Académique Documents

Professionnel Documents

Culture Documents

8.0 Pressure Plate Design: Check For Bending

Transféré par

Ahammad Kabeer0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues4 pagesThis document summarizes the design of a pressure plate and screws for a glass curtain wall subject to wind loads. It calculates wind loads on the glass and pressure plate, checks the bending capacity of the 1mm thick aluminum pressure plate, and verifies the shear, tension, and pullout capacity of 5.5mm diameter screws spaced 300mm apart. All checks show the design is safe and meets the required factors of safety.

Description originale:

AAADFAF

Titre original

NCR

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document summarizes the design of a pressure plate and screws for a glass curtain wall subject to wind loads. It calculates wind loads on the glass and pressure plate, checks the bending capacity of the 1mm thick aluminum pressure plate, and verifies the shear, tension, and pullout capacity of 5.5mm diameter screws spaced 300mm apart. All checks show the design is safe and meets the required factors of safety.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues4 pages8.0 Pressure Plate Design: Check For Bending

Transféré par

Ahammad KabeerThis document summarizes the design of a pressure plate and screws for a glass curtain wall subject to wind loads. It calculates wind loads on the glass and pressure plate, checks the bending capacity of the 1mm thick aluminum pressure plate, and verifies the shear, tension, and pullout capacity of 5.5mm diameter screws spaced 300mm apart. All checks show the design is safe and meets the required factors of safety.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

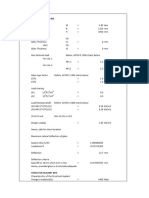

8.

0 PRESSURE PLATE DESIGN

Wind load, W = 1.60 kPa

Width of glass,b = 1007 mm

Height of glass, h = 2400 mm

Tributary width, tw = 0.5 x 1007 = 503.5 mm

Wind Load on pressure plate, Rz = 1.60 x 0.504 = 0.8064 KN/m

Check for Bending:

Thickness of pressure plate, tp = 1 mm

Eccentricity, e = 17 mm

Considering 1mm strip,

Moment due to eccentricity, M = Rz x e = 0.8064 x 0.017

= 0.0137 KNm

Section Modulus, Syy = 1 x tp2/6 = 0.167 mm3

Actual bending stress of Aluminium pressure plate, fb = M/ Syy

= 0.0137 x 1000 / 0.167

= 82.088 Mpa

Allowable bending stress of 6063-T6 , Fb = 160 MPa

Pressure plate Bending Capacity = fb / Fb

= 0.51 < 1

Hence safe

8.1 CHECK FOR PRESSURE PLATE SCREW

Wind Load, WL = 1.60 kPa

Width of Cap, Wc = 12 mm

Distance between couple Force, Sf = 42 mm

Spacing of Screw, Ss = 300 mm

Distributed Load on Aluminium Fin, w = WL x Wc

= 0.0192 N/mm

Couple Force due to Fin, Rf = w x (0.5 x Wc) / Sf

= 0.002743 N/mm

Diameter of Screw, d = 5.5 mm

Ultimate Tensile Strength of Screw, Ub = 700MPa (As Per AAMA-TIR-A9)

Yield Strength of Screw, Yb = 450MPa (As Per AAMA-TIR-A9)

Number of Thread per mm, Nt = 0.945/mm

Tensile Stress Area, As = 0.7854 x ( d – 0.9743 / Nt)2

= 18.014mm2

Thread Root Area, Ar = 0.7854 x ( d – 1.2269 / Nt)2

= 16.059mm2

Internal Thread Stripping Area, TSAI = 12.258mm2

External Thread Stripping Area, TSAE = 8.387mm2

Allowable Shear Stress on Screw, Fvs = min ((0.4xUb/√3) , (0.75xYb/√3))

= 161.65MPa

Allowable Tensile Stress on Screw, Fts = 0.4 x Ub

= 280 MPa

CHECK FOR SHEAR

Maximum Shear Force Per Screw, Fsmax = w x Ss

= 0.00576 kN

Allowable Shear Force, Fsallow = Fvs x Ar

= 2.595 kN

Shear Ratio = Fsmax / Fsallow < 1

= 0.0022 < 1,

Hence Safe.

