Académique Documents

Professionnel Documents

Culture Documents

IRDH275 DB en PDF

Transféré par

NaveedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IRDH275 DB en PDF

Transféré par

NaveedDroits d'auteur :

Formats disponibles

Dipl.-Ing. W. Bender GmbH & Co. KG • Londorfer Str. 65 • 35305 Grünberg • Tel.

: 06401 807-0 • Fax: 06401 807-259

A-ISOMETER® IRDH275 Insulation monitoring device for unearthed

AC, AC/DC and DC systems (IT systems)

Product description

The A-ISOMETER® of the IRDH275 series is designed to monitor the insulation resistance

of unearthed main circuits (IT systems) AC, AC/DC 0…793 V resp. DC 0…650 V. The

AMPPlus measuring principle meets the particular requirements of modern power sup-

plies which often include rectifiers, converters, thyristor-controlled DC drives and directly

connected DC components. In these systems often high leakage capacitances against

earth occur due to interference suppression measures. The IRDH275 automatically ad-

apts itself to the existing system conditions.

In combination with a coupling device, the Isometers can also be used for higher vol-

tages. An external supply voltage allows de-energized systems to be monitored too. For

door mounting into distribution panels, refer to type IRDH375(B).

A-ISOMETER® IRDH275

Application

Device features • AC, DC or AC/DC main circuits • Heaters with phase control

• Insulation monitoring for unearthed sy- • AC/DC main circuits with directly • Systems including switched-mode

stems AC, AC/DC 0…793 V, connected DC components, such as rec- power supplies

DC 0…650 V tifiers, converters, and thyristor-con- • IT systems including high lekage

trolled DC drives capacitances

• Nominal voltage extendable via

coupling device • UPS systems, battery systems • Coupled IT systems

• Two separately adjustable response va- Function

lues 1 kΩ…10 MΩ When the insulation resistance between the system conductors and earth falls below the

• AMPPlus measuring principle set response value, the alarm relays switch and the alarm LEDs light up. Two separately

• Automatic adaptation to the system lea- adjustable alarm relays allow to distinguish between prewarning and alarm. The mea-

kage capacitance sured value is indicated on the LC display or an externally connectable measuring instru-

• Info key to display device settings and ment. In this way any changes, for example when circuits are connected to the system,

the system leakage capacitance can be recognized easily. The fault message can be stored. The fault memory can be re-

set by pressing the reset button. By pressing the test button, the function of the device

• Self monitoring with automatic alarm as well as the connections to system and earth can be tested. Pressing the INFO key pro-

1.5

message vides additional information, such as the existing system leakage capacitance or device

• Automatic self test, selectable settings.

• Connection for external kΩ indication The function of the device and the system and earth connections are continuously moni-

• test and reset button tored. When a fault occurs, the system fault relay switches and the alarm LED "system

fault" lights up. The parameterization of the device can be carried out via the LC display

• Connection external test/reset button

or the function keys integrated in the front plate.

• Two separate alarm relays with two vol-

tage-free changeover contacts Device version IRDH275B

• N/O or N/C operation Device version IRDH275B includes the following additional functions:

• Backlit LC display • History memory with real-time clock to store all alarm messages with date and time stamp.

• RS-485 interface • Galvanically isolated RS-485 interface (BMS protocol) for data exchange with other

BENDER devices

Approvals

• Isometer disconnecting relays for the operation of several A-ISOMETER®s in intercon-

nected IT systems

• Current output 0(4 )…20 mA (electrically isolated)

Use in coupled IT systems

Only one A-ISOMETER® may be active when several IT systems are coupled. Isometer

disconnecting relays and the control inputs F1/F2 integrated in version IRDH275B gua-

rantee that this requirement will always be met and make them suitable for coupled

systems too.

Measuring principle

The IRDH275(B) series uses the patented AMPPlus measuring principle

(refer to chapter Annex – "Technical aspects…“). This measuring prin-

ciple allows concise monitoring of modern power supply systems, also in case of exten-

sive, directly connected DC components and high system leakage capacitances.

