Académique Documents

Professionnel Documents

Culture Documents

SS WPS

Transféré par

MOHAMEDABBASCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SS WPS

Transféré par

MOHAMEDABBASDroits d'auteur :

Formats disponibles

9

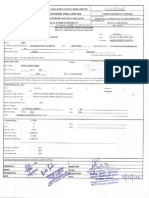

WELD PROCEDUXE XBECIFICATION W S )

Date :15/13 / 2009

ACCORDING TO WPS ~a : 09 /ZO@

RSliWE IX EDITION2007 ADD-JULY2006 REK :1

Q.A / Q.C

DEPARllMENT &ASME B31.3 EDITION2006 ADD.MA Y 2007 Shed , : lofl

COMPANY NAME BURULLUS GAS COWANY

PROJECT NAME PRRTE VTI - M4IN COWRE9SION

WELDING PROCEDURE SPECIFICATION No. 09 12009

SUPPORTING PQR NO. PSS-4 & 123

PROCESS GTAW& SMAW

TYPES ( Manual, Automatic, Semi Auto.) MANUAL

>

-

Tmm

&+i-qh

6.0 in 0 Diam.

1

-,

/

--,:(A,

\

.BASE

-

METAL

t .. t2 -3 - --)I

I ! I

I i t

POSTWELD HEAT TREATMENT

> Temperature Range : NIA

Material Spec. : A312 & A312 Time Range : NIA

Type or Grade :TP-316&TP-316 Other : NIA

P No. :08&08

Group No. : 01 &01 GAS

Thickness ( T) mm : 3.06 GTAW & 40 SMAW of Gas Or : ARGON

Dieter :ALL Composition of Gas Mixture : 99.9%

: 1 53 5 T 5 60 mm Other : FLOW RATE 8-10 LIT/MM

Thickness Rang

Gas Backing Argon 99.9%

FILLER METALS

ELECTRICAL CHARACTERPSTICS

Weld Metal Analysis A No. :A8 Current : DC

Size of Electrode : 2.4,Z.S &3.25 mm Polarity : Electrode -ve (SP) & +ve

Filler Metal No. :F6 &F5

S F A Specification : A 5.9 & A5.4 Weld FILLER METAL CURRENT Volt Travel

AWS Classification :ER316L&E316L-17

-SITION

L- -

Position of Groove : 6G 3d ~316~-17 2.5 +ve 12Cbt6f1 31-34

Weld Progression : UPHILL 4w ~316~-17 3.25 +ve 120-160 31-34

Other : PIPING

PREHEAT

TECHNIQE

Preheat Temp, ( OC ) ( Min) : Ambient : Grinding & wire brush

Interpass Cleaning

Inter pass Temp. ( OC ) (Max.) : 150 O C String or Weave Bead :Both

Method of enter pass temp : see attachment (1) Multipass or Single Pass : Mulitpasses

control Single or Multiple Electrodes : Multiple

Ofln;e or Gas Cup Si :9-16mm

Vous aimerez peut-être aussi

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Philpost RRDocument6 pagesPhilpost RRGene AbotPas encore d'évaluation

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasPas encore d'évaluation

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidPas encore d'évaluation

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezPas encore d'évaluation

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolPas encore d'évaluation

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaPas encore d'évaluation

- Skilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitiesDocument2 pagesSkilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitieswesamPas encore d'évaluation

- Iroquois Clothes and WampumDocument3 pagesIroquois Clothes and Wampumapi-254323856Pas encore d'évaluation

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehPas encore d'évaluation

- 1035 03Document2 pages1035 03Anuj ShahiPas encore d'évaluation

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanPas encore d'évaluation

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisPas encore d'évaluation

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyPas encore d'évaluation

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinPas encore d'évaluation

- WPS FormatDocument2 pagesWPS FormatAmit SarkarPas encore d'évaluation

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- WPS PDFDocument1 pageWPS PDFSarah DeanPas encore d'évaluation

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28Pas encore d'évaluation

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoPas encore d'évaluation

- WPS PQR-02Document8 pagesWPS PQR-02Ranjan Kumar100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertPas encore d'évaluation

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- WPS API1104 A516 GR 70Document1 pageWPS API1104 A516 GR 70Erick HoganPas encore d'évaluation

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónPas encore d'évaluation

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarPas encore d'évaluation

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiPas encore d'évaluation

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviPas encore d'évaluation

- QW 483Document2 pagesQW 483delta lab sangliPas encore d'évaluation

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiPas encore d'évaluation

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Hamza Nouman100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouPas encore d'évaluation

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyPas encore d'évaluation

- Aws d1.1 Tubular Vs Non TubularDocument1 pageAws d1.1 Tubular Vs Non TubularrendraPas encore d'évaluation

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepPas encore d'évaluation

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusPas encore d'évaluation

- Hardox 450Document3 pagesHardox 450Marko RisticPas encore d'évaluation

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaPas encore d'évaluation

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliPas encore d'évaluation

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaPas encore d'évaluation

- Workplace Health and Safety Manual: Third EditionDocument77 pagesWorkplace Health and Safety Manual: Third EditionMOHAMEDABBASPas encore d'évaluation

- Kie TP R297Document35 pagesKie TP R297Muhamad Dahlan STPas encore d'évaluation

- LCA Methodology ReportDocument95 pagesLCA Methodology ReportMOHAMEDABBASPas encore d'évaluation