CHECK FOR TENSION

Maximum Tension Force Per Screw, FTmax = (2 x (Rz + Rf )- Rf) x Ss)

= 0.613 kN

Allowable Tension Force, FTallow = Fts x Ar

= 4.496 kN

Tension Ratio = FTmax / FTallow < 1

= 0.136 < 1,

Hence Safe.

CHECK FOR COMBINED STRESS RATIO

Combined Stress Ratio = (Fsmax / Fsallow)2 + (FTmax / FTallow)2 < 1

= 0.136 < 1,

Hence Safe.

CHECK FOR TENSION OR PULLOUT STRENGTH

Allowable Shear Strength, V Allow = 95 N/mm2

Length of Screw Engagement provided, LEP = 15 mm

Length of Screw Engagement required, LER = (LEp – (1/ Nt)) x 0.4 x VAallow x TSAI x Nt

= 6.31 kN

Major Radius of Screw, R = 0.5 x d = 2.75 mm

Minor Radius of Screw, r = 2.29 mm

Angle Defining limit of Screw, α = 2 x a x cos(r/R) = 1.174 rad

Ratio of engagement, Re = R2 x ((α-sin(α)) / (∏ x (R2 – r2))

= 26.106%

Effective Length of Fastener, Peff = Re x LER = 1.64 kN

Screw Pullout Capacity, Spcapacity = FTmax / Peff < 1

= 0.405 < 1,

PROJECT : DUBAI CHAMBER CW 01

CONSULTANT : WSP

MAIN CONTRACTOR: AL TAYER STOCKS

DOCUMENT TYPE : COMMENTS RESPONSE STATEMENT

DATE : 31-03-2020

Sl.No. COMMENTS/OBSERVATIONS FENCON MAZAMEER RESPONSE

Wind load and load combination

1 should be as per ASCE 7-05 hence Noted and Complied , Refer page No. 6

not accepted

Glass is a part of Item curtain wall

hence to be included where live

2 Noted and Complied. Refer page No. 19

load per BS 6180 1.5 kN/m Is

applied

PREP: SARATH AHAMMAD KABEER MS

CHECKED : ATHIRA RAJAN

Vous aimerez peut-être aussi

- Total Width of The ACP PanelDocument8 pagesTotal Width of The ACP PanelARYA100% (1)

- Design Data: Design of Floor SlabDocument1 pageDesign Data: Design of Floor SlabDrafters EngineeringPas encore d'évaluation

- 1 Slab-1wayDocument5 pages1 Slab-1wayjuliyet strucPas encore d'évaluation

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiPas encore d'évaluation

- Design of Mullion For C W Wall System: Project NameDocument3 pagesDesign of Mullion For C W Wall System: Project NameSales AlufacadesPas encore d'évaluation

- Design of Box CulvertDocument34 pagesDesign of Box CulvertAl Patrick Dela CalzadaPas encore d'évaluation

- Anchor BTD DefgDocument5 pagesAnchor BTD DefgAKSHAY BHATKARPas encore d'évaluation

- DSOS Design of Stair + Deflection R0Document5 pagesDSOS Design of Stair + Deflection R0Sneha RedkarPas encore d'évaluation

- SlabDocument6 pagesSlabBishal ShresthaPas encore d'évaluation

- Design of Slab As Per IS:456-2000: Input DataDocument6 pagesDesign of Slab As Per IS:456-2000: Input DataMainali IshuPas encore d'évaluation

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaPas encore d'évaluation

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- NODE - 30 - 4 Nos ANC BOLT STRENGTH CHECKDocument2 pagesNODE - 30 - 4 Nos ANC BOLT STRENGTH CHECKAS DesignanddraftPas encore d'évaluation

