Académique Documents

Professionnel Documents

Culture Documents

Roof Truss P2 Trial

Transféré par

Lemark R.Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Roof Truss P2 Trial

Transféré par

Lemark R.Droits d'auteur :

Formats disponibles

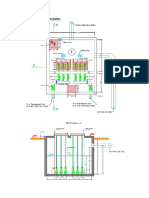

1.

) Dimensional Requirements

Remarks

STORIES (LEVELS)

Levels Storey Height (m)

0-GF 3.5 m

GF-2F 3.5 m

2F-3F 3.5 m

Roof Beam - Apex 1.5 m

12 m

Mean roof height (h) 11.25 m

Dimensions

Purlin Spacing 0.40 m 0.40

Purlin Span 1.84 m 1.84

Truss Spacing 1.84 m 1.84

Truss Span 5.95 m 6.95 including 1m overhang 0.386111

4.) Design

A.) Loadings

NSCP Table 204.2

GI Sheets (Includes Laps and Fastenings) = 0.12 kPa taken as metal deck gauge 20

Insulation = 0.02943 kPa taken as Rockwool, 50mm, 60kg/m3

NSCP Table 205.3 Minimum Roof Live Load = 1 kPa A purlins = 1.8x1.5 = 2.7 sqm

Miscellaneous = 0.1 kPa

B.) Selected Section

AISC Steel Sections Section w (kg/m) A (mm2) R (mm) xo (mm)

Top Chords

2L2x2x1/4 9.565624071 1,219.35

3 3

Ix (x10 mm4) Sx (mm3) rx (mm) Iy (x10 mm4) Sy (mm3) ry (mm)

15.37 21.39

AISC Steel Sections Section w (kg/m) A (mm2) R (mm) xo (mm)

Bottom Chords

2L2x2x1/4 9.565624071 1,219.35

3 3

Ix (x10 mm4) Sx (mm3) rx (mm) Iy (x10 mm4) Sy (mm3) ry (mm)

15.37 21.39

AISC Steel Sections Section w (kg/m) A (mm2) R (mm) xo (mm)

Diagonal Web

L2x2x1/4 4.775373759 609.03

3 3

Ix (x10 mm4) Sx (mm3) rx (mm) Iy (x10 mm4) Sy (mm3) ry (mm)

15.37 15.37

Fy = 248 Mpa

C.) Load Calculations for STAAD Input

Purlins Weight/lm = 2.17000 kg/m

Mass/lm = 0.02129 kN/m

Area Load = Wt x SpacingP

= 0.05322 kPa

Line Load = Aload x SpacingT

= 0.09792 kN/m

GI + Insulation Area Load = 0.14943 kPa

Line Load = Aload x SpacingT

= 0.27495 kN/m

Misc: MEP Area Load = 0.10000 kPa

Line Load = Aload x SpacingT

= 0.18400 kN/m

Live Load Area Load = 1.00000 kPa

Line Load = Aload x SpacingT

= 1.84000 kN/m

WL1 Line Load = 2.26320 kN/m

WL2 Line Load = -10.15680 kN/m

D.) Input STAAD Load Data

Top Chord Max Load = 171.94 kN C

L = 400 mm

r = 15.37 mm

Bottom Chord Max Load = 121.30 kN T

L = 400

r = 15.367

Angled Web Chord Max Load' = 36.31 kN T

L = 301 mm

r = 15.37 mm

E.) Design of Members

E.1) Design of Top Chord

E.1.a.) In Compression

Test for Bucking

NSCP 505.2, AISC 360-10 E2 kL/r < 200 where k = 1

26.03 < 200 OK

where k = 200000 Mpa

2

Cc = √ [ 2π E/Fy ]

2

= √ [ 2π * 200000 / 248 ]

= √[ 15918.71678 ]

= 126.17

Since kL/r < Cc INTERMEDIATE COLUMN

Solving for FS

3

5.00 3(kL/r) (kL/r)

FS = + - 3

3.00 8Cc 8(Cc)

78.08941238 17636.51208

= 1.666666667 + -

1009.355177 16067639.19

= 1.74

2

Thus (kL/r) Fy

Fa = [1 -

2

]

