump Room: .................................................. 17

10.0. PRESSURE RELIEF DAMPER SIZING: ..................................................................... 18

10.1. Pressure Relief Damper Sizing for VSD ROOMS:.................................................... 18

11.0. LIST OF APPENDICES: ............................................................................................... 18

12.0. APPENDIX-1................................................................................................................. 19

13.0. APPENDIX-2................................................................................................................. 20

14.0. APPENDIX-3................................................................................................................. 21

15.0. APPENDIX-4................................................................................................................. 22

16.0. APPENDIX-5................................................................................................................. 23

17.0. APPENDIX-6................................................................................................................. 24

18.0. APPENDIX-7................................................................................................................. 25

19.0. APPENDIX-8................................................................................................................. 26

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 3 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

1.0. GENERAL

1.1. Introduction

The Yanbu-Madina Phase 4 WTS has been designed to supply (mainly) Madina with

potable water as an extension to the capacity of the existing lines. Its water sources are

the existing and new Desalination Plants located at PS1 area in the region of Yanbu.

The pumped system is operated as a closed system with one initial pump station located

at PS1 Yanbu and one intermediate pump station PS2. The diameter of the mainline

from PS1-D to Tap-off HPR-D1 is 84” reducing to 80” up to HPR-D2.

The connection line from HPR-D2 to MET and TSS is operated as a gravity line. The

diameter of this section down to the tap-off TSS is 80” followed by 68” pipeline to MET.

The maximum design flow rate at the beginning of the pipeline at PS1-D is 578,947m³/d,

whereby the standard operation will be 473,684m³/d.

Additionally the YMWTS-4 shall be operated in backflow operation from HPR-D1 and/or

HPR-D2 to PS1 tank farm as an exceptional load case with a flow rate of 233,000m³/d.

The storage capacity of the existing Yanbu Plant Tank Farm at PS1 will be increased by

additional two (2) steel tanks of 140,000 m³ and two (2) steel tanks of 100,000 m³. The

entire tank farm will be in pool operation. In case the Pump Stations of Phase 2 or

Phase 3 are in operation the tank farm can be operated down to a TLmin of 6.8masl.

The system of YMWTS-4 can be operated with down to a TLmin of 4.5masl.

The YMWTS-4 is hydraulically connected to Yanbu Phase 2 Pumps Station PS2 at PS2-

D, to Phase 3 MST and MET and Phase 2 HPR at HPR-D1. Nevertheless YMWTS-4

shall be operated separately and independently.

1.2. Scope of this document

This document contains ventilation and cooling system, which shall be applied for “PS2-D VSD

Building” of the Yanbu Madina Water Transmission System Phase-4 (YMWTS4).

1.3. Purpose of this document

The purpose of this document is to provide the technical input data for preparation of material

specifications for purchase, and to give the ruling guidelines and boundaries for the guide

design, as well for the detail design of the mechanical systems, equipment and material.

1.4. Definitions

For the purpose of this document, the following definitions shall apply:

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 4 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

PROJECT : YANBU – MADINA WATER TRANSMISSION SYSTEM

PHASE 4

EMPLOYER : Saline Water Conversion Corporation (SWCC)

ENGINEER : Refers to the Organization or Engineering Firm assigned by

the EMPLOYER to perform vetting of the design and to

supervise the implementation of the Contract and Works.

EPC CONTRACTOR : Refers to the Organization or Engineering firm assigned by

the EMPLOYER to perform the Engineering, Procurement

& Construction (EPC) of the Contract and Works.

Engineering : Refers to the Organization or Engineering firm assigned by

SUBCONTRACTOR the EPC CONTRACTOR to perform the Detailed

Engineering of the PROJECT. The ENGINEERING

SUBCONTRACTOR refers to IBK Consulting Engineers.

VENDOR : Manufacturers/Suppliers of goods/equipment

SUBVENDOR : Part of Manufacturers/Suppliers of goods/equipment

Vendor

Pipeline or Pipeline : Mean the complete entity of a particular pipeline, including

System all the pipeline segments, the pumping stations, the

reservoir stations, the tie-in stations, the tap-off station, the

one-way surge tanks and the line valve, vent and drain

stations.

System : Shall mean the Yanbu-Madina Water Transmission System

Phase 4, containing the complete works including the

pipeline segments, the pumping stations, the reservoir

stations and tank farms, the tap-off and tie-in stations and

the line valve, vent, drain and wash-out stations.

Mainline : Shall mean all pipeline segments (with all accessories like

cathodic protection facilities, etc.), which connect the initial

pumping station, the intermediate pumping station, the

highpoint reservoir stations and the tap-off stations with

each other. The pipeline segments together with these

stations form the backbone of the system.

Branch Line : Shall mean a lateral pipeline segment which connects a

tap-off station from the mainline with a distributed reservoir

or tie-in station.

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 5 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

Station : Shall mean all works for the system which are related to the

starting, intermediate or endpoint as well as all other

special locations along the pipeline routes (e.g. tap-off

station, line valve station, vent station, tie-in station). When

referring to a “station” without specifying a certain part

thereof, this expression shall mean all installations at the

given location.

Tap-off Station : Shall mean all installations at the starting point of a branch

line from the mainline to a distributed reservoir or tie-in

station.

Tie-in Station : Shall mean all installations at the connection to existing

(third party) facilities at the end of a branch line or mainline.

Endpoint Station : Shall mean the general term for terminal station

Reservoir Station : Shall mean all installation at the given location of the

branch line or mainline including erection of new

reservoir(s) or tank(s).

