Académique Documents

Professionnel Documents

Culture Documents

PDS en-GB 37820

Transféré par

Anuar SalehDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PDS en-GB 37820

Transféré par

Anuar SalehDroits d'auteur :

Formats disponibles

Product Data

Hempaline Defend 630 Cure 72

Hempaline Defend 630 Cure 72: Hempaline Defend 630 Base: Hempel's Curing Agent 9780S

Description: Hempaline Defend 630 is a solvent free high performance Epoxy Phenolic Lining with excellent

chemical resistance to a wide range of chemicals and solvents.

Hempaline Defend 630 may be applied as a 1 or 2 coat scheme, and as part of a hand lay or spray

applied glass fibre reinforced system.

Hempaline Defend 630 is available in Standard (Cure 72) and in Fast Return to Service (Cure 24)

grades, which both offer the same high performance.

Recommended use: Hempaline Defend 630 is intended as a high performance tank lining for the storage of a wide range of

petrochemicals including (but not limited to) crude oil up to 93°C /200˚F, MTBE, produced water,

alcohols, aromatic and aliphatic solvents, aviation fuels, gasoline blends, select acidic and caustic

chemicals.

Service temperature: Immersion service: <93°C/200°F

Dry: <150°C/302°F

Availability: Not included in Group Assortment. Availability subject to special agreement.

PHYSICAL CONSTANTS:

Shade nos/Colours: 36641* / Blue.

Finish: Semi-gloss

Volume solids, %: 100

Theoretical spreading rate: 2 m2/l [80.2 sq.ft./US gallon] / 500 micron/20 mils.

Flash point: 149 °C [300.2 °F]

Specific gravity: 1.4 kg/litre [11.9 lbs/US gallon]

Surface-dry: 8 hour(s) 20°C/68°F

Through-dry: 16 hour(s) 20°C/68°F

Fully cured: 72 hour(s) 20°C/68°F

VOC content: 21 g/l [0.2 lbs/US gallon]

Shelf life: 1.5 years 25°C/77°F for BASE and 1.5 years for CURING AGENT (stored in closed container)

- *other shades according to assortment list.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: Hempaline Defend 630 Cure 72

Mixing ratio: Hempaline Defend 630 Base: Hempel's Curing Agent 9780S

3:1 by volume

Application method: Airless spray /Brush /Roller

Thinner (max.vol.): Do not dilute.

Pot life: 40 minute(s) 20°C/68°F

Nozzle orifice: 0.021 - 0.029 " (0.53 -0.74 mm)

Nozzle pressure: 200 bar [2900 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: Hempel's Thinner 08960

Indicated film thickness, dry: 500 micron [20 mils] ( see REMARKS overleaf )

Indicated film thickness, wet: 500 micron [20 mils] (see REMARKS overleaf )

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: February 2019 Page: 1/2

Product Data

Hempaline Defend 630 Cure 72

SURFACE PREPARATION: Steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive grit blasting to minimum Sa 2½ (ISO

8501-1:2007). Recommended surface profile is Rz 75-100 micron/3-4 mils, corresponding to Rugotest

No. 3, BN10, Keane-Tator Comparator, minimum 3.0 G/S, or ISO Comparator, Medium (G). After

blasting clean the surface carefully from abrasives and dust. (Consult the separate APPLICATION

INSTRUCTIONS)

Concrete: According to specification.

APPLICATION CONDITIONS: Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

The optimal paint temperature for proper mixing, pumping and spraying is 20-25°C/68-77°F. Use only

where application can proceed at temperatures above: 10°C/50°F. Maximum relative humidity: 80%. In

confined spaces provide adequate ventilation during application and drying.

PRECEDING COAT: Steel: None,Hempadur 85671 or Hempaline Prepare 150.

Concrete: Hempaline Prepare 110 or according to specification.

SUBSEQUENT COAT: None or Hempaline Defend 630

REMARKS:

Colours/Colour stability: There might be a slight difference in colour from batch to batch.

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and overcoating interval. Normal range dry is:

300-1000 micron/ 12-40 mils.

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment Immersion

Surface temperature: 10°C (50°F) 20°C (68°F) 40°C (104°F)

Min Max Min Max Min Max

Hempaline Defend 630 24 h 28 d 16 h 21 d 16 h 14 d

(Cure 72)

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Note: Hempaline Defend 630 Cure 72 For professional use only.

