Académique Documents

Professionnel Documents

Culture Documents

Saic H 2060

Transféré par

jerinTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saic H 2060

Transféré par

jerinDroits d'auteur :

Formats disponibles

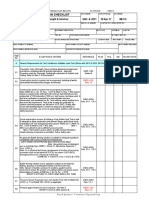

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process & Final Inspection of Internal coating

SAIC-H-2060 30-Apr-17 COAT-

Application on Field Girth Welds

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

Coating application procedure incorporates all the mandatory

SAES-H-201,

A1 requirements of SAES-H-201 and is approved by CSD

Section 1

FBE Powder material, Batch Number, Date of Manufacture, expiry SAES-H-201,

A2

date meets with the requirements of APCS-102A, 102B & 102C Para. 5.3 & 6.1

FBE Coating Repair Material is supplied or approved by the

SAES-H-201,

A3 manufacturer of the powder epoxy coating and conform to CSD

Para. 8.5.3

approved Coating Procedure.

SAES-H-002,

Internal coatings for potable water service are certified by FDA,

Para.

A4 NSF or equivalent.

5.2.14

Note: The certificate shall be renewed every 24 months.

The coating system has been selected for specific service from the SAES-H-002,

A5 various SAP Material Numbers specified in APCS-117 and Para.

approved by CSD/Coatings Team . (Refer to Attachment #1) 5.2.11

Robotic crawler (consisting of blasting and coating equipment, dry

film thickness gauge and holiday detector) are used for onshore

SAES-H-002,

application for internal field girth welds of pipe strings with

A6 Para. 5.2.4

diameters ranging from 8 to 36".

Note: If isotope is used as the girth weld locator, it should be

backed up with a video camera for real time inspection.

For pipe diameters larger than 36", the coating application is done SAES-H-002,

A7 manually by qualified contractors with the approval of Para. 5.2.4

CSD/Coatings Team.

A semi-robotic system is used for offshore applications of specialty

SAES-H-002,

A8 liquid coating on internal girth welds with diameters ranging from 8"

Para. 5.2.5

and above qualified and experienced contractors shall be utilized.

Crawler Equipment for internal coating is verified for correct

SAES-H-201,

functioning and calibration on a test spool.

A9 Para. 7.1.6

Note: The Length & diameter of the test spool shall be decided &

agreed by contractor, CSD & SA inspector before work begins.

Coating personnel hold a valid certification as follows :

SAEP-316

B) Equipment operator (trained & certified by Coating Contractor)

A10 Para 1.1 & Para.

C) Crew supervisor (trained & certified by Coating Contractor)

1.3

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process & Final Inspection of Internal coating

SAIC-H-2060 30-Apr-17 COAT-

Application on Field Girth Welds

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B In-Process Inspection of Internal FBE Coating

Coating operations are only allowed to proceed in bad weather

SAES-H-201,

B1 conditions (rain, high winds, etc.)if protective canopies approved

Para. 7.3.6

by SA Inspector are used.

Coating is applied with in 4 hrs, of blast cleaning before any rust

blooming of the prepared metal surface occurs.. SAES-H-201,

Para. 7.3.2

B2

Any flash rusting observed shall be re-blasted prior to coating. SAES-H-002

Refer to the surface preparation and coating application APCS-Sheets

requirements given in APCS Data sheets

Application of phenolic primer prior to the application of FBE is

carried out using a machine to ensure that the travel of application

is constant and that the DFT will not exceed 25 microns (One mil) SAES-H-002,

B3

in all areas. Para. 5.2.3

Note : One mil thickness is exceeded if the “peaks” of steel

substrate are no longer visible.

Substrate Pre-Heat Temperature meets the temperature specified Approved

in the procedure. * Required Pre-heat Temp = ___________ Procedure

SAES-H-201,

B4

1 . Preheating shall be accomplished by induction heating coils. Para. 7.3.1

2. Preheating temperatures shall be measured with contact &

pyrometers. Temperature crayons shall not be used. Para. 7.3.4

The powder application is started immediately after correct metal SAES-H-201,

B5

temp is reached. Para. 7.3.5

Coating Machine applies the powder uniformly to correct width SAES-H-201,

B6 centered on girth weld to achieve a target dry film thickness of 325 Para.

to 625 microns in least number of passes possible. 7.3.5.1

SAES-H-201,

Coated areas are protected from contamination of dirt or

B7 Para.

deleterious materials during application & curing.

