Académique Documents

Professionnel Documents

Culture Documents

PDI - PDA-s-Manual-20July1

Transféré par

Thoong Yew ChanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PDI - PDA-s-Manual-20July1

Transféré par

Thoong Yew ChanDroits d'auteur :

Formats disponibles

22

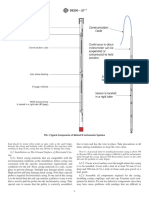

further assumed, and required, that the pile is of a linear elastic material. In high strain

situations, the pile material may go into the plastic range and pile top damage may

result. This could result in unrealistic and inconsistent strain measurements, and

therefore erroneous forces, stresses, energies and capacities. Since the acceleration

signals are generally very similar, one good unit is normally all that is required for a

successful test. A second accelerometer serves as backup and also confirms both

accelerometers are properly functioning when they do yield similar velocity data.

The transducers also should (if at all possible) be attached at least two and preferably

three or more diameters below the pile top to avoid end effects and local contact

stresses. In general for steel piles or pre-stressed concrete piles, the farther from the pile

top the sensors are attached, the better quality the data becomes. The only difference

lower sensor placement makes is that the maximum energy (EMX) is reduced due to the

energy required to compress the pile above the transducers. Attaching near cross section

changes, cracks, welds (horizontal, axial, or spiral), splices, stiffeners or other non-

uniformities should be avoided. It should be noted that “telltale” pipes cause

complications which must be properly accounted for.

For regularly reinforced concrete piles (not prestressed), the transducers should always

be near the pile top (within 1.5 to 3 diameters of pile top) to avoid including cracks

between the strain transducer attachment points which could induce serious errors. For

drilled shafts, using four strain transducers is strongly recommended as it produces

better data, especially if attaching two diameters below the top is impractical.

Composite sections, such as a fully cased drilled shaft, require special considerations for

material properties which are outlined in Section 10.6 on page 127.

3.2 Good Policy Measures

As a word of caution, the following safety measures during sensor attachment and

subsequent field testing are recommended.

• Construction sites can be dangerous. Safety should always be your first priority. Do

not place your head and hands between the hammer and pile. Avoid standing near

the hammer or pile while in operation and do not stand under any object being

lifted. Falling objects cause serious injuries. Plan an escape route before you need

it. If you feel endangered stop what you are doing until the situation is corrected.

• The 8G unit has a replaceable battery, and pile preparation is commonly done with

battery powered drills. However, if corded drills are used, be sure a generator with

adequate power will be available. The generator should be properly grounded.

Take all precautions necessary to avoid potentially fatal electronic shock

if using an AC power source.

• In bad weather (cold, rain, etc.), place the 8G unit in your car or other shelter. Keep

the unit warm and dry. If the ambient air temperature is warm, it is highly advisable

to shade the unit from direct sun. In extreme conditions, air conditioning may be

beneficial.

• Be sure all sensors, drills, bolts, and tools are with you at any test site. Assemble

and test sensors and cables or wireless transmitters on the ground to avoid delays

to the contractor.

• If sensors are to be attached a significant distance above ground, obtaining the

assistance of the pile driving crew to attach sensors is highly recommended. Take

Sensor Attachment: Good Policy Measures

Vous aimerez peut-être aussi

- KS7802T - GATOR WEB - Manual-MinDocument13 pagesKS7802T - GATOR WEB - Manual-Mintyler CLausPas encore d'évaluation

- Installation Guidelines enDocument2 pagesInstallation Guidelines enAyman AlhalfawyPas encore d'évaluation

- Installation Guidelines ENDocument2 pagesInstallation Guidelines ENSharbelPas encore d'évaluation

- Important Safety Instructions: Installation Instructions For Freestanding Electric RangeDocument8 pagesImportant Safety Instructions: Installation Instructions For Freestanding Electric RangeJohn DoePas encore d'évaluation

- MR-NGR-10-EN User ManualDocument32 pagesMR-NGR-10-EN User ManualFelipe Gallardo CatrilPas encore d'évaluation

- Kathrein CAS 80Document26 pagesKathrein CAS 80Claudiu UscaPas encore d'évaluation