2(Cc) Fs

= [1 - 677.5507028 ] 248

31837.43355 1.74

= 139.26 Mpa

Solving for Required Area

Fa = P/A

139,260.62 = 171.942 / A

A = 1,234.68 mm2 NOT OK 1

E.2) Design of Bottom Chord

E.2.b.) In Tension

Thus Ft = 0.6Fy

= 0.60 * 248

= 148.80 Mpa

Solving for Required Area

Ft = P/A

148,800.00 = 121.30 / A

A = 815.16 mm2 OK 0

E.3) Design of Web Members - Angled

E.3.a.) In Tension

Ft = 0.6Fy

= 0.60 * 248

= 148.80 Mpa

Solving for Required Area

Ft = P/A

148,800.00 = 36.31 / A

A = 244.01 mm2 OK 0

Therefore use CHANGE SECTION for Top Chord,

2L2x2x1/4 for Bottom Chord,

L2x2x1/4 for Web

Vous aimerez peut-être aussi

- Mancave - PurlinsDocument3 pagesMancave - PurlinsLemark R.Pas encore d'évaluation

- Algorithm For S.R BeamDocument6 pagesAlgorithm For S.R BeamArbaz AhmedPas encore d'évaluation

- Beam and Column Design in Reinforced ConcreteDocument21 pagesBeam and Column Design in Reinforced ConcreteSambhav PoddarPas encore d'évaluation

- One Way Slab Design Basic DataDocument2 pagesOne Way Slab Design Basic DataXe GodPas encore d'évaluation

- Column DesignDocument25 pagesColumn DesignNikhil100% (1)

- RC Rroject 22Document24 pagesRC Rroject 22ellocster21Pas encore d'évaluation

- Slab DesignDocument22 pagesSlab DesignethjetjetPas encore d'évaluation

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangalorePas encore d'évaluation

- DESIGN OF COMBINED FOOTINGS FOR TOWER PROJECTDocument12 pagesDESIGN OF COMBINED FOOTINGS FOR TOWER PROJECTRupesh KhandekarPas encore d'évaluation

- Combined Footing DesignDocument12 pagesCombined Footing DesignAbhishek MishraPas encore d'évaluation

- Column Design PDFDocument4 pagesColumn Design PDFRaju SainiPas encore d'évaluation

- Γs (Kn/M3) : 239771.21 Mu < ϴmn Therefore T = 450Mm Is OkDocument1 pageΓs (Kn/M3) : 239771.21 Mu < ϴmn Therefore T = 450Mm Is OkAzaina1Pas encore d'évaluation

- Calc Note Report-R2Document19 pagesCalc Note Report-R2layaljamal2Pas encore d'évaluation

- Design of Two Way Slab: Project Detail: Slab IdDocument6 pagesDesign of Two Way Slab: Project Detail: Slab Idmaheshu78Pas encore d'évaluation

- Beam design and analysisDocument5 pagesBeam design and analysisjanethPas encore d'évaluation

- Design Stair Case Longitudinal TypeDocument15 pagesDesign Stair Case Longitudinal TypePrakash GuragainPas encore d'évaluation

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalPas encore d'évaluation

- Design of Two Way SlabDocument4 pagesDesign of Two Way Slabpepe wosPas encore d'évaluation

- 230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Document4 pages230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Mustafa RupawalaPas encore d'évaluation

- WWTP1-Structural Design CalculationDocument81 pagesWWTP1-Structural Design CalculationMesfin100% (1)

- Steel Column DesignDocument4 pagesSteel Column Designanshutomar7915100% (2)

- Steel Column Design for India PavilionDocument4 pagesSteel Column Design for India PavilionEly Jane DimaculanganPas encore d'évaluation

- ETABS 2016 16.2.1-Detailed Report ViewerDocument1 117 pagesETABS 2016 16.2.1-Detailed Report ViewerRJPas encore d'évaluation

- Isolated Footing DesignDocument11 pagesIsolated Footing DesignPadmanabh Shridhar DesaiPas encore d'évaluation

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsPas encore d'évaluation

- g+4 Building DesignDocument22 pagesg+4 Building Designellocster21Pas encore d'évaluation

- Eccentrically Loaded ColumnDocument4 pagesEccentrically Loaded ColumnOmar TariqPas encore d'évaluation