- Facade Toggle CalculationDocument11 pagesFacade Toggle CalculationSudhakar KrishnamurthyPas encore d'évaluation

- Open Well Staircase: 1. Design DataDocument7 pagesOpen Well Staircase: 1. Design DataEr Saroj Paudel100% (1)

- Anchor Bolts DesignDocument6 pagesAnchor Bolts DesignAKSHAY BHATKARPas encore d'évaluation

- Aluminium Cladding DesignDocument3 pagesAluminium Cladding Designjatin100% (1)

- Pedestal and Foundation For Piping Support ACI 318 (American Code)Document21 pagesPedestal and Foundation For Piping Support ACI 318 (American Code)Nikhil Tawade100% (1)

- Structural Cals For UCWDocument11 pagesStructural Cals For UCWShubham SoniPas encore d'évaluation

- 1424-S-RP-002 A Support Reactions and Anchor Bolt DesignDocument15 pages1424-S-RP-002 A Support Reactions and Anchor Bolt DesignAmarjit KulkarniPas encore d'évaluation

- 4Document11 pages4Smit PatelPas encore d'évaluation

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beaglePas encore d'évaluation

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Node - 3453 - Anc Bolt Strength CheckDocument1 pageNode - 3453 - Anc Bolt Strength CheckAS DesignanddraftPas encore d'évaluation

- Node - 3656 - Anc Bolt Strength CheckDocument1 pageNode - 3656 - Anc Bolt Strength CheckAS DesignanddraftPas encore d'évaluation

- Node - 3656 - Anc Bolt Strength CheckDocument1 pageNode - 3656 - Anc Bolt Strength CheckAS DesignanddraftPas encore d'évaluation

- D.2.1 Design of Two Way Roof Slab (Between A-B & 7-8) DataDocument9 pagesD.2.1 Design of Two Way Roof Slab (Between A-B & 7-8) DatamohanPas encore d'évaluation

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhanePas encore d'évaluation

- Perhitungan CorbelDocument2 pagesPerhitungan CorbelRonny WPas encore d'évaluation

- StariDocument28 pagesStariBikal BastakotiPas encore d'évaluation

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Document5 pagesCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Anchor Bolt BiAxialDocument10 pagesAnchor Bolt BiAxialALPHYL BALASABASPas encore d'évaluation

- Pavement Slab Design For RTGDocument2 pagesPavement Slab Design For RTGBishal karki100% (1)

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoPas encore d'évaluation

- Design Strength of Screw AAMA TIR-A9Document1 pageDesign Strength of Screw AAMA TIR-A9Giri DharanPas encore d'évaluation

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SPas encore d'évaluation

- Node - 342 - Anc Bolt Strength CheckDocument1 pageNode - 342 - Anc Bolt Strength CheckAS DesignanddraftPas encore d'évaluation

- Tread - Riser StaircaseDocument3 pagesTread - Riser StaircasemeenuPas encore d'évaluation

- Node - 343 - Anc Bolt Strength CheckDocument1 pageNode - 343 - Anc Bolt Strength CheckAS DesignanddraftPas encore d'évaluation

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Design of Staircase 1 Staicase DatasDocument3 pagesDesign of Staircase 1 Staicase Datasmeenu100% (1)

- 2 2 y CK X Y: Dust Load On Slab KN/M Other Load On Slab KN/M 0 0Document1 page2 2 y CK X Y: Dust Load On Slab KN/M Other Load On Slab KN/M 0 0Mariappan .PPas encore d'évaluation

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhanePas encore d'évaluation

- Design of Pilecaps BS 8110Document3 pagesDesign of Pilecaps BS 8110thanigai veluPas encore d'évaluation

- 10.0m LIGHTING POLES - Concrete Design BS8110Document7 pages10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianPas encore d'évaluation

