Académique Documents

Professionnel Documents

Culture Documents

Job Safety Analysis Installation (JSA)

Transféré par

Aser Batoy Jr.Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Job Safety Analysis Installation (JSA)

Transféré par

Aser Batoy Jr.Droits d'auteur :

Formats disponibles

Office Address: 2nd Floor Rudanel Building Southpoint

Brgy Banay banay Cabuyao Laguna 4025

Near Malayan colleges and Cabuyao exit

Contact No.: (049)544-6786 (02)519-4620

Fax No.: (049)544-6773

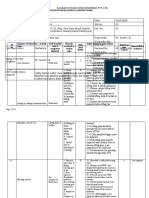

JHA OF INSTALLATION OF RACKS AND BEAMS

Description of Task Step Hazard- potential Control Measure

incident

1. Toolbox meeting and start Miscommunication Use understandable language to

of work preparation. Lack of Knowledge minimal language barrier during

Lack of PPE toolbox.

Train or discuss Approved

methodology Ensure PPE is

complete, hard hat, eye glasses,

and uniform/w long sleeve, rubber

gloves, reflectorized vest, safety

shoes, and full body harness.

Unaware of Safe Undergo safety briefing/

2. Preparation of workers, Work Practices orientation, including journey plan

equipment, tools at a job familiarization.

site. Secure work permit. Follow all

safety precaution stipulated in the

permit.

Wear appropriate PPE at all times.

(hard hat with chin strap, rubber

gloves, safety shoes, safety vest,

Do Toolbox meeting (TBM) before

commencing work.

Project kick of meeting should be

covered by permit to be handled

by TGC.

Deployment of competent

personnel or training for installer.

Pre job safety briefing should

always be conducted prior to

work.

3. Mobilization loading and Pinning of hands Mechanized lifting as much as

Unloading, positioning of Communication possible.

racks frame, Beams, failure Follow safe lifting procedure. Ask

accessories of racking and Bumping for help when necessary. Do not

tools materials. Exceed 25 kilos when doing manual

lifting.

Always wear PPE (hard hat, with

chin strap, rubber gloves, safety

shoes, reflectorized vest, and

safety glasses.

4. Potential and material

hauling of racks frame, Physical Sharp and Secure appropriate work permit

Beams pointed edges not prior to start of work.

easily spotted or Provide guards to sharp edges of

seen. all equipment.

Tie Barricade tapes provide

warning signs on sharp materials

to make it visible for all employee

present in the work place.

Provide proper personal protective

equipment to all employee

assigned for the activity.

Wear Appropriate PPE (hard hat,

Safety glasses, rubber gloves,

safety shoes, reflectorized vest.

5. Transport of Materials and Struck by moving load Clean up area before

Accessories Tripping when moving the actual lifting or moving to

load the designated area.

Miscommunication. Provide spotter for long

material to maneuver.

Follow safe lifting

procedure. Ask for help

when necessary

Mechanized lifting as

much as possible.

Wear appropriate PPE

(hard hat, rubber gloves,

safety glasses,

reflectorized vest.

6. Re- installation of racks Hand pinning Pre job safety briefing

7. Installation of racks. Communication failure should be conducted prior

Slip and trip to work as a requirement.

Isolate the area thru cone

and caution tapes due of

unwanted falling

materials.

Wear appropriate PPE

(hard hat, safety shoes,

safety glasses,

reflectorized vest, rubber

gloves.)

8. Installation of Beam Work at height (possible Make work permit has

9. Installation of Spacer fall from heights) been done and approved

10. Installation of pallet Serious Injury/Fatality prior to start of work.

support Isolate the area thru cone

and caution tape due to

unwanted falling

materials.

Make sure that the

workers were given a clear

instruction on their job by

conducting toolbox

meeting to discuss the

hazard associated in every

task to be done and the

control measure to be

taken and or to be on

place prior to start work

Wear Appropriate PPE

(hard hat, safety glasses,

safety shoes, reflectorized

vest. Hollister packet and

full body harness.

11. Tightening Bolts and nuts Struck by beams, and plan Make sure that all tools

Of Beam and plan Bracing Bracing. (Seriously Injury have been secured with

or Fatality lanyard when performing

working on heights.

Barricade the working

area to avoid

unauthorized entry in the

area.

Provide signage to warn

other people working

around the area.

Make sure work permit

has been done and

approved prior to start of

work.

Make sure that the

workers were given a clear

instruction on their job by

conducting toolbox to

discuss the hazard

associated in every task to

be in place prior to start of

work.

Avoid Vertical parallel

works (no work will be

permitted underneath

during appearing the

beams. Use pulley and

rope to appearing the

beams, plan bracing and

PSB.

Use tagline to properly

manage the beam, PSB

and plan bracing when

pull- up.

Make sure pulley and rope

has been inspected and

safe to use.

Always coordinate the job

to be done to the area

owner prior to start of any

activity.

Proper coordinate

between the workers.

Assigned a trained worker

for the job.

Full supervision of safety

officer and lead man on

site

Use the right tools for the

job

Proper handling and use

of tools

Wear hard hat w/chin

strap and other basic PPE

required for the job.

12. Installation of post Excusive noise from Wear ear plug when using

protector and post barrier, Impact Wrench And wrench to reduce the

drilling, fixing. Rotary noise level impact emitted

by the said power tools.

Rotation of workers if

needed

Wear Appropriate PPE

(hard hat, safety vest,

safety glasses, safety

shoes, reflectorized vest.

Vous aimerez peut-être aussi

- JSA For Erection Modification QSTECDocument7 pagesJSA For Erection Modification QSTECMohamed NouzerPas encore d'évaluation

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuPas encore d'évaluation

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirPas encore d'évaluation

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyPas encore d'évaluation

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimPas encore d'évaluation

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithPas encore d'évaluation

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerPas encore d'évaluation

- Abrasive Blasting Check ListDocument2 pagesAbrasive Blasting Check ListSaravanan JambunathanPas encore d'évaluation

- BargeDocument4 pagesBargeanon_222140886Pas encore d'évaluation

- Working at Height PresentationDocument11 pagesWorking at Height PresentationAbdul Hameed OmarPas encore d'évaluation

- 014 - Site Safety & Health Induction ChecklistDocument2 pages014 - Site Safety & Health Induction ChecklistRosli Bin Abdul Shukor100% (1)

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustPas encore d'évaluation

- ExcavationDocument9 pagesExcavationabidPas encore d'évaluation

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummiePas encore d'évaluation

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarPas encore d'évaluation

- JSA For HOT JobDocument1 pageJSA For HOT JobEquipment MaterialsPas encore d'évaluation

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajPas encore d'évaluation

- Painting, Taping, Texturing or Epoxy CoatingsDocument1 pagePainting, Taping, Texturing or Epoxy CoatingsHenryOdohPas encore d'évaluation

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubPas encore d'évaluation

- RISK ASESSMENT For CorianDocument12 pagesRISK ASESSMENT For Corianadeoye AdeyemiPas encore d'évaluation

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamPas encore d'évaluation

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariPas encore d'évaluation

- 2640.011SWP - Excavations and TrenchesDocument7 pages2640.011SWP - Excavations and TrenchesHasanuddin HAMIDPas encore d'évaluation

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Pas encore d'évaluation

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatPas encore d'évaluation

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 pagesIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasPas encore d'évaluation

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerPas encore d'évaluation

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehPas encore d'évaluation

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraPas encore d'évaluation

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelPas encore d'évaluation

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaPas encore d'évaluation

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarPas encore d'évaluation

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHePas encore d'évaluation

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballePas encore d'évaluation

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanPas encore d'évaluation

- (JSA) Concreting in FoundationDocument2 pages(JSA) Concreting in FoundationGunjan Sinha AdityaPas encore d'évaluation

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarPas encore d'évaluation

- Critical Risk: Housekeeping: What Is The Risk?Document5 pagesCritical Risk: Housekeeping: What Is The Risk?Zegera MgendiPas encore d'évaluation

- SWP-22 Lock Out Tag Out DaimanDocument2 pagesSWP-22 Lock Out Tag Out DaimanHassan AbdullahPas encore d'évaluation

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilPas encore d'évaluation

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerPas encore d'évaluation

- Safety Moment There Is No Shortcut To Safety 448cuoDocument6 pagesSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaPas encore d'évaluation

- Crane Safety Tool Box TalkDocument2 pagesCrane Safety Tool Box Talksathees4329Pas encore d'évaluation

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiPas encore d'évaluation

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaPas encore d'évaluation

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghPas encore d'évaluation

- Risk Assesment For Lighting Protection SystemDocument2 pagesRisk Assesment For Lighting Protection SystemAsfand AyazPas encore d'évaluation

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarPas encore d'évaluation

- Environment ProtectionDocument7 pagesEnvironment ProtectionPhilip YapPas encore d'évaluation

- Laydown Yard ChecklistDocument5 pagesLaydown Yard ChecklistTomin ThomasPas encore d'évaluation