- Planning Criteria Location Petrol Filling StationDocument2 pagesPlanning Criteria Location Petrol Filling StationobanizePas encore d'évaluation

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedPas encore d'évaluation

- Steel CalcsDocument3 pagesSteel Calcsloc khaPas encore d'évaluation

- Channel Steel Beam Torsion Design (EN1993)Document5 pagesChannel Steel Beam Torsion Design (EN1993)Anupam AjayanPas encore d'évaluation

- Design of Cantilever Slab:: Area of The Footing RDocument4 pagesDesign of Cantilever Slab:: Area of The Footing RNarayan WPas encore d'évaluation

- Design of Cantilever Slab:: Area of The Footing RDocument4 pagesDesign of Cantilever Slab:: Area of The Footing RNarayan WPas encore d'évaluation

- Footing design calculationsDocument4 pagesFooting design calculationsNarayan WPas encore d'évaluation

- Combined Footing 348Document4 pagesCombined Footing 348Narayan WPas encore d'évaluation

- WSD Connection MasterDocument5 pagesWSD Connection MasterSteelfab Structural AssociatesPas encore d'évaluation

- RHS BeamDocument3 pagesRHS Beamkkgc100% (1)

- RCC DesignDocument39 pagesRCC DesignMariappan .PPas encore d'évaluation

- Hitungan Structure Beban AtapDocument3 pagesHitungan Structure Beban Atapdimas cahyoPas encore d'évaluation

- Combined Footing DesDocument7 pagesCombined Footing Desansar700Pas encore d'évaluation

- ETABS Steel Frame Design Strength SummaryDocument18 pagesETABS Steel Frame Design Strength Summarylayaljamal2Pas encore d'évaluation

- DESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Document4 pagesDESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Mahananda RKPas encore d'évaluation

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel SheetCleth Hiren Santos25% (4)

- Check Deflection For Beams (R-Section) : InputsDocument1 pageCheck Deflection For Beams (R-Section) : InputsOmar SalahPas encore d'évaluation

- Rauf Khan Column EstimationDocument4 pagesRauf Khan Column EstimationRauf KhanPas encore d'évaluation

- 7762.isolated Footing OutputDocument14 pages7762.isolated Footing Outputmichael murakamiPas encore d'évaluation

- Design of Two-Way Slab: X y y XDocument5 pagesDesign of Two-Way Slab: X y y XNitin BhatiPas encore d'évaluation

- Core Wall DesignDocument10 pagesCore Wall Designhala_azhari50% (2)

- Two Way SlabDocument130 pagesTwo Way SlabMayank Rawat100% (1)

- HDD Calc As Per PRCDocument8 pagesHDD Calc As Per PRClive4sankar100% (1)

- Strip Footing (Exterior)Document4 pagesStrip Footing (Exterior)Kelvin MutetiPas encore d'évaluation

- Isolated Footing DesignDocument8 pagesIsolated Footing DesignSuson DhitalPas encore d'évaluation

- A Short Course in Foundation EngineeringD'EverandA Short Course in Foundation EngineeringÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Flag Fen, Peterborough: Excavation and Research 1995-2007D'EverandFlag Fen, Peterborough: Excavation and Research 1995-2007Pas encore d'évaluation

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresD'EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresÉvaluation : 4 sur 5 étoiles4/5 (1)

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextD'EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextPas encore d'évaluation

- Design of Members For Compression: Chapter EDocument3 pagesDesign of Members For Compression: Chapter ELemark R.Pas encore d'évaluation

- Initial Sizing of BeamsDocument2 pagesInitial Sizing of BeamshgorPas encore d'évaluation

- The Darth SideDocument58 pagesThe Darth SideAndrewBowmanPas encore d'évaluation

- Structural Analysis EXAMPLEDocument8 pagesStructural Analysis EXAMPLEmodulor3dPas encore d'évaluation

- NS18steeldesign 3 PDFDocument51 pagesNS18steeldesign 3 PDFLemark R.Pas encore d'évaluation

- Three load types and safety factors in structural designDocument2 pagesThree load types and safety factors in structural designmalganissPas encore d'évaluation

