Académique Documents

Professionnel Documents

Culture Documents

Sop 01 Material Requisition

Transféré par

M Junaid LatifDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sop 01 Material Requisition

Transféré par

M Junaid LatifDroits d'auteur :

Formats disponibles

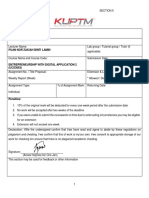

HAMAZ PHARMACEUTICAL PVT LTD MULTAN PAKISTAN Page 1 of 2

Standard Operating Effective Date: 23-05-2018 Revision# 00

Procedure:

Department Production Doc# HP/PRO/MA-01

TITLE: SOP FOR “MATERIAL REQUISITION”

Written by: Approved by: Approved by: Authorized by:

Designation: PHARMACIST Production Manager Q.C Manager Q.A Manager

Signature/ Name /Miss Shaista /Mr.Barkat /Mr.Ashraf /Mr. Shakeel

Date:

1. Objective:-

To draw raw material / packing material from ware house of a batch.

2. Responsibility:-

i) Production officer

ii) Store Officer

iii) Production Manager

3. Accountability:-

i) Production Manager

ii) Q.A officer

iii) Q.C Manager

4. Procedure:-

The raw material/packing material requisition is filled by production pharmacist which

provides the following informations

i) Product Code

ii) Product Name

iii) Batch size

iv) Batch Number

v) Mfg. & Exp. Date of a batch.

4.1 The production manager check the above information & sign the raw material/packing

material requisition for its further processing.

4.2 Store officer enters the requisition of raw material / packing material against product

code to verify the batch of raw material /packing materials. Finally after verification store

officer sign the requisition slip & issue the computer number, the computer section print

out the raw material/ packing material requisition against the computer number.

4.3 Production pharmacist follows the weekly production planning (DOC# HP/MPS/) which is

CONTROLLED COPY: NO COPYING WITHOUT MANAGEMENT’S PERMISSION

HAMAZ PHARMACEUTICAL PVT LTD MULTAN PAKISTAN Page 2 of 2

Standard Operating Effective Date: 23-05-2018 Revision# 00

Procedure:

Department Production Doc# HP/PRO/MA-01

TITLE: SOP FOR “MATERIAL REQUISITION”

Written by: Approved by: Approved by: Authorized by:

Designation: PHARMACIST Production Manager Q.C Manager Q.A Manager

Signature/ Name /Miss Shaista /Mr.Barkat /Mr.Ashraf /Mr. Shakeel

Date:

provided by the production manager.

4.4 After getting the permission from production manager of a planned batch the production

officer enter it in section product batch record register (DOC#HP/PRO/05) then the production

officer calculate the API( active pharmaceutical ingredient) according to specific approved

standard formulation.

4.5 Then QA department provides control number and issue the raw material/ packing material

requisition according to data provided by production and QC department along with master

formula/BMR

4.6 Production officer fill up tags/ (Doc# HP/PRO/08) for each raw material to be dispensed and

send it to ware house for further processing.

CONTROLLED COPY: NO COPYING WITHOUT MANAGEMENT’S PERMISSION

Vous aimerez peut-être aussi

- Risk Assessment HandbookDocument35 pagesRisk Assessment HandbookmeliaminorPas encore d'évaluation

- Mock RecallDocument14 pagesMock RecallQuality DeptPas encore d'évaluation

- PICS Inspection QC LabDocument18 pagesPICS Inspection QC LabMax HuangPas encore d'évaluation

- BMR PraperationDocument9 pagesBMR PraperationwondwossengPas encore d'évaluation

- Issuing Date Doc No: Effective Date Department Next Review Date SectionDocument5 pagesIssuing Date Doc No: Effective Date Department Next Review Date SectionAmer Abu RahmahPas encore d'évaluation

- SOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesDocument2 pagesSOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesMosub Al.Dirdiry100% (1)

- Sop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateDocument17 pagesSop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateSreelakshmi RakeshPas encore d'évaluation

- Ludhiana Flour & General Mills Private Limited: M L SOPDocument3 pagesLudhiana Flour & General Mills Private Limited: M L SOPMilan BankPas encore d'évaluation

- QA 5.15 Allergens Materials Handling General ProcedureDocument3 pagesQA 5.15 Allergens Materials Handling General ProcedureangeldrandevPas encore d'évaluation

- Temperature Mapping Protocol: Lincoln Parenteral LTDDocument7 pagesTemperature Mapping Protocol: Lincoln Parenteral LTDRajender SinghPas encore d'évaluation

- OOS InvestigationDocument5 pagesOOS Investigationmarkandey gupta100% (2)

- Process Validation Protocol (500 MG Tablet)Document6 pagesProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- SOP InventoryDocument5 pagesSOP InventoryNilay SharmaPas encore d'évaluation

- Standard Operating Procedure (SOP)Document5 pagesStandard Operating Procedure (SOP)Sagar M JadhavPas encore d'évaluation

