Académique Documents

Professionnel Documents

Culture Documents

CV

Transféré par

Mansoor KhanaliDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CV

Transféré par

Mansoor KhanaliDroits d'auteur :

Formats disponibles

Mansoor Ali Khan

C-273,Block -6

Federal B Area Karachi

Cell # 0300-2045261

Email: mansoor551@hotmail.com

A Weaving Technician with a wide range of experience in the Textile Weaving industry. Able to

work on own initiative and as part of a team. Proven leadership skills involving managing,

developing and motivating teams to achieve their objectives. First-class analytical, design and

problem solving skills. Dedicated to maintaining high quality standards.

Professional Experience

Fateh Weaving Unit 01 (Hyd) 2008-Novmeber 2010

Miils Manager

Directed daily activities of the fabric production and development Home Textile ,negotiated

griege fabric issues and also look after Three warehouse of griege receiving mending ; Issuance

for print and dyeing issues ; including labor scheduling, personnel management, space

utilization, inventory and maintain

1 100% On-time delivery to printing and dyeing with accuracy as per Plan .

2 Improved delivery accuracy from 80% to 97% as a result of initiating a cycle-count

procedure maintenance and production of Sulzer PU and Tw11 and Nuovo Pignone

for all weaving ,warp, and sizing rooms.

3 Streamlined daily shift and reduce down time through applying process time and motion

study.

4 Maintained staffing adequate staffing levels ensuring appropriate productivity levels.

5 Managed about 2 Million Meters Inventory warehouse.

6 Controlled maintenance of the griege store facility.

7 Provided ongoing excellent customer service resulting in high customer satisfaction

rating.

8 Consistently met or exceeded company service and cost objectives

Major Buyer: Ikea Trading , JC Penny, Wal mart .

Hiba weaving SITE 2007 - 2008

Weaving Manager

Responsible for

1 Maintaining quality of fabric and coordinate between Production and maintenance of

Sulzer Pu 72 looms.

2 Control Spare and repairing and maintain their loom history.

3 Maintain Ghatti and restrict them to maintain wastage with in the target

Major Buyer : Commission weaving for YUNUS Brother Limited

Ethio Japan Synthetic & Cotton (Ethiopia) 2006- 2007

Manager Weaving Cum Operations Mills

1 Responsible over all activity of weaving mills and commission weaving Terry Towels.

2 Developed new system and lead to product development and planning department team.

3 Organized maintenance and production and assist to prepare Preventive maintenance of

mills.

4 Looked after sourcing, effectively negotiate commission weaving contracts and issuance

of work order,

5 supervise cost reduction team and assist to prospective buyer quality requirement of in

the process and it’s implementation .

6 Maintain positive working environment and work in flow out flow for the two line

production Synthetic and Cotton on Tsudakoma (Water Jet) and Sulzer Pu ,Vamatex

Rapier and Tsudakoma Air Jet Zax and 205I Loom .

Major Buyer: Ikea Trading

Arkay Fabrics and Arkay Terry Towels (Bangladesh) 2002- 2005

Weaving Manager

1. Duties over all activity of the Sulzer PU Woven fabric , Terry Towels and it’s

finishing and shipments .

2. Made Improvement and communicating with all employees, setting up Procedure and

following up to insure results. Carried out the plan from onset to successful

completion.

Major Buyer : Tonrose ,Micro Mighani , Gailards , Turner Bianca

Zabir & Zubair Fabrics Limited (Bangladesh) 2000- 2002

Technical Manger Weaving

Responsible of over all operation management of 4 weaving Unit of Sulzer (Shuttles) 400

looms and one line conventional weaving 300 looms Shuttle ; Unit . Managed staff and

operations and approve final configuration of products in a built-to-order facility.

1 Streamlined loom allocation; planning within the buyer require delivery schedule.

2 Recommended procedures to Master Production Scheduler to attain proper product mix

within the build plan.

3 Designed & implemented custom reports for production control resulting in improved

response time.

4 Sizing department cost reduction and performance management.

5 Optimized work efficiency, structured discipline, and met on-time delivery requirements,

enhanced customer satisfaction and reduced quality complaints.

6 Defined and wrote standard operating procedures to supplement new qualifications by

reviewing and updating through use of Rapids.