56 Main catalogue part 1 – 08.2007 / Update 07.2008 / Insulation monitoring

Right to modifications reserved ! – © Dipl.-Ing. W. Bender GmbH & Co. KG, Germany

A-ISOMETER® IRDH275

Operating elements IRDH275 Wiring diagram

3 4

1 2 3 4 5 6 7 8 2 5

1- INFO key: to query standard information

ESC key: back to the menu function

1 6

2- TEST button: to call up the self test.

Arrow up key: Parameter change, scroll.

3- LC display

4- RESET button: to delete alarm and fault messages

Arrow down key: Parameter change, scroll.

5- MENU key: to activate the MENU system

Enter key: To confirm parameter change.

6- Alarm LED 1 lights: insulation fault, 1st warning level reached

7- Alarm LED 2 lights: insulation fault, 2nd warning level reached

8- LED lights: a system fault exists

1.5

Response times 7 8 9 10 11 12 13

1- Supply voltage US (see ordering information) via fuse

2,3 - Connection to the 3AC system being monitored:

Connect the terminals L1, L2 to neutral conductor N or

terminals L1, L2 to conductor L1, L2

4 Connection to the AC system being monitored:

Connect terminals L1, L2 to conductor L1, L2.

5- Connection to the DC systems being monitored:

Connect terminal L1 to conductor L+ and terminal L2 to

conductor L-.

6- Separate connection of the equipotential bonding

conductor to PE and KE.

7- External test button (N/O contact)

8- External reset button (N/C contact or wire jumper). When

the terminals are open, the fault message will not be stored.

A-ISOMETER® response times in relation to the system leakage 9- STANDBY by means of the function input F1, F2: When the

capacitances: Ce = 1…500 μF, Un = 0…793 V/50 Hz contact is closed, no insulation measurement takes place.

(Isometer disconnection B version only/no disconnection

when operated via coupling device)

10 - IRDH275: Currrent output, electrically isolated: 0…400 μA

IRDH275B: Currrent output, electrically isolated:

0…20 mA or 4…20 mA

11 - RS-485 interface

12 - Alarm relay: Alarm 1

13 - Alarm relay: Alarm 2/system

Main catalogue part 1 – 08.2007 / Update 07.2008 / Insulation monitoring 57

A-ISOMETER® IRDH275

Wiring diagrams – Ordering information A-ISOMETER® IRDH275

IRDH275 connected to different types of coupling devices

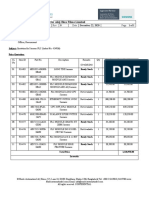

Type Nominal Supply Art. No.

A-ISOMETER® IRDH275 with coupling device AGH150W-4 voltage Un voltage US

IRDH275-435 AC 0…793 V/ AC 88…264/ B 9106 5100

DC 0…650 V* DC 77…286 V*

IRDH275B-435 AC 0…793 V/ AC 88…264/ B 9106 5101

DC 0…650 V* DC 77…286 V*

IRDH275-427 AC 0…793 V/ DC 19.2…72 V B 9106 5104

DC 0…650 V*

IRDH275B-427 AC 0…793 V/ DC 19.2…72 V B 9106 5105

DC 0…650 V*

IRDH275B-425 AC 0…793 V/ DC 10.2…36 V B 9106 5108

DC 0…650 V*

* Absolute values

Accessories

External kΩ measuring instrument 400 μA

Type Art. No.

A-ISOMETER® IRDH275 with coupling device AGH204S-4 7204-1421 B 986 763

9604-1421 B 986 764

1

External kΩ measuring instrument 20 mA

2 Type Art. No.

9620-1421 B 986 841

Coupling devices

1.5

Type Nominal system voltage Un Art. No.