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajPas encore d'évaluation

- Design of Sign Board Gantry 20.2 M SpanDocument10 pagesDesign of Sign Board Gantry 20.2 M SpanVrusha BendarPas encore d'évaluation

- Vessel Supported On 2 PedestalsDocument7 pagesVessel Supported On 2 PedestalsNitesh SinghPas encore d'évaluation

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Document2 pagesE.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Johny Mark AsuncionPas encore d'évaluation

- 2 Way Slab Menuka FinalDocument1 page2 Way Slab Menuka Finalabhisek adhikariPas encore d'évaluation

- 1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLDocument3 pages1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLAshlin AarthiPas encore d'évaluation

- Typical Column DesignDocument2 pagesTypical Column DesignAbdul khaliquPas encore d'évaluation

- Mullion AnalysisDocument4 pagesMullion AnalysisganeshPas encore d'évaluation

- Angle Section DesignDocument6 pagesAngle Section DesignmangeshPas encore d'évaluation

- Static Analysis of Hydraulic Cylinder: 430/210 X 3300 StrokeDocument3 pagesStatic Analysis of Hydraulic Cylinder: 430/210 X 3300 StrokebrahmaPas encore d'évaluation

- Shutter Beam Check and Plate StresDocument2 pagesShutter Beam Check and Plate StresНемања КараклајићPas encore d'évaluation

- 7 Check For Crack Width: A) Deck SlabDocument2 pages7 Check For Crack Width: A) Deck SlabAnonymous jLLjBdrPas encore d'évaluation

- Design Calculation For Column (Staad Member No. 1219) : Section PropertiesDocument63 pagesDesign Calculation For Column (Staad Member No. 1219) : Section PropertiesSreeraja SreevilasanPas encore d'évaluation

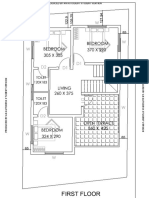

- Bedroom 390 X 290 Bedroom 285 X 306: First Floor 665 SQ - FTDocument1 pageBedroom 390 X 290 Bedroom 285 X 306: First Floor 665 SQ - FTAhammad KabeerPas encore d'évaluation

- Ground Floor 782 SQ - FT: W W3 W D1Document1 pageGround Floor 782 SQ - FT: W W3 W D1Ahammad KabeerPas encore d'évaluation

- Ground Floor 807 SQ - FT First Floor 810 SQ - FT Terrace 85.0 SQ - FTDocument1 pageGround Floor 807 SQ - FT First Floor 810 SQ - FT Terrace 85.0 SQ - FTAhammad KabeerPas encore d'évaluation

- Ground Floor 788 SQ - FT: Kitchen 285 X 270 Bedroom 390 X 290Document1 pageGround Floor 788 SQ - FT: Kitchen 285 X 270 Bedroom 390 X 290Ahammad KabeerPas encore d'évaluation

- First Floor 660 SQ - FT: Bedroom 370 X 290 Bedroom 305 X 305Document1 pageFirst Floor 660 SQ - FT: Bedroom 370 X 290 Bedroom 305 X 305Ahammad KabeerPas encore d'évaluation

- First Floor 665 SQ - FT: Open Terrace 280 X 320Document1 pageFirst Floor 665 SQ - FT: Open Terrace 280 X 320Ahammad KabeerPas encore d'évaluation

- Ground Floor 760 SQ - FT First Floor 760 SQ - FT Terrace 105.5 SQ - FTDocument1 pageGround Floor 760 SQ - FT First Floor 760 SQ - FT Terrace 105.5 SQ - FTAhammad KabeerPas encore d'évaluation

- Cochin University of Science and TechnologyDocument3 pagesCochin University of Science and TechnologyAhammad KabeerPas encore d'évaluation

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionAhammad KabeerPas encore d'évaluation

- First Floor 625 SQ - FT: Open Terrace 280 X 320 Bedroom 330 X 320Document1 pageFirst Floor 625 SQ - FT: Open Terrace 280 X 320 Bedroom 330 X 320Ahammad KabeerPas encore d'évaluation

- Ground Floor 790 SQ - FT: Work Area 280 X 150Document1 pageGround Floor 790 SQ - FT: Work Area 280 X 150Ahammad KabeerPas encore d'évaluation

- Ground Floor 760 SQ - FT: Work Area 280 X 150Document1 pageGround Floor 760 SQ - FT: Work Area 280 X 150Ahammad KabeerPas encore d'évaluation

- Drawing1 Recover Recover002-ModelDocument1 pageDrawing1 Recover Recover002-ModelAhammad KabeerPas encore d'évaluation

- JK"V H Izks - KSFXDH Lalfkku Flfdde: National Institute of Technology SikkimDocument1 pageJK"V H Izks - KSFXDH Lalfkku Flfdde: National Institute of Technology SikkimAhammad KabeerPas encore d'évaluation

- Ground Floor 760 SQ - FT First Floor 760 SQ - FT Terrace 105.5 SQ - FTDocument1 pageGround Floor 760 SQ - FT First Floor 760 SQ - FT Terrace 105.5 SQ - FTAhammad KabeerPas encore d'évaluation

- Dynamic Analysis of Offshore Jacket Sub Structure Using FEMDocument5 pagesDynamic Analysis of Offshore Jacket Sub Structure Using FEMAhammad KabeerPas encore d'évaluation

- Strip Beam Design 24 07 19Document37 pagesStrip Beam Design 24 07 19Ahammad KabeerPas encore d'évaluation

- 9.0 Design of L Angles Connecting Mullion To Steel TUBE (120x120x12)Document1 page9.0 Design of L Angles Connecting Mullion To Steel TUBE (120x120x12)Ahammad KabeerPas encore d'évaluation

- 1.0 General Description: Elevation of Dubai CommercityDocument1 page1.0 General Description: Elevation of Dubai CommercityAhammad KabeerPas encore d'évaluation

- Structural Calculation For The Ground Floor Curtain WallDocument73 pagesStructural Calculation For The Ground Floor Curtain WallAhammad KabeerPas encore d'évaluation

- 1 PDFDocument1 page1 PDFAhammad KabeerPas encore d'évaluation

- 3 PDFDocument1 page3 PDFAhammad KabeerPas encore d'évaluation

- 1Document19 pages1Ahammad KabeerPas encore d'évaluation

- 7.2.2 Check For Bolt - Grade Ss A4-70: Hence OkDocument2 pages7.2.2 Check For Bolt - Grade Ss A4-70: Hence OkAhammad KabeerPas encore d'évaluation

- Wind Loading Analysis: British Standard Cp3, Chapter V (1972)Document3 pagesWind Loading Analysis: British Standard Cp3, Chapter V (1972)Ahammad KabeerPas encore d'évaluation

- 6.2 Design of Bottom BracketDocument1 page6.2 Design of Bottom BracketAhammad KabeerPas encore d'évaluation

- 4 PDFDocument1 page4 PDFAhammad KabeerPas encore d'évaluation

- Structural Calculation For The Curtain Wall Glazed Facade With Sunshade Louver (First To 6 TH Floor)Document1 pageStructural Calculation For The Curtain Wall Glazed Facade With Sunshade Louver (First To 6 TH Floor)Ahammad KabeerPas encore d'évaluation

- Lite Sketch: Wednesday, 6 May, 2020Document2 pagesLite Sketch: Wednesday, 6 May, 2020Ahammad KabeerPas encore d'évaluation

- Check For ShearDocument1 pageCheck For ShearAhammad KabeerPas encore d'évaluation

- Solucionario Charter 15 Pag 11-20Document10 pagesSolucionario Charter 15 Pag 11-20web SoftNert ChilePas encore d'évaluation

- Aisc Steel Construction Manual 13 TH 26Document31 pagesAisc Steel Construction Manual 13 TH 26Fritzie VegaPas encore d'évaluation

- WameedMUCLecture 2021 92127201Document7 pagesWameedMUCLecture 2021 92127201Jitu GudinaPas encore d'évaluation

- Stress-Strain Relationship For Reinforced Concrete in TensionDocument8 pagesStress-Strain Relationship For Reinforced Concrete in TensionManprit SinghPas encore d'évaluation

- BG C11 Shaft 2019 EN2Document15 pagesBG C11 Shaft 2019 EN2Do Cao DuyPas encore d'évaluation

- Wpe ComDocument18 pagesWpe ComShreyas AtrePas encore d'évaluation

- Access Engineering: Combined Footing Design Based On ACI 318-99Document7 pagesAccess Engineering: Combined Footing Design Based On ACI 318-99আসিফ মাহমুদPas encore d'évaluation

- Nonlinear Analysis: Linear Response: P1/d1 P2/d2Document13 pagesNonlinear Analysis: Linear Response: P1/d1 P2/d2LabinotMMorinaPas encore d'évaluation

- 1500 Animated Mechanical MechanismsDocument121 pages1500 Animated Mechanical MechanismsFaruk GunacanPas encore d'évaluation

- Che323 Lecture 2 Humidification Wet BulbDocument19 pagesChe323 Lecture 2 Humidification Wet Bulbifiok100% (1)

- Beam FormulasDocument4 pagesBeam FormulasAelaizza Jane DumdumPas encore d'évaluation

- BOLTGRPDocument18 pagesBOLTGRPJBARTOLOMEPas encore d'évaluation

- Buoyancy V1Document2 pagesBuoyancy V1Andy Jun Sanchez-BautistaPas encore d'évaluation

- Effect of Wind Force On Manoeuvrability Chapter - 10Document7 pagesEffect of Wind Force On Manoeuvrability Chapter - 10erudite_0206Pas encore d'évaluation

- Science 9 - Q4 - Week 1Document18 pagesScience 9 - Q4 - Week 1Rhyan Zero-four BaluyutPas encore d'évaluation

- Vector Addition PracticeDocument5 pagesVector Addition Practicekaede WooPas encore d'évaluation

- Homework No2Document3 pagesHomework No2vitorctbaPas encore d'évaluation

- Bulls Eye Lab-Physics2013Document3 pagesBulls Eye Lab-Physics2013api-267685991Pas encore d'évaluation

- PHYSICS 2 (Electric Charge) SHORTDocument7 pagesPHYSICS 2 (Electric Charge) SHORTMark Lorence CuevasPas encore d'évaluation

- Lab Manual Exp 1-Mass TransferDocument3 pagesLab Manual Exp 1-Mass TransferChong EkPas encore d'évaluation

- Shear Force and Bending Moment: Learning ObjectivesDocument29 pagesShear Force and Bending Moment: Learning ObjectivesBoopathi YoganathanPas encore d'évaluation

- Review For Test 3Document3 pagesReview For Test 3Ellen Michelle RamiaPas encore d'évaluation

- CE124 FInals Exam Problem SolvingDocument1 pageCE124 FInals Exam Problem SolvingZENRIRPas encore d'évaluation

- Eddy Current TestingDocument18 pagesEddy Current Testingvickysrk20017073100% (2)

- Wave Phenomena: Physics 15cDocument29 pagesWave Phenomena: Physics 15cKattari DwiPas encore d'évaluation

- ME 05-T Thermodynamics 2Document54 pagesME 05-T Thermodynamics 2Kakashi JuniorPas encore d'évaluation

- EnergyDocument9 pagesEnergymisbahrauf8585Pas encore d'évaluation

- PerturbationsDocument7 pagesPerturbationsdeardestiny0% (1)

- SERIES 4600: Horizontal Split Case PumpDocument2 pagesSERIES 4600: Horizontal Split Case PumppeerlessPas encore d'évaluation