- Purpose: Preventive & Breakdown Maintenance of Equipments and InstrumentsDocument3 pagesPurpose: Preventive & Breakdown Maintenance of Equipments and InstrumentsMayson BaliPas encore d'évaluation

- List of QC SopDocument3 pagesList of QC SopPrince MoniPas encore d'évaluation

- Standard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationDocument3 pagesStandard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationMajed HossainPas encore d'évaluation

- SOP065RMSD - 04 Raw Material Specification Development FormDocument4 pagesSOP065RMSD - 04 Raw Material Specification Development FormGrace ChenPas encore d'évaluation

- SOP of Sanitation of PW SystemDocument6 pagesSOP of Sanitation of PW Systemanon_350461302100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi YadavPas encore d'évaluation

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDocument4 pages2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniPas encore d'évaluation

- Risk-Management Assessment of Visible-Residue LimitsDocument4 pagesRisk-Management Assessment of Visible-Residue LimitsPrince MoniPas encore d'évaluation

- 11.2.0 Product Recall ProcedureDocument12 pages11.2.0 Product Recall ProcedureZed100% (1)

- SOP On Calibration PolicyDocument3 pagesSOP On Calibration PolicyYousifPas encore d'évaluation

- SOP Personnel HygieneDocument4 pagesSOP Personnel HygieneBejoy Karim100% (3)

- Validation of Dynamic Pass BoxDocument5 pagesValidation of Dynamic Pass BoxMichele Volpe100% (1)

- SOP of Glassware HandlingDocument1 pageSOP of Glassware HandlingPrince Moni100% (2)

- SOP On Monitoring of Temperature and Relative Humidity.Document2 pagesSOP On Monitoring of Temperature and Relative Humidity.RainMan75100% (2)

- New Supplier Survey FormDocument14 pagesNew Supplier Survey Formsutharitessh100% (1)

- SOP For Operation of Carton Coding MachineDocument3 pagesSOP For Operation of Carton Coding MachineJayant Kumar JhaPas encore d'évaluation

- SOP For Product Recall - Pharmaceutical GuidelinesDocument2 pagesSOP For Product Recall - Pharmaceutical GuidelinesJose Ramon Dalo BautistaPas encore d'évaluation

- Antonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Document52 pagesAntonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Kim Cyrelle Samson Umbalin100% (2)

- 4700 00001-Up MM LNK 1160093ADocument307 pages4700 00001-Up MM LNK 1160093AEmanuel VelascoPas encore d'évaluation

- SOP For Monitoring of Compressed Air - GasesDocument2 pagesSOP For Monitoring of Compressed Air - GasesAnonymous FZs3yBHh70% (1)

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixPas encore d'évaluation

- TTL ExaminationDocument5 pagesTTL ExaminationShairon palma75% (4)

- 05.SOP For Storage and Use of Reagents & ChemicalsDocument4 pages05.SOP For Storage and Use of Reagents & ChemicalsBejoy Karim75% (4)

- Robotic Process AutomationDocument11 pagesRobotic Process AutomationPankaj SharmaPas encore d'évaluation

- Power Flex 70Document50 pagesPower Flex 70Gott PlankPas encore d'évaluation

- SOP On Calculation of YieldsDocument2 pagesSOP On Calculation of YieldsYousif100% (1)

- Receipt and Testing of Raw MaterialDocument8 pagesReceipt and Testing of Raw MaterialJyoti Yadav100% (2)

- PQ Sample Protocol - Water SyatemDocument45 pagesPQ Sample Protocol - Water SyatemProcesos Industriales De Transformacion FarmaceuticaPas encore d'évaluation

- What Is BMR (Batch Manufacturing Record)Document2 pagesWhat Is BMR (Batch Manufacturing Record)Prince Moni100% (1)

- Sop For in - Process Fill Weight DeterminationDocument1 pageSop For in - Process Fill Weight DeterminationPrince MoniPas encore d'évaluation

- ReprocessingDocument3 pagesReprocessingswanandkul86% (7)

- Arabian Mate Company ProfileDocument19 pagesArabian Mate Company ProfileXee ShanPas encore d'évaluation

- APPLE Strategic AnalysisDocument22 pagesAPPLE Strategic AnalysisChua Lee Woon60% (5)

- Food Repacking SOPDocument4 pagesFood Repacking SOPKayla OcampoPas encore d'évaluation

- ASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal HygieneDocument5 pagesASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal Hygienesunny mgxPas encore d'évaluation

- SOP For Handling of Market ComplaintDocument32 pagesSOP For Handling of Market Complaintsubbu_281Pas encore d'évaluation

- Sop For Personnel Monitoring in Aseptic AreaDocument2 pagesSop For Personnel Monitoring in Aseptic AreaDolly BijaniPas encore d'évaluation

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75Pas encore d'évaluation

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodDocument1 pageQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinPas encore d'évaluation

- SOP For Cleaning of StirrerDocument2 pagesSOP For Cleaning of StirrerPrince Moni100% (1)

- Recall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDocument12 pagesRecall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDiana BlueseaPas encore d'évaluation