- INSTALL CEILING SPLIT AIR CONDITIONERDocument16 pagesINSTALL CEILING SPLIT AIR CONDITIONERMarlou RabinaPas encore d'évaluation

- ARRL QST Antenna - And.tower - Safety. (2001)Document1 pageARRL QST Antenna - And.tower - Safety. (2001)Nestor Alberto EscalaPas encore d'évaluation

- SIRIO - NEW Mighty Vector 4000 - ManualDocument8 pagesSIRIO - NEW Mighty Vector 4000 - ManualLeonardus Suryo SuhartoPas encore d'évaluation

- Solar Panel Installation - What You Need To Know To Work SafelyDocument4 pagesSolar Panel Installation - What You Need To Know To Work SafelyUlviyye Cavid-Umid ElesgerovaPas encore d'évaluation

- Specification of Safety NetDocument5 pagesSpecification of Safety Netdeepak_023Pas encore d'évaluation

- Ma & Ls Range: Carl Zeiss SMT - Nano Technology Systems DivisionDocument6 pagesMa & Ls Range: Carl Zeiss SMT - Nano Technology Systems DivisionVidas MakareviciusPas encore d'évaluation

- Steps To Ensure Effective Substation GroundingDocument15 pagesSteps To Ensure Effective Substation GroundingrbrajatbaliPas encore d'évaluation

- Tsl910 Rsl900 STL System: Operator and Service ManualDocument19 pagesTsl910 Rsl900 STL System: Operator and Service ManualCarlos MonzonPas encore d'évaluation

- OK NO OK: Recommendations For Correct Installation Recommendations For Correct InstallationDocument2 pagesOK NO OK: Recommendations For Correct Installation Recommendations For Correct InstallationPiero CaprettiPas encore d'évaluation

- Impedance Neutral Grounding Assembly Installation and Maintenance InstructionsDocument10 pagesImpedance Neutral Grounding Assembly Installation and Maintenance InstructionsRodPas encore d'évaluation

- Moonraker 4 CB Antenna User ManualDocument16 pagesMoonraker 4 CB Antenna User Manualcb2783% (6)

- Electrical Safety in The LaboratoryDocument5 pagesElectrical Safety in The LaboratoryShaik WazeedPas encore d'évaluation

- 005 038Document11 pages005 038shaicoPas encore d'évaluation

- Bu2100a eDocument35 pagesBu2100a eSenthil KumarPas encore d'évaluation

- Manual de Instalacion Se, CompletoDocument16 pagesManual de Instalacion Se, CompletoFlores CesarPas encore d'évaluation

- Important!: Read Before Proceeding!Document10 pagesImportant!: Read Before Proceeding!Digeo MachadoPas encore d'évaluation

- Zigzag TransformerDocument2 pagesZigzag TransformerRaditya Wika BaskaraPas encore d'évaluation

- Astm d6230 - Part 2Document4 pagesAstm d6230 - Part 2leegoon82Pas encore d'évaluation

- RTN 980L V100R009 Quick Installation GuideDocument30 pagesRTN 980L V100R009 Quick Installation GuideMuhammad AdilPas encore d'évaluation

- RTN 980L V100 Quick Installation Guide (Split LH, Outdoor Components, Compact BU) 02 PDFDocument31 pagesRTN 980L V100 Quick Installation Guide (Split LH, Outdoor Components, Compact BU) 02 PDFpandiPas encore d'évaluation

- Caution and PrecausionsDocument5 pagesCaution and PrecausionsSumit SharmaPas encore d'évaluation

- Strain GaugeDocument7 pagesStrain GaugeIanosi SorinPas encore d'évaluation

- 2m/70cm Dual Band High Performance Gain Base Station AntennaDocument2 pages2m/70cm Dual Band High Performance Gain Base Station Antennardf12345Pas encore d'évaluation

- Warning: Safety Information SheetDocument6 pagesWarning: Safety Information SheetMichał KalbarczykPas encore d'évaluation

- Warning: Safety Information SheetDocument5 pagesWarning: Safety Information SheetHusein ZolotićPas encore d'évaluation