Final Design : Shall mean the design to be performed by the Contractor in

accordance with the requirements stipulated in the Contract

Documents.

System Operator : Person in the Central Control Room (CCR), who is

responsible for operation of pipeline system

Station Operator : Person receiving instructions from the System Operator

and who is responsible for the operation of a station

Shall : Indicates a mandatory requirement

Should : Indicates a strong recommendation

1.5. Abbreviations

1.5.1. Parties

SWCC Saline Water Conversion Corporation

ILF ILF Consulting Engineers

MAPA MAPA CONSTRUCTION & TRADE COMPANY

IBK IBK Consulting Engineers

MEWA Ministry of Environment, Water & Agriculture

MOT Ministry of Transport

NWC National Water Company

SEC Saudi Electric Company

STC Saudi Telephone Company

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 6 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

1.5.2. Institutes for Standardization

ANSI American National Standards Institute

API American Petroleum Institute

ASME American Society of Mechanical Engineers

AWWA American Water Works Association

DIN German Institute of Standardization

1.5.3. Systems / Locations / Stations

Systems:

YMWTS-1 Existing Yanbu-Madina Phase 1 WTS

YMWTS-2 Existing Yanbu-Madina Phase 2 WTS

YMWTS-3 Existing Yanbu-Madina Phase 3 WTS

YMWTS-4 New Yanbu-Madina Phase 4 WTS

Pipelines:

Line 4 (First) Mainline of new YMWTS-4 included in base and optional offer

Line 5 Second mainline of new YMWTS-4 included in base offer only

Pumping Stations:

PS1-B Existing Pumping Station PS1 for YMWTS-2 at Yanbu Plant

PS1-C Existing Pumping Station PS1 for YMWTS-3 at Yanbu Plant

PS1-D New Pumping Station PS1 for YMWTS-4 at Yanbu Plant

PS2-A Existing Pumping Station PS2 for YMWTS-1 in Musayjid

PS2-B Existing Pumping Station PS2 for YMWTS-2 in Musayjid

PS2-C Existing Pumping Station PS2 for YMWTS-3 in Musayjid

PS2-D New Pumping Station PS2 for YMWTS-4 in Musayjid

Reservoir, Terminal and Tap-off Stations:

HPR-D1 New Highpoint Reservoir Station at Mufrihat

HPR (Phase 2) Existing Highpoint Reservoir Station of YMWTS-2 at Mufrihat

HPR-C Existing Highpoint Reservoir Station of YMWTS-3

HPR-D2 New Highpoint Reservoir Station of YMWTS-4

MWT Madina West Terminal Station owned by MEWA

MST Madina South Terminal Station owned by MEWA

MET Madina East Terminal Station owned by MEWA

TSS Terminal Station Shoran owned by MEWA

TO-HPR-D1 New Tap-off Station for Branch line to HPR-D1 and MWT of YMWTS-4

TO-MST New Tap-off Station for Branch line to MST of YMWTS-4

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 7 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

1.5.4. Equipment, Hydraulic Indications

AoR Allocation of Responsibility

BP(x) Booster Pump (number x)

BEP Best Efficiency Point

CA Central Automatic

CC Control Center

CCTV Closed Circuit Television

CM Central Manual

CP Command Power

CV Control Valve

CVHFP Control Valve High Flow Protection

CVLFP Control Valve Low Flow Protection

CWS Cooling Water System

DP Demand Predictor

DS Drain Station

ESD Emergency Shut-Down

FAT Factory Acceptance Test

FC Flow Control

FCV Flow Control Valve

FOC Fiber Optic Cable

HMI Human Machine Interface

I/O Input / Output (panel)

LAL Level Alarm Low

LALL Level Alarm Low Low

LAH Level Alarm High

LAHH Level Alarm High High

LCH Level Control High

LCL Level Control Low

LCP Local Control Panel

LDS Leak Detection System

LSL Level Switch Low

LSLL Level Switch Low Low

LSH Level Switch High

LSHH Level Switch High High

LV_yy Line Valve (number yy)

LVS Line Valve Station

MAOP Max. Allowable Operating Pressure (pipe pressure bearing capacity)

MATP Max. Allowable Transient Pressure (MAOP +10%)

MOP Maximum Operating Pressure (max. HGL in Steady State Hydraulics)

MDF Maximum Design Flow Rate

MP(x) Main Pump (number x)

MTP Maximum Transient Pressure

NPSHavail Available Net Positive Suction Head (System Conditions)

NPSHrec/req Recommended / required Net Positive Suction Head (Pump Conditions)

OOS Operation Optimization System

OVR Override

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 8 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

P Pressure

PABX Private Automatic Branch Exchange (Telephone)

PAH Pressure Alarm High

PAL Pressure Alarm Low

PCH Pressure Control High

PCL Pressure Control Low

PFD Process Flow Diagram

PHFP Pump High Flow Protection

PISH Pressure Indicator Switch High

PISL Pressure Indicator Switch Low

PK Pipeline Kilometer, horizontal length

PLC Programmable Logic Controller

PLFP Pump Low Flow Protection

PS Pump Station

PRV Pressure Relief Valve

PSH Pressure Switch High

PSL Pressure Switch Low

PPL Pipeline

P&ID Piping & Instrumentation Diagram

QBEP Flow rate at best efficiency point

Qmax Maximum possible flow rate

REC-BY Recirculation Bypass

RES Reservoir

RPM Rounds per minute

SA Station Automatic

SCADA Supervisory Control and Data Acquisition

SCS Station Control System

SD Shut-down

SDS Shut-down sequence

SM Station Manual

SP Set Point

SSS Station Safety Sequence

STATCON Station Control System

SVP Surge Vessel Plant

SVS Station Valve Sequence

SV Surge Vessel

SYS System

SYSAD System Administrator

SYSCON System Control

T Temperature

TC Telecontrol

TCS Telecontrol System

TDR Technical Document Register

TL Tank Level

TOS Tap-off Station

TO Tap-Off

UNCON Unit Control System

UPS Uninterruptable Power Supply

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 9 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