- LRFD SteelDocument280 pagesLRFD SteelKhalid YousafPas encore d'évaluation

- NS18steeldesign 4 PDFDocument51 pagesNS18steeldesign 4 PDFGinerPas encore d'évaluation

- Topic - Connections - Typical Joints PDFDocument56 pagesTopic - Connections - Typical Joints PDFKanako NozawaPas encore d'évaluation

- DET-838C Resi Electronic Circuit InterruptersDocument8 pagesDET-838C Resi Electronic Circuit InterruptersLemark R.Pas encore d'évaluation

- Additional Rules and Regulation On Signs or Signboard StructuresDocument15 pagesAdditional Rules and Regulation On Signs or Signboard StructuresD.F. de LiraPas encore d'évaluation

- Hot Rolled Carbon Steel Structural Shapes 1948 PDFDocument73 pagesHot Rolled Carbon Steel Structural Shapes 1948 PDFAmmar AyubPas encore d'évaluation

- Features: Interior Freestanding Cash DispenserDocument2 pagesFeatures: Interior Freestanding Cash DispenserLeomark RespondePas encore d'évaluation

- Residential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Document7 pagesResidential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Hussein JaberPas encore d'évaluation

- Dea 437aDocument4 pagesDea 437amailisafPas encore d'évaluation

- 18FN0067 Ilovepdf Compressed PDFDocument224 pages18FN0067 Ilovepdf Compressed PDFLeomark RespondePas encore d'évaluation

- DET843B - Residential Products Brochure PDFDocument8 pagesDET843B - Residential Products Brochure PDFLemark R.Pas encore d'évaluation

- PriceList Firefly Conventional Lighting Price List JAN 2018Document12 pagesPriceList Firefly Conventional Lighting Price List JAN 2018John EstremeraPas encore d'évaluation

- C&zpurlin ProfileDocument8 pagesC&zpurlin ProfileRyan BeciosPas encore d'évaluation

- Comparison of Structural Design CodesDocument4 pagesComparison of Structural Design CodesMaria Rose Giltendez - BartianaPas encore d'évaluation

- Features: New Branch SolutionDocument2 pagesFeatures: New Branch SolutionLemark R.Pas encore d'évaluation

- Capitol Steel Price List November 2002Document1 pageCapitol Steel Price List November 2002Steven Joseph IncioPas encore d'évaluation

- 0648 RCC CodeDocument8 pages0648 RCC CodeKajalPas encore d'évaluation

- Repair and Reinforcement Method For Reinforced Concrete Beamcolumn JointsDocument4 pagesRepair and Reinforcement Method For Reinforced Concrete Beamcolumn JointsLemark R.Pas encore d'évaluation

- NBCPDocument17 pagesNBCPArch. Jan EchiverriPas encore d'évaluation

- Lesson 3Document15 pagesLesson 3ahmedsabercgPas encore d'évaluation

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 pagesCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105Pas encore d'évaluation

- Repair and Retrofitting Manual For RCC Structure: Government of Nepal National Reconstruction AuthorityDocument57 pagesRepair and Retrofitting Manual For RCC Structure: Government of Nepal National Reconstruction AuthorityJaydeep ZankatPas encore d'évaluation

- PP-R Piping Accessories Price ListDocument2 pagesPP-R Piping Accessories Price ListLemark R.Pas encore d'évaluation

- Cold Water Pipe Gate Valve: Pipes AccessoriesDocument2 pagesCold Water Pipe Gate Valve: Pipes AccessoriesLemark R.Pas encore d'évaluation

- TSLC Civil Post SLC Final, 2014Document98 pagesTSLC Civil Post SLC Final, 2014Rabi Krishna Budha ChhetriPas encore d'évaluation

- Sedimentologi - Transport Dan Pengendapan Sedimen Silisiklastik PDFDocument45 pagesSedimentologi - Transport Dan Pengendapan Sedimen Silisiklastik PDFIndah LestariPas encore d'évaluation

- Rec Erc 78 08Document22 pagesRec Erc 78 08Jerry PellerPas encore d'évaluation

- Vertical Drains May Not Work Alone Due To Thick Uniform Soft ClayDocument77 pagesVertical Drains May Not Work Alone Due To Thick Uniform Soft ClayChitharanjan VishnukripalPas encore d'évaluation