- Id-048 06-12-2019 Boomeang SerieDocument6 pagesId-048 06-12-2019 Boomeang SerieHuMoVaPas encore d'évaluation

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- Taf Truss Manual en EsDocument14 pagesTaf Truss Manual en Esagustin senoffPas encore d'évaluation

- Understanding Product Handling and ESD Precautions (For Hybrid Devices)Document8 pagesUnderstanding Product Handling and ESD Precautions (For Hybrid Devices)qualipalhaPas encore d'évaluation

- Installation Guide 12000BTUDocument9 pagesInstallation Guide 12000BTUBao VuPas encore d'évaluation

- QA&QC Earthing SystemDocument6 pagesQA&QC Earthing SystemMuhammadZahirKhanPas encore d'évaluation

- Manual For Induction Motors and Generators ABBDocument152 pagesManual For Induction Motors and Generators ABBMiguel MartinezPas encore d'évaluation

- Personal Weather Station - Siting: Ideal Scenario - StandardsDocument8 pagesPersonal Weather Station - Siting: Ideal Scenario - StandardsStrifeDeliveryPas encore d'évaluation

- Weather Station SitingDocument8 pagesWeather Station SitingselooePas encore d'évaluation

- TH AS52ALDocument31 pagesTH AS52ALJack BilyPas encore d'évaluation

- MRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDocument12 pagesMRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDan RotariPas encore d'évaluation

- Basic Installation GuideKFR32GW - NEW 0409Document12 pagesBasic Installation GuideKFR32GW - NEW 0409B_ogdanPas encore d'évaluation

- Diathermy Safety BrochureDocument3 pagesDiathermy Safety BrochureLizhen LinPas encore d'évaluation

- PDA Methodology Kohelia BridgeDocument10 pagesPDA Methodology Kohelia Bridgembp planningPas encore d'évaluation

- Solar Panel InstallationDocument33 pagesSolar Panel InstallationsamuelPas encore d'évaluation

- Electrical safety devices and precautionsDocument7 pagesElectrical safety devices and precautionsUFC Fight ClubPas encore d'évaluation

- NGR Installation GuideDocument10 pagesNGR Installation Guidemartins73Pas encore d'évaluation

- TH ASR525 548CLDocument32 pagesTH ASR525 548CLRagnar RagnarsonPas encore d'évaluation

- X300A InstructionsDocument2 pagesX300A Instructionsyu3zaPas encore d'évaluation

- Manual InductiosnMotorsDocument147 pagesManual InductiosnMotorsclickanant4171Pas encore d'évaluation

- Construction Seq. WallDocument3 pagesConstruction Seq. WallYassin Abd El AalPas encore d'évaluation

- Service Manual K-Range Overcurrent and Directional Overcurrent RelaysDocument196 pagesService Manual K-Range Overcurrent and Directional Overcurrent RelaysakmezimPas encore d'évaluation

- Design and Analysis of 3d Capacitive AccelerometerDocument6 pagesDesign and Analysis of 3d Capacitive AccelerometerInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Interpreting Strain Measurements from Pile Load TestsDocument7 pagesInterpreting Strain Measurements from Pile Load TestsHồ ThắngPas encore d'évaluation

- Installation of The RectifierDocument1 pageInstallation of The RectifierremaldarioPas encore d'évaluation

- Air Conditioning Euroline Service Manual TH AW52 - 64ALDocument47 pagesAir Conditioning Euroline Service Manual TH AW52 - 64ALmdquangPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Ultimate Guide: Wiring, 8th Updated EditionD'EverandUltimate Guide: Wiring, 8th Updated EditionÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Contractual Relationship of Parties in Housing Sell Then BuildDocument1 pageContractual Relationship of Parties in Housing Sell Then BuildThoong Yew ChanPas encore d'évaluation

- 156 Pertubuhan Akitek MalaysiaDocument1 page156 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- Managing Changes & Uncertainty: Moral EthicalDocument1 pageManaging Changes & Uncertainty: Moral EthicalThoong Yew ChanPas encore d'évaluation