VS Vent Station

VSD Variable Speed Drive

WAN Wide Area Network

WITCS Operation with TCS

WOTCS Operation without TCS

WL Water Level

WST Water Storage Tank

WPCC Water Pipeline Control Center

WQM Water Quality Monitoring

WTP Water Treatment Plant

1.6. Units

°C degree Celsius

bara absolute pressure

barg relative pressure, gauge pressure

db(A) Sound pressure level, decibel

gpm gallon per minute

h hour

km kilometer

m meter

Mbps Mega bit per second

m³ cubic meter

m³/d Flow rate, cubic meters per day

m³/h Flow rate, cubic meters per hour

m³/s Flow rate, cubic meters per second

masl meters above sea level

mlc Pressure, metres liquid column, according to Bernoulli formula

N Newton

Pa Pascal

s second

A, kA current, ampere or kiloampere

W, kW, MW active power, watt or kilowatt or megawatt

VA, kVA, MVA apparent power, volt-ampere, kilo or megavolt-ampere

V, kV Voltage, volt or kilovolt

2.0. REFERENCES

Package of Tender/FEED Documents

0

QA10-G-9057 Rev.2 General Specification G02 - Description of Project and Works

QC10-H-055 Rev. 4 Specification M15-HVAC Equipment

Package of Detailed Design Documents

90-UV00-H-400 Rev. 0 HVAC Basic Design Criteria

11-ZG20-S-005 Rev. A PS1-D Line4 VSD Building Guide Drawings

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 10 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

3.0. DESIGN PARAMETER:

Site Location Al-Musayjid

Site Elevation (Altitude) 440 m. Above mean sea level

Site Latitude 24° 04' 17.52'' N

DESIGN CONDITION

Out Door Temperature during summer

Design ambient Dry bulb temperature 44.0 °C

Design ambient Wet bulb temperature 24.3 °C

Daily Range 12.5 °C

Out Door Temperature during winter

Design ambient Dry bulb temperature 11.6 °C

In Door Temperature during summer & winter

Design ambient Dry bulb temperature <50.2 °C

YANBU VSD BUILDING HVAC INTERNAL DESIGN CRITERIAS

WEATHER DESIGN PARAMETERS

HOT SEASON COLD SEASON

SPACE

DB RH DB RH

˚C % ˚C %

VSD ROOM 30°C 30-60 5°C N/A

COOLING PUMP ROOM 30°C 30-60 5°C N/A

Note: Indoor/Outdoor condition during summer and winter are designed as per General

Specification G 02.

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 11 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

4.0. U VALUE FOR WALL, ROOF, DOOR & GLASS:

4.1. Coefficient of Transmission (U) for Roof:

Roof Details

Outside Surface Color………………….Medium

Absorbtivity………………………………0.675

Overall U-Value………………………....0.305 W/(m²·K)

Roof Layers Details (Inside to Outside)

Specific

Thickness Density R-Value Weight

Ht.

Layers m kg/m³ kJ / (kg K) (m²·K)/W kg/m²

Inside surface resistance 0,000 0,0 0,00 0,13000 0,0

Concrate 0,250 2400,0 1,27 0,10000 600,0

Slopıng Screed 0,800 2000,0 0,84 0,05700 160,0

Water Insulation 0,010 2000,0 1,84 0,05300 20,0

Heat Insulation 0,100 25,0 1,30 2,85700 2,5

Slopıng Screed 0,020 2000,0 0,84 0,01400 40,0

Gravel 0,500 1700,0 1,26 0,02500 85,0

Outside surface resistance 0,000 0,0 0,00 0,04000 0,0

Totals 0,510 - 3,27600 907,5

4.2. Coefficient of Transmission (U) for External Wall:

Wall Details

Outside Surface Color………………….Medium

Absorbtivity………………………………0.675

Overall U-Value………………………....0.328 W/(m²·K)

Wall Layers Details (Inside to Outside)

Specific

Thickness Density R-Value Weight

Ht.

Layers m kg/m³ kJ / (kg K) (m²·K)/W kg/m²

Inside surface resistance 0,000 0,0 0,00 0,13000 0,0

Cement Mortar 0,020 2000,0 0,84 0,01300 40,0

Heat Insulation 0,080 200,0 0,84 2,28600 16,0

Common brick 0,340 650,0 0,96 0,57100 221,0

Cement Mortar 0,020 2000,0 0,84 0,01300 40,0

Outside surface resistance 0,000 0,0 0,00 0,04000 0,0

Totals 0,460 - 3,05300 317,0

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 12 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

4.3. Coefficient of Transmission (U) for Door:

D1_2.70x3.30

Door Details:

Gross Area ..................................... 8.9 m²

Door U-Value ............................. 6.000 W/(m²·K)

D2_1.10x2.40

Door Details:

Gross Area ..................................... 2.6 m²

Door U-Value ............................. 6.000 W/(m²·K)

D3_1.36x3.30

Door Details:

Gross Area ..................................... 4.5 m²

Door U-Value ............................. 6.000 W/(m²·K)

4.4. Coefficient of Transmission (U) for Glass:

W1_4.50x0.90

Window Details:

Detailed Input ................................. No

Height .......................................... 0.90 m

Width ........................................... 4.50 m

Overall U-Value ......................... 1.500 W/(m²·K)

Overall Shade Coefficient .......... 0.400

Note: (U) Values are taken from Carrier Hourly Analysis Program 5.11 version.

