Académique Documents

Professionnel Documents

Culture Documents

TC Corrective Maintenance

Transféré par

Luis RomeiroTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TC Corrective Maintenance

Transféré par

Luis RomeiroDroits d'auteur :

Formats disponibles

Alcatel-Lucent GSM

TC Corrective Maintenance

Handbook

BSC & TC Document

Procedural Handbook

Release B11

3BK 21656 AAAA PCZZA Ed.23

BLANK PAGE BREAK

Status RELEASED

Short title Maintenance Handbook

All rights reserved. Passing on and copying of this document, use

and communication of its contents not permitted without written

authorization from Alcatel-Lucent.

2 / 46 3BK 21656 AAAA PCZZA Ed.23

Contents

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Safety Rules and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Safety Rules for Equipment Under Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Electrostatic Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.2 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.3 Transportation and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.4 Components and PBAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.5 Handling Optical Fiber Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.6 Handling Coaxial and Optical Fiber Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

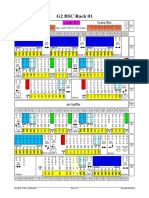

2 G2 TC Transmission RITs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Before You Start to Replace Transmission RITs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.2 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.3 Impact on System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.4 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Replace Transmission RITs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.1 Replace ASMC, ATBX or DT16 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.2 Replace MT120 Board (Legacy, NarrowBand or WideBand) . . . . . . . . . . . . . . . . 18

2.2.3 Replace JBFAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 9125 TC RITs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Replace MT120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1.2 Impact on System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.3 Replace MT120 in TCIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.4 Replace MT120 in HSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Replace TCIF/TCIFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.2 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.3 Impact on System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.4 Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3 Replace FANU for MT120 Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3.2 Impact on System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3.3 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4 Replace FANU for TCIF/TCIFI Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.2 Impact on System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.3 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.5 Replace SFP Module from TCIF/TCIFI Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.5.1 Remove SFP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.5.2 Insert SFP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3BK 21656 AAAA PCZZA Ed.23 3 / 46

Tables

Tables

Table 1: Transmission RITs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 / 46 3BK 21656 AAAA PCZZA Ed.23

Preface

Preface

Purpose The TC Corrective Maintenance Handbook describes how to perform TC

maintenance. It breaks down each maintenance task into a series of

step-by-step instructions, and tells you what tools and materials are required.

The handbook covers the following equipment configurations:

G2 TC

9125 TC.

Note: The following convention applies for a 9125 TC equipped with a TC

STM1 - IP subrack:

TC STM1 interface board is also referred as TCIF

TC STM1 IP interface board is also referred as TCIFI.

Your network may not have some of the hardware included in the

handbook.

Note: JBMTE is a generic name of SBL associated to MT120 boards and may

also refer to JBMTE2, JBMTE3NB and JBMTE3WB.

For more information about these configurations, refer to the functional

description documents.

The Alcatel-Lucent Radio Solutions include the G2 TC and 9125 TC equipment

described in this document:

Document Pertinence This document applies to release B11 of the Transcoder.

This document contains IP transport in the BSS related information. This

feature is available commercially from Release B12.

3BK 21656 AAAA PCZZA Ed.23 5 / 46

Preface

What’s New In Edition 23

Document Pertinence was updated to specify that IP transport in the BSS is

available from Release B12.

In Edition 22

Description improvement in:

Replace MT120 (Section 3.1)

Replace MT120 Board (Legacy, NarrowBand or WideBand) (Section 2.2.2).

In Edition 21

Updates were made in the following sections:

Replace MT120 Board with One of the Same Type (Section 2.2.2.1)

Replace an MT120 Board with One of the Same Type (Section 3.1.4.1)

In Edition 20

Section Board Replacement Procedure (Section 3.2.4) was updated.

In Edition 19

Description improvement in Replace MT120 in HSI (Section 3.1.4).

In Edition 18

Release name was changed in Document pertinence.

In Edition 17

Description improvement in

Replace MT120 in HSI (Section 3.1.4)

Replace an MT120 Board with One of the Same Type (Section 3.1.4.1).

In Edition 16

Updates were made in Replace MT120 in HSI (Section 3.1.4) and in the

preface pard of the method.

Description improvement in:

Replace MT120 Board with One of a Different Type (Section 2.2.2.2)

Replace MT120 Board with One of a Different Type (Section 3.1.3.2)

Replace MT120 Board with One of a Different Type (Section 3.1.4.2).

In Edition 15

Restriction 3BKA20FBR286374 was removed from Replace MT120 in HSI

(Section 3.1.4).

In Edition 14

Updates made in Replace MT120 Board (Legacy, NarrowBand or WideBand)

(Section 2.2.2) and Replace MT120 (Section 3.1).

In Edition 13

Updates were made in section Replace TCIF/TCIFI (Section 3.2).

6 / 46 3BK 21656 AAAA PCZZA Ed.23

Preface

In Edition 12

The document was updated regarding the MT120 board replacement for

the G2 and G2.5 TC.

In Edition 11

The document was updated for:

Anti-static wrist strap usage

Checking the system status before and after performing the boards

replacement.

In Edition 10

Updates were made in Board Replacement Procedure (Section 3.2.4).

In Edition 09

Updates were made in:

Replace MT120 Board in 9125 TC Equipped with STM1-IP Subrack

Board Replacement Procedure (Section 3.2.4).

In Edition 08

Restriction 3BKA20FBR286374 was added in Replace MT120.

Description improvement done in:

Replace MT120 Board in 9125 TC Equipped with STM1-IP Subrack

Replace MT120 Board for G2 TC and 9125 TC not Equipped with STM1-IP

Subrack.

In Edition 07

The naming convention for the TCIF/TCIFI board was added in the document.

In Edition 06

Section Board Replacement Procedure (Section 3.2.4) was updated.

In Edition 05

Description improvement in Replace TCIF/TCIFI (Section 3.2).

In Edition 04

Description improvement in

Replace MT120 Board with One of the Same Type (Section 3.1.3.1)

Install the New Board.

In Edition 03

Description improvement in Replace TCIF/TCIFI (Section 3.2).

3BK 21656 AAAA PCZZA Ed.23 7 / 46

Preface

In Edition 02

Description improvement in:

Replace MT120 (Section 3.1)

MT120 in HSI or MT120 in TCIL but with Direct Connection to the Board

Replace MT120 Board in 9125 TC Equipped with STM1-IP Subrack

Install the New Board

Upgrade the IPTC Doughter Board (Section 3.3.2).

In Edition 01

First official release of document for B11.

8 / 46 3BK 21656 AAAA PCZZA Ed.23

Preface

Audience The handbook is intended for:

Maintenance engineers

System support engineers

Network technicians

Network operators.

Assumed Knowledge You must have a basic understanding of the following:

Unix operating system

Alcatel-Lucent operations and maintenance concepts for the BSS

TSC and 9153 OMC-R terminals

Online Alcatel-Lucent Customer Documentation

Windows 2000, Windows XP and Windows Vista operating system

Telecommunications engineering

Anti-static procedures

RF test and measurement equipment

Signal analyzers as used on GSM networks

Electronic test equipment.

3BK 21656 AAAA PCZZA Ed.23 9 / 46

Preface

10 / 46 3BK 21656 AAAA PCZZA Ed.23

1 Safety Rules and Precautions

1 Safety Rules and Precautions

This chapter contains the following safety rules and precautions:

Safety rules for equipment under power

Electrostatic precautions.

Injury from Equipment

Possible death or serious physical harm to personnel and damage to equipment

may result from mishandling.

While performing any maintenance tasks or procedures, you must follow any

local safety requirements, and those mentioned in General Safety Instructions

for Field Operations and this chapter.

3BK 21656 AAAA PCZZA Ed.23 11 / 46

1 Safety Rules and Precautions

1.1 Safety Rules for Equipment Under Power

For maintenance purposes, field operators may have to work on equipment

under power (-48 VDC or -60 VDC). This means that it is possible to touch

some parts under power, that are only protected by heavy fuses. Maintenance

activities must be carried out carefully to avoid short circuits and to prevent

serious personal injury.

Remove all conductive objects from the hands, such as rings, bracelets,

metallic wrist watches and so on. Use appropriate insulated tools for

maintenance activities.

1.2 Electrostatic Precautions

The following electrostatic precautions must be observed:

1.2.1 Environment

Ensure that work benches, stools, and floor mats have a conducting surface

connected to ground. Before handling static-sensitive components and

assemblies, ground yourself to the conducting surface using an anti-static

wrist strap.

When handling static-sensitive components and assemblies, do not wear

or use clothes made of wool, nylon or any other synthetic material. Such

fabrics are major sources of static build-up.

When handling static-sensitive components and assemblies, do not use

gloves and finger covers, unless they are made of cotton.

1.2.2 Tools

Ensure that all the tools which come into contact with static-sensitive

components are at the same voltage level as the conducting work surfaces

and floor mats.

These tools include soldering irons, oscilloscopes, power supplies, and

metal parts of tools and fixtures that are used to hold, assemble or test PBAs.

Do not use rough cleaners or erasers to clean the gold-plated contacts

on PBAs.

Do not mark a PBA with a lead pencil or any other writing instrument.

Do not use synthetic brushes to clean equipment, and do not use dry

cleaning methods.

12 / 46 3BK 21656 AAAA PCZZA Ed.23

1 Safety Rules and Precautions

1.2.3 Transportation and Storage

Pack all containers used to transport and store static-sensitive components,

and use aluminium container tubes if possible. If not, insert the component

terminations into electrically conductive foam.

Before shipping a PBA, wrap it in a conducting synthetic bag or in aluminium

foil. Also pack the PBA in a polyethylene transport box.

Before shipping a PBA which has MOS components, ensure that an

appropriate warning symbol is displayed on the package.

Store spare PBAs in their appropriate polyethylene boxes. Keep the boxes

closed except when access to their contents is required.

Do not store PBAs in an area where the air is polluted with smoke, dust,

dangerous gases or other air-borne particles that may cause damage.

Do not stack PBAs side-by-side or on top of each other with the board

surfaces or components in contact with one another.

Before cleaning a PBA, remove or disconnect the damage protection, such

as protective foam, to allow the PBA to be cleaned thoroughly. Replace the

damage protection upon completion of the task.

1.2.4 Components and PBAs

Components and PBAs not in protective containers, must only be handled

by trained personnel in static-controlled work areas.

Before removing a PBA from an equipment rack, discharge any static by

touching the metal frame of the rack with your hand.

Always handle a PBA by the edges.

Do not handle or carry a PBA by any of the mounted components.

Do not handle a PBA by the gold-plated contact terminals and do not apply

direct pressure to the components.

Do not touch PBA connection pins or conductor paths.

Do not touch PBAs with wet hands.

Place PBAs that have been removed during maintenance with the soldered

side downwards on a conductive surface.

Do not scratch or rub the soldered side of a PBA with a sharp or rough

object.

Do not repair PBAs in the switch room.

Do not handle components and assemblies by their leads.

Do not use excessive force when inserting connection boards.

3BK 21656 AAAA PCZZA Ed.23 13 / 46

1 Safety Rules and Precautions

1.2.5 Handling Optical Fiber Devices

Depending on installed options the equipment may contain fiber optic devices

that can radiate laser beams:

Do not look directly in the laser beam

Take into account that infrared laser radiation is not visible. Additional labels

can be added to classify the laser.

Respect the warnings given by labels provided on equipment.

1.2.6 Handling Coaxial and Optical Fiber Cables

When handling coaxial or optical fiber cables:

Do not cut coaxial or optical fiber cables to adjust the cable length.

Do not bend to tighten the coaxial or optical fiber cable.

Furthermore, for handling coaxial or optical fiber cables respect the cable

manufacturer specifications.

14 / 46 3BK 21656 AAAA PCZZA Ed.23

2 G2 TC Transmission RITs

2 G2 TC Transmission RITs

This chapter tells you how to remove and replace Transmission RITs of the

TC G2

3BK 21656 AAAA PCZZA Ed.23 15 / 46

2 G2 TC Transmission RITs

2.1 Before You Start to Replace Transmission RITs

Read this section before starting the procedure in this chapter.

2.1.1 Prerequisites

Note the following conditions. You must:

Have read Chapter 1 before performing any maintenance procedures.

Be familiar with electrostatic precautions. Refer to Section Electrostatic

Precautions (Section 1.2) for more information.

Know the location of the RIT to be replaced.

The location of the RIT to be replaced is defined in terms of the site,

cabinet, shelf and slot position. This information is obtained from the 9153

OMC-R operator.

Establish an efficient means of communication with an 9153 OMC-R

operator in order to lock (disable) and unlock (initialize) the appropriate

MO (SBL) when required.

2.1.2 Tools and Materials

You must have a:

RS-232 asynchronous communication link cable to connect it to an MT120

legacy board (3BK 07951 AA)

Ethernet crossedcable to connect it to an MT120 NB/WB board.

An anti-static wrist strap

A TSC terminal to configure the ASMC, ATBX, DT16 boards

A TC-NEM PC to configure an MT120 board

Tera Term Pro or Windows HyperTerminal.

A serviceable replacement RIT with an identical part number.

2.1.3 Impact on System

Replacing a RIT causes alarms to be sent to the 9153 OMC-R. If the

replacement RIT clears a fault condition, the corresponding alarms

automatically clears after a short delay. If the replaced board carries traffic

there will be a traffic reduction during the replacement.

In order to reduce the outage, ensure that the board used for replacement is

loaded with the correct software version. If it is not the case, download the

required software version before starting the replacement.

2.1.4 Restrictions

None.

16 / 46 3BK 21656 AAAA PCZZA Ed.23

2 G2 TC Transmission RITs

2.2 Replace Transmission RITs

The following table lists the Transmission RITs.

RIT Description

ASMC Ater Submultiplexer Type C

ATBX Alcatel-Lucent Branching and Switching

DT16 Dual Rate Transcoder for 16 Channels

JBFAN Fan Unit

MT120 Multirate Transcoder with 120 channels

MT120 WB MT120 board which supports the AMR WB ( Adaptive

Multi-Rate Wideband)

MT120 NB MT120 board which supports the AMR NB ( Adaptive

Multi-Rate Narrowband)

Table 1: Transmission RITs

2.2.1 Replace ASMC, ATBX or DT16 Board

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. At the equipment site, locate the position of the faulty RIT.

3. If appropriate, disconnect the front panel cables from the RIT, carefully

noting their positions for re-connection.

4. Connect the anti-static wrist strap.

5. Unlock the retaining clips on the RIT.

6. Carefully disengage the RIT from the backplane and fully withdraw it from

the slot.

Backplane Damage

Do not use excessive force when inserting the RIT.

7. Push the replacement RIT fully into the empty slot ensuring that pins and

sockets are correctly aligned.

8. Lock the retaining clips on the RIT.

9. Disconnect the anti-static wrist strap.

10. Replace any front panel connectors removed in Step 3 .

11. Use the terminal to download the configuration data.

12. Disconnect the terminal.

13. Record the state of the LEDs on the replacement RIT when they are stable.

3BK 21656 AAAA PCZZA Ed.23 17 / 46

2 G2 TC Transmission RITs

14. Inform the 9153 OMC-R operator that the faulty RIT has been replaced,

and report the state of the LEDs.

15. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

2.2.2 Replace MT120 Board (Legacy, NarrowBand or WideBand)

2.2.2.1 Replace MT120 Board with One of the Same Type

Note: This procedure must be used when replacing a board by a similar one

(MT120 legacy by MT120 legacy, MT120 WB by MT120 WB or MT120

NB by MT120 NB).

If the replaced MT120 board has the factory software, alarmsTCSM-ADAPT

[75] INT-BUS-FLT-G25 [209] andTCSM-ADAPT [75] NO-Q1-CONN [202] might

be raised until commissioning is finished.

To replace an MT120 board:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. Lock the related JBMTE SBL from OMC-R.

4. Unlock and open the front door of the TC rack.

5. From the TC-NEM PC, using a direct connection (serial cable for MT120

legacy or Ethernet crossed cable for MT120 NB/WB board), physically

connect to the board to be replaced on serial (MT120legacy) or MMI

(WB/NB) connection.

6. Start the TC-NEM on serial (for MT120 legacy) or MMI (for MT120 NB/WB)

connection.

7. Execute the board replacement command from TC NEM:

If not on display, open the TCC Tree:

Window ->TCC -> Overview

In the TCC Tree, select the board.

In the ’Configuration/Replacement’ area, select [ MT120 Replacement ]

and click on [ Execute ].

The "Replacement Wizard" dialog box opens. The ’Configuration file’

field shows which file is used to configure software on the new board.

8. Connect the anti-static wrist strap.

9. Physically replace the faulty MT120 board by a new one of the same type.

Backplane Damage

Do not use excessive force when inserting the new MT120 board.

10. Disconnect the anti-static wrist strap.

18 / 46 3BK 21656 AAAA PCZZA Ed.23

2 G2 TC Transmission RITs

11. If the new board is an MT120 WB or NB, it is possible that the IP address is

different from the IP address of the old MT120 WB or NB. Therefore, after

inserting the new board in the rack, it is necessary to use a serial connection

(HyperTerminal or TeraTerm) to check its IP address as described in section

Check MT120 NB/WB IP Address of document 9125 Transcoder NEM User

Guide (3BK 21630 AAAA PCZZA).

If the IP address of the new board is:

different, it is necessary to:

configure TC NEM PC Ethernet network interface so as the IP

address of the TC NEM PC is in the same subnetwork with the IP

address of the new MT120 NB/WB board. For details see section For

Configure TC NEM PC Ethernet Network Interface of document 9125

Transcoder NEM User Guide.

start the TC-NEM on MMI connection using the IP address of the new

MT120 NB/WB board.

click on [ Next ] to continue the procedure using the Replacement

Wizard dialog box.

If not already performed, upgrade the software as described in

section Download Software via TCC of document 9125 Transcoder

NEM User Guide.

ensure that the [ Connect ] button of the TC-NEM is pressed in order

to continue the procedure using the Replacement Wizard dialog box.

the same, click on [ Next ] to continue the procedure using the

Replacement Wizard dialog box. When the MT120 board is up and

running press the [ Connect ] button of the TC-NEM.

If not already performed, upgrade the software as described in section

Download Software via TCC of document 9125 Transcoder NEM

User Guide.

12. If the new board is a legacy one, start the TC-NEM on serial connection

and perform the following tasks:

click on [ Next ] to continue the procedure using the Replacement

Wizard dialog box

ensure that the [ Connect ] button of the TC-NEM is pressed in order to

continue the procedure using the Replacement Wizard dialog box.

If not already performed, upgrade the software as described in section

Download Software via TCC of document 9125 Transcoder NEM User

Guide.

13. Wait for the automatic procedure to be finished.

14. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer:

If not on display, open the TCC Tree

In the TCC Tree, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

3BK 21656 AAAA PCZZA Ed.23 19 / 46

2 G2 TC Transmission RITs

Enter your modifications

Click on [ Save ] and close the MT120 board window.

15. Disconnect the TC NEM.

16. Shut the front door of the TC rack and lock it.

17. From OMC-R,unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

18. Unlock the related JBMTE SBL from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed on

OMC-R, in "BSSUSM" window you must trigger a manual BSC

HW Audit.

19. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

20 / 46 3BK 21656 AAAA PCZZA Ed.23

2 G2 TC Transmission RITs

2.2.2.2 Replace MT120 Board with One of a Different Type

Note: This procedure must be used when replacing a board by a different one

(MT120 legacy by MT120 NB, MT120 legacy by MT120 WB, MT120 WB

by MT120 legacy , MT120 WB by MT120 NB, MT120 NB by MT120

legacy or MT120 NB by MT120 WB).

If the replaced MT120 board has the factory software, alarmsTCSM-ADAPT

[75] INT-BUS-FLT-G25 [209] andTCSM-ADAPT [75] NO-Q1-CONN [202] might

be raised until commissioning is finished.

To replace an MT120 board:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. Lock the related JBMTE SBL from OMC-R.

4. Unlock and open the front door of the TC rack.

5. Connect the anti-static wrist strap.

6. Unbolt the MT120 board. As there is no disable command, carefully extract

the MT120 board from the backplane and fully withdraw it from the slot.

7. Replace the faulty MT120 board by a new one.

Backplane Damage

Do not use excessive force when inserting the new MT120 board.

8. Disconnect the anti-static wrist strap.

9. If the new board is an MT120 NB/WB board you must:

Use a serial connection (HyperTerminal or TeraTerm) to check its IP

address as described in section Check MT120 NB/WB IP Address

of document 9125 Transcoder NEM User Guide (3BK 21630 AAAA

PCZZA)..

Configure TC NEM PC Ethernet network interface so as the IP address

of the TC NEM PC is in the same subnetwork with the IP address of

the new MT120 NB/WB board. For details see section Configure TC

NEM PC Ethernet Network Interface of document 9125 Transcoder

NEM User Guide.

start the TC-NEM on MMI connection using the IP address of the new

MT120 NB/WB board.

10. If the new board is an MT120 legacy board you must start the TC-NEM on

serial connection.

For details, see section Settings for Serial Connection of document 9125

Transcoder NEM User Guide.

3BK 21656 AAAA PCZZA Ed.23 21 / 46

2 G2 TC Transmission RITs

11. Check if the software version of the newly inserted board corresponds to

the target release of the TC. If not, perform a software upgrade on the new

MT120 (legacy or MT120 NB/WB) to the target software version.

If the new MT120 is a:

MT120NB/WB it is necessary to physically connect to the new MT120

NB/WB board using an Ethernet crossed cable and to download and

activate the target B11 software version that will run on this TC .

legacy MT120, it is necessary to physically connect to the new legacy

MT120 board using a serial cable and to download and activate the

target B11 software version that is running on this TC.

For details, see section Download and Activate Software via TCC of

document 9125 Transcoder NEM User Guide.

12. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer:

If not on display, open the ’TCC Tree’

In the ’TCC Tree’, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

Enter your modifications

Click on [ Save ] and close the MT120 board window.

13. For the new MT120 board introduced in the rack ensure that management

mode is TCIL:

Open the TCC "Overview" panel

Window -> TCC -> Overview

Right-click on the board to display the pop-up context menu

Select Change Mode –> TCIL if it is the case.

Wait for the board to restart.

Note: If the selection of TCIL management mode is not possible, it

means that the board is already running in TCIL. Continue with

the next step.

14. Configure the new MT120 for operational mode (i.e. enter for the new MT120

the configuration parameters: the BSC number, the Atermux number, the

Qmux timeslot configuration - if it is the case).

15. Disconnect the TC NEM.

16. Shut the front door of the TC rack and lock it.

17. From OMC-R,unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

22 / 46 3BK 21656 AAAA PCZZA Ed.23

2 G2 TC Transmission RITs

18. Unlock the related JBMTE SBL from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed on

OMC-R, in "BSSUSM" window you must trigger a manual BSC

HW Audit.

19. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

2.2.3 Replace JBFAN

1. Unlock and open the front door of the TC rack.

2. Connect the anti-static wrist strap.

3. Unbolt the latch at the front to release the JBFAN, and then pull it out from

the backpanel and fully withdraw it from the slot.

Replace it by a new one. Check that the latch snaps are into the locked

position.

Backplane Damage

Do not use excessive force when inserting the new fan board.

4. Disconnect the anti-static wrist strap.

5. Use the TCC window at the TC NEM to check that the new JBFAN board is

working (no FAN Alarm on the MT120 board).

Ensure that all alarms are cleared and no new alarms occurred.

6. Disconnect the TC NEM.

7. Shut the front door of the TC rack and lock it.

3BK 21656 AAAA PCZZA Ed.23 23 / 46

2 G2 TC Transmission RITs

24 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3 9125 TC RITs

This chapter tells you how to replace 9125 TC RITs.

It contains procedures for replacing the following RITs:

MT120

MT120 WB

MT120 NB

TCIF

Fan cassettes.

3BK 21656 AAAA PCZZA Ed.23 25 / 46

3 9125 TC RITs

3.1 Replace MT120

The 9125 TC rack is equipped with MT120 boards for Ater-E1. There are four

subracks, each containing up to twelve MT120 boards.

There are three types of MT120 boards: MT120, MT120 WideBand (WB) and

MT120 NarrowBand (NB).

The following procedure applies for all types of MT120 boards.

The part number of the MT120 board is:

3BK 08882 xx for MT120 legacy

3BK 27897 xx for MT120 WB

3BK 28280 xx for MT120 NB.

There are two ways to perform an MT120 board replacement on the 9125

TC rack:

The first is by using the Replace Command on the TC NEM. This command

is used to ease the replacement procedure; the actions of the operator

are limited to the ones that are strictly necessary. The only constraint is

that the TC NEM must be able to retrieve the current configuration of the

MT120 board to replace (this includes the SW version and the configuration

parameters to run the MT120).

The second way to replace the MT120 is needed when the TC NEM cannot

retrieve the current configuration of the board to be replaced.

If the replaced MT120 board has the factory software, alarmsTCSM-ADAPT

[75] INT-BUS-FLT-G25 [209] andTCSM-ADAPT [75] NO-Q1-CONN [202] might

be raised until commissioning is finished.

3.1.1 Tools and Materials

You must have a:

TC NEM PC

RS-232 asynchronous communication link cable to connect it to an MT120

legacy board (3BK 07951 AA)

Ethernet crossed cable to connect it to an MT120 NB/WB board.

An anti-static wrist strap

Tera Term Pro or Windows HyperTerminal.

Only one TC-NEM application should be connected to the TC rack at one time,

regardless of the software management mode of the MT120 boards.

If the MT120 boards are running in TCIL management mode, only one TC-NEM

can be connected (via MMI or Serial) to the TC rack

26 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3.1.2 Impact on System

All telecommunications resources of the MT120 board to be replaced are

lost during replacement procedure.

3.1.3 Replace MT120 in TCIL

3.1.3.1 Replace MT120 Board with One of the Same Type

Note: This procedure must be used when replacing a board by a similar

one (MT120 legacy by MT120 legacy , MT120 WB by MT120 WB

or MT120 NB by MT120 NB).

To replace an MT120 board:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. Lock the related JBMTE SBL from OMC-R.

4. Unlock and open the front door of the TC rack.

5. From the TC-NEM PC, using a direct connection (serial cable for MT120

legacy or Ethernet crossed cable for MT120 NB/WB board), physically

connect to a different MT120 board than the one to be replaced via serial

(for MT120 legacy) or MMI (for MT120WB/NB) connection.

6. Start the TC-NEM either on serial (for MT120 legacy) or on MMI (for MT120

NB/WB) connection.

7. Select (double click on) the MT120 required board (the faulty board which

needs to be replaced).

8. Execute the board replacement command from TC NEM:

If not on display, open the TCC Tree:

Window ->TCC -> Overview

In the TCC Tree, select the board that has to be replaced.

In the ’Configuration/Replacement’ area, select [ MT120 Replacement ]

and click on [ Execute ].

The "Replacement Wizard" dialog box opens. The ’Configuration file’

field shows which file is used to configure software on the new board.

9. Connect the anti-static wrist strap.

10. Physically replace the faulty MT120 board by a new one of the same type.

Backplane Damage

Do not use excessive force when inserting the new fan board.

11. Disconnect the anti-static wrist strap.

12. Continue the procedure following the Replacement Wizard dialog box.

Wait for the automatic procedure to be finished.

3BK 21656 AAAA PCZZA Ed.23 27 / 46

3 9125 TC RITs

13. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer:

If not on display, open the ’TCC Tree’

In the ’TCC Tree’, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

Enter your modifications

Click on [ Save ] and close the MT120 board window.

14. Disconnect the TC NEM.

15. Shut the front door of the TC rack and lock it.

16. From OMC-R,unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

17. Unlock the related JBMTE SBL from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed at

the OMC-R, in the "BSSUSM" window you must trigger a manual

BSC HW Audit.

18. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

28 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3.1.3.2 Replace MT120 Board with One of a Different Type

Note: This procedure must be used when replacing a board by a different one

(MT120 legacy by MT120 NB, MT120 legacy by MT120 WB, MT120 WB

by MT120 legacy , MT120 WB by MT120 NB, MT120 NB by MT120

legacy or MT120 NB by MT120 WB).

To replace an MT120 board:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. Lock the related JBMTE SBL from OMC-R.

4. Unlock and open the front door of the TC rack.

5. Connect the anti-static wrist strap.

6. Unbolt the MT120 board. As there is no disable command, carefully extract

the MT120 board from the backplane and fully withdraw it from the slot.

7. Replace the faulty MT120 board by a new one of a different type.

Backplane Damage

Do not use excessive force when inserting the new MT120 board.

8. Disconnect the anti-static wrist strap.

9. If the new board is an MT120 NB/WB board you must:

Use a serial connection (HyperTerminal or TeraTerm) to check its IP

address as described in section Check MT120 NB/WB IP Address

of document 9125 Transcoder NEM User Guide (3BK 21630 AAAA

PCZZA).

Configure the TC NEM PC Ethernet network interface so as the IP

address of the TC NEM PC is in the same subnetwork with the IP

address of the new MT120 NB/WB board. For details see section

Configure TC NEM PC Ethernet Network Interface of document 9125

Transcoder NEM User Guide.

Start the TC-NEM on MMI connection using the IP address of the new

MT120 NB/WB board.

10. If the new board is an MT120 legacy board you must start the TC-NEM on

serial connection.

For details, see section Settings for Serial Connection of document 9125

Transcoder NEM User Guide.

11. Check if the software version of the newly inserted board corresponds to

the target release of the TC. If not, perform a software upgrade on the new

MT120 (legacy or MT120 NB/WB) to the target software version.

If the new MT120 is a:

MT120NB/WB it is necessary to physically connect to the new MT120

NB/WB board using an Ethernet crossed cable and to download and

3BK 21656 AAAA PCZZA Ed.23 29 / 46

3 9125 TC RITs

activate the target B11 software version that is running on all other

MT120 boards associated to the required BSC..

Legacy MT120, it is necessary to physically connect to the new legacy

MT120 board using a serial cable and to download and activate the

target B11 software version that is running on all other MT120 boards

associated to the required BSC.

For details, see section Download Software and Activate Software via TCC

of document 9125 Transcoder NEM User Guide.

12. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer.

If not on display, open the TCC Tree

In the TCC Tree, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

Enter your modifications

Click on [ Save ] and close the MT120 board window.

13. For the new MT120 board introduced in the rack, use a direct connection

(serial for legacy or MMI for NB/WB), and ensure that management mode

is TCIL:

Open the TCC "Overview" panel

Window -> TCC -> Overview

Right-click on the board to display the pop-up context menu

Select Change Mode –> TCIL, if it is possible.

Wait for the board to restart.

Note: If the selection of TCIL management mode is not possible, it

means that the board is already running in TCIL. Continue with

the next step.

14. Configure the new MT120 for operational mode (i.e. enter for the new MT120

the configuration parameters , the BSC number , the Atermux number and

the Qmux timeslot configuration, if it is the case).

15. Disconnect the TC NEM.

16. Shut the front door of the TC rack and lock it.

17. From OMC-R,unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

18. Unlock the related JBMTE SBL from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed on

OMC-R, in "BSSUSM" window you must trigger a manual BSC

HW Audit.

30 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

19. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

3.1.4 Replace MT120 in HSI

3.1.4.1 Replace an MT120 Board with One of the Same Type

Note: This procedure must be used when replacing a board by a similar one

(MT120 legacy by MT120 legacy, MT120 WB by MT120 WB or MT120

NB by MT120 NB).

To replace an MT120 board using the Replacement Command:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. From OMC-R:

if the BSC is in TDM mode, lock the impacted JBMTE SBL

if the BSC is in IP Mode, lock the TC_OM SBL

4. Unlock and open the front door of the TC rack.

5. From TC-NEM PC, using a direct connection (serial cable for MT120 legacy

or Ethernet crossed cable for MT120 NB/WB board), physically connect to

the board to be replaced, on serial (for MT120 legacy) or MMI (for MT120

WB/NB) connection.

6. Start the TC-NEM on serial (for MT120 legacy) or MMI (for MT120 NB/WB)

connection.

7. Execute the board replacement command from TC NEM:

If not on display, open the TCC Tree:

Window ->TCC -> Overview

In the TCC Tree, select the MT120 board.

In the MT120 window go to ’Config. (changeable)’

In the ’Configuration/Replacement’ area, select [ MT120 Replacement ]

and click on [ Execute ].

The "Replacement Wizard" dialog box appears. The ’Configuration file’

field shows which file is used to configure software on the new board.

8. Connect the anti-static wrist strap.

9. Physically replace the faulty MT120 board by a new one of the same type.

Backplane Damage

Do not use excessive force when inserting the new MT120 board.

10. Disconnect the anti-static wrist strap.

11. If the new board is an MT120 WB or NB, it is possible that the IP address is

different from the IP address of the old MT120 WB or NB. Therefore, after

3BK 21656 AAAA PCZZA Ed.23 31 / 46

3 9125 TC RITs

inserting the new board in the rack, it is necessary to use a serial connection

(HyperTerminal or TeraTerm) to check its IP address as described in section

Check MT120 NB/WB IP Address of document 9125 Transcoder NEM User

Guide (3BK 21630 AAAA PCZZA).

If the IP address of the new board is:

different, it is necessary to:

Configure TC NEM PC Ethernet network interface so as the IP

address of the TC NEM PC is in the same subnetwork with the IP

address of the new MT120 NB/WB board. For details see section For

Configure TC NEM PC Ethernet Network Interface of document 9125

Transcoder NEM User Guide.

Start the TC-NEM on MMI connection using the IP address of the

new MT120 NB/WB board.

Click on [ Next ] to continue the procedure using the Replacement

Wizard dialog box.

If not already performed, upgrade the software as described in

section Download Software via TCC of document 9125 Transcoder

NEM User Guide.

Ensure that the [ Connect ] button of the TC-NEM is pressed in order

to continue the procedure using the Replacement Wizard dialog box.

the same, click on [ Next ] to continue the procedure using the

Replacement Wizard dialog box. When the MT120 board is up and

running press the [ Connect ] button of the TC-NEM.

If not already performed, upgrade the software as described in section

Download Software via TCC of document 9125 Transcoder NEM

User Guide.

12. If the new board is a legacy one, start the TC-NEM on serial connection

and perform the following tasks:

click on [ Next ] to continue the procedure using the Replacement

Wizard dialog box

ensure that the [ Connect ] button of the TC-NEM is pressed in order to

continue the procedure using the Replacement Wizard dialog box.

If not already performed, upgrade the software as described in section

Download Software via TCC of document 9125 Transcoder NEM User

Guide.

13. Wait for the automatic procedure to be finished.

14. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer:

If not on display, open the ’TCC Tree’

In the ’TCC Tree’, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

Enter your modifications

32 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

Click on [ Save ] and close the MT120 board window.

15. Disconnect the TC NEM.

16. Restart the TC-NEM on IP connection (using the floating IP address

of the TCIF board) and perform a Write Configuration on the replaced

MT120 board.

The MT120 board is restarting.

17. Wait until the new MT120 board is up and running. Check the status of this

MT120 board, it must be aligned.

18. Disconnect the TC NEM.

19. Shut the front door of the TC rack and lock it.

20. From OMC-R, unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

21. Unlock the related JBMTE SBL and TC_OM SBL (in case of MT120 board

running in HSI2b management mode) from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed on

OMC-R, in "BSSUSM" window you must trigger a manual BSC

HW Audit.

22. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

3BK 21656 AAAA PCZZA Ed.23 33 / 46

3 9125 TC RITs

3.1.4.2 Replace MT120 Board with One of a Different Type

Note: This procedure must be used when replacing a board by a different one

(MT120 legacy by MT120 NB, MT120 legacy by MT120 WB, MT120

WB by MT120 legacy, MT120 WB by MT120 NB, MT120 NB by MT120

legacy or MT120 NB by MT120 WB).

To replace an MT120 board:

1. From OMC-R, check and write down the status of the system. Ensure that

the status for all degraded SBLs and functions and all alarms is available

before starting the action.

2. From OMC-R, shutdown all impacted N7 links and AterTPs (WTC=3).

For details see section Shut Down Traffic on One Ater of document BSS

Configuration Handbook (3BK 21601 AAAA PCZZA).

3. From OMC-R:

if the BSC is in TDM mode, lock the impacted JBMTE SBL

if the BSC is in IP Mode, lock the TC_OM SBL

4. Unlock and open the front door of the TC rack.

5. Connect the anti-static wrist strap.

6. Unbolt the MT120 board. As there is no disable command, carefully extract

the MT120 board from the backplane and fully withdraw it from the slot.

7. Replace the faulty board by a new one.

Backplane Damage

Do not use excessive force when inserting the new MT120 board.

8. Disconnect the anti-static wrist strap.

9. If the new board is an MT120 NB/WB board you must:

use a serial connection (HyperTerminal or TeraTerm) to check its IP

address as described in section Check MT120 NB/WB IP Address

of document 9125 Transcoder NEM User Guide (3BK 21630 AAAA

PCZZA).

Configure TC NEM PC Ethernet network interface so as the IP address

of the TC NEM PC is in the same subnetwork with the IP address of

the new MT120 NB/WB board. For details see section Configure TC

NEM PC Ethernet Network Interface of document 9125 Transcoder

NEM User Guide.

Start the TC-NEM on MMI connection using the IP address of the new

MT120 NB/WB board.

10. If the new board is an MT120 legacy board you must start the TC-NEM on

serial connection.

For details, see section Settings for Serial Connection of document 9125

Transcoder NEM User Guide.

11. Check if the software version of the newly inserted board is the same with the

software version which is running on all existing MT120 boards associated

34 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

to the required BSC. If not, perform a software upgrade on the new MT120

(legacy or MT120 NB/WB) to the target software version.

If the new MT120 is a:

MT120 NB/WB it is necessary to physically connect to the new MT120

NB/WB board using an Ethernet crossed cable and to download and

activate the target B11software version that is running on all other

MT120 boards associated to the required BSC.

Legacy MT120, it is necessary to physically connect to the new legacy

MT120 board using a serial cable and to download and activate the

target B11 software version that is running on all other MT120 boards

associated to the required BSC.

For details, see section Download Software and Activate Software via

TCC of document 9125 Transcoder NEM User Guide.

12. Set up the MT120 Remote Inventory (e.g. commissioning date, network

identity, logical site name, etc.) according to the data received from the

customer:

If not on display, open the ’TCC Tree’

In the ’TCC Tree’, select the board for which you want to modify the

Remote Inventory

Open the ’Remote Inventory’ panel of the board

Enter your modifications

Click on [ Save ] and close the MT120 board window.

13. For the new MT120 board introduced in the rack, use a direct connection

(serial for legacy or MMI for NB/WB), and ensure that management mode is

HSI:

Open the TCC "Overview" panel

Window -> TCC -> Overview

Right-click on the board to display the pop-up context menu

Select Change Mode –>HSI, if it is possible.

Wait for the board to restart. The board will run in HSI2a management

mode.

Note: If the selection of HSI management mode is not possible, it

means that the board is already running in HSI. Continue with

the next step.

Disconnect the TC-NEM from direct connection.

14. If the MT120 needs to run in HSI2b, restart the TC-NEM on IP connection

(using the floating IP address of the TCIF board) and set up the

management mode as HSI2b. For more details see section Activate HSI for

MT120 Boards of document 9125 Transcoder NEM User Guide.

15. Set the correct parameters on the new MT120 (i.e. enter for the new MT120

the configuration parameters: the BSC NodeID, the Atermux number, clock

priority) and perfom Write Configuration. The MT120 board is restarting.

Wait until the new MT120 board is up and running and check that the status

of this board is aligned.

3BK 21656 AAAA PCZZA Ed.23 35 / 46

3 9125 TC RITs

16. Disconnect the TC NEM.

17. Shut the front door of the TC rack and lock it.

18. From OMC-R, unlock related AterTPs and N7 links.

For details see section Unlock Traffic on One Ater of document BSS

Configuration Handbook.

19. Unlock the related JBMTE SBL and TC_OM SBL (in case of MT120 board

running in HSI2b management mode) from the OMC-R.

Note: If an automatic BSC HW Audit was not already launched, to see

immediately the correct type of the new MT120 board displayed on

OMC-R, in "BSSUSM" window you must trigger a manual BSC

HW Audit.

20. From OMC-R, check the status of the system. Ensure that the status for

all impacted SBLs and functions and all alarms is cleared and no new

alarms occurred.

36 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3.2 Replace TCIF/TCIFI

This procedure applies for replacement of:

TCIF with TCIF

TCIFI with TCIFI

Replacement of TCIF with TCIFI or TCIFI with TCIF is not allowed, unless

hardware upgrade is necessary (refer to document Upgrade 9125 Transcoder

for details).

3.2.1 Prerequisites

The TCIF/TCIFI board replacement, described herein, is possible beginning

with TCIF AZ03A software version and AZ01M software version for TC-NEM.

3.2.2 Tools and Materials

The following items must be available before starting the replacement

procedure:

New TCIF/TCIFI board

PC/laptop with serial DB9 port interface (or USB to DB9 adaptor) for

connection to the TCIF/TCIFI board

Ethernet crossed cable for connecting the two TCIF/TCIFI boards during the

replacement procedure.

DB9 to RJ45 adapter (JADB9RJ), with part number 3BK 27547 AAAA for

the serial connection to the TCIF/TCIFI front panel on the RS port

An anti-static wrist strap

Tera Term Pro or Windows HyperTerminal

A list of IP addresses set during commissioning phase (TCIF/TCIFI active

and standby board, floating TCIF/TCIFI IP addresses and Internal IP

Network Address)

This information is obtained from the network administrator.

3.2.3 Impact on System

This procedure implies supervision outage.

3BK 21656 AAAA PCZZA Ed.23 37 / 46

3 9125 TC RITs

3.2.4 Board Replacement Procedure

Replace Faulty Board To replace the faulty (standby) board:

1. Check and write down the status of the system. Ensure that the status

for all degraded SBLs and functions and all alarms is available before

starting the action.

2. Lock the faulty (standby) board. There are two possibilities:

From TC NEM (remote connection):

Connect to the TC NEM using the steps described in the section

Connect and Disconnect from the document 9125 Transcoder NEM

User Guide.

Click on the "Rack Overview" tab in the "TCIF" window

In the "Rack Overview" bottom frame, the board displayed in bold is

the active TCIF/TCIFI board, and the other one is the standby board.

Right-click on the faulty (standby) TCIF/TCIFI board to display the

context menu.

Click on [ Lock ] to lock the faulty (standby) TCIF/TCIFI board.

Wait until this board becomes red in TC NEM "Rack Overview"

window.

Disconnect from the TC NEM using the steps described in the section

Connect and Disconnect from the document 9125 Transcoder NEM

User Guide.

From OMC-R:

In the "BSSUSM: Main View" window select the required TC.

Right click and select Expand All from the popup menu.

Select the required TCIF/TCIFI board, right click and select Lock

from the popup menu to lock the board.

3. Unplug the normal (straight) Ethernet cable from the back panel,

corresponding to the faulty (standby) TCIF/TCIFI:

If TCIF/TCIFI 1 (Slot 0) is faulty: RJ2-0 or/and RJ1-0

If TCIF/TCIFI 2 (Slot 1) is faulty: RJ2-1 or/and RJ1-1

4. Connect the anti-static wrist strap.

5. If it is the case, disconnect the optical fiber connectors and unplug SFP

modules.

6. Remove the faulty board from the subrack.

7. Insert the new board in the same slot.

8. Disconnect the anti-static wrist strap.

9. Power ON the new board (push the metallic lever on the right side).

The blue LED switches OFF.

Wait for about 8 minutes in order for this new board to start up.

38 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

Install the New Board 10. Open a serial connection to this new board:

Connect the DB9 to RJ45 adapter and Ethernet (straight) cable between

the COMx port of the PC and the RS port on the TCIF/TCIFI front panel.

Start the HyperTerminal (or TeraTerm). Follow the menu path:

Start -> Programs -> Accessories -> Communications ->

HyperTerminal

The "Connection Description" window opens.

In the "Connection Description" window enter a name and select an icon

for the connection, then click on [ OK ].

The "Connect to" window opens.

In the "Connect to" window select the used serial port, then click on [ OK ].

The "COMx Properties" window opens.

In the "COMx Properties" window enter:

Bits per second: 115200

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Click on [ Apply ] then on [ OK ]

In the HyperTerminal (or TeraTerm) window click on [ Enter ] and login as:

’Username:’ root

’Password:’ tcif

11. If the new board has been installed before with a different software/firmware,

the prompter asks for a password change.If the password for the root user

needs to be changed, perform the following steps:

Enter the old password:

You are required to change your password

immediately (root enforced)..

Changing password for root:

(current) UNIX password:

For current UNIX password type:

tcif

Change the old password:

Enter new UNIX password:

For a new UNIX password type, for example:

Alcatel1

Retype new UNIX password:

Alcatel1

The ’Password’ for the ’root’ user is changed from tcif to Alcatel1.

Type the following commands (ensure that the value to be written after

chage —d is the number 1 and not the letter l):

chage –d 1 HDEV

chage –d 1 root

3BK 21656 AAAA PCZZA Ed.23 39 / 46

3 9125 TC RITs

12. Check the content of /mnt/flash:

cd /mnt/flash

ls —altr

Note that if there are some files present in the /mnt/flash directory, the board

must be cleaned. This action will be performed later in the procedure.

13. Connect the Ethernet crossed cable between the ETH connectors on the

front panel of the two TCIF/TCIFI boards.

14. On serial connection stop the dhcpd process:

pkill -9 dhcpd

Note: This command will stop the dhcpd process and will not generate

any output.

15. Enter the following commands:

dhcpcd eth2

The output of the command is the eth2_ip address (which can be , for

example, 192.168.30.2).

This eth2_ip address must be from the same subnetwork as the

Internal IP Network Address received from the network administrator.

Note: If this is not the case (the two addresses are from different

subnetworks) then it is necessary to:

Launch the following command:

pkill -9 dhcpcd-bin

Enter once again the command from step 15

Check again that the new board eth2_ip address is from the same

subnetwork with the Internal IP Network Address.

In case a reboot occurs, it is necessary to perform all actions described from

step 11 to step 15 of this procedure.

16. Change the owner of the /mnt/flash, /usr/lib and /dev/mtd1 directories:

chown HDEV -R /mnt/flash

chown HDEV -R /usr/lib

chown HDEV /dev/mtd1

17. Remove the serial cable from the new board but ensure that the Ethernet

crossed cable between the ETH connectors on the front panel of the two

TCIF/TCIFI boards remains connected.

18. Establish the serial connection to the RS port on the front panel of the active

TCIF/TCIFI board (see step 10 for more details).

19. Check that the connectivity to the new board using the cross cable is

established:

ping <eth2_ip address>

Where the eth2_ip address is the IP address of the new replaced board.

Note: In order to stop the ping process press Ctrl+C.

20. If the new board has been previously installed with TCIF/TCIFI software (see

result of step12 above), clean the new board:

cd /opt/tcifR-1.1/scripts

./clean_board.sh <eth2_ip address>

where <eth2_ip address> is the IP address obtained in step 15.

40 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

Wait for Successfully cleaned the board or No need to clean the

board messages to be displayed on the screen.

If the operation was not performed successfully it is necessary to:

remove the serial cable from the active TCIF/TCIFI board

plug the serial cable in the standby TCIF/TCIFI board and establish the

serial connection to this board

go to tmp directory and launch the following command:

/tmp/launch_clean.sh

Wait until the board is cleaned.

remove the serial cable from the standby board and reestablish the serial

connection with the active board.

21. Launch the board replacement script:

cd /opt/tcifR-1.1/scripts

./board_repl.sh <eth2_ip address>

where <eth2_ip address> is the IP address of the new installed board

obtained at point 15.

This procedure takes about 40 minutes.

When the board replacement script is finished, the active TCIF/TCIFI board

will automatically trigger the reboot of the new board.

The reboot starts only when Reset standby board and Board

replacement done messages appear.

Wait for about 8 minutes for the board to power up.

22. Remove the serial cable from the RS port of the active TCIF/TCIFI board and

plug it in the new standby board.

23. Establish again the serial connection on the standby TCIF/TCIFI board

as described in step 10.

24. On serial connection, change the owner of the /mnt/flash, /usr/lib and

/dev/mtd1 directories:

chown root:root -R /mnt/flash

chown root:root -R /usr/lib

chown root:root /dev/mtd1

25. Remove both the Ethernet crossed cable connected between the ETH

connector of the two TCIF/TCIFI boards (the cable connected in step

(13)) and the serial cable connected in the RS port on the new standby

TCIF/TCIFI board.

Ensure that on the front panel of the TCIF/TCIFI board no cable remains

connected.

26. Plug the Ethernet (straight) cable/cables at the back panel, to connectors

corresponding to the replaced TCIF/TCIFI board (the cables which were

removed in step (3)).

27. If it is the case, plug back the SFP modules and connect the optical fiber

connectors on the new TCIF/TCIFI board according to their old position

(connectors which were removed in step (5)).

3BK 21656 AAAA PCZZA Ed.23 41 / 46

3 9125 TC RITs

Unlock the Standby 28. Unlock the standby board. There are two possibilities:

Board From TC NEM (remote connection):

Connect to the TC NEM using the steps described in the section

Connect and Disconnect from the document 9125 Transcoder NEM

User Guide.

Click on the "Rack Overview" tab in the "TCIF" window.

In the "Rack Overview" bottom frame, the board displayed in bold is

the active TCIF/TCIFI board, and the other one is the standby board.

Right-click on the new (standby) TCIF/TCIFI board to display the

context menu.

Click on [ Unlock ] to unlock the new (standby) TCIF/TCIFI board.

Wait until this board becomes black in TC NEM "Rack Overview"

window.

Disconnect from the TC NEM using the steps described in the section

Connect and Disconnect from the document 9125 Transcoder NEM

User Guide.

From OMC-R:

In the "BSSUSM: Main View" window select the required TC.

Right click and select Expand All from the popup menu.

Select the required TCIF/TCIFI board, right click and select Unlock

from the popup menu to lock the board.

29. From TC-NEM reset the new TCIF board (standby TCIF).

The board will become black italic in TC NEM "Rack Overview" window.

Wait about 8 minutes for the rebooting of the new TCIF board.

The board will become black in TC NEM "Rack Overview" window.

30. Check the status of the system. Ensure that the status for all impacted SBLs

and functions and all alarms is cleared and no new alarms occurred.

42 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3.3 Replace FANU for MT120 Boards

There are three fan cassettes (including two fans each) below each MT120

subrack. The reference number of this 9125 TC Cooling Fan Stage (FANU)

is: 3BK 30802 AA.

3.3.1 Tools and Materials

You must have a TC NEM and an RS-232 asynchronous communication link

cable to connect it to an MT120 board.

3.3.2 Impact on System

The FANU can be replaced by hot-swapping (no power supply switched off),

and there is no loss of telecommunications resources.

3.3.3 Procedure

To replace a FANU:

1. Unlock and open the front door of the TC rack

2. Connect the TC NEM to the TC rack

3. Start the program of the TC NEM; use the TCC window to locate the

defective fan cassette.

4. Check and write down the status of the system. Ensure that the status

for all degraded SBLs and functions and all alarms is available before

starting the action.

5. Unbolt the latch at the front to release the FANU, and then pull it out from

the backpanel and fully withdraw it from the slot.

Replace it by a new one. Check that the latch snaps into the locked position.

Backplane Damage

Do not use excessive force when inserting the new fan cassette.

6. Use the TCC window at the TC NEM to check that all fans are working

properly.

Measurement Interval

When checking the fan status the temperature measurement interval has

to be taken into account.

7. Check the status of the system. Ensure that the status for all impacted SBLs

and functions and all alarms is cleared and no new alarms occurred.

8. Disconnect the TC NEM.

9. Shut the front door of the TC rack and lock it.

3BK 21656 AAAA PCZZA Ed.23 43 / 46

3 9125 TC RITs

3.4 Replace FANU for TCIF/TCIFI Boards

There are two fan cassettes (including two fans each) placed one on the left

and one on the right side of the TCIF subrack. The reference number of this

9125 TC Cooling Fan Stage (FANU) is: 3BK 30802 AA.

3.4.1 Tools and Materials

You must have a TC NEM and an Ethernet crossed cable connected to

a TCIF board.

3.4.2 Impact on System

The FANU can be replaced by hot-swapping (no power supply switched off),

and there is no loss of telecommunications resources.

3.4.3 Procedure

To replace a FANU:

1. Unlock and open the front door of the TC rack.

2. Connect the TC NEM to the TC rack.

3. Start the program of the TC NEM; use the TCIF window to locate the

defective fan cassette.

4. Check and write down the status of the system. Ensure that the status

for all degraded SBLs and functions and all alarms is available before

starting the action.

5. Unbolt the latch at the front to release the FANU, and then pull it out from

the backpanel and fully withdraw it from the slot.

Replace it by a new one. Check that the latch snaps into the locked position.

Backplane Damage

Do not use excessive force when inserting the new fan cassette.

6. Use the TCIF window at the TC NEM to check that all fans are working

properly.

Measurement Interval

When checking the fan status the temperature measurement interval has

to be taken into account.

7. Check the status of the system. Ensure that the status for all impacted SBLs

and functions and all alarms is cleared and no new alarms occurred.

8. Disconnect the TC NEM.

9. Shut the front door of the TC rack and lock it.

44 / 46 3BK 21656 AAAA PCZZA Ed.23

3 9125 TC RITs

3.5 Replace SFP Module from TCIF/TCIFI Boards

3.5.1 Remove SFP Module

To remove a SFP Module:

1. Open the front doors of the TC.

2. Connect the anti-static wrist strap.

3. Identify the SFP module (STM1-TTP) to be replaced.

4. Check and write down the status of the system. Ensure that the status

for all degraded SBLs and functions and all alarms is available before

starting the action.

5. From OMC-R, lock the SFP module. The SBL associated to SFP module is

STM1-TTP (from 1 to 8).

The SFP modules from 1 to 4 are on the first TCIF/TCIFII board and 5 to 8

to the second TCIF/TCIFI board.

The fibre is switched off.

6. Carefully remove the optical cable from the SFP module. Be attentive,

do not harm it.

7. Open the SFP hinged face to approximately ninety degrees and then grap

the hinged face and carefully pull the SFP straight out of the slot.

8. Disconnect the anti-static wrist strap.

9. Close the front doors of the TC.

3.5.2 Insert SFP Module

To insert a SFP Module:

1. Open the front doors of the TC.

2. Connect the anti-static wrist strap.

3. Replace the protective rubber from the new SFP module and insert straight

into the slot until the module clicks firmly into place. When inserting the SFP,

be sure that the hinged face is closed.

3BK 21656 AAAA PCZZA Ed.23 45 / 46

3 9125 TC RITs

4. Insert the optical cable with caution.

5. Disconnect the anti-static wrist strap.

6. From OMC-R, unlock the SFP module. The SBL associated to SFP module

is STM1-TTP (from 1 to 8).

The SFP modules from 1 to 4 are on the first TCIF/TCIFI board and 5 to 8

to the second TCIF/TCIFI board.

7. Check the status of the system. Ensure that the status for all impacted SBLs

and functions and all alarms is cleared and no new alarms occurred.

8. Close the front doors of the TC.

46 / 46 3BK 21656 AAAA PCZZA Ed.23

Vous aimerez peut-être aussi

- Add TRE To Equipped BTS 9YZ-03803-0450-RJZZA - Issue - 7Document50 pagesAdd TRE To Equipped BTS 9YZ-03803-0450-RJZZA - Issue - 7Luis RomeiroPas encore d'évaluation

- Eng Rules MBOE MC-TRX 2G 2rDocument16 pagesEng Rules MBOE MC-TRX 2G 2rLuis RomeiroPas encore d'évaluation

- Description BSC G2Document3 pagesDescription BSC G2Luis RomeiroPas encore d'évaluation

- TC Troubleshoot Guide B11 Ed01Document27 pagesTC Troubleshoot Guide B11 Ed01Luis RomeiroPas encore d'évaluation

- New Features in Release B11 216090000e29Document344 pagesNew Features in Release B11 216090000e29Luis RomeiroPas encore d'évaluation

- 9135 MFS IMT User Guide - 216340000e05Document90 pages9135 MFS IMT User Guide - 216340000e05Luis RomeiroPas encore d'évaluation

- BTS Capabilities With TWIN TRX Ed2 p2Document6 pagesBTS Capabilities With TWIN TRX Ed2 p2Luis RomeiroPas encore d'évaluation

- 9120 BSC Cable Description - 216370000e01 PDFDocument74 pages9120 BSC Cable Description - 216370000e01 PDFLuis RomeiroPas encore d'évaluation

- IO78 BTSRules 3df003000078uazza 08 ADocument218 pagesIO78 BTSRules 3df003000078uazza 08 ALuis RomeiroPas encore d'évaluation

- Distributed BTS 9100 BTS 9110 Micro BTS Corrective Maintenance Handbook 216430000e29bDocument224 pagesDistributed BTS 9100 BTS 9110 Micro BTS Corrective Maintenance Handbook 216430000e29bLuis Romeiro100% (1)

- BSC Maintenance HandbookDocument130 pagesBSC Maintenance HandbookLuis RomeiroPas encore d'évaluation

- IO 78 - Configuration Des BTS PDFDocument256 pagesIO 78 - Configuration Des BTS PDFLuis RomeiroPas encore d'évaluation

- BSC Maintenance HandbookDocument130 pagesBSC Maintenance HandbookLuis RomeiroPas encore d'évaluation

- TOC - LTE Evolution - v1.00Document4 pagesTOC - LTE Evolution - v1.00Luis RomeiroPas encore d'évaluation

- From LTE To LTE Advanced - v1.700 TOCDocument6 pagesFrom LTE To LTE Advanced - v1.700 TOCLuis RomeiroPas encore d'évaluation

- LTE Training Programs: Course OutlinesDocument21 pagesLTE Training Programs: Course OutlinesLuis RomeiroPas encore d'évaluation

- LTE From A Z Reloaded - v3.210 TOC PDFDocument9 pagesLTE From A Z Reloaded - v3.210 TOC PDFmeysamRajabiPas encore d'évaluation

- LTE Training Programs: Course OutlinesDocument21 pagesLTE Training Programs: Course OutlinesLuis RomeiroPas encore d'évaluation

- LTE Signaling & Protocol AnalysisDocument6 pagesLTE Signaling & Protocol AnalysisLuis RomeiroPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)