- Gi-0006 011Document2 pagesGi-0006 011malika_00Pas encore d'évaluation

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdPas encore d'évaluation

- Job Hazard AnalysisDocument3 pagesJob Hazard Analysisaser batoyPas encore d'évaluation

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimPas encore d'évaluation

- JHA Overhead Cleaning MP16Document4 pagesJHA Overhead Cleaning MP16Jay JocoPas encore d'évaluation

- 3TM Vacuum Contactors: Medium-Voltage EquipmentDocument44 pages3TM Vacuum Contactors: Medium-Voltage EquipmentDennyIndPas encore d'évaluation

- Error CodesDocument24 pagesError CodesGustavo Rodriguez89% (47)

- Preventive Maintenance Checklist - KR150Document7 pagesPreventive Maintenance Checklist - KR150Juan c sanchezPas encore d'évaluation

- r56 Dme Failure Question - Mini Cooper ForumDocument9 pagesr56 Dme Failure Question - Mini Cooper Forumjohn larson100% (1)

- Siemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019Document12 pagesSiemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019SARAVANAN APas encore d'évaluation

- Caterpillar Part 2Document29 pagesCaterpillar Part 2lionkinghdPas encore d'évaluation

- Scram 411 BrochureDocument12 pagesScram 411 BrochureKaliarasan arasuPas encore d'évaluation

- The RVV Electric WireDocument4 pagesThe RVV Electric WireAnonymous 8xHUWBPas encore d'évaluation

- Istilah TMKDocument2 pagesIstilah TMKmuryce795139Pas encore d'évaluation

- Aircraft Parking and Storage 2Document8 pagesAircraft Parking and Storage 2Nguyễn Minh KhôiPas encore d'évaluation

- Hydraulic Puller Kit TMHC 110E: ApplicationDocument2 pagesHydraulic Puller Kit TMHC 110E: Applicationsbosch54Pas encore d'évaluation

- GPU KhoruzhenkoDocument5 pagesGPU KhoruzhenkoOlhaPas encore d'évaluation

- Motor Hidrostatico SauerDocument80 pagesMotor Hidrostatico SauerAlexis Peña100% (1)

- Toyota Hilux 1KD y 2KDDocument11 pagesToyota Hilux 1KD y 2KDOtto BrignolePas encore d'évaluation

- Metal Detectors - UKDocument53 pagesMetal Detectors - UKAndrew Harvey100% (5)

- My Flowmax Regulator Iom Gea19584a English PDFDocument32 pagesMy Flowmax Regulator Iom Gea19584a English PDFElias ElHossariPas encore d'évaluation

- 1SFC151003C0201 81Document1 page1SFC151003C0201 81psatyasrinivasPas encore d'évaluation

- O-Ring - NOK AS568 SeriesDocument4 pagesO-Ring - NOK AS568 SeriestungPas encore d'évaluation

- Intel - Coffeelake-S Plamform: System ChipsetDocument49 pagesIntel - Coffeelake-S Plamform: System ChipsetbizongodPas encore d'évaluation

- Alcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Document13 pagesAlcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Kshitij Kumar Singh ChauhanPas encore d'évaluation

- Technical ManualDocument151 pagesTechnical ManualGiannis KavathasPas encore d'évaluation

- Paradise Cable Catalouge PDFDocument112 pagesParadise Cable Catalouge PDFtanzir40% (5)

- CMP Cable Gland Americas Px2kx Tds649 Issue2 0815Document1 pageCMP Cable Gland Americas Px2kx Tds649 Issue2 0815Ahmed MenshawyPas encore d'évaluation

- Terex - Luminarias Repuestos PDFDocument62 pagesTerex - Luminarias Repuestos PDFIliana Georgina RamirezPas encore d'évaluation

- Crossvent-3+: Operation & Service ManualDocument102 pagesCrossvent-3+: Operation & Service ManualIngenieria NemoconPas encore d'évaluation

- Owner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392Document42 pagesOwner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392ckkimblePas encore d'évaluation

- File 1438715980Document3 pagesFile 1438715980ical iculPas encore d'évaluation

- Aeron Systems: Inertial Sensors and Navigation SystemsDocument7 pagesAeron Systems: Inertial Sensors and Navigation SystemsBhagavad GitaPas encore d'évaluation

- 11 Types of Fasteners Pins and KeysDocument12 pages11 Types of Fasteners Pins and KeysPRASAD326100% (2)

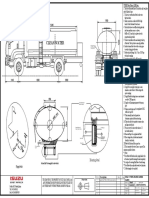

- FVR90L WATER TANKER MAAIF-ModelDocument1 pageFVR90L WATER TANKER MAAIF-ModelAvi AtoPas encore d'évaluation