AGH150W-4 DC 0…1760 V B 9801 8006

AGH204S-4 AC 0…1650 (1300) V B 914 013

AGH520S AC 0…7200 V B 913 033

1- without rectifier Un = 3AC 0…1650 V (DC max. 1000 V)

2- with rectifier Un = 3AC 0…1300 V (peak voltage down-

stream of the rectifier or intermediate

voltage max. 1840 V)

A-ISOMETER® IRDH275 with coupling device AGH520S

58 Main catalogue part 1 – 08.2007 / Update 07.2008 / Insulation monitoring

A-ISOMETER® IRDH275

Technical data A-ISOMETER® IRDH275

Insulation coordination acc. to IEC 60664-1 Serial interfaces

Rated insulation voltage AC 800 V IRDH275 RS-485/ASCII

Rated impulse voltage/pollution degree 8 kV/3 IRDH275B RS-485/BMS

Max. cable length 1200 m

Voltage ranges

Recommended cable (shielded, shield on one side connected to PE) J-Y(ST)Y 2 x 0.6

Nominal system voltage Un AC, 3(N)AC 0…793 V, DC 0…650 V Terminating reistor 120 Ω (0.5 W)

Rated frequency fn DC, 0.2…460 Hz

Supply voltage US AC 88…264 V, DC 77…286 V Switching elements

Frequency range US 20…460 Hz Number of switching elements 2 x 1 changeover contact

Power consumption ≤ 14 VA Operating principle N/O or N/C operation

Factory setting N/O operation

Response values Electrical service life, number of cycles 12000

Response value Ran1 (Alarm 1) 1 kΩ…10 MΩ Contact class IIB in accordance with DIN IEC 60255-0-20

Response value Ran2 (Alarm 2) 1 kΩ…10 MΩ Rated contact voltage AC 250 V/DC 300 V

Absolute error (1 kΩ…10 kΩ) + 2 kΩ Making capacity AC/DC 5 A

Relative percentage error (10 kΩ…10 MΩ) 0 %…+ 20 % Breaking capacity 2 A, AC 230 V, cos phi = 0.4 – 0.2 A, DC 220 V, L/R = 0.04 s

Response time tan at RF = 0.5 x Ran and Ce = 1 μF <5s Minimum contact current at DC 24 V 2 mA (50 mW)

Measuring time see characteristic curves (TGH page 69)

General data

Hysteresis (1 kΩ…10 kΩ)/(10 kΩ…10 MΩ) + 2 kΩ/25 %

Shock resistance IEC 60068-2-27 (during operation) 15 g/11 ms

Measuring circuit Bumping IEC 60068-2-29 (during transport) 40 g/6 ms

Measuring voltage Um (peak value) ± 50 V Vibration resistance IEC 60068-2-6 (during operation) 1 g/10…150 Hz

Measuring current Im (at RF = 0 Ω) ≤ 278 μA Vibration resistance IEC 60068-2-6 (during transport) 2 g/10…150 Hz

Internal DC resistance Ri ≥ 180 kΩ Ambient temperature (during operation/during storage) - 10 °C…+ 55 °C/- 40 °C…+ 70 °C

Impedance Zi at 50 Hz ≥ 180 kΩ Climatic class acc. to DIN IEC 60721-3-3 3K5

Permissible extraneous DC voltage Ufg ≤ 1200 V Operating mode continuous operation

Permissible system leakage capacitance ≤ 500 μF Mounting display oriented

Factory setting 150 μF Connection screw-type terminals

Connection properties rigid/flexible 0.2…4 mm2/0.2…2.5 mm2

Displays Degree of protection, internal components /terminal (DIN EN 60529) IP30 / IP20

1.5

Display (illuminated) two-line display DIN rail mounting acc. to DIN EN 60715/IEC 60715

Characters (number of characters, height) 2 x 16 characters/4 mm Screw mounting, mounting plate 2 x M4

Display range, measuring value 1 kΩ…10 MΩ Flammability class UL94V-0

Absolute error (1 kΩ…10 kΩ) ± 1 kΩ Product standards DIN EN 61557-8: 1998-05

Relative percentage error (10 kΩ…10 MΩ) ± 10 % EN 61557-8: 1997-03, IEC 61557-8: 1997-02

ASTM F1669M-96, ASTM F1207M-96

Outputs

Operating manual TGH1361

Test/reset button internal/external Weight approx. 510 g

Current output measuring instrument 120 kΩ

Load ≤ 400 μA (12.5 kΩ) Option „W“

Load B version ≤ 20 mA (500 Ω) Shock resistance IEC 60068-2-27 (during operation) 30 g/11 ms

Bumping IEC 60068-2-29 (during transport) 40 g/6 ms

Vibration resistance IEC 60068-2-6 1.6 mm/10…25 Hz, 4 g/25…150 Hz

Ambient temperature (during operation) - 40 °C…+ 70 °C

Ambient temperature (during transport) - 40 °C…+ 85 °C

Dimension diagram XM112

Dimensions in mm

Main catalogue part 1 – 08.2007 / Update 07.2008 / Insulation monitoring 59

Vous aimerez peut-être aussi

- Irdh275 D00122 D XxenDocument6 pagesIrdh275 D00122 D XxenCarlos PintoPas encore d'évaluation

- Isometer® Irdh275: Insulation Monitoring Device For Unearthed AC, AC/DC and DC Systems (IT Systems)Document6 pagesIsometer® Irdh275: Insulation Monitoring Device For Unearthed AC, AC/DC and DC Systems (IT Systems)Ooi Ban JuanPas encore d'évaluation

- Bender IRDH275 enDocument6 pagesBender IRDH275 enam198801Pas encore d'évaluation

- Ir1575 PDFDocument3 pagesIr1575 PDFNaveedPas encore d'évaluation

- Isometer - IRDH275-375-575Document6 pagesIsometer - IRDH275-375-575Ursula JohnsonPas encore d'évaluation

- IRDH275 Datasheet NAE1012021Document7 pagesIRDH275 Datasheet NAE1012021culjak_iPas encore d'évaluation

- ISOMETER® Iso685 - PDocument10 pagesISOMETER® Iso685 - PchungnvPas encore d'évaluation

- Megohmmeter/IR TesterDocument2 pagesMegohmmeter/IR TesterSandro ChiliquingaPas encore d'évaluation

- Irdh265 4Document4 pagesIrdh265 4Deepak JainPas encore d'évaluation

- IRDH375 Series: Digital Ground Fault Monitor / Ground Detector Ungrounded (Floating) AC/DC SystemsDocument6 pagesIRDH375 Series: Digital Ground Fault Monitor / Ground Detector Ungrounded (Floating) AC/DC SystemsZaw Thet OoPas encore d'évaluation

- isoHV425 D00082 D XXENDocument8 pagesisoHV425 D00082 D XXENwakasPas encore d'évaluation

- isoMED427P DB enDocument6 pagesisoMED427P DB enMirwansyah TanjungPas encore d'évaluation

- Multilin 350 Fider Protection System PDFDocument12 pagesMultilin 350 Fider Protection System PDFEddison191Pas encore d'évaluation

- ES Series Protection Relays: Eatures EnefitsDocument2 pagesES Series Protection Relays: Eatures EnefitsgusmilexaPas encore d'évaluation

- 3bht490300 E01 B oDocument8 pages3bht490300 E01 B oadinamartinsPas encore d'évaluation

- HariffDocument20 pagesHariffMuflich PuteraPas encore d'évaluation

- Lithium Ion Battery Management System: Main Features Input / OutputDocument2 pagesLithium Ion Battery Management System: Main Features Input / OutputСергей СалтыковPas encore d'évaluation

- Isometer® Isomed427X - (PT) : Insulation Monitoring Device For Medical ApplicationsDocument6 pagesIsometer® Isomed427X - (PT) : Insulation Monitoring Device For Medical ApplicationswakasPas encore d'évaluation

- 107TD47 DB enDocument6 pages107TD47 DB enNaveedPas encore d'évaluation

- HA032952 - 4 - EPC3000 - Data SheetDocument12 pagesHA032952 - 4 - EPC3000 - Data SheetRavi Kant GuptaPas encore d'évaluation

- Lehe3225 02Document5 pagesLehe3225 02Piranha ParabolaPas encore d'évaluation

- Foxboro 2500 Controller: Specification SheetDocument8 pagesFoxboro 2500 Controller: Specification SheetMohamed HammamPas encore d'évaluation

- Isometer Ir470ly - D00119 - D - XxenDocument6 pagesIsometer Ir470ly - D00119 - D - Xxenguillen j-cPas encore d'évaluation

- 350Document12 pages350András KozákPas encore d'évaluation

- Infineon Ikcs12f60b2a C Rev1 0 201006283-1168599Document19 pagesInfineon Ikcs12f60b2a C Rev1 0 201006283-1168599علی امامیPas encore d'évaluation

- A Isometer IRDH575Document5 pagesA Isometer IRDH575Ursula JohnsonPas encore d'évaluation

- Busbar Protection IED: - Centralized ModelDocument37 pagesBusbar Protection IED: - Centralized ModelHuynh DuongPas encore d'évaluation

- SR 345 Transformer Protection System TrainingDocument97 pagesSR 345 Transformer Protection System TrainingLong Luong VanPas encore d'évaluation

- Industrial Power BrochureDocument32 pagesIndustrial Power BrochurebuiquangsangPas encore d'évaluation

- Isom-Digiware Brochure 2020-01 Doc312043i enDocument14 pagesIsom-Digiware Brochure 2020-01 Doc312043i enMauro MadeiraPas encore d'évaluation

- Digital PWM System Controller: FeaturesDocument38 pagesDigital PWM System Controller: FeaturesAnamPas encore d'évaluation

- Comfort Controller 6400: Product DataDocument4 pagesComfort Controller 6400: Product DataAlexander Rojas BejaranoPas encore d'évaluation

- 165420Document16 pages165420santoshkumarPas encore d'évaluation

- ES Relay - Feb 2019Document18 pagesES Relay - Feb 2019Filipe BrandaoPas encore d'évaluation

- How To Determine Thermal Resistance For A Power Semiconductor Heat Sink in An SMPSDocument2 pagesHow To Determine Thermal Resistance For A Power Semiconductor Heat Sink in An SMPShdabhr463Pas encore d'évaluation

- 2012 Neo3000 SubstationDocument8 pages2012 Neo3000 Substationjoydeep_d3232Pas encore d'évaluation

- Isometer - IR125YDocument2 pagesIsometer - IR125YUrsula JohnsonPas encore d'évaluation

- RTP Rata Flujo ManualDocument18 pagesRTP Rata Flujo ManualFabian PerezPas encore d'évaluation

- In Waste Water Treatment Facilities: High Availability For Reliable OperationDocument4 pagesIn Waste Water Treatment Facilities: High Availability For Reliable OperationJose CaceresPas encore d'évaluation

- Woodward SEG MaualDocument16 pagesWoodward SEG MaualKishore KrishnaPas encore d'évaluation

- Cooper Edison Idea iXP-420 Differential RelayDocument16 pagesCooper Edison Idea iXP-420 Differential Relay6bngdz4xhkPas encore d'évaluation

- isoPV1685xxx D00007 D XXENDocument6 pagesisoPV1685xxx D00007 D XXENwakasPas encore d'évaluation

- Intelligent Component Series Direct Coupled Damper Actuator (High Torque Type) Model MY8042ADocument12 pagesIntelligent Component Series Direct Coupled Damper Actuator (High Torque Type) Model MY8042Avubac11Pas encore d'évaluation

- Family: Advanced Protection, Control and Monitoring SystemDocument4 pagesFamily: Advanced Protection, Control and Monitoring Systemhoàng nguyễnPas encore d'évaluation

- SN 65 Hvs 885Document28 pagesSN 65 Hvs 8851553Pas encore d'évaluation

- CM2000 BrochureDocument6 pagesCM2000 Brochureabdulkawi alasharyPas encore d'évaluation

- Voltage Relay REU 610: Product Guide - ANSI VersionDocument12 pagesVoltage Relay REU 610: Product Guide - ANSI Versionabdullah_ghanPas encore d'évaluation