7.3.5.2

C Final Inspection Visual Check or Video Camera:

Internally coated pipeline with diameters from 10" to 20" shall be SAES-H-201,

C1

inspected by the cameras fitted on the crawling machine. Para 8.2.5

SAES-H-201,

Finished coating has a uniform, glossy appearance free of defects

C2 Para 8.2.4

such as holidays, fish eyes, lumps, dry spray, sags, and runs.

Coating overlap shall be within the thickness specified in SAES-H- SAES-H-201,

C3 200 and / or as per the applicator's procedure approved. Para 8.2.4

Cure Test is performed on first five joints coated and twice each

SAES-H-201,

C4 day there after, and found acceptable the results are recorded

Para 8.2.3

using SATR-H-2009.

Adhesion Test is conducted as per the frequency specified in

SAES-H-201 found acceptable and test result recorded on SATR-

SAES-H-201,

C5 H-2010.

Section 8.4

Note: Coatings failing the adhesion test criteria shall be completely

removed and areas recoated.

D Dry Film Thickness (DFT) measurement & Holiday Testing

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process & Final Inspection of Internal coating

SAIC-H-2060 30-Apr-17 COAT-

Application on Field Girth Welds

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Thickness measurements made on each coated weld joint using

an

SAES-H-201,

approved, correctly calibrated dry film thickness gauge (per SSPC

Para. 8.2.2

D1 PA-2). A minimum of 6 readings shall be taken on each field joint

&

including weld seam.

Para. 7.3.5.1

Refer to attachment # 1 for Coating thickness specified for

Various Coating Systems.

Holiday test applied on 100% of the joints coated, at test voltage of SAES-H-201,

125 volts DC per 25 microns of maximum coating thickness. Para. 8.3

D2

(Surface temp of pipe shall not exceed 88). 09-SAMSS-091

Test results are recorded on SATR-H-2008 Para 10.6.3

All holidays, imperfections, and damaged areas are carefully SAES-H-201,

D3

identified as required by the procedure. (Joint ID Number) Para 8.3.2

E Repairs

Girth welds with more than 3 holidays are completely blasted off SAES-H-201,

E1

and the area recoated Para 8.5.1

Pipe surface to be repaired are cleaned of all dirt and damaged or

disbonded coating using abrasive blasting or other suitable means.

SAES-H-201,

E2 The edges of the original coatings are "feathered out"

Para 8.5.2

approximately 50 mm around the specific area to be coated, and

all dust wiped off before applying the patch coating.

Approved

Patch-up coating is applied using materials & methods specified in

E3 Coating

the approved Repair Procedure.

Procedure

Patch Repair areas are 100% holiday tested applying procedures

SAES-H-201,

E4 used for original coating (Refer to D2 above) and found

Para 8.5.4

acceptable, results recorded on SATR-H-008

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process & Final Inspection of Internal coating

SAIC-H-2060 30-Apr-17 COAT-

Application on Field Girth Welds

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Remarks:

ATTACHMENTS # 1

REFERENCE DOCUMENTS:

1. SAES-H-201: General Specification for Over-the-Ditch External and Internal FBE Coating of Field Girth Welds (16 November 2011)

2. SAES-H-001, Coating Selection and Application Requirements for Industrial Plants and Equipment (10 April 2011)

3. SAES-H-002 Internal and External Coatings for Steel Pipelines and Piping (2 June 2012)

4. 09-SAMSS-091, Shop-Applied Internal FBE Coatings (15 October 2011)

5. SAEP-316 Performance Qualification of Coating Personnel (11 MAR. 2015)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and

Name, Initials and Date:

Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and

Name, Initials and Date:

Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Comp of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process & Final Inspection of Internal coating SAIC-H-

30-Apr-13 COAT-

Application on Field Girth Welds 2060

PROJECT TITLE WBS / BI / JO NUM CONTRACTOR / SUBCONTRACTOR

Attachment- 1

REQUIREMENTS- SAUDI ARAMCO APPROVED PROTECTIVE COATING SYSTEMS for INTERNAL COATINGS

S.R. No APCS

Coating Specific Requirements for Coating Application

Type/Service Total DFT #1 #2

Specialty Liquid Coating Systems 1- Ceramic/Alloy Filled Epoxy 2- Glass Flakes Filled

for Pumps, Valves, Piping, Fitting Coatings Coatings

and Exchanger Boxes. Filler Coatings: Filler Coatings:

Service Temp: Up to 105C. Belzonas 1311/1111 Corroglass 100, 200,

Purchase Specifications: 09- Barrier Coatings: 600, Polyglass VEF

SAMSS-067

1 APCS-28 750 – 1500 microns Belzonas 1341/1321/ 1391S/1391T / Barrier Coatings &

SAMS Stock Numbers: N/A 5891 Top Coat:

Fluiglide and/or Veil

cote

Shop-Applied Fusion Bonded APCS-102A shall not be used on the SAP M/N: (Refer to

Epoxy for Internal Coating of girth welds of any pipe and fittings SAES-H-002V)

Treated Seawater and Potable coated with either APCS-28, APCS- Purchase Spec: 09-

Water Pipelines (Service Temp: 375-625 117 or APCS-118. SAMSS-091.