Major Buyer ; Sears Canada , Dan River, Ikea Trading

RK Textiles Mills (Bhai Pharu 1998- 1999

Mills Manager Technical

Responsible of over all production and Maintenance Sulzer P7100 and Sulzer Tw11.

Kanop International Uzbekistan 1996- 1998

General Manager Technical

Responsible of over all production and Maintenance Air Jet and Sulzer Tw11.

Gul Ahmed Textile mills Ltd (Pakistan) 1990- 1996

Weaving Engineer

Began Engineer Installation and raised to Weaving Engineer to looked after Tsudakoma Air Jet

mod: 205i, 96 looms, oversaw all aspects of the operation . Made many improvements by

working, communicating with all employees and gave training to staff of quality control, setting

up routine and preventive procedures, and following up to insure results. Orchestrated many cost

reductions through developing new supplying chain ,waste reduction and through operation cost.

Modern Textile Mills (Pakistan) 1988- 1990

Senior Technician

Began with Trainee weaving Technician position, promoted as senior weaving Technician looked

after Article Setting and schedule maintenance of PICANOL PAT-A- AIR Jet 74 Set

Major Buyer: Commission Weaver

EDUCATION

Diploma of Associate Engineering in Mechanical June 1988

B-tech Hon’s (Preston Institute of Science and Management)2008.

Appeared MBA Executive

SKILLS & TRAININGS

MS Office, Internet

2 month Tsudakoma Air Jet Preventive maintenance under supervision Of Tudakoma Japan

Dornier 2 Weeks training Held at TEXTIMA at Tashkent

Short Course Weaving Technology from Tashkent.1997

DATE OF BIRTH

29/8/1966

Vous aimerez peut-être aussi

- 2012 EASA Resource GuideDocument25 pages2012 EASA Resource Guidejuliocanales100% (1)

- Homeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Document10 pagesHomeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Mansoor Khanali100% (2)

- Publications: Fibre & YarnDocument14 pagesPublications: Fibre & YarnvigneshbalajirsPas encore d'évaluation

- Textile Handbook-1Document36 pagesTextile Handbook-1Celeste Rodríguez100% (1)

- Yarn Count/Yarn Size/ Yarn NumberDocument15 pagesYarn Count/Yarn Size/ Yarn NumberManjul MungaliPas encore d'évaluation

- SERT Stalker & Shadow Tactical CarriersDocument5 pagesSERT Stalker & Shadow Tactical CarriersSERTUSAPas encore d'évaluation

- Quality Policy: Weinu Curtain Trading PLCDocument1 pageQuality Policy: Weinu Curtain Trading PLCMansoor KhanaliPas encore d'évaluation

- Spin Plan WorksheetDocument9 pagesSpin Plan WorksheetNaveedPas encore d'évaluation

- Checklist Audit ISO 22000Document18 pagesChecklist Audit ISO 22000Abhishek Kumar Singh95% (20)

- Paragua Food Products Project ProposalDocument9 pagesParagua Food Products Project ProposalAlvin100% (5)

- Antonio RendinaDocument30 pagesAntonio RendinaPhan Trần Bá100% (2)

- Carr and Latham's Technology of Clothing ManufactureD'EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerÉvaluation : 4 sur 5 étoiles4/5 (1)

- Airjet PracDocument12 pagesAirjet PracJunaid SuhailPas encore d'évaluation

- Rapier LoomDocument19 pagesRapier LoomMayur PatilPas encore d'évaluation

- Short Introduction of Sizing / Warping / WeavingDocument14 pagesShort Introduction of Sizing / Warping / WeavingAmir YasinPas encore d'évaluation

- A Report On Industrial Visit To ParleDocument39 pagesA Report On Industrial Visit To ParleHardik Jogani100% (1)

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDPas encore d'évaluation

- Training Report of Gcti Tarinees MS WORDDocument55 pagesTraining Report of Gcti Tarinees MS WORDAakash NagpalPas encore d'évaluation

- Mechanical Properties of Weft Knitted FabricsDocument6 pagesMechanical Properties of Weft Knitted FabricsAhmad SamerPas encore d'évaluation

- Ecoverde BrochureDocument12 pagesEcoverde BrochureRicardina Rosibel Rodriguez MendozaPas encore d'évaluation

- National Foods LimitedDocument11 pagesNational Foods Limitedfbhamani100% (1)

- Normas TAPPI - ListadoDocument92 pagesNormas TAPPI - Listadoclaudio poncePas encore d'évaluation

- 44 45 Spinning HRS CardingDocument2 pages44 45 Spinning HRS CardingMansoor KhanaliPas encore d'évaluation

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument17 pagesStenter Exhaust Heat Recovery For Combustion Air PreheatingMansoor Khanali100% (1)

- Modern Developments in WeavingDocument13 pagesModern Developments in WeavingRakeahkumarDabkeyaPas encore d'évaluation

- SyllabusDocument6 pagesSyllabusHasmukh ShahPas encore d'évaluation

- Arvind Textiles Internship ReportDocument107 pagesArvind Textiles Internship ReportDipan SahooPas encore d'évaluation

- Fabric IV PPT MahasinDocument12 pagesFabric IV PPT MahasinS.m. MahasinPas encore d'évaluation

- Application of Kaizen Methodology For Process Improvementin Textile MillDocument6 pagesApplication of Kaizen Methodology For Process Improvementin Textile MillMuhammad Rofiq muhammadrofiq.2020Pas encore d'évaluation

- Yarn Preparation For WeavingDocument5 pagesYarn Preparation For WeavingSenthilPas encore d'évaluation

- Gujarat Technological University: W.E.F. AY 2018-19Document2 pagesGujarat Technological University: W.E.F. AY 2018-19Rushi TannaPas encore d'évaluation

- Effect of Spindle Speed of Ring Frame On Yarn QualityDocument5 pagesEffect of Spindle Speed of Ring Frame On Yarn QualityVijay PandeyPas encore d'évaluation

- Welcome To Our PresentationDocument40 pagesWelcome To Our PresentationAbdul AzizPas encore d'évaluation

- List of BooksDocument4 pagesList of BooksPrathmesh BharukaPas encore d'évaluation

- BSL PrintDocument62 pagesBSL Printrishi100% (1)

- Qualifications Pack Production SupervisorDocument33 pagesQualifications Pack Production SupervisorANKITPas encore d'évaluation

- Textile ScienceDocument22 pagesTextile ScienceAbhinav VermaPas encore d'évaluation

- Global Service Network: Total Customer Support Based On Total Customer ServiceDocument6 pagesGlobal Service Network: Total Customer Support Based On Total Customer ServiceHardik VavdiyaPas encore d'évaluation

- A Internship Report in Brabch Textile Technology For Diploma Holders.Document54 pagesA Internship Report in Brabch Textile Technology For Diploma Holders.Pawan Kumar RajputPas encore d'évaluation

- Course Outline Weave Design Studio-II - NewDocument9 pagesCourse Outline Weave Design Studio-II - NewMudassir AbbasPas encore d'évaluation

- 5-6 Winding Part 2Document28 pages5-6 Winding Part 2Md. Towfiq ImrozPas encore d'évaluation

- Assignment On Textured YarnsDocument13 pagesAssignment On Textured YarnsdelwarPas encore d'évaluation

- Study of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineDocument12 pagesStudy of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineIAEME PublicationPas encore d'évaluation

- Spin Plan Bengal ThesisDocument149 pagesSpin Plan Bengal Thesisstylish eaglePas encore d'évaluation

- Factors Influencing Costing of Woven Fabrics - General - Features - The ITJDocument6 pagesFactors Influencing Costing of Woven Fabrics - General - Features - The ITJmatiq06Pas encore d'évaluation

- Pivot Table ExerciseDocument25 pagesPivot Table ExerciseMd. Roukon UddinPas encore d'évaluation

- Ring TravellersDocument3 pagesRing TravellersSohaib Ul Haq100% (1)

- Textile Science - Session 3Document35 pagesTextile Science - Session 3ALOK KUMARPas encore d'évaluation

- Concept of High Volume Instrument (HVI) HVI Used in Bale MDocument15 pagesConcept of High Volume Instrument (HVI) HVI Used in Bale MS.m. MahasinPas encore d'évaluation

- Yarn Manufacturing Tandem CardingDocument5 pagesYarn Manufacturing Tandem CardingIndrajit BosePas encore d'évaluation

- Lecture Three Natural Bast FiberDocument46 pagesLecture Three Natural Bast FiberGemeda GebinoPas encore d'évaluation

- BASE Textiles LimitedDocument76 pagesBASE Textiles LimitedPushpa BaruaPas encore d'évaluation

- Complete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Document98 pagesComplete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Muhammad IlyasPas encore d'évaluation

- Yarn Defect-Final - ReadyDocument47 pagesYarn Defect-Final - Readyparash rajPas encore d'évaluation

- Yarn Count VHS 703: Submitted by Name Pooja (H.S) Neelam CLASS M .Voc (A.M)Document27 pagesYarn Count VHS 703: Submitted by Name Pooja (H.S) Neelam CLASS M .Voc (A.M)Anonymous UoRu4sPas encore d'évaluation

- Vortex FDocument2 pagesVortex FNipu SenPas encore d'évaluation

- Sulur Ranga TextilesDocument38 pagesSulur Ranga TextilesraviPas encore d'évaluation

- Title of The Project ThesisDocument87 pagesTitle of The Project ThesisIrfan IqbalPas encore d'évaluation

- 2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Document10 pages2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Ferdaus Hasan BappiPas encore d'évaluation

- Plasma Treatment For TextilesDocument30 pagesPlasma Treatment For TextilesTuan Nguyen Minh100% (2)

- Industrial Attachment of Alltex Industries LimitedDocument79 pagesIndustrial Attachment of Alltex Industries LimitedNur E Alam Nuru100% (1)

- Calculation of Package Density in Yarn Dyeing - Textile CalculationDocument3 pagesCalculation of Package Density in Yarn Dyeing - Textile CalculationHodPas encore d'évaluation

- Study On Reduction of Air Consumption On Air-Jet Weaving MachinesDocument11 pagesStudy On Reduction of Air Consumption On Air-Jet Weaving MachinesNatraj kanaharajPas encore d'évaluation

- Akshara Spinning MillsDocument42 pagesAkshara Spinning MillsbalaPas encore d'évaluation

- False Twist Texturing PDFDocument2 pagesFalse Twist Texturing PDFDutchess50% (2)

- The Process Flow of Drawing-In and Tying-InDocument7 pagesThe Process Flow of Drawing-In and Tying-InRehan Saeedi100% (1)

- Anant Spinning MillDocument18 pagesAnant Spinning MillgaganPas encore d'évaluation

- Spin Plan - Synthetic YarnDocument1 pageSpin Plan - Synthetic Yarnardhendu1Pas encore d'évaluation

- Mansoor Ali Khan: Summary of QualificationsDocument6 pagesMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- Dail Visit Report: Discussion About ProporsalDocument3 pagesDail Visit Report: Discussion About ProporsalMansoor KhanaliPas encore d'évaluation

- Illumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaDocument6 pagesIllumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaMansoor KhanaliPas encore d'évaluation

- We Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentDocument6 pagesWe Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentMansoor KhanaliPas encore d'évaluation

- 1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverDocument3 pages1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverMansoor KhanaliPas encore d'évaluation

- Commonwealth of Independent States )Document3 pagesCommonwealth of Independent States )Mansoor KhanaliPas encore d'évaluation

- Mansoor Ali Khan: Summary of QualificationsDocument6 pagesMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- Economizer 01 No. S. # Description SizeDocument1 pageEconomizer 01 No. S. # Description SizeMansoor KhanaliPas encore d'évaluation

- Parts RequestDocument4 pagesParts RequestMansoor KhanaliPas encore d'évaluation

- Sample Resume - Executive CVDocument4 pagesSample Resume - Executive CVMansoor KhanaliPas encore d'évaluation

- Hall Exb 4Document2 pagesHall Exb 4Mansoor KhanaliPas encore d'évaluation

- Count, Construction and Width of Common Cotton FabricsDocument3 pagesCount, Construction and Width of Common Cotton FabricsMansoor KhanaliPas encore d'évaluation

- 11 - Chapter 6 PDFDocument14 pages11 - Chapter 6 PDFMansoor KhanaliPas encore d'évaluation