- Sentinel Power: 5-6 kVA 6.5-10 kVADocument4 pagesSentinel Power: 5-6 kVA 6.5-10 kVAAhmed TitawiPas encore d'évaluation

- 1kha000951 Uen Re 216Document1 062 pages1kha000951 Uen Re 216chichid2008Pas encore d'évaluation

- ACS75Document11 pagesACS75peron_666Pas encore d'évaluation

- Comfort Controller 6400 (Outdoor Duty Rated) : Product DataDocument4 pagesComfort Controller 6400 (Outdoor Duty Rated) : Product Datalecau50cdlPas encore d'évaluation

- Infinity S Flex, CPB-NESFlex 10-29-15Document16 pagesInfinity S Flex, CPB-NESFlex 10-29-15Anonymous z631suOmPas encore d'évaluation

- Lm317 3-Terminal Adjustable Regulator: 1 Feateeures 3 DescriptionDocument32 pagesLm317 3-Terminal Adjustable Regulator: 1 Feateeures 3 DescriptiontheservicePas encore d'évaluation

- Voltage Source Inverter Design Guide: TI Designs: TIDM-HV-1PH-DCACDocument47 pagesVoltage Source Inverter Design Guide: TI Designs: TIDM-HV-1PH-DCACamrehmaniPas encore d'évaluation

- Practical Data Acquisition for Instrumentation and Control SystemsD'EverandPractical Data Acquisition for Instrumentation and Control SystemsPas encore d'évaluation

- XHHW-2: XLP Insulation, 600 VoltsDocument2 pagesXHHW-2: XLP Insulation, 600 VoltsNaveedPas encore d'évaluation

- FTC470XET TGH en PDFDocument84 pagesFTC470XET TGH en PDFNaveedPas encore d'évaluation

- ATICS-DIO-Operation TKA en PDFDocument4 pagesATICS-DIO-Operation TKA en PDFNaveedPas encore d'évaluation

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedPas encore d'évaluation

- 1083fm PDFDocument46 pages1083fm PDFMohamed NaserPas encore d'évaluation

- XHHW 2 PDFDocument2 pagesXHHW 2 PDFNaveedPas encore d'évaluation

- ATICS-DIO TGH enDocument100 pagesATICS-DIO TGH enNaveedPas encore d'évaluation

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedPas encore d'évaluation

- EDS151 DB enDocument4 pagesEDS151 DB enNaveedPas encore d'évaluation

- Title Sheets Dallah Submittal PDFDocument1 pageTitle Sheets Dallah Submittal PDFNaveedPas encore d'évaluation

- ATiCS Praxis PPT en 20110308Document12 pagesATiCS Praxis PPT en 20110308NaveedPas encore d'évaluation

- CDocument10 pagesCNaveedPas encore d'évaluation

- IPPDocument4 pagesIPPNaveedPas encore d'évaluation

- Network and Transmission Lines 100 MCQDocument21 pagesNetwork and Transmission Lines 100 MCQNandakumar ReddyPas encore d'évaluation

- FTC470XET TGH en PDFDocument84 pagesFTC470XET TGH en PDFNaveedPas encore d'évaluation

- Control System 32 Important MCQDocument7 pagesControl System 32 Important MCQDINESHPas encore d'évaluation

- Analog and Power Electronics Important MCQ PDF: All Exam Review AddaDocument12 pagesAnalog and Power Electronics Important MCQ PDF: All Exam Review AddaNoor AhmedPas encore d'évaluation

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedPas encore d'évaluation

- Transformer - Datasheet - NFPA (American) PDFDocument4 pagesTransformer - Datasheet - NFPA (American) PDFNaveedPas encore d'évaluation

- Engineering Materials 74 Important MCQ PDFDocument10 pagesEngineering Materials 74 Important MCQ PDFNaveedPas encore d'évaluation

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedPas encore d'évaluation

- 300+ TOP CABLES Objective Type Questions and Answers Electrical Engineering Multiple Choice QuestionsDocument16 pages300+ TOP CABLES Objective Type Questions and Answers Electrical Engineering Multiple Choice QuestionsNaveedPas encore d'évaluation

- IR145YDocument3 pagesIR145YAndy Kong KingPas encore d'évaluation

- Neca Nacma 120 Track ChangesDocument43 pagesNeca Nacma 120 Track ChangesAhmed H. HassanPas encore d'évaluation

- 107TD47 DB enDocument6 pages107TD47 DB enNaveedPas encore d'évaluation

- IR1575 DB enDocument3 pagesIR1575 DB enNaveedPas encore d'évaluation

- ATICS-DIO-Operation TKA en PDFDocument4 pagesATICS-DIO-Operation TKA en PDFNaveedPas encore d'évaluation

- Electrical PM Program (By Hanover Risk Solution)Document16 pagesElectrical PM Program (By Hanover Risk Solution)didiekilham100% (2)

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- 12 Step Worksheet With QuestionsDocument26 pages12 Step Worksheet With QuestionsKristinDaiglePas encore d'évaluation

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulPas encore d'évaluation

- Inverter 2 chiềuDocument2 pagesInverter 2 chiềuKhánh Nguyễn MinhPas encore d'évaluation

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuPas encore d'évaluation

- OTP User Manual For English) v1,0Document15 pagesOTP User Manual For English) v1,0auyinPas encore d'évaluation

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTDocument27 pagesTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonPas encore d'évaluation

- 5.1 Behaviour of Water in Rocks and SoilsDocument5 pages5.1 Behaviour of Water in Rocks and SoilsHernandez, Mark Jyssie M.Pas encore d'évaluation

- RSW - F - 01 " ": Building UtilitiesDocument4 pagesRSW - F - 01 " ": Building Utilities62296bucoPas encore d'évaluation

- English Test For Grade 7 (Term 2)Document6 pagesEnglish Test For Grade 7 (Term 2)UyenPhuonggPas encore d'évaluation

- CL Honours Report NamanDocument11 pagesCL Honours Report NamanNaman VermaPas encore d'évaluation

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbPas encore d'évaluation

- Transfert de Chaleur AngDocument10 pagesTransfert de Chaleur Angsouhir gritliPas encore d'évaluation

- Thesis TipsDocument57 pagesThesis TipsJohn Roldan BuhayPas encore d'évaluation

- JUnit 5 User GuideDocument90 pagesJUnit 5 User GuideaawaakPas encore d'évaluation

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhPas encore d'évaluation

- Sheet-Metal Forming Processes: Group 9 PresentationDocument90 pagesSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyPas encore d'évaluation

- PDFDocument653 pagesPDFconstantinPas encore d'évaluation

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioPas encore d'évaluation

- Waves and Ocean Structures Journal of Marine Science and EngineeringDocument292 pagesWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billPas encore d'évaluation

- 5620 SAM Rel 14 License Point Configuration ToolDocument416 pages5620 SAM Rel 14 License Point Configuration Toolluis100% (1)

- Mahindra&mahindraDocument95 pagesMahindra&mahindraAshik R GowdaPas encore d'évaluation

- Aristotle - OCR - AS Revision NotesDocument3 pagesAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- Department of Ece, Adhiparasakthi College of Engineering, KalavaiDocument31 pagesDepartment of Ece, Adhiparasakthi College of Engineering, KalavaiGiri PrasadPas encore d'évaluation

- Sony x300 ManualDocument8 pagesSony x300 ManualMarcosCanforaPas encore d'évaluation

- Concrete Pumping.: Squeeze PumpsDocument2 pagesConcrete Pumping.: Squeeze PumpsALINDA BRIANPas encore d'évaluation

- Transportation of CementDocument13 pagesTransportation of CementKaustubh Joshi100% (1)

- MATH CIDAM - PRECALCULUS (Midterm)Document4 pagesMATH CIDAM - PRECALCULUS (Midterm)Amy MendiolaPas encore d'évaluation