Académique Documents

Professionnel Documents

Culture Documents

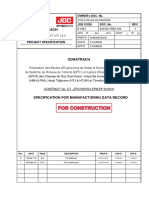

MTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018

Transféré par

AliZenatiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018

Transféré par

AliZenatiDroits d'auteur :

Formats disponibles

ATTACHEMENT 1: METERING LOADING SYSTEM TECHNICAL BID EVALUATION

TECHNICAL BID EVALUATION

BIDDER-1- MULTITERM

Compliant Not

DESIGNATION REQUIREMENTS Complia

nt Supplier offer Observations Supplier Reply (July 16, 2018)

MANDATORY CRITERIA

Supplier Certification

please clarify requirement

1 Certificate/ License Required Not Provided to be provided {Multiterm & Manufacture are registered

& operate in UK.}

2 Vendor list inclusion Required X Included

METERING LOADING SYSTEM CHARACTERISTICS

3 Handled Fluid Gasoil Mogas Kerosene X Gasoil, Mogas and Kerosene

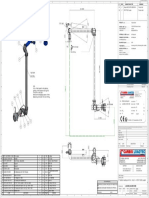

4 Loading Arms Type Top Loading Arms X Top Loading Arms- Long Reach ( Boom)

5 Metering Skid Required Provided

supplier have to provide

1 skid for equipments per skid as

1 skid For Mogas

3 skid for Gasoil Kerosene required and as

(2 load arms + 2

(2 load arms + 2 (1 load arms + 1 mentioned in PID KMPP- Noted: Shall be provided for client review

6 SKID Quantity single stream 9 loading arms

single stream custody single stream 06-PRO-DW-004, offer and approval after award.

custody metering

metering per skid) custody metering shall classified by skid, .

per skid)

per skid) Data shall be provided

for each skid one by one

7 Type of loading arm Rigid with flexible connection Not indicated long reach top loading arm with swivels

8 Vapor Recovery with Return Line Required X Provided

- Manual

'- Optional Pendent pneumatic control for

9 Loading Arms Manipulation Manual X

UP/DOWN/HOLD DOWN function. The

Horizontal is always manually.

10 Operating pressure 4 X Operating range 3-5 barg

11 Design Pressure 10 Barg X 10 Bar

12 Design temperature 70 °C X - 15°C / + 65°C -15°C / + 70°C

13 Flow Rate 60-75 m3/h X 250m3/hour max

ESSENTIAL CRITERIA

DESIGN CONDITION

Loading arms comply with applicable

Design & Safety standards & Codes:

§ ATEX – 2014/34/EU directive

§ PED – 2014/68/EU directive

14 Design Standard Manufacturer standard (*) Not indicated

§ 2006/42/EC Machinery directive

§ ASME B31.3 – Process Piping

§ WPS – WPQR – WPQ comply with

relevant ASME IX and EN standards

15 Installation Outdoor (*) Not indicated confirmed

16 Density 840 kg/m3 740.6 kg/m3 794 kg/m3 (*) Not indicated confirmed

Fill Round barrel or ISO container road

17 Application Filling Road tanker X

tankers

18 Balance Type by supplier X Compression spring

19 Arm Configuration self supported on base riser (by supplier) X self supported on stand post

20 To tanker Semi-closed Connection Via Cone X Connection Via Cone

Arm Connection

21 To plant Flanged X Flanged

Produ

size by supplier Open pipe ( T-Piece) Size shall be specified 4" (DN100)

ct

To tanker

Vapor

size by supplier Acceptable 3" - # 150 to vapor cone

return

Multiterm/Loadtec do not recommend 6"

for these products for possible high

electrostatic charges and

for gasoil and mogas c

Produ size NPS size: 6" NPS size: 6" NPS size: 4" X 4"(DN100)

size shall be 6 inch

4" has a max flow rate of 135m3/hr at

Specifications For

22 ct 5m/s velocity which fit the design &

Connections

operation requirement (6" have significant

To plant

cost impact)

Class # 150 RF / ANSI B16.5 X # 150 RF

size by supplier Acceptable 3"

Vapor

return Class by supplier Acceptable # 150 RF

material grade shall be

within Pipe Carbon Steel Carbon Steel

specified

ASTM A106 Gr B

metering

Skid material grade shall be

Valves by supplier Carbon Steel

specified

ASTM A106 Gr B

material grade shall be

Inboard arm by supplier Carbon steel

specified

ASTM A106 Gr B

material grade shall be

Outboard arm by supplier Carbon steel

specified

ASTM A106 Gr B

material grade shall be

Drop Pipe by supplier Carbon Steel

specified

ASTM A106 Gr B

Cone by supplier Acceptable Aluminum

The SJ410 swivel joints is a 4 piece design,

single hardened ball race with stainless

23 Materials steel balls and stainless steel seal seat,

material grade shall be nickel plated carbon steel (42CrMo4)

within Swivels Joint by supplier Carbon Steel

specified bearing module for strength with butt

Loading Arm

weld end flanges. The wetted material

parts are the flanges, stainless steel seal

seat and the PTFE H block seal holder.