- Developing An Incentive Scheme For A ProjectDocument14 pagesDeveloping An Incentive Scheme For A ProjectMansoor KhanaliPas encore d'évaluation

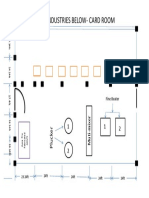

- Amna Below RoomDocument1 pageAmna Below RoomMansoor KhanaliPas encore d'évaluation

- Pcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchDocument2 pagesPcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchMansoor KhanaliPas encore d'évaluation

- AESA Air Engineering ProjectsDocument2 pagesAESA Air Engineering ProjectsMansoor KhanaliPas encore d'évaluation

- YarnsDocument2 pagesYarnsvin_sinPas encore d'évaluation

- Complex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionDocument1 pageComplex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionMansoor KhanaliPas encore d'évaluation

- Mantex Carbon BobbinsDocument2 pagesMantex Carbon BobbinsMansoor KhanaliPas encore d'évaluation

- Item No. Item Total Price Quantity (Per Piece) Unit Price (In Peso)Document3 pagesItem No. Item Total Price Quantity (Per Piece) Unit Price (In Peso)Hannah Pamela LegaspiPas encore d'évaluation

- Crucible Dictionary German-Chinese-EnglishDocument13 pagesCrucible Dictionary German-Chinese-EnglishOliver FischerPas encore d'évaluation

- Dehydration SugarDocument2 pagesDehydration SugarAyu Dara KharismaPas encore d'évaluation

- Marketing EssayDocument4 pagesMarketing Essaydaves125125Pas encore d'évaluation

- Overview - Garments Industry in BangladeshDocument24 pagesOverview - Garments Industry in Bangladeshzubair07077371100% (1)

- Haleeb Food Opration ManagementDocument3 pagesHaleeb Food Opration ManagementMuddaser Nawaz100% (1)

- Woven Fabric Defects PracticalDocument2 pagesWoven Fabric Defects PracticalAlemu HailePas encore d'évaluation

- Main ProjectDocument90 pagesMain Projectshwetha-pavu05Pas encore d'évaluation

- Dmaic PanaderiaDocument10 pagesDmaic PanaderiacarlosPas encore d'évaluation

- All About VeebaDocument3 pagesAll About VeebaSupriya PhukanPas encore d'évaluation

- DTG Printer T Shirt PrinterDocument10 pagesDTG Printer T Shirt PrinterphamPas encore d'évaluation

- World University of Bangladesh: Submitted byDocument23 pagesWorld University of Bangladesh: Submitted byAtick ArmanPas encore d'évaluation

- Mcdonald'S and KFC: Consumer Perceptions of Food Franchise: A Study ofDocument8 pagesMcdonald'S and KFC: Consumer Perceptions of Food Franchise: A Study ofMukesh ManwaniPas encore d'évaluation

- Coconut Water in PET BottlesDocument8 pagesCoconut Water in PET Bottlesgunjan88Pas encore d'évaluation

- Poultry Farming Gains Popularity in SomaliaDocument3 pagesPoultry Farming Gains Popularity in SomaliaAMISOM Public Information Services100% (1)

- Cold ChainDocument9 pagesCold ChainManan TyagiPas encore d'évaluation

- The Rieter Manual of Spinning Leaflet 2769-V1 en OriginalDocument2 pagesThe Rieter Manual of Spinning Leaflet 2769-V1 en OriginalakashPas encore d'évaluation

- Indian RayonDocument86 pagesIndian RayonNikunj Gevariya100% (1)

- A Study On Financial Performance of Rural Area Marketing: Dr. A. Jayakumar, G. AnbalaganDocument5 pagesA Study On Financial Performance of Rural Area Marketing: Dr. A. Jayakumar, G. AnbalaganbikshapatiPas encore d'évaluation

- 2 The Petrochemical Industry in ChinaDocument14 pages2 The Petrochemical Industry in ChinaNouran BakerPas encore d'évaluation

- CRDDocument33 pagesCRDAnonymous JIxU3T8Pas encore d'évaluation

- Nahar PresentationDocument28 pagesNahar Presentationsurbhi168950% (2)