- Jacob Johnson - All About BridgesDocument11 pagesJacob Johnson - All About Bridgesapi-405484446Pas encore d'évaluation

- Structural FPD P.sanchezDocument9 pagesStructural FPD P.sanchezHailley DensonPas encore d'évaluation

- Tuff Tile CalculationDocument12 pagesTuff Tile CalculationFareena FatimaPas encore d'évaluation

- KDU Auditorium Field Visit ReportDocument14 pagesKDU Auditorium Field Visit ReportTharindu DissanayakePas encore d'évaluation

- Load Calculations On To The BeamsDocument26 pagesLoad Calculations On To The BeamsGadige ChandraPas encore d'évaluation

- CladdingDocument21 pagesCladdingVaibhav HireraddiPas encore d'évaluation

- Construction Facilities, Temporary Utilities, and ControlsDocument14 pagesConstruction Facilities, Temporary Utilities, and ControlsAllan EscobarPas encore d'évaluation

- Line Item Renovation Budget: Cost As % of Total Accepted Bid or Cost Change OrdersDocument4 pagesLine Item Renovation Budget: Cost As % of Total Accepted Bid or Cost Change OrdersAswad TonTong100% (1)

- CE-212: Fluid Mechanics-II Turbulent Flow Entrance Condition and Velocity Profile, Problems, Pipes in Series, Pipes in ParallelDocument25 pagesCE-212: Fluid Mechanics-II Turbulent Flow Entrance Condition and Velocity Profile, Problems, Pipes in Series, Pipes in ParallelMashal Shah JehanPas encore d'évaluation

- Assignment 1 Part 1Document6 pagesAssignment 1 Part 1Aditi AgrawalPas encore d'évaluation

- Norwegian Tunnelling Method ExplainedDocument31 pagesNorwegian Tunnelling Method ExplainedmandeepgeologyPas encore d'évaluation

- Importance Impact of Stress Intensification Factor SIF in Piping With PDFDocument8 pagesImportance Impact of Stress Intensification Factor SIF in Piping With PDFBogdan ChivulescuPas encore d'évaluation

- LP Solidstart I-Joists Residential Construction: Canadian (LSD) Technical GuideDocument28 pagesLP Solidstart I-Joists Residential Construction: Canadian (LSD) Technical GuidepghasaeiPas encore d'évaluation

- Steel Portal Frame Design and Construction GuideDocument28 pagesSteel Portal Frame Design and Construction GuideLingka100% (1)

- Metal Building Crane Load RequirementsDocument6 pagesMetal Building Crane Load RequirementstuansteelsPas encore d'évaluation

- TR 4 062017Document51 pagesTR 4 062017david francoPas encore d'évaluation

- Ra 544Document45 pagesRa 544jay trinidadPas encore d'évaluation

- Microsoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3Document9 pagesMicrosoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3nn-85614Pas encore d'évaluation

- Top 4 Innovative Formworks in IndiaDocument40 pagesTop 4 Innovative Formworks in IndiakrmcharigdcPas encore d'évaluation

- Halpen HijsankersDocument56 pagesHalpen HijsankersLaurens VerheyenPas encore d'évaluation

- PSC Beam Training in MIDAS FEADocument32 pagesPSC Beam Training in MIDAS FEAGeorgeEdwardPas encore d'évaluation

- Plumbing Quotation RatesDocument3 pagesPlumbing Quotation RatesbabukcdPas encore d'évaluation

- IntroductionDocument18 pagesIntroductionteddykeyPas encore d'évaluation

- CE 4780 - Introduction To Slope StabilityDocument15 pagesCE 4780 - Introduction To Slope StabilityEdwin CornejoPas encore d'évaluation

- DS - en 1992-1-1 DK Na - 2011 eDocument33 pagesDS - en 1992-1-1 DK Na - 2011 ep_meulendijks108Pas encore d'évaluation

- Concrete Quantity of Box Culvert 2x3x3 Reinforcement Calculation For BC 2X3X3Document3 pagesConcrete Quantity of Box Culvert 2x3x3 Reinforcement Calculation For BC 2X3X3Vorn Ra VuthPas encore d'évaluation