Académique Documents

Professionnel Documents

Culture Documents

X B en

Transféré par

awpm0 évaluation0% ont trouvé ce document utile (0 vote)

82 vues2 pagescatalogo bombas de piston

Titre original

650408-X-B-EN

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentcatalogo bombas de piston

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

82 vues2 pagesX B en

Transféré par

awpmcatalogo bombas de piston

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

OPERATOR’S MANUAL 650408-X-B

INCLUDING: SPECIFICATIONS, SERVICE KITS, GENERAL INFORMATION, TROUBLESHOOTING. RELEASED: 02-24-88

INCLUDE MANUALS: 65106-X Lower Pump End (pn 97999-578), 6544X-X Air Motor (pn 97999-64) & REVISED: 4-18-07

S-632 General Information Manual (pn 97999-624). (REV. E)

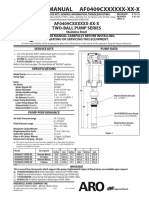

4-1/4” AIR MOTOR 650408-X-B

9:1 RATIO

4” STROKE TWO-BALL PUMP SERIES

Stainless Steel

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS PUMP DATA

y Use only genuine ARO® replacement parts to assure compat-

ible pressure rating and longest service life. MODEL 650408-X-B

y 61268 for repair of air motor section.

y 637010 for repair of 65108 and 65108-5 lower pump ends. Air Exhaust (female)

y 637010-4 for repair of 65108-4 and 65108-6 lower pump ends. 1-1/4 - 11-1/2 N.P.T.F. - 1

y 637010-5 for repair of 65108-7 and 65108-9 lower pump ends.

y 637011 for replacement of lower ball check. Air Inlet (female) (not shown)

1/2 - 14 N.P.T.F - 1

SPECIFICATIONS

65444-X-B Air Motor

(see manual 6544X-X)

Model Series (refer to option chart) . . . . . . . . . . . 650408-X-B

Pump Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air Operated, Two-Ball

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9:1

Air Motor Spacer Section (see back)

650408-B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B 31-27/32”

650408-2-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-2-B (808.8 mm)

650408-4-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B Material Outlet (female)

650408-5-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B 3/4 - 14 N.P.T.F. - 1

650408-6-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B

650408-7-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B

650408-8-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65444-B

Motor Repair Kit . . . . . . . . . . . . . . . . . . . . . . . 61268 11” 65108-X Lower Pump

Motor Diameter . . . . . . . . . . . . . . . . . . . . . . . 4-1/4” (10.795 cm) (279.4 mm)

(see manual 65106-X)

Stroke (double acting). . . . . . . . . . . . . . . . . 4” (10.16 cm)

Air Inlet (female) . . . . . . . . . . . . . . . . . . . . . . . 1/2 - 14 N.P.T.F. - 1

Air Exhaust (female). . . . . . . . . . . . . . . . . . . . 1-1/4 - 11-1/2 N.P.T.F. - 1

Lower Pump End Series Material Inlet (female)

650408-B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65108 1-1/4 - 11-1/2 N.P.S.M.

650408-2-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-4

650408-4-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-4 Figure 1

650408-5-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-5

NOTE: Dimensions are shown in inches and (mm) and are supplied for reference only.

650408-6-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-6

650408-7-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-7

650408-8-B. . . . . . . . . . . . . . . . . . . . . . . . . . . 65108-9

Lower Pump Repair Kit . . . . . . . . . . . . . . . . 637010-X

Material Inlet (female) . . . . . . . . . . . . . . . . . 1-1/4 - 11-1/2 N.P.S.M.

Material Outlet (female) . . . . . . . . . . . . . . . 3/4 - 14 N.P.T.F. - 1

IMPORTANT

This is one of four documents which support the pump. Re-

placement copies of these forms are available upon request.

