Académique Documents

Professionnel Documents

Culture Documents

8-1284-7 Pipe Class HF-6 PDF

Transféré par

Jesus MendezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

8-1284-7 Pipe Class HF-6 PDF

Transféré par

Jesus MendezDroits d'auteur :

Formats disponibles

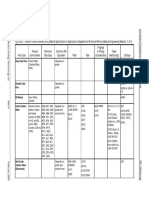

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

8-1284-7 Page 1 of 2

DATE STATUS APVD AUTHD

PIPE CLASS

HF-6,HF-60 12FEB14 Revised AB RGP

Service Material and Flange Class Corrosion Allowance

Non Acid Process Killed Carbon Steel Class 150 RF See Note 1

TemperatureRange (Design) PressureRange

-20F (-29C) through 500F (260C) Per ASME B16.5 for sizes to 24 inch

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

Flanges ASME Class 150 forged raised face. ASTM A 105.

1 1/2 inch and smaller socket weld.

2 inch to 24 inch welding neck bored to match ID of pipe.

Gaskets Spiral wound in accordance with ASME B16.20 with Alloy 400 windings and flexible

(Note 2) graphite filler. Carbon Steel inner retaining ring for all sizes.

Fittings 1 1/2 and smaller forged socket weld. ASTM A 105.

(Note 3) 2 inch and larger welding same thickness as pipe. ASTM A 234 WPB.

Branch connection welding fittings. ASTM A 105.

Globe Valves Cast or forged, OS&Y, bolted bonnet, corrosion-inhibited die formed flexible graphite

packing with braided anti-extrusion rings. ASTM A 216 Grade WCB or ASTM A 105

body/bonnet, 13Cr trim, hardfaced seat, corrugated soft iron single sheet or spiral

wound Alloy 400 windings and flexible graphite filler bonnet gasket, in compliance

with ASME B16.34.

1 1/2 inch and smaller ASME Class 800 socket weld.

Bonney Forge HL-30-HF6, PetrolValves F 102 UHF 7G, Vogt SW-12141-HF6, Xanik

BB08W-WCB-8-V-H or equal.

2 inch to 6 inch, ASME Class 150 flanged.

PetrolValves 1021 UHF 6G, Powell 1531-HF6, Xanik BB01R-WCB-8-V-H or equal.

Gate Valves Cast or forged, OS&Y, bolted bonnet, corrosion-inhibited die formed flexible graphite

packing with braided anti-extrusion rings. ASTM A 216 Grade WCB or ASTM A 105

body/bonnet, 13Cr trim, hardfaced seats, corrugated soft iron single sheet or spiral

wound Alloy 400 windings and flexible graphite filler bonnet gasket.

1 1/2 inch and smaller ASME Class 800 socket weld, in compliance with API 602.

Bonney Forge H-10-HF6, PetrolValves F 101 UHF 7G, Vogt SW-12111-HF6, Xanik

GB08W-WCB-8-R-H or equal.

2 inch to 24 inch, ASME Class 150 flanged, in compliance with API 600.

PetrolValves 1011 UHF 6G, Powell 1503-HF6, Xanik GB01R-WCB-8-F-H or equal.

Form QUA-32-3 Qualtrax 9429

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

8-1284-7 Page 2 of 2

DATE STATUS APVD AUTHD

PIPE CLASS

HF-6,HF-60 12FEB14 Revised AB RGP

Check Valves Cast or forged, bolted bonnet cap. ASTM A 216 Grade WCB or ASTM A 105

body/bonnet cap, 13Cr trim, hardfaced seat, corrugated soft iron single sheet or spiral

wound Alloy 400 bonnet gasket, in compliance with ASME B16.34 respectively.

1 1/2 inch and smaller ASME Class 800 socket weld, ball or piston type.

PetrolValves F 501 UHF 7G, Vogt SWB-701-HF6, Xanik LB08W-WCB-8-B-N or

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

equal.

2 inch to 24 inch, ASME Class 150 flanged.

Bonney Forge HL-40,HF6, PetrolValves 1031 UHF 6G, Powell 1561-HF6, Xanik

WB01R-WCB-8-W-N or equal.

Bolting Stud bolts ASTM A 193 Grade B7 or B7M threaded full length with 2 ASTM A 194

Grade 2H or 2HM nuts.

Pipe ASTM A 106 Grade B seamless.

(Note 4) Contractor to calculate wall thickness.

Notes: 1. Corrosion allowances are as follows:

Class HF-6 – 0.063 inch (1.5mm)

Class HF-60 – 0.125 inch (3.0 mm)

2. Flexible graphite shall be minimum of 95% by weight pure carbon.

3. 1 1/2 inch and smaller fittings are as follows:

HF-6 – Class 3000

HF-60 – Class 6000

4. Minimum wall thickness for 1 1/2 inch and smaller pipe shall be as follows:

Class HF-6 – No less than Schedule 80

Class HF-60 – No less than Schedule 160

Manufacturer (or Equal):

Bonney Forge, PetrolValves, Powell, Vogt, Xanik

Form QUA-32-3 Qualtrax 9429

Vous aimerez peut-être aussi

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- 8-1282-11 Pipe Class HF 4 PDFDocument4 pages8-1282-11 Pipe Class HF 4 PDFJesus MendezPas encore d'évaluation

- 8-1283-12 Pipe Class HF-5Document4 pages8-1283-12 Pipe Class HF-5Jesus MendezPas encore d'évaluation

- 8-1280-13 Pipe Class HF-1Document4 pages8-1280-13 Pipe Class HF-1Jesus MendezPas encore d'évaluation

- Ipromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Document5 pagesIpromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Cristobal Leal ArandaPas encore d'évaluation

- FINAL BOQ-Civil-07052020Document1 pageFINAL BOQ-Civil-07052020vinoj chandranPas encore d'évaluation

- How To Order Alfa Forged Gate, Globe, and Check ValvesDocument1 pageHow To Order Alfa Forged Gate, Globe, and Check ValvesAndri AjaPas encore d'évaluation

- Piping Class CS1 300 4Document3 pagesPiping Class CS1 300 4rakicbg100% (1)

- OrificeMaster Single Chamber Orifice FittingDocument8 pagesOrificeMaster Single Chamber Orifice FittingPaul Wowor100% (1)

- LT11100300 TB No. 3 - Attachments PDFDocument67 pagesLT11100300 TB No. 3 - Attachments PDFVedran KosanovicPas encore d'évaluation

- StrainerDocument2 pagesStrainerRanjithPas encore d'évaluation

- M10S Ball Valve DN " To DN2 ": Full BoreDocument4 pagesM10S Ball Valve DN " To DN2 ": Full BoreTsion GtatiosPas encore d'évaluation

- Optional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Document2 pagesOptional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Oscar Horta PolaniaPas encore d'évaluation

- Cast Steel Swing Check Valve Class 150: MaterialDocument1 pageCast Steel Swing Check Valve Class 150: Materialadewunmi olufemiPas encore d'évaluation

- JIS B 0601-2001 Surface RoughnessDocument4 pagesJIS B 0601-2001 Surface RoughnessMatthew Johnston0% (1)

- P KjsDocument38 pagesP Kjsmajmor-1Pas encore d'évaluation

- KEDDCO BinderDocument74 pagesKEDDCO BinderWillian FigueroaPas encore d'évaluation

- Rsgv-As: Resilient Seated Gate Valve Approved To As2638.2Document3 pagesRsgv-As: Resilient Seated Gate Valve Approved To As2638.2MalonePas encore d'évaluation

- Piping Fitting Spec Rev 0 AFCDocument1 pagePiping Fitting Spec Rev 0 AFCsobariPas encore d'évaluation

- Categorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Document26 pagesCategorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Geovanny MarquezPas encore d'évaluation

- Stud Bolts 2hex Nuts Weight Imperial SizesDocument12 pagesStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- Piping Class - F1E0U2Document3 pagesPiping Class - F1E0U2AMBYPas encore d'évaluation

- Piping - Material - Class - Index - Resonse CommentDocument1 pagePiping - Material - Class - Index - Resonse CommentSubash Gold KingPas encore d'évaluation

- WPQ Cinasa 01-2022Document1 pageWPQ Cinasa 01-2022Erick VazquezPas encore d'évaluation

- Manufacturers & Suppliers of Forged Flanges: Corporate OfficeDocument4 pagesManufacturers & Suppliers of Forged Flanges: Corporate Officeabhishek_negi_41Pas encore d'évaluation

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitPas encore d'évaluation

- Astm, Sae and Iso Bolting MaterialDocument7 pagesAstm, Sae and Iso Bolting MaterialSds Mani SPas encore d'évaluation

- DATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedDocument1 pageDATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedQualival EgyptPas encore d'évaluation

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarPas encore d'évaluation

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimPas encore d'évaluation

- Snamprogetti: Gaskets For Flanged PipingDocument10 pagesSnamprogetti: Gaskets For Flanged PipingTerrance Badree100% (3)

- Carbon Steel Pipe Standards 1Document1 pageCarbon Steel Pipe Standards 1phoneme79Pas encore d'évaluation

- 00 Valve Design and ConstructionDocument3 pages00 Valve Design and ConstructionAndri AjaPas encore d'évaluation

- Choke Valve Data SheetDocument1 pageChoke Valve Data SheetFabricio Vega Estrella100% (1)

- 360 Reference Tables: Gray Cast Iron Fresh WaterDocument5 pages360 Reference Tables: Gray Cast Iron Fresh WaterGuido BerdinaPas encore d'évaluation

- 150 10xaa1 H50 21RDCH 1004 1Document1 page150 10xaa1 H50 21RDCH 1004 1uma ranePas encore d'évaluation

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingUNNIKRISHNAN NAIRPas encore d'évaluation

- Catalogo KEDDCO Figuras 8 Swages Filtros Accesorios ELIDocument55 pagesCatalogo KEDDCO Figuras 8 Swages Filtros Accesorios ELIFrancisco Xavier Geronimo GarciaPas encore d'évaluation

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiPas encore d'évaluation

- Piping Material Specification: Pipe DataDocument3 pagesPiping Material Specification: Pipe DataBhaumik BhuvaPas encore d'évaluation

- VHM Lu01 Pi SP 001 - Piping Material SpecificationDocument7 pagesVHM Lu01 Pi SP 001 - Piping Material SpecificationchintanPas encore d'évaluation

- 1 - Differences Between API 600 & API 6DDocument9 pages1 - Differences Between API 600 & API 6Dعزت عبد المنعمPas encore d'évaluation

- ME.S.008 Piping Material - ASL - 2012Document3 pagesME.S.008 Piping Material - ASL - 2012Ahmed AbdoPas encore d'évaluation

- Piping Material Data SheetDocument1 pagePiping Material Data SheetbrunorodorPas encore d'évaluation

- Code Ansi: Pipes and Fittings CLASS 150Document3 pagesCode Ansi: Pipes and Fittings CLASS 150Eduardo Salabert RosaPas encore d'évaluation

- Engineering Tools Standard Flange Dimension: Download ANSI StandardsDocument1 pageEngineering Tools Standard Flange Dimension: Download ANSI Standardsandersson benito herreraPas encore d'évaluation

- Abstract of ASTM A320 A320M 2000Document10 pagesAbstract of ASTM A320 A320M 2000Jesse ChenPas encore d'évaluation

- Slurry Flo BrochureDocument4 pagesSlurry Flo BrochureChristian Andres Campa HernandezPas encore d'évaluation

- V5-GRS-A125: Gate ValveDocument1 pageV5-GRS-A125: Gate ValveChristian oliverosPas encore d'évaluation

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDocument32 pagesDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesPas encore d'évaluation

- Binder 109221Document2 pagesBinder 109221andres mezaPas encore d'évaluation

- Sample Implementation StampDocument1 pageSample Implementation Stampaateka02Pas encore d'évaluation

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoPas encore d'évaluation

- Exhaust Gas Piping Specification-5ADocument2 pagesExhaust Gas Piping Specification-5AbhaskarPas encore d'évaluation

- 2.V3 Gan A125Document1 page2.V3 Gan A125Arthur DeiparinePas encore d'évaluation

- FlowBiz Double Block & Bleed Plug ValveDocument4 pagesFlowBiz Double Block & Bleed Plug ValveSHAKIR ANSARIPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Dextrid® Lte™: Filtration Control AdditiveDocument1 pageDextrid® Lte™: Filtration Control Additivesajad gohariPas encore d'évaluation

- Ful 56 Introducción A La Maquina ÍnternaDocument4 pagesFul 56 Introducción A La Maquina Ínternafernando rochaPas encore d'évaluation

- Public Area CleaningDocument16 pagesPublic Area Cleaningnitty lovePas encore d'évaluation

- Perar Compact Ball ValvesDocument16 pagesPerar Compact Ball ValvesUday GokhalePas encore d'évaluation

- Technical Data Sheet LG11 ENG 2021Document2 pagesTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXPas encore d'évaluation

- Daikin Presentation - Chiller SystemDocument112 pagesDaikin Presentation - Chiller Systemlucio ruiz jr100% (1)

- Typical Loads For Common Electrical EquipmentDocument3 pagesTypical Loads For Common Electrical EquipmentJohn HowardPas encore d'évaluation

- BT2353 NolDocument69 pagesBT2353 NolHari Priya0% (1)

- C Ce 0432 CPD 221051 enDocument54 pagesC Ce 0432 CPD 221051 enKhuyến Nguyễn VănPas encore d'évaluation

- After Ultra CoolantDocument8 pagesAfter Ultra CoolantEmrah KutluPas encore d'évaluation

- Strength Evaluation of Existing Structures As Per NSCP 2015Document30 pagesStrength Evaluation of Existing Structures As Per NSCP 2015cruzser100% (7)

- Small Capacity Industrial Cold Room With Sliding DoorDocument5 pagesSmall Capacity Industrial Cold Room With Sliding DoorEdy LasmanaPas encore d'évaluation

- Datasheet - Uni QNB CDocument4 pagesDatasheet - Uni QNB CYeisonPas encore d'évaluation

- 2014 Hyundai Equus 90049Document479 pages2014 Hyundai Equus 90049Anonymous bH1GoYuPas encore d'évaluation

- List Din STD For PipeDocument11 pagesList Din STD For PipeybazyariPas encore d'évaluation

- 2181355g 2 3 PDFDocument32 pages2181355g 2 3 PDFPraxedes PxPas encore d'évaluation

- Lubrication SystemDocument3 pagesLubrication Systemmellon3duwenPas encore d'évaluation

- As 4176.3-2010 Multilayer Pipes For Pressure Applications Multilayer Piping Systems For Hot and Cold Water PLDocument8 pagesAs 4176.3-2010 Multilayer Pipes For Pressure Applications Multilayer Piping Systems For Hot and Cold Water PLSAI Global - APACPas encore d'évaluation

- Astm A358 A358mDocument11 pagesAstm A358 A358mShashank SaxenaPas encore d'évaluation

- SCH VsdSpeedstar2000 UmDocument93 pagesSCH VsdSpeedstar2000 Umyasser_nasef5399Pas encore d'évaluation

- Volvo 8400 City Bus Brochure For Sales KitDocument8 pagesVolvo 8400 City Bus Brochure For Sales KitER Balram YadavPas encore d'évaluation

- VentPro CatalogueDocument26 pagesVentPro Cataloguesamiransw2014Pas encore d'évaluation

- 3.1method Statment For Installation of Fire Protection System FinalDocument31 pages3.1method Statment For Installation of Fire Protection System Finalمقاول تكييف كهرباء وصحيPas encore d'évaluation

- Paper Manufacturing Technology by VoithDocument76 pagesPaper Manufacturing Technology by VoithMarcWorldPas encore d'évaluation

- AM009KNQDCHAZDocument2 pagesAM009KNQDCHAZRichard CarvajalPas encore d'évaluation

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Box Culverts - Humes BookletDocument17 pagesBox Culverts - Humes BookletScott Downs100% (3)

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- STD - Form of Separation (IEC 60439-1)Document7 pagesSTD - Form of Separation (IEC 60439-1)Kiliardt ScmidtPas encore d'évaluation

- Exercise 2.1 Concepts of MatterDocument3 pagesExercise 2.1 Concepts of MatterKesuma DewiPas encore d'évaluation