- Steel Recycling ProcessDocument14 pagesSteel Recycling ProcessMOHAMEDABBASPas encore d'évaluation

- HF08 EngDocument124 pagesHF08 EngMOHAMEDABBASPas encore d'évaluation

- CWIDocument30 pagesCWIMOHAMEDABBAS100% (5)

- Breda PipingDocument6 pagesBreda PipingMOHAMEDABBASPas encore d'évaluation

- OSHA Shipyard Industry StandardsDocument275 pagesOSHA Shipyard Industry Standardsovantovalle80% (5)

- Egypt: CairoDocument14 pagesEgypt: CairoMOHAMEDABBASPas encore d'évaluation

- Hazop Training GuideDocument9 pagesHazop Training GuideAdyBorsosPas encore d'évaluation

- ISO 9000 WikipediaDocument11 pagesISO 9000 WikipediaMOHAMEDABBASPas encore d'évaluation

- All About OSHADocument32 pagesAll About OSHASafetybossPas encore d'évaluation

- EMC (1) ScopeDocument1 pageEMC (1) ScopeMOHAMEDABBASPas encore d'évaluation

- Group DynamicsDocument27 pagesGroup DynamicsMOHAMEDABBAS100% (2)

- Chemistry II EM Basic Learning MaterialDocument40 pagesChemistry II EM Basic Learning MaterialMAHINDRA BALLAPas encore d'évaluation

- Different Principles Tools and Techniques in Creating A BusinessDocument5 pagesDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaPas encore d'évaluation

- Internship Report PDFDocument71 pagesInternship Report PDFNafiz FahimPas encore d'évaluation

- Invoice ApprovalDocument54 pagesInvoice ApprovalHamada Asmr AladhamPas encore d'évaluation

- Nuttall Gear CatalogDocument275 pagesNuttall Gear Catalogjose huertasPas encore d'évaluation

- 6 RVFS - SWBL Ojt Evaluation FormDocument3 pages6 RVFS - SWBL Ojt Evaluation FormRoy SumugatPas encore d'évaluation

- Molde Soldadura TADocument1 pageMolde Soldadura TAMarcos Ivan Ramirez AvenaPas encore d'évaluation

- Aavi 3Document4 pagesAavi 3Arnie IldefonsoPas encore d'évaluation

- PixiiDocument3 pagesPixiiFoxPas encore d'évaluation

- PMDG 737NGX Tutorial 2 PDFDocument148 pagesPMDG 737NGX Tutorial 2 PDFMatt HenryPas encore d'évaluation

- Hatayoga 1Document11 pagesHatayoga 1SACHIDANANDA SPas encore d'évaluation

- Chapter 10 Translation ExposureDocument14 pagesChapter 10 Translation ExposurehazelPas encore d'évaluation

- List of Bird Sanctuaries in India (State-Wise)Document6 pagesList of Bird Sanctuaries in India (State-Wise)VISHRUTH.S. GOWDAPas encore d'évaluation

- Pepperberg Notes On The Learning ApproachDocument3 pagesPepperberg Notes On The Learning ApproachCristina GherardiPas encore d'évaluation

- SQLDocument13 pagesSQLRadhakrishnan__7263Pas encore d'évaluation

- Assignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementDocument3 pagesAssignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementGenithon PanisalesPas encore d'évaluation

- Name of The Business-Rainbow Blooms LLC. Executive SummaryDocument17 pagesName of The Business-Rainbow Blooms LLC. Executive SummaryAhamed AliPas encore d'évaluation

- Small Business and Entrepreneurship ProjectDocument38 pagesSmall Business and Entrepreneurship ProjectMădălina Elena FotachePas encore d'évaluation

- M.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanDocument43 pagesM.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanSSPas encore d'évaluation

- Offshore Training Matriz Matriz de Treinamentos OffshoreDocument2 pagesOffshore Training Matriz Matriz de Treinamentos OffshorecamiladiasmanoelPas encore d'évaluation

- Technical DescriptionDocument2 pagesTechnical Descriptioncocis_alexandru04995Pas encore d'évaluation

- Text Extraction From Image: Team Members CH - Suneetha (19mcmb22) Mohit Sharma (19mcmb13)Document20 pagesText Extraction From Image: Team Members CH - Suneetha (19mcmb22) Mohit Sharma (19mcmb13)suneethaPas encore d'évaluation

- Coefficient of Restitution - Center of MassDocument3 pagesCoefficient of Restitution - Center of MassMannyCesPas encore d'évaluation

- OracleCarrierManifestingPartnerIntegration PDFDocument40 pagesOracleCarrierManifestingPartnerIntegration PDFvishal_vishnu11Pas encore d'évaluation

- Atoll 1400Document2 pagesAtoll 1400David M. SeoanePas encore d'évaluation

- Bobcat E34 - E35Z Brochure - Adare MachineryDocument8 pagesBobcat E34 - E35Z Brochure - Adare MachineryNERDZONE TVPas encore d'évaluation

- Training Course For 2 Class Boiler Proficiency Certificate (Gujarat Ibr)Document3 pagesTraining Course For 2 Class Boiler Proficiency Certificate (Gujarat Ibr)JAY PARIKHPas encore d'évaluation