: 650408-X-B Model Operator’s Manual (pn 97999-22)

S-632 General Information - Industrial Piston Pumps (pn

97999-624)

65106-X Lower Pump End Operator’s Manual (pn 97999-578)

6544X-X Air Motor Operator’s Manual (pn 97999-64)

INGERSOLL RAND COMPANY LTD

P.O. BOX 151 y ONE ARO CENTER y BRYAN, OHIO 43506-0151

(800) 276-4658 y FAX (800) 266-7016 © 2007 CCN 81649790

PUMP OPTION DESCRIPTION CHART

DESCRIPTION

650408 - X - B - Teflon® packing / Plain Rod & Tube, Standard Motor

2- UHMW-PE packing / Plain Rod & Tube, Counter Motor

DESCRIPTION 4- UHMW-PE packing / Plain Rod & Tube, Standard Motor

5- Teflon packing / Ceramic Coated Rod & Tube, Standard Motor

6- UHMW-PE packing / Ceramic Coated Rod & Tube, Standard Motor

7- Viton® / UHMW-PE packing / Ceramic Coated Rod & Tube, Standard Motor

8- Viton / UHMW-PE packing / Plain Rod, Ceramic Coated Tube, Standard Motor

GENERAL DESCRIPTION PUMP CONNECTION - UPPER / LOWER

The two-ball design provides for easy priming of the lower foot NOTE: All threads are right hand.

valve. The double acting feature is standard in all ARO industrial 1. Loosen (90606) lock nut and unscrew the entire pump from

pumps. Material is delivered to the pump discharge outlet on both the air motor. This will expose (90609) retaining screw (see fig-

the up and down stroke. ure 2).

The motor is connected to the lower pump end with a spacer tube 2. Unscrew (90609) retaining screw to remove pump assembly

and solvent cup. This allows for lubrication of the upper packing from the air motor.

gland and to prevent air motor contamination because of normal 3. Remove the (90608) shoulder nut to remove (90609) retaining

wear and eventual leakage through the material packing gland. screw.

WARNING HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 1,350 p.s.i. (93.1 bar) at 150

p.s.i. (10.3 bar) inlet air pressure. PUMP CONNECTOR DETAIL

Pump Ratio X = Maximum Pump Pump Motor Piston Rod

Inlet Pressure to Pump Motor Fluid Pressure

Pump ratio is an expression of the relationship between the pump motor area

and the lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure Retaining Screw 90609

is supplied to the motor of a 9:1 ratio pump, it will develop a maximum of 1,350

p.s.i. (93.1 bar) fluid pressure (at no flow) - as the fluid control is opened, the flow

rate will increase as the motor cycle rate increases to keep up with the demand.

Lock Nut 90606 (Ref.)

WARNING Refer to general information sheet for additional

safety precautions and important information. Shoulder Nut 90608

NOTICE: Thermal expansion can occur when the fluid in the mate-

rial lines is exposed to elevated temperatures. Example: Material

Lower Pump Plunger

lines located in a non-insulated roof area can warm due to sunlight.

Install a pressure relief valve in the pumping system.

Replacement warning label (pn 92325) is available upon re- Figure 2

quest.

TROUBLE SHOOTING REASSEMBLY

1. Slide (90609) retaining screw over air motor rod (see figure 2).

Pump problems can occur in either the air motor section or the 2. Screw (90608) shoulder nut to air motor rod.

lower pump end section. Use these basic guidelines to help deter- 3. Apply Loctite® 242 to threads of (90609) retaining screw and

mine which section is affected. Be sure to eliminate any possible screw (90609) retaining screw into lower pump plunger.

non-pump problems before suspecting pump malfunction. 4. Screw the lower pump assembly to the air motor.

Pump will not cycle. 5. Position air motor exhaust port approximately 90° from lower

y No pressure to the motor. See motor manual. pump outlet.

y Restricted return lines. Clean obstruction. 6. Screw (90606) lock nut against the air motor base and tighten

y Damaged motor. Service the motor. to 50 - 65 ft. lbs (67.8 - 88.1 Nm).

No material at the outlet (pump continually cycles).

y Check the material supply, disconnect or shut off the air supply

and replenish the material, reconnect.

Material on one stroke only (fast downstroke).

y The lower check may not be seating in the foot valve (see lower

pump disassembly). Remove the check from the foot valve,

clean and inspect the valve seat area. If the check or foot valve

are damaged, replace.

Material on one stroke only (fast upstroke).

y The middle packings may be worn (see lower pump disassem-

bly). Replace the seals as necessary.

Material leakage out of the solvent cup or material appears on

the pump plunger rod.

y Tighten the solvent cup until leakage discontinues. If this

procedure does not aid in stopping the leakage problem, the

upper packings may be worn (see lower pump disassembly).

Replace the seals as necessary.

y Teflon® and Viton® are registered trademarks of the DuPont Company y

y ARO® is a registered trademark of Ingersoll-Rand Company y

y Loctite® is a registered trademark of Henkel Loctite Corporation y

PN 97999-22

Page 2 of 2 650408-X-B (en)

Vous aimerez peut-être aussi

- Operator's Manual for 662420-B Air Motor Oil PumpDocument11 pagesOperator's Manual for 662420-B Air Motor Oil PumpgnunezisventecPas encore d'évaluation

- Operator'S Manual 613100-1: 613100 - 1 Wash Pump 613104 Detergent Pump Assembly 4-1/4" AIR MOTOR 10:1 RATIO 4" StrokeDocument6 pagesOperator'S Manual 613100-1: 613100 - 1 Wash Pump 613104 Detergent Pump Assembly 4-1/4" AIR MOTOR 10:1 RATIO 4" StrokeFernando FloresPas encore d'évaluation

- Operator'S Manual NM2304B-X-XDocument2 pagesOperator'S Manual NM2304B-X-Xisraf bhaiPas encore d'évaluation

- Procedimiento de Pulido CrankshaftsDocument19 pagesProcedimiento de Pulido CrankshaftsJavier Hector CayaPas encore d'évaluation

- SM Pw170es-6k-962Document625 pagesSM Pw170es-6k-962Эрнест Бекиров100% (1)

- Io-550-Series-Maintenance and OverhaulDocument824 pagesIo-550-Series-Maintenance and OverhaulFábio VieiraPas encore d'évaluation

- SB/SBH/SBI Manual Installation and Maintenance GuideDocument24 pagesSB/SBH/SBI Manual Installation and Maintenance GuideErkan TakPas encore d'évaluation

- Pistons and Connecting Rods - AssembleDocument6 pagesPistons and Connecting Rods - AssemblealonsoPas encore d'évaluation

- BTR (DSI), M78: 6 SPEED RWD/4WD (Electronic Control)Document5 pagesBTR (DSI), M78: 6 SPEED RWD/4WD (Electronic Control)DewisPas encore d'évaluation

- BTR (DSI), M78 6 SPEED RWD/4WD Transmission Parts CatalogDocument5 pagesBTR (DSI), M78 6 SPEED RWD/4WD Transmission Parts CatalogzinhoabreuPas encore d'évaluation

- Crankshaft - InstallDocument5 pagesCrankshaft - InstallalonsoPas encore d'évaluation

- BPM-DOWNHOLE MOTOR USER'S MANUALDocument80 pagesBPM-DOWNHOLE MOTOR USER'S MANUALXueying LiPas encore d'évaluation

- Manitou Forklift Mast Parts ManualDocument42 pagesManitou Forklift Mast Parts ManualRazvan MitruPas encore d'évaluation

- ARO AF0409C Two Ball Piston Pump DatasheetDocument4 pagesARO AF0409C Two Ball Piston Pump DatasheetGezzy Boys 28Pas encore d'évaluation

- Parts ManualDocument116 pagesParts ManualCarri Tezaa50% (2)

- SF Ter 0421Document21 pagesSF Ter 0421suraj pandeyPas encore d'évaluation

- SF Ter Iv 22Document21 pagesSF Ter Iv 22Aria HimePas encore d'évaluation

- Magentos Series s20-200Document140 pagesMagentos Series s20-200Julio Palacios Vera100% (3)

- S-20/S-200 Series High Tension Magneto Service ManualDocument132 pagesS-20/S-200 Series High Tension Magneto Service ManualYoonjoon Huh67% (3)

- Reuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesDocument38 pagesReuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesJuan Pujol100% (2)

- Culata 3406E C15Document19 pagesCulata 3406E C15carlos moralesPas encore d'évaluation

- pdf142 6l80e PDFDocument5 pagespdf142 6l80e PDFLuisPas encore d'évaluation

- Documents - Pub - Caterpillar Cat 325 LN Excavator Prefix 3ll Service Repair Manual 3ll00001 and Up 1616114926Document26 pagesDocuments - Pub - Caterpillar Cat 325 LN Excavator Prefix 3ll Service Repair Manual 3ll00001 and Up 1616114926temesgenPas encore d'évaluation

- 4800 SERIES: Manitou North America, IncDocument48 pages4800 SERIES: Manitou North America, IncRazvan MitruPas encore d'évaluation

- 4800 SERIES: Manitou North America, IncDocument48 pages4800 SERIES: Manitou North America, IncRazvan MitruPas encore d'évaluation

- 4G9 Engine Service SpecificationsDocument475 pages4G9 Engine Service SpecificationsIbrahim Pagbelem100% (1)

- GM 6T70/75 & Ford 6F50/55: 6 Speed FWD (Electronic Control)Document5 pagesGM 6T70/75 & Ford 6F50/55: 6 Speed FWD (Electronic Control)Hola ValdePas encore d'évaluation

- Service Manual for Caterpillar 3304 and 3306 Industrial & Marine EnginesDocument827 pagesService Manual for Caterpillar 3304 and 3306 Industrial & Marine Enginesruss mathis100% (35)

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковPas encore d'évaluation

- Caterpillar 3406b Specification Industrial Marine EngineDocument10 pagesCaterpillar 3406b Specification Industrial Marine Enginebryan100% (38)

- Mitsubishi Engine 4g1 Series Shop ManualDocument10 pagesMitsubishi Engine 4g1 Series Shop Manualtheresa100% (49)

- Procedure To Measure and Straighten Bent Crankshaft PDFDocument26 pagesProcedure To Measure and Straighten Bent Crankshaft PDFbetoven8437100% (1)

- Copt ManualDocument79 pagesCopt ManualPradeep Shukla94% (17)

- Proton Waja 1.6L 4G18 Engine Service ManualDocument144 pagesProton Waja 1.6L 4G18 Engine Service ManualyusufPas encore d'évaluation

- SEBF8043 Crankshaft Visual InspectionDocument49 pagesSEBF8043 Crankshaft Visual InspectionpramPas encore d'évaluation

- PARTS MANUAL PN 9918837 and MICROFICHE PN 9918838 3/03Document66 pagesPARTS MANUAL PN 9918837 and MICROFICHE PN 9918838 3/03larkat2339Pas encore d'évaluation

- Deflexión de CigueñalDocument21 pagesDeflexión de CigueñalCatalina HuenumanPas encore d'évaluation

- Specs for 3500B and 3500C Marine EnginesDocument240 pagesSpecs for 3500B and 3500C Marine Engineslacoth100% (1)

- John Deree 450 550 650j Crawler Parts CatalogDocument20 pagesJohn Deree 450 550 650j Crawler Parts Catalogmichael100% (28)

- SEBF8054 - Procedure To Measure and Straighten Bent CrankshaftsDocument28 pagesSEBF8054 - Procedure To Measure and Straighten Bent Crankshaftsyahmanmahira4Pas encore d'évaluation

- Operator'S Manual Af0409Cxxxxxx-Xx-XDocument4 pagesOperator'S Manual Af0409Cxxxxxx-Xx-Xtaller.copiapoPas encore d'évaluation

- Mahindra 475 DI Total Parts ManualDocument60 pagesMahindra 475 DI Total Parts ManualSrinivas Sri100% (3)

- KF40AA Parts CatalogueDocument109 pagesKF40AA Parts CataloguePapas MamasPas encore d'évaluation

- 4G93 PDFDocument130 pages4G93 PDFMarco Diaz100% (2)

- zf8hp45x PDFDocument4 pageszf8hp45x PDFZakaria KalomarPas encore d'évaluation

- Product Information Service Instructions: COT / S 250 - 750 / 800 - 1600A COT 250 - 450 / 1600 - 3150ADocument8 pagesProduct Information Service Instructions: COT / S 250 - 750 / 800 - 1600A COT 250 - 450 / 1600 - 3150AMarcos Baldoceda ValverdePas encore d'évaluation

- Bulsosser Jhon Deere 550Document511 pagesBulsosser Jhon Deere 550Daniel MoraPas encore d'évaluation

- 2005 Deep Snow Polaris 900 Service ManualDocument308 pages2005 Deep Snow Polaris 900 Service ManualManual Guy100% (6)

- 924K Wheel Loader PWR00001-UP (MACHINE) POWERED BY C6.6 Engine (SEBP5135 - 70) - Sistemas y Componentes 1 PDFDocument2 pages924K Wheel Loader PWR00001-UP (MACHINE) POWERED BY C6.6 Engine (SEBP5135 - 70) - Sistemas y Componentes 1 PDFubaldo caraballoPas encore d'évaluation

- Hyundai d6gf1Document4 pagesHyundai d6gf1EduardoSalgueroPas encore d'évaluation

- Valves, Valve Springs, Valve Rotocoils, and LocksDocument55 pagesValves, Valve Springs, Valve Rotocoils, and Locksbetoven8437Pas encore d'évaluation

- SM47013 PDFDocument8 pagesSM47013 PDFHENKO7659Pas encore d'évaluation

- Biselador de 3 AntorchasDocument7 pagesBiselador de 3 AntorchasIrving Israel IrvingPas encore d'évaluation

- STP550Document22 pagesSTP550waleedyehia0% (1)

- 8044-13 Hyd PartsDocument119 pages8044-13 Hyd PartsthailanPas encore d'évaluation

- CASE 580SR+ SERIES 3 BACKHOE LOADER Service Repair Manual PDFDocument64 pagesCASE 580SR+ SERIES 3 BACKHOE LOADER Service Repair Manual PDFjkmmmmPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- How to Rebuild & Modify Rochester Quadrajet CarburetorsD'EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsÉvaluation : 5 sur 5 étoiles5/5 (2)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceD'EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceÉvaluation : 5 sur 5 étoiles5/5 (2)

- For 320Xpc Drills With 2 Pipe Racks FIRST USED ON 320174 & 320175Document3 pagesFor 320Xpc Drills With 2 Pipe Racks FIRST USED ON 320174 & 320175jose Antonio100% (1)

- Fig.17. Gasket Set: 3TNV80F-SPSUDocument1 pageFig.17. Gasket Set: 3TNV80F-SPSUliuzj7254Pas encore d'évaluation

- Updated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Document31 pagesUpdated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Francisco Wilson Bezerra FranciscoPas encore d'évaluation

- ValvesDocument27 pagesValvesWade ColemanPas encore d'évaluation

- VALVEDocument2 pagesVALVEOlink Achmad KafaillahPas encore d'évaluation

- Rising Main DesignDocument3 pagesRising Main DesignJaspal Singh0% (1)

- Catalago de GemflexDocument51 pagesCatalago de GemflexDanny ApontePas encore d'évaluation

- Valvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FDocument2 pagesValvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FGrecia Paola Garza RodriguezPas encore d'évaluation

- Section08 - Pilot Operated Check ValvesDocument28 pagesSection08 - Pilot Operated Check ValvesHENRY LLOFREL CORREA LOPEZPas encore d'évaluation

- CC Pump Handbook by SK ThapaDocument50 pagesCC Pump Handbook by SK ThaparonyjohnsonPas encore d'évaluation

- Marine Valves Jis Standard: All Products Are Mill Certifi Cated 3.1BDocument2 pagesMarine Valves Jis Standard: All Products Are Mill Certifi Cated 3.1BSatyabrat GaanPas encore d'évaluation

- Saes S 050Document17 pagesSaes S 050Hamza ChPas encore d'évaluation

- 7 - Control Valve CharacteristicsDocument11 pages7 - Control Valve CharacteristicsAhmed ShahabiPas encore d'évaluation

- Woodhouse Stock Jan 2019Document720 pagesWoodhouse Stock Jan 2019Anonymous VNu3ODGav100% (2)

- Poster in Pneumatic From Hamiti Festo DidacticDocument1 pagePoster in Pneumatic From Hamiti Festo DidacticHAMIT100% (4)

- Pressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Document5 pagesPressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Y.Ebadi100% (2)

- Pilot Valve (Command Control Steering) 966Document16 pagesPilot Valve (Command Control Steering) 966Ahmed RezkPas encore d'évaluation

- Chapter2-Pneumatics Components and Symbols RepresentationDocument38 pagesChapter2-Pneumatics Components and Symbols RepresentationNurainin SofiyaPas encore d'évaluation

- Test 1: Aircraft English TestsDocument45 pagesTest 1: Aircraft English Testshunganhngoc100% (2)

- Valve Solutions For Pipelines PDFDocument8 pagesValve Solutions For Pipelines PDFCristhian Niño MartinezPas encore d'évaluation

- Build Program: Hydraulic Fluid Power B.VDocument12 pagesBuild Program: Hydraulic Fluid Power B.Vrakhikishore143Pas encore d'évaluation

- Duct Calculation Original Xls SheetDocument39 pagesDuct Calculation Original Xls Sheetsaimudduluru88Pas encore d'évaluation

- Module 8 - Pumps PDFDocument48 pagesModule 8 - Pumps PDFRomeo Paulo Aquino CabuyadaoPas encore d'évaluation

- High Pressure Booster Pumps Add Pressure Long LinesDocument1 pageHigh Pressure Booster Pumps Add Pressure Long Linescristobal_tl2277Pas encore d'évaluation

- Volume5 Study of Hydraulic CircuitsDocument64 pagesVolume5 Study of Hydraulic CircuitsMdp DhandapaniPas encore d'évaluation

- Bleed Air from the Hydraulic SystemDocument2 pagesBleed Air from the Hydraulic SystemohbabyohbabyPas encore d'évaluation

- Centrifugal Pumps IntroductionDocument6 pagesCentrifugal Pumps IntroductionKhemiri Houssem EddinePas encore d'évaluation

- Guide to Watertight Sliding Door Operation and MaintenanceDocument21 pagesGuide to Watertight Sliding Door Operation and MaintenanceRajan BhandariPas encore d'évaluation

- LADWER API 510 - API RP 576 - April 2017Document8 pagesLADWER API 510 - API RP 576 - April 2017Luthfi ArdiansyahPas encore d'évaluation

- Bentley Watercad V8I (Selectseries 5) (08.11.05.61) Bentley Systems, Inc. Haestad Methods Solution Center Water System - WTGDocument3 pagesBentley Watercad V8I (Selectseries 5) (08.11.05.61) Bentley Systems, Inc. Haestad Methods Solution Center Water System - WTGHemn Rafiq TofiqPas encore d'évaluation