- Standard Operating Procedure For Product Mock RecallsDocument3 pagesStandard Operating Procedure For Product Mock RecallsSolomonPas encore d'évaluation

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7550% (2)

- Batch Manufacturing Record Requisition FormDocument1 pageBatch Manufacturing Record Requisition FormSolomon GamanuelPas encore d'évaluation

- SOP On Operation and Cleaning of Paste KettleDocument3 pagesSOP On Operation and Cleaning of Paste KettleRakesh RauniyarPas encore d'évaluation

- Haccp PlanDocument1 pageHaccp Planjlordmercader100% (1)

- Annexure - II Product DevelopmentDocument50 pagesAnnexure - II Product DevelopmentLife PearlPas encore d'évaluation

- SOP OP-0100 Rev 0Document3 pagesSOP OP-0100 Rev 0Joe Reaction-NutritionPas encore d'évaluation

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFDocument3 pagesASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFAnuradha yadavPas encore d'évaluation

- Orbital Welding Procedure For Purified Water System - Pharmaceutical GuidanceDocument2 pagesOrbital Welding Procedure For Purified Water System - Pharmaceutical Guidancedecio ventura rodrigues miraPas encore d'évaluation

- Types of RecordsDocument16 pagesTypes of RecordsGurpreet KaurPas encore d'évaluation

- Corrective And Preventative Action A Complete Guide - 2020 EditionD'EverandCorrective And Preventative Action A Complete Guide - 2020 EditionPas encore d'évaluation

- 07 - CIC 2016 Detailed Design PDFDocument8 pages07 - CIC 2016 Detailed Design PDFLívia A. SouzaPas encore d'évaluation

- Biblio PDFDocument2 pagesBiblio PDFcms124dPas encore d'évaluation

- ResDocument4 pagesResJose JohnPas encore d'évaluation

- ReadingDocument7 pagesReadingmarisa0% (1)

- Software House: Bookme - PK: NO. Project Monitoring and ControlDocument2 pagesSoftware House: Bookme - PK: NO. Project Monitoring and ControlAdeel AhmedPas encore d'évaluation

- IChemE GetChartered ExtlDocument78 pagesIChemE GetChartered Extlthlim19078656Pas encore d'évaluation

- Lion-4500 Manual 1-21-10 PDFDocument48 pagesLion-4500 Manual 1-21-10 PDFmackross1Pas encore d'évaluation

- Timesheet Submission Dates 2022 - 2023Document1 pageTimesheet Submission Dates 2022 - 2023Matias FigueirasPas encore d'évaluation

- Ah1222 CP PDFDocument1 pageAh1222 CP PDFAlfredo Fdez BandalaPas encore d'évaluation

- Interfacing GPS With LPC2148 ARM: Arm How-To GuideDocument12 pagesInterfacing GPS With LPC2148 ARM: Arm How-To Guidesaiprathyusha chintalapatiPas encore d'évaluation

- How To Test The LED Driver Using The 3341G Series LED DC Electronic Load SimulatorDocument17 pagesHow To Test The LED Driver Using The 3341G Series LED DC Electronic Load SimulatorPredrag NemcicPas encore d'évaluation

- Weekly Report Ameer Najmee (AM2101008727)Document11 pagesWeekly Report Ameer Najmee (AM2101008727)Supercube jiePas encore d'évaluation

- StreamServe Persuasion SP5 StreamStudioDocument30 pagesStreamServe Persuasion SP5 StreamStudioJackson ParfaitPas encore d'évaluation

- Exercise IcpnaDocument1 pageExercise Icpnajorge_rosas_12Pas encore d'évaluation

- Axon Virtual PBX Software Crack - : DownloadDocument4 pagesAxon Virtual PBX Software Crack - : Downloaddiana blancoPas encore d'évaluation

- Ts201 Technical Standard For Telecommunications SystemsDocument55 pagesTs201 Technical Standard For Telecommunications SystemsHimdad TahirPas encore d'évaluation

- CCNA Cross-References - V1 OnlyDocument12 pagesCCNA Cross-References - V1 OnlynandipuraPas encore d'évaluation

- Technology in CounsellingDocument18 pagesTechnology in CounsellingWilly TanPas encore d'évaluation

- Sales Invoice Template With Discount Amount Column in PDF FormatDocument2 pagesSales Invoice Template With Discount Amount Column in PDF FormatCyprusPas encore d'évaluation

- Guideline For Typical Appliance Ratings To Assist in Sizing of PV Solar SystemsDocument8 pagesGuideline For Typical Appliance Ratings To Assist in Sizing of PV Solar SystemspriteshjPas encore d'évaluation

- Config It y Skin Nig TerDocument9 pagesConfig It y Skin Nig TerGPU FANBOYPas encore d'évaluation

- Moulded - Case - Circuit BreakerDocument84 pagesMoulded - Case - Circuit BreakerSanatan JhaPas encore d'évaluation

- A Vision Base Application For Virtual Mouse Interface Using Hand GestureDocument6 pagesA Vision Base Application For Virtual Mouse Interface Using Hand GestureInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation