Académique Documents

Professionnel Documents

Culture Documents

Prosthdontic Managemnt of Edentate PT of Microstomia

Transféré par

Noor MuhammadTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prosthdontic Managemnt of Edentate PT of Microstomia

Transféré par

Noor MuhammadDroits d'auteur :

Formats disponibles

[Downloaded free from http://www.jofs.in on Friday, February 1, 2019, IP: 182.179.160.

203]

Case Report

Prosthodontic management of a completely

edentulous microstomia patient

Chiramana Sandeep, O. Swetha Hima Bindu, B. Sreedevi, K. Sai Prasad

Department of Prosthodontics, Sibar Institute of Dental Sciences, Thakkellapadu, Guntur, Andhra Pradesh, India

ABSTRACT

Prosthodontic management of a completely edentulous patient with microstomia is

challenging for both the operator and the patient. Limited mouth opening can be caused

by the head and neck radiation, surgically treated head and neck tumors, connective tissue

diseases, facial burns, reconstructive lip surgeries and the most common factor oral submucous

fibrosis. It is often difficult to apply conventional clinical procedures to construct dentures

for patients who demonstrate limited mouth opening, as it is difficult to insert or remove the

custom trays, denture bases and the final prosthesis is in one piece because of the constricted

opening of the oral cavity. However, with careful treatment planning and designing, many

of the apparent clinical difficulties can be overcome. This article deals with a case report

of treatment procedure and sectional prosthesis design for a patient with microstomia. All

the procedures were intended for better function, health, esthetics and overall well-being

of the patient.

Key words: Flexible tray, microstomia, oral submucous fibrosis, sectional denture,

sectional trays

INTRODUCTION replacement of missing teeth. Case history

revealed that patient had a habit of

Oral submucous fibrosis is a precancerous smoking two packets of cigarettes per day,

condition, affecting any part of the oral since 7 years. On extra oral examination,

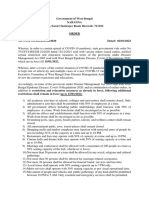

cavity and is caused by prolonged use the patient’s mouth opening was only

of tobacco, areca nut, spices, etc. This 26 mm vertically and 30 mm horizontally

condition is characterized by a burning [Figure 1]. This posed a practical challenge

sensation of the mouth, stiffening of for the fabrication of the complete

certain areas of the oral mucosa with dentures in a conventional way. Intraoral

difficulty in opening the mouth. examination revealed moderately resorbed

maxillary and mandibular completely

Address for correspondence:

Dr. O. Swetha Hima Bindu, This condition hinders conventional edentulous ridges. Mucosa appeared

Department of Prosthodontics,

Sibar Institute of Dental Sciences,

prosthetic treatment of edentulous blanched with palpable fibrotic bands

Thakkellapadu, Guntur - 522 509, patients.[1] Particularly the fabrication of extending all over the oral mucosa up

Andhra Pradesh, India.

E-mail: obr.bindu@gmail.com complete denture is complicated by the to soft palate region. On palpation, the

loss of resiliency of tissues, limited tongue mucous membrane was firm. There was a

Access this article online

movements and the constant adjustments minimal to zero resiliency of the tissues.

Website:

www.jofs.in

required accommodating the changing

periphery.[2] Various treatment modalities Mandibular primary impression and

DOI:

10.4103/0975-8844.132590 include surgery,[3] dynamic opening cast

Quick Response Code: devices called microstomia orthoses[4] and For making the mandibular impression

modification of denture design.[5] the smallest available stock tray (size-0)

was selected whose flanges were modified

CASE REPORT as required until it could be inserted in

patients mouth and the impression was

A 45-year-old male patient was referred made with alginate impression material

to Department of Prosthodontics, for and the primary cast was obtained.

Journal of Orofacial Sciences

65

Vol. 6• Issue 1• January 2014

[Downloaded free from http://www.jofs.in on Friday, February 1, 2019, IP: 182.179.160.203]

Sandeep, et al.: Sectional denture for microstomia patient

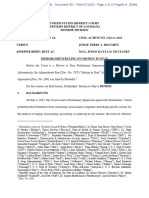

Maxillary primary impression and cast

It was impossible to make an impression with stock

tray for maxillary arch. Hence a flexible tray was

prepared by manually dispensing silicone putty

impression material intra-orally. After dispensing, it

was carefully positioned onto denture-bearing areas

and molded to appropriate contour using functional

and manual manipulation and was kept in place until

it set completely. Later, a wash impression was made

using light body elastomer over the molded putty tray

[Figure 2]. The cast was poured by stabilizing the

flexible tray in a non-displacing mix of dental stone as

a supporting base prior to pouring it in dental plaster

to obtain the primary cast.

Figure 1: Mouth opening of the patient

Final impressions and casts

An auto polymerizing acrylic resin custom tray was

fabricated for maxillary arch, however, it could not be

introduced in the patient’s mouth in one piece therefore,

it was planned to section the tray into two halves to

insert into the mouth. Press buttons were fixed to the

handle of the sectional custom tray so that the tray

could be exactly reassembled [Figure 3]. Border molding

was done alternatively for the right and left halves of

the sectional tray using low fusing compound and final

impression of the two halves was made separately

using light body elastomer. After the impression was

completed, the sectional trays were separated intra-

orally and reassembled externally. The impression was

boxed and poured using dental stone.

A single piece auto polymerizing acrylic custom tray Figure 2: Maxillary primary impression with flexible tray

was used for mandibular arch, as it could be inserted

and removed with little difficulty. The border molding

and final impression was done conventionally. The

master cast was poured by inversion method with

dental stone.

Jaw relations and try in

For better stability permanent denture bases were

planned for recording jaw relations. Mandibular

denture base was fabricated in a conventional way,

but the maxillary denture had to be sectioned, hence

a special metallic inlay structure was designed to be

incorporated into the denture base, which consisted of

two parts, right and left that were joined length-wise by

a custom-made inlay structure at the overlapping metal

base (5 mm wide) along the midline.

Figure 3: Maxillary sectional custom tray with snap button

The right half of the wax pattern was designed to have attachments

three square inlay structures and it was fabricated on

a refractory cast obtained by duplicating the master included three square-shaped holes (2 mm wide and 2

cast. Following this, it was invested, casted, trimmed, mm high) with parallel walls. The inlay structures on

polished and returned to master cast. This entire the right half framework could precisely fit through the

assembly was duplicated to get a second refractory holes when the segments were joined with their tops at

cast, on which the left wax pattern was formed, which the same level as the surface [Figure 4].

Journal of Orofacial Sciences

66

Vol. 6• Issue 1• January 2014

[Downloaded free from http://www.jofs.in on Friday, February 1, 2019, IP: 182.179.160.203]

Sandeep, et al.: Sectional denture for microstomia patient

Figure 4: Custom made metal inlay structure right and left parts

Figure 5: Patient inserting the right and left maxillary denture

sections

Following this, maxillary permanent denture base was

fabricated incorporating the metallic inlay structure and Figure 6: Final denture insertion

was sectioned with care without disturbing the seal, jaw

relations record was made and teeth arrangement was modified stock trays and sectional trays with different

done conventionally on a semi-adjustable articulator attachments.[6-9] And for connecting sectional dentures

developing neutrocentric occlusion. Try in was done cast Co-Cr hinges,[5,10] swing-lock attachments,[11,12] stud

and was found to be satisfactory. The dentures were attachments,[13] clasps[14] and magnets[15,16] were used.

processed in a conventional way.

In this case report, we used a simple method of snap

Insertion and recall visits fit buttons attachment for maxillary sectional tray

At the insertion stage the patient was trained as to how and later the sectional denture segments were joined

to place and remove the sectional maxillary denture. by means of a custom-made inlay structure on the

The right segment of the maxillary denture was first overlapping metal base. This was a simple and the

inserted into the mouth. Then the left segment was cost-effective way. Patient was able to use this design,

inserted to join the right one by placing the inlay when inserting or removing the denture with ease

structures into the corresponding holes [Figure 5]. [Figure 6].

Patient was given home-care instructions on the

operation of the custom-made inlay structure assembly REFERENCES

along with other instructions. Evaluation was done at

recall visits and adjustments were done as required. 1. Naylor WP, Manor RC. Fabrication of a flexible prosthesis for the

Patient expressed immense sense of gratification with edentulous scleroderma patient with microstomia. J Prosthet Dent

the treatment rendered. 1983;50:536-8.

2. Benetti R, Zupi A, Toffanin A. Prosthetic rehabilitation for a patient

with microstomia: A clinical report. J Prosthet Dent 2004;92:322-7.

DISCUSSION 3. Ichimura K, Tanaka T. Trismus in patients with malignant tumours

in the head and neck. J Laryngol Otol 1993;107:1017-20.

Microstomia or limited mouth opening condition poses 4. Khan Z, Banis JC Jr. Oral commissure expansion prosthesis. J

Prosthet Dent 1992;67:383-5.

a problem during each step of prosthetic reconstruction. 5. al-Hadi LA. A simplified technique for prosthetic treatment

Hence several methods have been put forward for of microstomia in a patient with scleroderma: A case report.

impression making which includes flexible trays, Quintessence Int 1994;25:531-3.

Journal of Orofacial Sciences

67

Vol. 6• Issue 1• January 2014

[Downloaded free from http://www.jofs.in on Friday, February 1, 2019, IP: 182.179.160.203]

Sandeep, et al.: Sectional denture for microstomia patient

6. Cura C, Cotert HS, User A. Fabrication of a sectional impression tray 13. Geckili O, Cilingir A, Bilgin T. Impression procedures and

and sectional complete denture for a patient with microstomia and construction of a sectional denture for a patient with microstomia:

trismus: A clinical report. J Prosthet Dent 2003;89:540-3. A clinical report. J Prosthet Dent 2006;96:387-90.

7. Whitsitt JA, Battle LW. Technique for making flexible impression 14. Winkler S, Wongthai P, Wazney JT. An improved split-denture

trays for the microstomic patient. J Prosthet Dent 1984;52:608-9. technique. J Prosthet Dent 1984;51:276-9.

8. Luebke RJ. Sectional impression tray for patients with constricted 15. Watanabe I, Tanaka Y, Ohkubo C, Miller AW. Application of

oral opening. J Prosthet Dent 1984;52:135-7. cast magnetic attachments to sectional complete dentures for

9. Mirfazaelian A. Use of orthodontic expansion screw in fabricating a patient with microstomia: A clinical report. J Prosthet Dent

section custom trays. J Prosthet Dent 2000;83:474-5. 2002;88:573-7.

10. Cheng AC, Wee AG, Morrison D, Maxymiw WG. Hinged mandibular 16. Matsumura H, Kawasaki K. Magnetically connected removable

removable complete denture for post-mandibulectomy patients. J sectional denture for a maxillary defect with severe undercut: A

Prosthet Dent 1999;82:103-6. clinical report. J Prosthet Dent 2000;84:22-6.

11. Wahle JJ, Gardner LK, Fiebiger M. The mandibular swing-lock

complete denture for patients with microstomia. J Prosthet Dent

How to cite this article: Sandeep C, Hima Bindu OS, Sreedevi B,

1992;68:523-7.

Prasad KS. Prosthodontic management of a completely edentulous

12. Suzuki Y, Abe M, Hosoi T, Kurtz KS. Sectional collapsed denture for microstomia patient. J Orofac Sci 2014;6:65-8.

a partially edentulous patient with microstomia: A clinical report. J

Source of Support: Nil, Conflict of Interest: None declared

Prosthet Dent 2000;84:256-9.

Journal of Orofacial Sciences

68

Vol. 6• Issue 1• January 2014

Vous aimerez peut-être aussi

- Recent Advancement in Complete Denture PDFDocument7 pagesRecent Advancement in Complete Denture PDFNoor MuhammadPas encore d'évaluation

- Measurement of Spee Curve in Individuals With Temp PDFDocument10 pagesMeasurement of Spee Curve in Individuals With Temp PDFNoor MuhammadPas encore d'évaluation

- Recent Advancement in Complete Denture PDFDocument7 pagesRecent Advancement in Complete Denture PDFNoor MuhammadPas encore d'évaluation

- Allergies 3Document5 pagesAllergies 3Noor MuhammadPas encore d'évaluation

- 1482-Article Text-2500-1-10-20181106Document5 pages1482-Article Text-2500-1-10-20181106Noor MuhammadPas encore d'évaluation

- Less Postoperative Pain & BleedingDocument3 pagesLess Postoperative Pain & BleedingNoor MuhammadPas encore d'évaluation

- Spread SheetDocument3 pagesSpread SheetNoor MuhammadPas encore d'évaluation

- Less Postoperative Pain & BleedingDocument3 pagesLess Postoperative Pain & BleedingNoor MuhammadPas encore d'évaluation

- Less Postoperative Pain & BleedingDocument3 pagesLess Postoperative Pain & BleedingNoor MuhammadPas encore d'évaluation

- Less Postoperative Pain & BleedingDocument3 pagesLess Postoperative Pain & BleedingNoor MuhammadPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hepatic EncephalopathyDocument16 pagesHepatic EncephalopathyChenyuZhu100% (1)

- Atow 459 00Document9 pagesAtow 459 00Javier Fernando Cabezas MeloPas encore d'évaluation

- ECG in PneumoniaDocument5 pagesECG in PneumoniaDiah Rachmania ThalibPas encore d'évaluation

- Vajiram 2023 Test-4Document16 pagesVajiram 2023 Test-4Satya PaulPas encore d'évaluation

- Study Material of 12th Class Physical EducationDocument61 pagesStudy Material of 12th Class Physical EducationashifPas encore d'évaluation

- Chordal Preservation During Mitral Valve Replacement: Basis, Techniques and ResultsDocument9 pagesChordal Preservation During Mitral Valve Replacement: Basis, Techniques and ResultsThanh BinhPas encore d'évaluation

- Intestinal Obstruction PDFDocument4 pagesIntestinal Obstruction PDFKiiza AloysiusPas encore d'évaluation

- Impact of Educational Programme On Patients HealtDocument14 pagesImpact of Educational Programme On Patients HealtArpita KulkarniPas encore d'évaluation

- West Bengal COVID-19 RestrictionsDocument2 pagesWest Bengal COVID-19 RestrictionsNDTV80% (10)

- Conduct of AnaesthesiaDocument30 pagesConduct of AnaesthesiaAnirban PalPas encore d'évaluation

- Transportation in Animals and Plants 1 2Document15 pagesTransportation in Animals and Plants 1 2DEVMOPas encore d'évaluation

- Case Study For PneumothoraxDocument4 pagesCase Study For PneumothoraxGabbii CincoPas encore d'évaluation

- Health TalkDocument8 pagesHealth TalkCatherine RoblesPas encore d'évaluation

- CovivaxDocument3 pagesCovivaxML BLPas encore d'évaluation

- GREENLEAFDocument5 pagesGREENLEAF-Cabinet de traduction NETWORDTPas encore d'évaluation

- Advanced PathophysiologyDocument3 pagesAdvanced Pathophysiologyulc33% (3)

- EBOOK Health Psychology Understanding The Mind Body Connection 3Rd Edition Ebook PDF Download Full Chapter PDF KindleDocument62 pagesEBOOK Health Psychology Understanding The Mind Body Connection 3Rd Edition Ebook PDF Download Full Chapter PDF Kindlejennifer.meyer988100% (35)

- Essay GalanDocument1 pageEssay GalanDaniel Angelo ArangoPas encore d'évaluation

- Pediatric History Taking-1Document21 pagesPediatric History Taking-1Blessed AbigaelPas encore d'évaluation

- Congenital Diaphragmatic HerniaDocument19 pagesCongenital Diaphragmatic HerniaMishel Rodriguez GuzmanPas encore d'évaluation

- Audio Visual Media For Education of Washing Hands PDFDocument3 pagesAudio Visual Media For Education of Washing Hands PDFastrid berlianPas encore d'évaluation

- Musa Et Al. (2021) - Assessing The Potential Impact of Immunity Waning On The Dynamics of COVID-19 An Endemic Model of COVID-19Document21 pagesMusa Et Al. (2021) - Assessing The Potential Impact of Immunity Waning On The Dynamics of COVID-19 An Endemic Model of COVID-19Cristian Fernando Sanabria BautistaPas encore d'évaluation

- Sunday Review 2Document15 pagesSunday Review 2Accey RamirezPas encore d'évaluation

- Oestoarthritis Oestoarthritis: Physiotherapy (Cardiff University) Physiotherapy (Cardiff University)Document3 pagesOestoarthritis Oestoarthritis: Physiotherapy (Cardiff University) Physiotherapy (Cardiff University)Waseem Khan AfridiPas encore d'évaluation

- Crawford - 1980 - Healthism and The Medicalization of Everyday LifeDocument24 pagesCrawford - 1980 - Healthism and The Medicalization of Everyday LifePaloma NavasPas encore d'évaluation

- Taila Bindu IntroductionDocument21 pagesTaila Bindu Introductioniftikhar ahmed100% (1)

- Gov - Uscourts.lawd.189520.301.0 1Document13 pagesGov - Uscourts.lawd.189520.301.0 1Susie MoorePas encore d'évaluation

- ME EngRW 11 Q3 0701 - SG - The Main Idea and Supporting Details in A ParagraphDocument13 pagesME EngRW 11 Q3 0701 - SG - The Main Idea and Supporting Details in A ParagraphROSEMARIE CAROPas encore d'évaluation

- Corilagine PropriétésDocument8 pagesCorilagine PropriétésAbderrahim Ait OuchaouiPas encore d'évaluation

- Medication: Expected Pharmacological Action Therapeutic UseDocument1 pageMedication: Expected Pharmacological Action Therapeutic UseMike EverettePas encore d'évaluation