ISSUED BY: HEMPEL A/S 3782036641

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: February 2019 Page: 2/2

Vous aimerez peut-être aussi

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Hempaline Prepare 130Document2 pagesHempaline Prepare 130CRISTIAN SILVIU IANUCPas encore d'évaluation

- Gas Sweetening and Processing Field ManualD'EverandGas Sweetening and Processing Field ManualÉvaluation : 4 sur 5 étoiles4/5 (7)

- Pds Hempadur 35900 En-GbDocument2 pagesPds Hempadur 35900 En-Gbluisbarrios104Pas encore d'évaluation

- Hempathane Hs 55610 55610 En-GbDocument2 pagesHempathane Hs 55610 55610 En-GbfaizalPas encore d'évaluation

- Creative Resin: Easy techniques for contemporary resin artD'EverandCreative Resin: Easy techniques for contemporary resin artPas encore d'évaluation

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarPas encore d'évaluation

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 pagesHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaPas encore d'évaluation

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehPas encore d'évaluation

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanPas encore d'évaluation

- PDS Hempel's Speed-Dry Primer 13770 en-GBDocument2 pagesPDS Hempel's Speed-Dry Primer 13770 en-GBSaul Antayhua0% (1)

- Pds Hempadur 85671 En-GbDocument2 pagesPds Hempadur 85671 En-GbPrabath Nilan GunasekaraPas encore d'évaluation

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanPas encore d'évaluation

- Product DataDocument2 pagesProduct DatapoerwntiPas encore d'évaluation

- PDS Hempadur 85671 en-GBDocument3 pagesPDS Hempadur 85671 en-GBvitharvanPas encore d'évaluation

- Hempadur Quattro InglesDocument3 pagesHempadur Quattro InglesElizabeth Maria Bazán MoralesPas encore d'évaluation

- Hempadur 85671Document2 pagesHempadur 85671EkoAndriAntoPas encore d'évaluation

- Pds Hempadur 85671Document2 pagesPds Hempadur 85671Namta GeorgePas encore d'évaluation

- Hempels - Anti Condens - 617usDocument3 pagesHempels - Anti Condens - 617usnarmathaPas encore d'évaluation

- PDS Hempatex Hi-Build 46330 en-GBDocument2 pagesPDS Hempatex Hi-Build 46330 en-GBSARAVANAPas encore d'évaluation

- Hempadur XP 87550: DescriptionDocument2 pagesHempadur XP 87550: DescriptionEngTamer50% (4)

- PDS HEMPADUR 47183 en-USDocument2 pagesPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- PDS HEMPADUR 85671 en-GB PDFDocument2 pagesPDS HEMPADUR 85671 en-GB PDFMohamed Farhan B PositivePas encore d'évaluation

- Hempalin Enamel 52140Document2 pagesHempalin Enamel 52140EngTamerPas encore d'évaluation

- Defend 740Document2 pagesDefend 740Mohamed NouzerPas encore d'évaluation

- Product Data: HEMPADUR 85671Document2 pagesProduct Data: HEMPADUR 85671EngTamerPas encore d'évaluation

- PDS Hempadur Mio 47950Document2 pagesPDS Hempadur Mio 47950VIKAS DAHIYA0% (2)

- HempadurDocument2 pagesHempadurLuciano SalituriPas encore d'évaluation

- Product DataDocument2 pagesProduct DataEngTamerPas encore d'évaluation

- PDS Hempadur Fast Dry 15560 en-GBDocument2 pagesPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinPas encore d'évaluation

- Product Data: Hempel's Antifouling Olympic Protect+Document2 pagesProduct Data: Hempel's Antifouling Olympic Protect+ululPas encore d'évaluation

- Product Data: HEMPADUR 37620Document2 pagesProduct Data: HEMPADUR 37620Juanda Mardohar Dantec SitompulPas encore d'évaluation

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaPas encore d'évaluation

- Hempadur 85531 PDFDocument2 pagesHempadur 85531 PDFvitharvan0% (1)

- PDS HEMPATHANE TOPCOAT 55210 en-GB PDFDocument2 pagesPDS HEMPATHANE TOPCOAT 55210 en-GB PDFQA QCPas encore d'évaluation

- PDS 15700Document2 pagesPDS 15700altipatlarPas encore d'évaluation

- PDS Hempel's Galvosil 15700 en-GBDocument2 pagesPDS Hempel's Galvosil 15700 en-GBbayuPas encore d'évaluation

- PDS Hempel's Antifouling Atlantic 73850 en-GBDocument2 pagesPDS Hempel's Antifouling Atlantic 73850 en-GBBoopesh MGPas encore d'évaluation

- Hempadur Primer 15300Document3 pagesHempadur Primer 15300vitharvanPas encore d'évaluation

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-GbIlham NugrohoPas encore d'évaluation

- PDS Hempalin Primer 12050 en-GBDocument2 pagesPDS Hempalin Primer 12050 en-GBErwin MalmsteinPas encore d'évaluation

- Hempel's Galvosil 15790 15790 En-GbDocument2 pagesHempel's Galvosil 15790 15790 En-GbRoberto_PrrPas encore d'évaluation

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarPas encore d'évaluation

- Product Data: HEMPADUR 45143Document2 pagesProduct Data: HEMPADUR 45143JoaoPas encore d'évaluation

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehPas encore d'évaluation

- PDS Hempaprime Multi 500 Summer en-GBDocument2 pagesPDS Hempaprime Multi 500 Summer en-GBFreddyPas encore d'évaluation

- PDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBDocument2 pagesPDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBFreddy Carl FredricksenPas encore d'évaluation

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehPas encore d'évaluation

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 pagesPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawPas encore d'évaluation

- Pds Hempel's Shopprimer e 15275 En-GbDocument2 pagesPds Hempel's Shopprimer e 15275 En-GbErwin MalmsteinPas encore d'évaluation

- Pds Hempadur Speed-Dry ZP 500 En-GbDocument3 pagesPds Hempadur Speed-Dry ZP 500 En-GbDHANOOPPas encore d'évaluation

- Pds Hemparea DTM 55973 En-GbDocument2 pagesPds Hemparea DTM 55973 En-GbFreddy Carl FredricksenPas encore d'évaluation

- PDS Hempadur 85671 en-GBDocument2 pagesPDS Hempadur 85671 en-GBfaisalfaiPas encore d'évaluation

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 pagesPDS Hempadur Multi-Strength 35842 en-GBIfrahimPas encore d'évaluation

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasPas encore d'évaluation

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbSachin NambiarPas encore d'évaluation

- Hempadur Zinc 17380Document2 pagesHempadur Zinc 17380sizmaruPas encore d'évaluation

- Product DataDocument2 pagesProduct DataegomoPas encore d'évaluation

- HEMPADUR QUATTRO 1763619990 en-USDocument11 pagesHEMPADUR QUATTRO 1763619990 en-USAnuar SalehPas encore d'évaluation

- Hempaline Defend 630 Base 3782910000 En-UsDocument10 pagesHempaline Defend 630 Base 3782910000 En-UsAnuar SalehPas encore d'évaluation

- HEMPATEX ENAMEL 5636010000 en-USDocument11 pagesHEMPATEX ENAMEL 5636010000 en-USAnuar SalehPas encore d'évaluation

- Hempadur Multi-Strength GF 35870Document11 pagesHempadur Multi-Strength GF 35870Anuar SalehPas encore d'évaluation

- Hempadur Mastic 45881Document7 pagesHempadur Mastic 45881Anuar SalehPas encore d'évaluation

- FAQ-Zinc Silicate Curing in Warm Humid ClimatesDocument1 pageFAQ-Zinc Silicate Curing in Warm Humid ClimatesAnuar SalehPas encore d'évaluation

- Hempadur Avantguard 550Document11 pagesHempadur Avantguard 550Anuar SalehPas encore d'évaluation

- PDS en-GB 16490Document2 pagesPDS en-GB 16490Anuar SalehPas encore d'évaluation

- Zinc SilicatesDocument4 pagesZinc SilicatesAnuar SalehPas encore d'évaluation

- Hempel Shopprimer 15890ZSDocument2 pagesHempel Shopprimer 15890ZSAnuar SalehPas encore d'évaluation

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehPas encore d'évaluation

- Hempadur Avantguard 550Document2 pagesHempadur Avantguard 550Anuar SalehPas encore d'évaluation

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehPas encore d'évaluation

- HempelDocument2 pagesHempelAnuar SalehPas encore d'évaluation

- Product Data: Hempel'S Silicone Zinc 16900Document2 pagesProduct Data: Hempel'S Silicone Zinc 16900Anuar SalehPas encore d'évaluation

- A Theoretical Model of UHF Propagation in Urban: EnvironmentsDocument9 pagesA Theoretical Model of UHF Propagation in Urban: Environmentsaibramai3Pas encore d'évaluation

- Research (Design of Water Tank-Appendix)Document19 pagesResearch (Design of Water Tank-Appendix)Alyssa Mae GomezPas encore d'évaluation

- Friction ExperimentDocument6 pagesFriction ExperimentsedraPas encore d'évaluation

- Rdso Weld NotesDocument18 pagesRdso Weld Notesvidya nareshPas encore d'évaluation

- Electrical-engineering-syllabus-R-2022 C - Mumbai-UniversityDocument57 pagesElectrical-engineering-syllabus-R-2022 C - Mumbai-UniversitySayali ParabPas encore d'évaluation

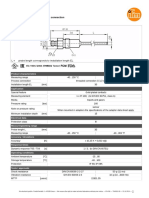

- Temperature Sensor With Process Connection: L Probe Length Corresponds To Installation Length ELDocument2 pagesTemperature Sensor With Process Connection: L Probe Length Corresponds To Installation Length ELImad YahyaPas encore d'évaluation

- Chemistry Paper 2 TZ2 SLDocument24 pagesChemistry Paper 2 TZ2 SLMaría JulianaPas encore d'évaluation

- Landslide and Hillslope HydrologyDocument16 pagesLandslide and Hillslope Hydrologyrienalen placaPas encore d'évaluation

- Simple Harmonic Motion, SuperpositionDocument9 pagesSimple Harmonic Motion, SuperpositionSaurav KumarPas encore d'évaluation

- Rineer Hydraulics Inc, Specifications PDFDocument2 pagesRineer Hydraulics Inc, Specifications PDFTulio Andres CoyPas encore d'évaluation

- 123 - Murad PDFDocument3 pages123 - Murad PDFArjunBanerjeePas encore d'évaluation

- CB123A - 48 - A24.AAA.015A1 - R1 - Eng - Digitale-MDocument4 pagesCB123A - 48 - A24.AAA.015A1 - R1 - Eng - Digitale-MRamius HamdaniPas encore d'évaluation

- HP Vs CCDocument1 pageHP Vs CCKhoinguyen NguyenPas encore d'évaluation

- Property SheetDocument6 pagesProperty SheetsivaPas encore d'évaluation

- ReportnDocument4 pagesReportnGavin MuganiPas encore d'évaluation

- Topic 05 One Dimensional Kinematics NotesDocument28 pagesTopic 05 One Dimensional Kinematics NotesRukiezillaPas encore d'évaluation

- Lecture 8: Voltage Regulation: ECE 5984: Power Distribution System AnalysisDocument34 pagesLecture 8: Voltage Regulation: ECE 5984: Power Distribution System Analysisante mitarPas encore d'évaluation

- Computed Torque Control of The Stewart Platform WiDocument8 pagesComputed Torque Control of The Stewart Platform WiJose ArhuiriPas encore d'évaluation

- Linear Equation in 2 Variables Class 9 CbseDocument9 pagesLinear Equation in 2 Variables Class 9 Cbseriya rajputPas encore d'évaluation

- T Proc Notices Notices 045 K Notice Doc 41060 991081109Document7 pagesT Proc Notices Notices 045 K Notice Doc 41060 991081109YusdianPas encore d'évaluation

- Das2019 PDFDocument15 pagesDas2019 PDFJian XuPas encore d'évaluation

- Module 1Document100 pagesModule 1Reyven Recon100% (1)

- Revised Structural DrawingDocument12 pagesRevised Structural DrawingmercyPas encore d'évaluation

- General Instructions:: PRACTICE PAPER (2018-19) Class: Xii Max. Marks:70 Subject: Chemistry Time: 3 HoursDocument8 pagesGeneral Instructions:: PRACTICE PAPER (2018-19) Class: Xii Max. Marks:70 Subject: Chemistry Time: 3 HoursHINDI CARTOONSPas encore d'évaluation

- Fireworks Research PaperDocument8 pagesFireworks Research Paperefjddr4z100% (1)

- CBSE Class 9 Physics Worksheet - GravitationDocument2 pagesCBSE Class 9 Physics Worksheet - GravitationSuyash JaiswalPas encore d'évaluation

- Manometer - Fluid MechanicsDocument5 pagesManometer - Fluid MechanicsVijaykumar NagathanPas encore d'évaluation

- Product Data Sheet: Circuit Breaker Compact Ns800H, 70 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 800 A, Fixed, 4 Poles 4DDocument3 pagesProduct Data Sheet: Circuit Breaker Compact Ns800H, 70 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 800 A, Fixed, 4 Poles 4DsoyalPas encore d'évaluation

- Sony Mds Jb920 Service ManualDocument72 pagesSony Mds Jb920 Service ManualLozzy_uk0% (1)

- Selection For Street Light Luminar - (PART-1) - Electrical Notes & ArticlesDocument9 pagesSelection For Street Light Luminar - (PART-1) - Electrical Notes & Articleslegasu zemenePas encore d'évaluation

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (82)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachD'EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachÉvaluation : 3.5 sur 5 étoiles3.5/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4 sur 5 étoiles4/5 (6)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceD'EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceÉvaluation : 5 sur 5 étoiles5/5 (5)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreD'EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreÉvaluation : 4.5 sur 5 étoiles4.5/5 (33)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationD'EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- The Knowledge: How to Rebuild Our World from ScratchD'EverandThe Knowledge: How to Rebuild Our World from ScratchÉvaluation : 3.5 sur 5 étoiles3.5/5 (133)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- The Book of the Moon: A Guide to Our Closest NeighborD'EverandThe Book of the Moon: A Guide to Our Closest NeighborÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- The Assassination Complex: Inside the Government's Secret Drone Warfare ProgramD'EverandThe Assassination Complex: Inside the Government's Secret Drone Warfare ProgramÉvaluation : 4 sur 5 étoiles4/5 (55)

- Project Management All-in-One For DummiesD'EverandProject Management All-in-One For DummiesÉvaluation : 5 sur 5 étoiles5/5 (6)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (54)

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)