- 156 Pertubuhan Akitek MalaysiaDocument1 page156 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- Pertubuhan Akitek Malaysia 157 Pertubuhan Akitek MalaysiaDocument1 pagePertubuhan Akitek Malaysia 157 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- Add 10% For The Contingencies and Inflation: 154 Pertubuhan Akitek MalaysiaDocument1 pageAdd 10% For The Contingencies and Inflation: 154 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- Pertubuhan Akitek Malaysia 157 Pertubuhan Akitek MalaysiaDocument1 pagePertubuhan Akitek Malaysia 157 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- Managing Changes & Uncertainty: Moral EthicalDocument1 pageManaging Changes & Uncertainty: Moral EthicalThoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking StructuDocument1 pageCCDC Boise Parking StructuThoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking StructDocument1 pageCCDC Boise Parking StructThoong Yew ChanPas encore d'évaluation

- Contractual Relationship of Parties in Housing Sell Then BuildDocument1 pageContractual Relationship of Parties in Housing Sell Then BuildThoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking StructureDocument1 pageCCDC Boise Parking StructureThoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking Structure 2Document1 pageCCDC Boise Parking Structure 2Thoong Yew ChanPas encore d'évaluation

- Add 10% For The Contingencies and Inflation: 154 Pertubuhan Akitek MalaysiaDocument1 pageAdd 10% For The Contingencies and Inflation: 154 Pertubuhan Akitek MalaysiaThoong Yew ChanPas encore d'évaluation

- CCDC Boise ParkingDocument1 pageCCDC Boise ParkingThoong Yew ChanPas encore d'évaluation

- CCDC Boise ParkingDocument1 pageCCDC Boise ParkingThoong Yew ChanPas encore d'évaluation

- C-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 3Document1 pageC-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 3Thoong Yew ChanPas encore d'évaluation

- C-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Document1 pageC-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Thoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking StructureDocument1 pageCCDC Boise Parking StructureThoong Yew ChanPas encore d'évaluation

- CCDC Boise Parking StructuDocument1 pageCCDC Boise Parking StructuThoong Yew ChanPas encore d'évaluation

- C-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 3Document1 pageC-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 3Thoong Yew ChanPas encore d'évaluation

- CCDC-Boise-Parking-Structure 2Document1 pageCCDC-Boise-Parking-Structure 2Thoong Yew ChanPas encore d'évaluation

- C Shaped Reinforced Concrete C Interaction Diagram ACI318 14 6Document1 pageC Shaped Reinforced Concrete C Interaction Diagram ACI318 14 6Thoong Yew ChanPas encore d'évaluation

- CCDC Boise ParkingDocument1 pageCCDC Boise ParkingThoong Yew ChanPas encore d'évaluation

- Principal Disadvantages of A Double-Threaded HelixDocument1 pagePrincipal Disadvantages of A Double-Threaded HelixThoong Yew ChanPas encore d'évaluation

- C-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 4Document1 pageC-Shaped-Reinforced-Concrete-C-Interaction-Diagram-ACI318-14 4Thoong Yew ChanPas encore d'évaluation

- C-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Document1 pageC-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Thoong Yew ChanPas encore d'évaluation

- C-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Document1 pageC-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Thoong Yew ChanPas encore d'évaluation

- Spcolumn Engineering Software Program Manual V6.50: F ' 4000 Psi FDocument1 pageSpcolumn Engineering Software Program Manual V6.50: F ' 4000 Psi FThoong Yew ChanPas encore d'évaluation

- C-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Document1 pageC-Shaped Concrete Core Wall Biaxial Bending Interaction Diagram (ACI 318-14)Thoong Yew ChanPas encore d'évaluation

- Wans and RoutersDocument17 pagesWans and RoutersPaulo DembiPas encore d'évaluation

- ParaGrid 15 FamilyDocument7 pagesParaGrid 15 FamilyOlimpo CamposPas encore d'évaluation

- Puppiece and Distance WeldmentDocument2 pagesPuppiece and Distance WeldmentwinarnobPas encore d'évaluation