2 APCS-102A

Min. 0°C Max. 90°C ) microns

Shop-Applied Fusion Bonded APCS-102B shall not be used on SAP M/N: (Refer to

Epoxy for Internal Coating of the girth welds of any pipe and SAES-H-002V)

Formation Water and Wet Crude fittings coated with either APCS-28, Purchase Spec: 09-

Pipelines (Service Temp: Min. 0°C 375-625 APCS-117 or APCS-118. SAMSS-091.

3 APCS-102B Max. 95°C ) microns

Shop-Applied Fusion Bonded Field Girth Weld Area: Crawler- Purchase Spec:

Epoxy for Internal Coating of applied FBE or liquid coating APCS- (Refer to CSD. The

Sour/Sweet Gas Pipelines. 120 for internal girth welds of pipe coating shall be

Pipe 625 – 750

(Primarily used for sour and strings. tested against the

microns

4 APCS-102C sweet gas pipelines excluding operating conditions.)

Girth Welds: As per

girth welds. Temp: Min. 0°C

Coating Data sheets

Max. 95°C)

Internal coating for water, oil or The coating system for specific

gas service. For spools, valves, service shall be selected from the

elbows, tees, wyes, nozzles, various SAP Material Numbers

flanges and other associated specified in APCS-117. SAP M/N:

pieces of piping systems. When In this regard, CSD/Coatings Team 1000180021,

the coating is glass fiber/flake shall be contacted 1000180023,

reinforced, a final coat of flow 1000180276,

5 APCS-117 500 to 1500 microns

coating should be used to ensure 1000180279,

a good flow property. 1000180328 and

(Service Temp: depends on 100018033

coating product) Purchase Spec: N/A

Saudi Aramco: Company General Use

Internal coating for oil, water and SAP M/N: N/A

gas service. Applied on internal Purchase

of spools, elbows, tees, wyes, Specification: N/A

APCS-118 nozzles, flanges and other

1,500 to 3,000

(This Coating System associated pieces of piping The coating system for specific

systems. This coating type microns

6 is removed from service shall be recommended by

(depending on

SAES-H-002 Revised creates a “pipe within a pipe” CSD/Coatings Team.

concept. (Service Temp: Min. product specification)

on 8-May-2011)

-20°C Max. 105°C or depends on

coating product)

Internal coating to prevent black Field and/or Shop Girth Weld Areas: SAP M/N: N/A

APCS-119 (This powder and/or enhance flow of Coating is not required Purchase

Coating System is sales gas in pipelines and piping Specification: API 5L2

7 removed from SAES- systems. (Service Temp: Min. 0°C 75 to 125 microns or ISO 15741

H-002 Revised on 8- Max. 90°C)

May-2011)

Internal coating for water, oil or SAP M/N: N/A

gas service in the girth weld area Purchase Spec: N/A

applied by special semi-robotic 500 to 1,000 microns

8 APCS-120 machines.(Service Temp: (depending on

depends on coating product) product specification)

Saudi Aramco: Company General Use

31-Mar-15

BER

NGS

ing Application

#2

2- Glass Flakes Filled

Coatings

Filler Coatings:

Corroglass 100, 200,

600, Polyglass VEF

Barrier Coatings &

Top Coat:

Fluiglide and/or Veil

cote

SAP M/N: (Refer to

SAES-H-002V)

Purchase Spec: 09-

SAMSS-091.

SAP M/N: (Refer to

SAES-H-002V)

Purchase Spec: 09-

SAMSS-091.

Purchase Spec:

Refer to CSD. The

coating shall be

ested against the

operating conditions.)

SAP M/N:

1000180021,

1000180023,

1000180276,

1000180279,

1000180328 and

100018033

Purchase Spec: N/A

Saudi Aramco: Company General Use

SAP M/N: N/A

Purchase

Specification: N/A

SAP M/N: N/A

Purchase

Specification: API 5L2

or ISO 15741

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015)

Saudi Aramco: Company General Use

Rev. 2015.03.00

4/30/2017

Saudi Aramco: Company General Use

3/31/2015

Saudi Aramco: Company General Use

Vous aimerez peut-être aussi

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanPas encore d'évaluation

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliPas encore d'évaluation

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387Pas encore d'évaluation

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasPas encore d'évaluation

- 00 Saip 10aDocument1 page00 Saip 10amalika_00Pas encore d'évaluation

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapPas encore d'évaluation

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandPas encore d'évaluation

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument10 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanPas encore d'évaluation

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.Pas encore d'évaluation

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinPas encore d'évaluation

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LonePas encore d'évaluation

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanPas encore d'évaluation

- Saic G 2002Document32 pagesSaic G 2002jerinPas encore d'évaluation

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289Pas encore d'évaluation

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistSajid ShaikhPas encore d'évaluation

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinPas encore d'évaluation

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanPas encore d'évaluation

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINPas encore d'évaluation

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Pas encore d'évaluation

- Saudi Aramco fastener inspection requirementsDocument2 pagesSaudi Aramco fastener inspection requirementsThaksenPas encore d'évaluation

- Saudi Aramco waterproofing inspectionDocument3 pagesSaudi Aramco waterproofing inspectionSatheesh Rama SamyPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289Pas encore d'évaluation

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyPas encore d'évaluation

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Document1 pageSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanPas encore d'évaluation

- Saudi Aramco checklist for buttering jointsDocument1 pageSaudi Aramco checklist for buttering jointskarioke mohaPas encore d'évaluation

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocument2 pagesSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyPas encore d'évaluation

- Active Doc ListDocument310 pagesActive Doc Listsalman1111aPas encore d'évaluation

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarPas encore d'évaluation

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWPas encore d'évaluation

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNAPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritPas encore d'évaluation

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaPas encore d'évaluation

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanPas encore d'évaluation

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniPas encore d'évaluation

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 Plumbbiplabpal2009Pas encore d'évaluation

- 1-Cover GCC Rev. 0Document27 pages1-Cover GCC Rev. 0Mohammed Mujeeb Ali FathaanPas encore d'évaluation

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinPas encore d'évaluation

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangPas encore d'évaluation

- PIM AgendaDocument1 pagePIM Agendagayas416100% (1)

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeAbu Anas M.SalaheldinPas encore d'évaluation

- UncontrolledDocument13 pagesUncontrolledSerajahmad56Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CAbdul HannanPas encore d'évaluation

- Satip M 100 07Document10 pagesSatip M 100 07munnaPas encore d'évaluation

- Saic H 2015Document4 pagesSaic H 2015jerinPas encore d'évaluation

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyPas encore d'évaluation

- Pressure Testing ChecklistDocument3 pagesPressure Testing Checklistjerin100% (3)

- Saic G 2011Document15 pagesSaic G 2011jerinPas encore d'évaluation

- Saic G 2002Document32 pagesSaic G 2002jerinPas encore d'évaluation

- Saic e 2003Document7 pagesSaic e 2003jerinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saic LPT 2001Document22 pagesSaic LPT 2001jerinPas encore d'évaluation

- Saic J 6903Document9 pagesSaic J 6903jerinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinPas encore d'évaluation

- Saic e 2002Document10 pagesSaic e 2002jerinPas encore d'évaluation

- Saic e 2001Document7 pagesSaic e 2001jerinPas encore d'évaluation

- Saic LPT 2003Document11 pagesSaic LPT 2003jerinPas encore d'évaluation

- Saic e 2004Document8 pagesSaic e 2004jerinPas encore d'évaluation

- Aramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerDocument13 pagesAramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerjerinPas encore d'évaluation

- Saic M 1002Document4 pagesSaic M 1002jerinPas encore d'évaluation

- Saic B 1002Document3 pagesSaic B 1002jerinPas encore d'évaluation

- Saudi Aramco Fence Pre-Pour ChecklistDocument2 pagesSaudi Aramco Fence Pre-Pour ChecklistjerinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saic F 2022Document4 pagesSaic F 2022jerinPas encore d'évaluation

- Saic B 1004Document2 pagesSaic B 1004jerinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saic A 2013Document6 pagesSaic A 2013jerinPas encore d'évaluation

- Saic F 2021Document11 pagesSaic F 2021jerinPas encore d'évaluation

- Saic A 2004Document4 pagesSaic A 2004jerinPas encore d'évaluation

- Saic A 1017Document1 pageSaic A 1017jerinPas encore d'évaluation

- Saic A 2011Document8 pagesSaic A 2011jerinPas encore d'évaluation

- Saic A 1016Document2 pagesSaic A 1016jerinPas encore d'évaluation

- Saic N 2031Document3 pagesSaic N 2031jerinPas encore d'évaluation

- PBS 1.1 Quiz Review (Sickels) 23Document158 pagesPBS 1.1 Quiz Review (Sickels) 23tyson.bergsrudPas encore d'évaluation

- References Edfd227 Group Assessment 2 Newsletter WebsiteDocument8 pagesReferences Edfd227 Group Assessment 2 Newsletter Websiteapi-523911286Pas encore d'évaluation

- 2019 Orientation PresentationDocument45 pages2019 Orientation Presentationaee2 gm2100% (1)

- Week February 15TH To 19THDocument18 pagesWeek February 15TH To 19THQUETEVALGAMADRESPas encore d'évaluation

- Iso Tc6 ĿDocument12 pagesIso Tc6 Ŀzrilek1Pas encore d'évaluation

- International Journal of Project Management: Lavagnon A. Ika, Jonas Söderlund, Lauchlan T. Munro, Paolo LandoniDocument11 pagesInternational Journal of Project Management: Lavagnon A. Ika, Jonas Söderlund, Lauchlan T. Munro, Paolo LandoniWarda IshakPas encore d'évaluation

- Giving OpinionsDocument3 pagesGiving OpinionsAndreea BudeanuPas encore d'évaluation

- Reading Skills Practice: Your Digital Footprint - ExercisesDocument2 pagesReading Skills Practice: Your Digital Footprint - ExercisesagnaldopedroPas encore d'évaluation

- Analysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck ConverterDocument12 pagesAnalysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck Converterdaber_huny20Pas encore d'évaluation

- Factors Affecting Reading at Elsie Lund SchoolDocument3 pagesFactors Affecting Reading at Elsie Lund SchoolLouise Mikylla LimPas encore d'évaluation

- Literature Review of Job Satisfaction of TeachersDocument7 pagesLiterature Review of Job Satisfaction of Teachersfeiaozukg100% (1)

- WCO - Data Model PDFDocument25 pagesWCO - Data Model PDFCarlos Pires EstrelaPas encore d'évaluation

- MHP 6 (Tugas 1 Diskusi Presentasi Laudon Dan Chafey)Document2 pagesMHP 6 (Tugas 1 Diskusi Presentasi Laudon Dan Chafey)Alexander William Wijaya OeiPas encore d'évaluation

- Steps To Design A PCB Using OrcadDocument3 pagesSteps To Design A PCB Using OrcadkannanvivekananthaPas encore d'évaluation

- McCloskey Wible Cohen (1988)Document11 pagesMcCloskey Wible Cohen (1988)ShaneLee102Pas encore d'évaluation

- Calculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEDocument4 pagesCalculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEAlaa RamadanPas encore d'évaluation

- Resume HarishArchitectDocument11 pagesResume HarishArchitectharishPas encore d'évaluation

- DEA462F - EntelliGuard G Circuit Breakers - Lo-ResDocument8 pagesDEA462F - EntelliGuard G Circuit Breakers - Lo-Resyasser foudaPas encore d'évaluation

- Dogtooth Film ReviewDocument6 pagesDogtooth Film ReviewAstrid JohnsonPas encore d'évaluation

- Physical Properties of SolutionsDocument23 pagesPhysical Properties of Solutions董青天Pas encore d'évaluation

- Manual Controlador C90Document442 pagesManual Controlador C90Fabián MejíaPas encore d'évaluation

- Type AKP20 MICRO-Axial Piston Pumps: Up To 300 Bar 0,012 CM /revDocument6 pagesType AKP20 MICRO-Axial Piston Pumps: Up To 300 Bar 0,012 CM /revpeterPas encore d'évaluation

- Shs Environmental AttitudeDocument19 pagesShs Environmental AttitudeProfTeng DePano RecentePas encore d'évaluation

- Nmsgcbok 440Document1 pageNmsgcbok 440Xk CPas encore d'évaluation

- J305GAC Trojan Data SheetsDocument2 pagesJ305GAC Trojan Data SheetsEdisson Alarcon MoraPas encore d'évaluation

- INDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYDocument5 pagesINDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYShane Khan50% (2)

- Mike-Rose - The-Language-of-Exclusion (Edited)Document20 pagesMike-Rose - The-Language-of-Exclusion (Edited)abankiPas encore d'évaluation

- Cat DP150 Forklift Service Manual 2 PDFDocument291 pagesCat DP150 Forklift Service Manual 2 PDFdiegoPas encore d'évaluation

- WorkshopDocument4 pagesWorkshopAmit GuptaPas encore d'évaluation

- Pipe Schedule MethodDocument4 pagesPipe Schedule MethodSanket PhatangarePas encore d'évaluation