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 13 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

5.0. EQUIPMENT HEAT DISSIPATION:

Zone Name Equipment load in Watts

Cooling Pump Room 1000

VSD Room-1 30000

VSD Room-2 30000

VSD Room-3 30000

6.0. LIGHTING HEAT DISSIPATION:

Zone Name Lighting load in Watts

Cooling Pump Room 126

VSD Room-1 1113

VSD Room-2 988

VSD Room-3 996

Note: See Appendix 1 for lighting loads.

7.0. OVERALL LOAD SUMMARY OF VSD BUILDING:

TOTAL (Watts)

Sensible Latent

DESCRIPTION (W) (W)

Window & Skylight Solar Loads 1907 -

Wall Transmission 2124 -

Roof Transmission 2625 -

Window Transmission 425 -

Door Loads 1803 -

Overhead Lighting 3223 -

Electric Equipment 90996 -

Safety Factor 5155 -

>> Total Zone Loads 108256 -

Central Cooling Coil 233231 -

>> Total Conditioning 341487 -

Note: Please refer Appendix-2 for Overall Load Summary.

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 14 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

8.0. SAND TRAP LOUVER CALCULATION & SELECTION:

Data :

Required Fresh Air = 19200 m³/h

Face velocity through louvers = 1.5 m/s

Minimum required face area to keep above velocity = 3.56 m²

From the Catalogue Selected size = See Appendix 3 for details

(1)

L= 1350 mm 55 in

H= 1350 mm 55 in

(2)

L= 1350 mm 55 in

H= 1350 mm 55 in

Actual face velocity = 5.333 m³/s /[(1.35m x 1.35m) x 2] = 1.46 m/s

9.0. VENTILATION CALCULATION

9.1. AS PER AIR CHANGES PER HOUR (ACPH):

9.1.1. As per Air Changes per Hour for VSD ROOM-1:

Data:

AREA OF VSD ROOM = 242 m²

HEIGHT OF VSD ROOM = 5.6m

No. OF AIR CHANGES PER HOUR = 1 ACH/h

Calculation :

Cooling Air Required = Room volume x No. of Air Changes/h

= 242 m² x 5.6 m x 1 ACH/h

Ventilation cooling air required = 1355.2 m³/h

9.1.2. As per Air Changes per Hour for VSD ROOM-2:

Data:

AREA OF VSD ROOM = 215 m²

HEIGHT OF VSD ROOM = 5.6 m

No. OF AIR CHANGES PER HOUR = 1

Calculation :

Cooling Air Required = Room volume x No. of Air Changes/h

= 215 m² x 5.6 m x 1 ACH/h

Ventilation cooling air required = 1204 m³/h

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 15 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

9.1.3. As per Air Changes per Hour for VSD ROOM-3:

Data:

AREA OF VSD ROOM = 217 m²

HEIGHT OF VSD ROOM = 5.6 m

No. OF AIR CHANGES PER HOUR = 1

Calculation :

Cooling Air Required = Room volume x No. of Air Changes/h

= 217 m² x 5.6 m x 1 ACH/h

Ventilation cooling air required = 1215.2 m³/h

Note: As per specification minimum number of air changes per hour required is 1.

9.1.4. As per Air Changes per Hour for Cooling Pump Room:

Data:

AREA OF PUMP ROOM = 28 m²

HEIGHT OF PUMP ROOM = 4 m

No. OF AIR CHANGES PER HOUR = 1

Calculation :

0

Cooling Air Required = Room volume x No. of Air Changes/h

= 28 m² x 4 m x 2 ACH/h

Ventilation cooling air required = 224 m³/h

Note: As per specification minimum number of air changes per hour required is 2.

9.2. AS PER HEAT DISSIPATION:

9.2.1. As per Heat Dissipation for VSD ROOM-1:

Data :

Q in : Heat Dissipation from Internal Load in VSD Room-1 = 6257 W

Qex : Heat Dissipation from External Load in VSD Room-1 = 30000 W

Q TOTAL : Total Heat Dissipation in VSD Room-1 = 36257 W

Cp : Specific Heat of Air = 1005 J/kg°C

ρ : Weight per Unit Volume of Air = 1.22 kg/m³

ΔT : Temperature Difference = 17 °C

V = Q TOTAL / (Cp x ρ x ΔT)

V = 36257 W / (1005 J/kg°C x 1.22 kg/m³ x 17 °C)

V = 1.739 m³/s = 6262 m³/h

Total Volume of Cooling Air Required V = 6262 m³/h

Since, the volume of cooling air as per heat dissipation greater than volume of ACPH, cooling air

flow rate is accepted as for VSD Room-1 is 6300 m³/h.

Supply Air to the VSD Room-1 = 6300 m³/h

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 16 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

Pressurized Air = 5% of Total volume of supply air

= 0.05 x 6300

= 400 m³/h

Total Exhaust Air = Total supply air - Total Pressurization air

= 6300 – 400

= 5900 m³/h

Note-1: Exhaust air shall be relieved through pressure relief damper.

Note-2: See Appendix-2 for detailed heat load calculations.

9.2.2. As per Heat Dissipation for VSD ROOM-2:

Data :

Q in : Heat Dissipation from Internal Load in VSD Room-2 = 5027 W

Qex : Heat Dissipation from External Load in VSD Room-2 = 30000 W

Q TOTAL : Total Heat Dissipation in VSD Room-2 = 35027 W

Cp : Specific Heat of Air = 1005 J/kg°C

ρ : Weight per Unit Volume of Air = 1.22 kg/m³

ΔT : Temperature Difference = 17 °C

V = Q TOTAL / (Cp x ρ x ΔT)

V = 35027 W / (1005 J/kg°C x 1.22 kg/m³ x 17 °C)

V = 1.682 m³/s = 6054 m³/h

Total Volume of Cooling Air Required V = 6054 m³/h

Since, the volume of cooling air as per heat dissipation greater than volume of ACPH, cooling air

flow rate is accepted as for VSD Room-2 is 6300m³/h.

Supply Air to the VSD Room-2 = 6300 m³/h

Pressurized Air = 5% of Total volume of supply air

= 0.05 x 6300

= 400 m³/h

Total Exhaust Air = Total supply air - Total Pressurization air

= 6300 – 400

= 5900 m³/h

Note-1: Exhaust air shall be relieved through pressure relief damper.

Note-2: See Appendix-2 for detailed heat load calculations.

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 17 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

9.2.3. As per Heat Dissipation for VSD ROOM-3:

Data :

Q in : Heat Dissipation from Internal Load in VSD Room-3 = 5692 W

Qex : Heat Dissipation from External Load in VSD Room-3 = 30000 W

Q TOTAL : Total Heat Dissipation in VSD Room-3 = 35692 W

Cp : Specific Heat of Air = 1005 J/kg°C

ρ : Weight per Unit Volume of Air = 1.22 kg/m³

ΔT : Temperature Difference = 17 °C

V = Q TOTAL / (Cp x ρ x ΔT)

V = 35692 W / (1005 J/kg°C x 1.22 kg/m³ x 17 °C)

V = 1.712 m³/s = 6165 m³/h

Total Volume of Cooling Air Required V = 6165 m³/h

Since, the volume of cooling air as per heat dissipation greater than volume of ACPH, cooling air

flow rate is accepted as for VSD Room-3 is 6300 m³/h.

Supply Air to the VSD Room-3 = 6300 m³/h

Pressurized Air = 5% of Total volume of supply air

= 0.05 x 6300

= 400 m³/h

Total Exhaust Air = Total supply air - Total Pressurization air

= 6300 – 400

= 5900 m³/h

Note-1: Exhaust air shall be relieved through pressure relief damper.

Note-2: See Appendix-2 for detailed heat load calculations.

9.2.4. As per Heat Dissipation for Cooling Pump Room:

Data :

Q in : Heat Dissipation from Internal Load in Pump Room = 782 W

Qex : Heat Dissipation from External Load in Pump Room = 1000 W

Q TOTAL : Total Heat Dissipation in Pump Room = 1782 W

Cp : Specific Heat of Air = 1005 J/kg°C

ρ : Weight per Unit Volume of Air = 1.22 kg/m³

ΔT : Temperature Difference = 17 °C

V = Q TOTAL / (Cp x ρ x ΔT)

V = 1782 W / (1005 J/kg°C x 1.22 kg/m³ x 17 °C)

V = 0.086 m³/s = 300 m³/h

Total Volume of Cooling Air Required V = 300 m³/h

Since, the volume of cooling air as per heat dissipation greater than volume of ACPH, cooling air

flow rate is accepted as for Cooling Pump Room is 300 m³/h.

Supply Air to the Cooling Pump Room = 300 m³/h

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

KINGDOM OF SAUDI ARABIA Page: 18 of 26

Saline Water Conversion Corporation

YANBU-MADINA PHASE 4 WTS

Subject: PUMPING STATION PS2-D LINE 4 VSD BUILDING Spec. No.

HVAC DESIGN CALCULATION REPORT ILF

Rev First Rev. A 0 Document Number

Index

Issue Date: 21.10.19 31.12.19 12-UV00-J-401

Pressurized Air = 5% of Total volume of supply air

= 0.05 x 300

= 100 m³/h

Total Exhaust Air = Total supply air - Total Pressurization air

= 300 – 100

= 200 m³/h

Note-2: See Appendix-2 for detailed heat load calculations.

10.0. PRESSURE RELIEF DAMPER SIZING:

10.1. Pressure Relief Damper Sizing for VSD ROOMS:

Air Required to Relief = Pressurization Air

= 400 m³/h

= 112 L/s

Pressure difference in relief damper (PRD) @ (AP)= 50 Pa

According to “Air Leakage Methods” from the Ashrae Handbook 2017;

(SI) Q = 840 x A x (AP)1/2

Where,

• Q is the airflow leakage in Liters per Second (L/s)

• A is the total leakage area in Square Meters

• AP is the differential pressure in Pascals

A = 228 L/s / 840 / (50 Pa)1/2

A = 0.02 m²

At 0.02 m² area, selected size as per catalogue

Selected size of the PRD = W = 200 mm, 8 in

H = 200 mm, 8 in See Appendix 5 for details

Note: There are 3 Relief Dampers in total. Each VSD Room has a Relief Damper.

11.0. LIST OF APPENDICES:

APPENDIX NO. TITLE

0 APPENDIX-1 LIGHTING LOAD DETAILS

APPENDIX-2 HEAT LOAD CALCULATION & PSYCHROMETRIC GRAPH

APPENDIX-3 SAND TRAP LOUVER SELECTION

APPENDIX-4 AIR CONDITIONING UNITS & AIR COOLED CONDENSING UNITS

SELECTION

APPENDIX-5 PRESSURE RELIEF DAMPER SELECTION

APPENDIX-6 VAV SELECTION

APPENDIX-7 PRESSURE LOSS CALCULATION IN DUCT

APPENDIX-8 DUCT SIZING CALCULATION

Engineering Subcontractor Subcontractor Subcontractor

IBK MAPA CONSTRUCTION & TRADE Co. Inc.

Vous aimerez peut-être aussi

- Machine Room Ventilation - International Code: InputDocument15 pagesMachine Room Ventilation - International Code: Inputirfanbaig36Pas encore d'évaluation

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JPas encore d'évaluation

- External & Internal Design Conditions: Project: 22 Tower Street, Bedford Row & Jockeys Field & 49-51 FARRINGDONDocument2 pagesExternal & Internal Design Conditions: Project: 22 Tower Street, Bedford Row & Jockeys Field & 49-51 FARRINGDONrahul anandPas encore d'évaluation

- Sabb Design ReportDocument8 pagesSabb Design Reportabdullah amanullahPas encore d'évaluation

- Design, Calculation and Cost Estimation of HVAC System For School BuildingDocument12 pagesDesign, Calculation and Cost Estimation of HVAC System For School BuildingMd KaleemPas encore d'évaluation

- Design HVAC System For Commercial HospitalDocument76 pagesDesign HVAC System For Commercial HospitalMohammed AbdulhabibPas encore d'évaluation

- 1.1.1. Design Basis PDFDocument310 pages1.1.1. Design Basis PDFVuthpalachaitanya KrishnaPas encore d'évaluation

- ZBP v3 Alsaad HQ DWG SD MC 129 Rev00Document2 pagesZBP v3 Alsaad HQ DWG SD MC 129 Rev00The Saudi TamizhanPas encore d'évaluation

- Acoustic Calculation of Ventilation SystemsDocument4 pagesAcoustic Calculation of Ventilation SystemsEngFaisal AlraiPas encore d'évaluation

- 10 STD Specifications - Building - 2018 (A1)Document902 pages10 STD Specifications - Building - 2018 (A1)Logan LiPas encore d'évaluation

- 2014.11.23 - Electrical Specifications Combined - Tender SubmissionDocument426 pages2014.11.23 - Electrical Specifications Combined - Tender Submissionfayas100% (1)

- Water Demand & Sewer Discharge Calculations KHARAMAA Water Installation Code 2016Document1 pageWater Demand & Sewer Discharge Calculations KHARAMAA Water Installation Code 2016Dăňĩêĺ RăĵăPas encore d'évaluation

- Air Grilles DiffusersDocument230 pagesAir Grilles DiffusersBader Shrbaji100% (1)

- Nuaire Commercial Useful InfoDocument10 pagesNuaire Commercial Useful InfoYaser AkarPas encore d'évaluation

- Sizing of Sewer DrainsDocument46 pagesSizing of Sewer DrainsvictorPas encore d'évaluation

- Goschen Estate Site Southwark MEP Engineering Stage 3 ReportDocument79 pagesGoschen Estate Site Southwark MEP Engineering Stage 3 ReportMichaelPurcell100% (1)

- BG 71 2017 Building Services ReportsDocument37 pagesBG 71 2017 Building Services ReportsFinlayPas encore d'évaluation

- NDS SD 345Document1 pageNDS SD 345mengineeringPas encore d'évaluation

- PICV Vs Manual Balancing With DP ControllerDocument1 pagePICV Vs Manual Balancing With DP ControllermajortayPas encore d'évaluation

- NBCDocument3 pagesNBCDharaniselvamPas encore d'évaluation

- Building Services and Equipment II-2Document18 pagesBuilding Services and Equipment II-2Thiru KumarPas encore d'évaluation

- Myanmar Fire Safety Code 2020 (Eng Version) PDFDocument439 pagesMyanmar Fire Safety Code 2020 (Eng Version) PDFThe' Nu AungPas encore d'évaluation

- Bs Iso 4190 LiftDocument9 pagesBs Iso 4190 LiftVivien John100% (1)

- General MEP (BOQ & COST)Document21 pagesGeneral MEP (BOQ & COST)Skill IndiaPas encore d'évaluation

- Is.2470.1.1985 Septic Tank Part 2Document29 pagesIs.2470.1.1985 Septic Tank Part 2V Jay KrPas encore d'évaluation

- Cooling TowersDocument10 pagesCooling TowersAvipsita DasPas encore d'évaluation

- Preparation of HVAC Ducting LayoutDocument6 pagesPreparation of HVAC Ducting Layoutarunima04Pas encore d'évaluation

- Technical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingDocument76 pagesTechnical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingSalaheddine Zantout100% (1)

- FLS Report - Burj Dubai - 14 Sept 2005 - Final Rev - 091505Document112 pagesFLS Report - Burj Dubai - 14 Sept 2005 - Final Rev - 091505SubharajkPas encore d'évaluation

- Staircase Pressurisation Calculation Rev-0Document30 pagesStaircase Pressurisation Calculation Rev-0Anish KumarPas encore d'évaluation

- External Static Pressure Calculation (Revision 1) 20/4/2016 SEF-B1-01 (Smoke Exhaust Fan For Compartment D Carpark SES System)Document14 pagesExternal Static Pressure Calculation (Revision 1) 20/4/2016 SEF-B1-01 (Smoke Exhaust Fan For Compartment D Carpark SES System)kkkkPas encore d'évaluation

- AHU InstallationDocument14 pagesAHU InstallationAyyappan VeeraputhiranPas encore d'évaluation

- FAHUDocument4 pagesFAHUSundar DAACPas encore d'évaluation

- Wind Load CalculationDocument32 pagesWind Load CalculationAbuAhmedQuaziPas encore d'évaluation

- Technical Handbook of Hvac AIRAH PDFDocument188 pagesTechnical Handbook of Hvac AIRAH PDFAhmed IdreesPas encore d'évaluation

- Seismic Design Specification For Buildings, Structures, Equipment, and Systems: 2020Document10 pagesSeismic Design Specification For Buildings, Structures, Equipment, and Systems: 2020AndreaAlberoPas encore d'évaluation

- Mohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation SummaryDocument1 pageMohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation Summaryroula abi rachedPas encore d'évaluation

- CIBSE Commissioning Code B 2002 BoilersDocument39 pagesCIBSE Commissioning Code B 2002 BoilersPeter Gardner0% (1)

- DBR Imphal AirportDocument24 pagesDBR Imphal AirportCreative GroupPas encore d'évaluation

- Fire Protection Piping Installation and Testing Feb 12 2014 PDFDocument104 pagesFire Protection Piping Installation and Testing Feb 12 2014 PDFArshath FleminPas encore d'évaluation

- DCD Smoke RevisedDocument9 pagesDCD Smoke RevisedMUBASHIRPas encore d'évaluation

- Chilled Water and Condensor Water Pump Head CalculaitonDocument3 pagesChilled Water and Condensor Water Pump Head CalculaitonYusuf RampPas encore d'évaluation

- Fire Fighting System - Tech SpecDocument22 pagesFire Fighting System - Tech SpecBhavin PatelPas encore d'évaluation

- MEP Light CalculationDocument2 pagesMEP Light CalculationAmit JhaPas encore d'évaluation

- Whitepaper - Design Considerations When Integrating Smoke and Fire CurtainsDocument13 pagesWhitepaper - Design Considerations When Integrating Smoke and Fire CurtainsHellen MartinssonPas encore d'évaluation

- TDA V (Smokespill)Document4 pagesTDA V (Smokespill)Chia Woon LimPas encore d'évaluation

- Fahu-L1-01 (Ashrae)Document6 pagesFahu-L1-01 (Ashrae)TanveerPas encore d'évaluation

- Villa SHD DWG List - Drawing List - R1Document1 pageVilla SHD DWG List - Drawing List - R1MageshKumarPas encore d'évaluation

- Mebs6000 1011 06 Sewage DisposalDocument72 pagesMebs6000 1011 06 Sewage DisposalJack LiPas encore d'évaluation

- RoadDocument59 pagesRoadlim saryPas encore d'évaluation

- HVAC LOAD CalculationDocument2 pagesHVAC LOAD CalculationbookjamanPas encore d'évaluation

- Final ReportDocument94 pagesFinal ReportAJITH KUMARPas encore d'évaluation

- CIBSE Engineering Practice Report: Dates Project/Episode DescriptionDocument17 pagesCIBSE Engineering Practice Report: Dates Project/Episode DescriptionMMMOH200Pas encore d'évaluation

- Design Basis ReportDocument102 pagesDesign Basis Reportmohdalal86100% (1)

- SN - Design Report - Enjera Production Building - Rev-00Document10 pagesSN - Design Report - Enjera Production Building - Rev-00Nuhamin Zablon100% (1)

- PP Aaa PP1 161Document26 pagesPP Aaa PP1 161Rabah AmidiPas encore d'évaluation

- Process Control and Shutdown PhilosophyDocument14 pagesProcess Control and Shutdown PhilosophyJoanrenis SaranyaPas encore d'évaluation

- PP Aaa PP1 115Document40 pagesPP Aaa PP1 115Rabah AmidiPas encore d'évaluation

- Circulation Water Pump 14-PC 1240 A/BDocument86 pagesCirculation Water Pump 14-PC 1240 A/Bmechmohan26Pas encore d'évaluation

- Terastandard - Bsi Bs en 6811 597 1514626330Document24 pagesTerastandard - Bsi Bs en 6811 597 1514626330soheila ghaderiPas encore d'évaluation

- BS - EN - 60811-504 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsDocument14 pagesBS - EN - 60811-504 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazPas encore d'évaluation

- BS - EN - 60811-505 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsDocument16 pagesBS - EN - 60811-505 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazPas encore d'évaluation

- BS - EN - 60811-604 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsDocument12 pagesBS - EN - 60811-604 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazPas encore d'évaluation

- BS - EN - 60811-411 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsDocument12 pagesBS - EN - 60811-411 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazPas encore d'évaluation

- BS - EN - 60811-407 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsDocument12 pagesBS - EN - 60811-407 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazPas encore d'évaluation

- LiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationDocument7 pagesLiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationBehçet Serdal CanbazPas encore d'évaluation

- LiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationDocument7 pagesLiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationBehçet Serdal CanbazPas encore d'évaluation

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazPas encore d'évaluation

- LiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationDocument7 pagesLiveRecovery Save of LiveRecovery Save of Swimming - Pool - CalculationBehçet Serdal CanbazPas encore d'évaluation

- 3.1 Selection of Turbine and Governing System PDFDocument72 pages3.1 Selection of Turbine and Governing System PDFtanujaayer100% (1)

- WT HesapDocument1 pageWT HesapBehçet Serdal CanbazPas encore d'évaluation

- Acdmac 2013 Autolisp Developers GuideDocument52 pagesAcdmac 2013 Autolisp Developers GuideSamuel MirajPas encore d'évaluation

- Introduction To AutoLISP ProgrammingDocument41 pagesIntroduction To AutoLISP ProgrammingSindraPas encore d'évaluation

- PRESSURE SURGE-180.00-163.00-180 SDocument1 pagePRESSURE SURGE-180.00-163.00-180 SBehçet Serdal CanbazPas encore d'évaluation

- HEAD SURGE-180.00-163.00-180 SDocument1 pageHEAD SURGE-180.00-163.00-180 SBehçet Serdal CanbazPas encore d'évaluation

- Advanced AutoLISP ProgrammingDocument42 pagesAdvanced AutoLISP Programmingnosena13Pas encore d'évaluation

- Design Considerations For GatesDocument1 pageDesign Considerations For GatesBehçet Serdal Canbaz0% (1)

- Air Changes Per HourDocument2 pagesAir Changes Per HourMARIJAN100% (1)

- Kitchen Ventilation ExampleDocument4 pagesKitchen Ventilation ExamplePretty NatyPas encore d'évaluation

- Habitat ERP For FIP-058 at DLD Rev03Document8 pagesHabitat ERP For FIP-058 at DLD Rev03Khairi KKamarPas encore d'évaluation

- HVAC Design For Healthcare FacilitiesDocument60 pagesHVAC Design For Healthcare Facilitiesaymanibrahim_71Pas encore d'évaluation

- Air Changes Per HourDocument1 pageAir Changes Per Hourpandu_chemeng75% (4)

- Nabh Ac For Ot AbrigedDocument5 pagesNabh Ac For Ot AbrigedAhmedBIowarPas encore d'évaluation

- Odor Control Design GuidelinesDocument9 pagesOdor Control Design GuidelinesZeina Farhat100% (1)

- Industrial Air Filtration and Technical Reference GuideDocument224 pagesIndustrial Air Filtration and Technical Reference GuideAxiv The GreatPas encore d'évaluation

- BioZone Scientific PR Owners Manual1Document8 pagesBioZone Scientific PR Owners Manual1thaitruong26Pas encore d'évaluation

- Recap ThermalDocument8 pagesRecap ThermalGunnerZedPas encore d'évaluation

- Heat Load Calculation FormatDocument6 pagesHeat Load Calculation Formatmeesam1Pas encore d'évaluation

- PHPP2007 English DemoDocument57 pagesPHPP2007 English DemoSrinivas SukhavasiPas encore d'évaluation

- HVACDocument48 pagesHVACBashar JaafrehPas encore d'évaluation

- Ventilation, Infiltration & ExfiltrationDocument22 pagesVentilation, Infiltration & ExfiltrationAnimesh NayakPas encore d'évaluation

- E741 - 11Document17 pagesE741 - 11cremsky100% (1)

- ACPH FormulaDocument4 pagesACPH FormulaRitesh RanjanPas encore d'évaluation

- Air Change Rates - Typical Rooms and BuildingsDocument5 pagesAir Change Rates - Typical Rooms and BuildingsBasil OguakaPas encore d'évaluation

- Hvac CalculationDocument7 pagesHvac CalculationPrasanna kumar subudhiPas encore d'évaluation

- Air Change RatesDocument3 pagesAir Change RatesErick QuintoPas encore d'évaluation

- Passive House Blower Door TestingDocument23 pagesPassive House Blower Door Testingtexas_petePas encore d'évaluation

- Matlab Code For Cooling Load CalculationDocument8 pagesMatlab Code For Cooling Load CalculationKidus yared100% (1)

- Horse Stable VentilationDocument16 pagesHorse Stable VentilationRenata C CalfatPas encore d'évaluation

- Basement Ventilation CalculationDocument4 pagesBasement Ventilation CalculationShubhajit ChakrabortyPas encore d'évaluation

- CFMDocument16 pagesCFMShoaibIqbalPas encore d'évaluation

- Ventilation in Dairy Cow FarmDocument13 pagesVentilation in Dairy Cow FarmNguyen Dang Binh ThanhPas encore d'évaluation

- ASHRAE - Demand-Based Control of Lab Air Change RatesDocument9 pagesASHRAE - Demand-Based Control of Lab Air Change RatesalbrgmailPas encore d'évaluation

- Manrose Ventilation Fan Catalogue PDFDocument108 pagesManrose Ventilation Fan Catalogue PDFRendani VelePas encore d'évaluation

- Fit-Out Guide For Energy Efficient LaboratoriesDocument60 pagesFit-Out Guide For Energy Efficient LaboratoriesEdmund YoongPas encore d'évaluation

- Calculation of Smoke Spilled SystemDocument2 pagesCalculation of Smoke Spilled SystemMFaiz RHamira100% (1)