- Sanghvi Estella BycullaDocument6 pagesSanghvi Estella BycullaMandar KadamPas encore d'évaluation

- CHAPTER 1: AUTOSAR Fundamentals Topics CoveredDocument14 pagesCHAPTER 1: AUTOSAR Fundamentals Topics CoveredSujit KumarPas encore d'évaluation

- Quay Wall Options AssessmentDocument13 pagesQuay Wall Options AssessmentYO Batia BiiPas encore d'évaluation

- Cheat Sheet: ProcessesDocument1 pageCheat Sheet: ProcessesRoxana VladPas encore d'évaluation

- Oracle SQL Developer Migrations Supported PlatformsDocument2 pagesOracle SQL Developer Migrations Supported PlatformsAnonymous 8RhRm6Eo7hPas encore d'évaluation

- Basic Ship Theory 5E VOLUME1Document400 pagesBasic Ship Theory 5E VOLUME1Carly Rheman0% (1)

- 50 Liberty / Fan Pier: BCDC Presentation 4/2015Document17 pages50 Liberty / Fan Pier: BCDC Presentation 4/2015The Fort PointerPas encore d'évaluation

- Bridge Cost Guidelines JICA SrilankaDocument158 pagesBridge Cost Guidelines JICA SrilankaAdamPas encore d'évaluation

- Asus A8n Sli PremiumDocument88 pagesAsus A8n Sli Premiumjohn.aboodPas encore d'évaluation

- Dereka Associates Profile 050510Document24 pagesDereka Associates Profile 050510David NGPas encore d'évaluation

- Abhishek Kumar Srivastava: Curriculum VitaeDocument3 pagesAbhishek Kumar Srivastava: Curriculum VitaeAbhishek SrivastavaPas encore d'évaluation

- Gambit TutorialDocument41 pagesGambit TutorialFikru GebrePas encore d'évaluation

- New Era University: Foundation Engineering (Lab)Document6 pagesNew Era University: Foundation Engineering (Lab)Hailley DensonPas encore d'évaluation

- RPA Course ContentDocument3 pagesRPA Course ContentUday KiranPas encore d'évaluation

- Indexed allocation method solves problems of contiguous and linked allocationDocument2 pagesIndexed allocation method solves problems of contiguous and linked allocationMashrekin HossainPas encore d'évaluation

- HP IMC Network Traffic Analyzer (NTA) Software ModuleDocument4 pagesHP IMC Network Traffic Analyzer (NTA) Software Modulescrib_nokPas encore d'évaluation

- Epsilon BrochureDocument8 pagesEpsilon BrochureAbdul Bijur VallarkodathPas encore d'évaluation

- The Master Plumbing Licensure Examination Syllabus: Leonardo C. Sawal, MSSEDocument16 pagesThe Master Plumbing Licensure Examination Syllabus: Leonardo C. Sawal, MSSErco548Pas encore d'évaluation

- Cisco Just Switch It PlaybookDocument49 pagesCisco Just Switch It PlaybooknenjamsPas encore d'évaluation

- HCMS Client Instructions V2.0Document19 pagesHCMS Client Instructions V2.0Hanu MadalinaPas encore d'évaluation

- Explore top temples and attractions in BangaloreDocument20 pagesExplore top temples and attractions in Bangaloreatrameshin7364Pas encore d'évaluation

- Common Problems (Complete)Document26 pagesCommon Problems (Complete)junreymorales100% (1)

- Sample Specification For FRP StrengtheningDocument8 pagesSample Specification For FRP Strengtheningsjpaul1973Pas encore d'évaluation

- God of War Ghost of Sparta - IGNDocument27 pagesGod of War Ghost of Sparta - IGNAndreas SchröderPas encore d'évaluation

- New Hire Procedures - RevisedDocument20 pagesNew Hire Procedures - RevisedTuan PhamPas encore d'évaluation

- Manual MotherboardDocument171 pagesManual Motherboardluzcy45Pas encore d'évaluation

- Host Driver Logs CurrentDocument5 pagesHost Driver Logs Currentvenosyah devanPas encore d'évaluation