Vapor recovery Flexible by supplier Acceptable Composite steel support

Seals by supplier Acceptable FKM

Stand post : Hot Dip Galvanised Carbon

Structure - Base frame by supplier Acceptable

Steel

Materials shall be

adequately selected to avoid To be confirmed (*) Not indicated confirmed

sparking

Painting shall be as

C5-I: Industrial areas with high humidity

project painting Client comments are noted &

24 Painting Manufacturer standard X and aggressive atmosphere Durability

specification No. KMPP- acknowledged.

range: MEDIUM (M)

00-PIP-SP-005

LOADING GANTRY SKID Accessories

25 Valves Required

26 Filters Required

1. supplier shall to

27 Drain / Vent Required provide separate

Meter prover connection Required datasheet for each skid

'(*) Not indicated

including all accessories

as required ( see

datasheet N° KMPP-06-

MEC-DS-029 and PID Acknowledged (Please refer to revised

within LOADING

N° PID KMPP-06-PRO- Techmical & Commercial Proposal dated

GANTRY SKID

DW-004 ). July 16, 2018 (attached)

2. Accessories Material

28 Isolation Valves Required MTO shall provided for

each skid separately

3. PID shall provided for

each skid

LOADING GANTRY SKID INSTRUMENTATION

30 TYPE CORIOLIS LOADING GANTRY SKID X coriolis mas flow meter

Proposed PID shall

LOADING GANTRY SKID WITH COMPLETE

31

INSTRUMENTATION

match with feed Confirmed

COMPLETE ASSEMBLY

document

GENERAL

32 FLOW COMPUTER INSTALLATION X

33 LOCAL FOR METERING X

MOUNTING Not included (pls provide more details if

34 CONTROL ROOM FOR FLOW COMPUTERS Not mentioned

needed as a part of the ITB)

FLOW INDICATOR TRANSMITTER

35 QTY. 1 (TYPICAL PER STREAM) X coriolis mas flow meter

CORIOLIS TYPE

PRESSURE DIFFERENTIAL

36

SWITCHES

QTY. 1 (TYPICAL PER STREAM) not indicated included

37 MOTOR OPERATED VALVES QTY. 1 (TYPICAL PER STREAM) not indicated included

38 THERMAL RELIEF VALVES QTY. 1 (TYPICAL PER STREAM) X

PRESSURE INDICATOR

39

TRANSMITTER

QTY. 1 (TYPICAL PER STREAM) not indicated included

40 INSTRUMENTATION FLOW CONTROL VALVE QTY. 1 (TYPICAL PER STREAM) X

TEMPERATURE INDICATOR

41 QTY. 1 (TYPICAL PER STREAM) X temperature transmitter

TRANSMITTER & THERMOWELL

42 GROUNDING UNIT QTY. 1 (TYPICAL PER STREAM) X EARTHING MONITOR

high level device with cabling and junction

43 OVERFILL SENSOR QTY. 1 (TYPICAL PER STREAM) X

box

44 required

45 CERTIFICATION Eexd IIB T3 X

46 INGRESS PROTECTION IP 65 not indicated confirmed

JUNCTION BOX

47 MATERIAL 316 SS not indicated Carbon steel same as per the loading arms

48 GLANDS AND PLUGS REQUIRED WITH JUNCTION BOX not indicated included

49 ACCESSORIES MOUNTING ACCESSORIES REQUIRED not indicated included.

MICROPROCESSOR BASED, WITH DIGITAL DISPLAY, ATEX certified Local Control Panel with SIL It is included as a standard at no cost

50 TYPE NO need for SIL rating

AND DATA ENTRY KEYBOARD rated impact.

51 BATCH CONTROLLER APPLICATION CUSTODY TRANSFERT CALCULATION not indicated MID

INGRESS PROTECTION IP 65 confirmed

52 POWER SUPPLY 240 VAC X X confirmed

53 CONTROLLER COMPLETELY WIRED FLOW COMPUTER TO CONFIRM confirmed

COMMUNICATION WITH PLC MODBUS

54 COMMUNICATION INTERFACES

PROTOCOLE RS232/ RS485

TO CONFIRM RS485

Not included, However interface station

computer and software are standard units,

HUMAN MACHINE INTERFACE STATION Multiterm can quote within 72 hours upon

55 TYPE not indicated

COMPUTER client confirmation with defined minimum

system specification (Function, memory,

SUPERVISORY SYSTEM processer ..etc).

56 SOFTWARE WINDOWS not indicated not included (Pls refer to point 55 above)

57 NUMBER OF STATIONS ONE STATION not indicated not included (Pls refer to point 55 above)

LCD 22" and KEYBORD, MOUSE, PRINTERS, TICKET

58 MONITOR & ACCESSORIES

PRINTER

not indicated not included (Pls refer to point 55 above)

Test, Inspection and plans

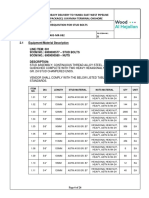

Material Certifications according to supplier have to details All certificate types shall comply to client

59 Certificates : Material , Test , Conformity... To be specified (*) EN10204 related parts for each requirements and to be provided upon

(2.1; 2.2; 3.1; 3.2) certificate type award for review & approval.

60 Inspection And Test Plan Preliminary ITP to be communicated (*) Not provided to be provided enclosed

Required (Hydrotest of complete loading arm assembly 1.5 times

61 Hydrostatic Test X 15 barg

of design pressure for minimum 30 minutes with full assembly)

please clarify what x-ray/gamma ray

62 NDT Required (*) Not indicated

percentage required for NDT

63 Balancing test Required (*) Not indicated included in FAT

64 Performance test Required, Description required. (*) Not indicated included in FAT

Training for 3 engineers 5working days in

Italy. Noted; Pls refer to revised commercial

65 On site Installation assistance and Training To be quoted separately. X

Optional Service, supervision of installation, offer dated July 16, 2018

commissioning and start-up.

GENERAL CRITERIA

DOCUMENTATION

Design package and P&ID shall have all

ITP , general arrangement technical & engineering details including

drawings for each skid , SPPC ITP as minimum. Detailed P&ID GAD

schedule, piping and valve and ED schedule etc shall submitted after

MTO for each skid ,

contract award as a part of design package

66 Documentations Refer to APP-KMPP-06-MEC-RE-004 REV. 1 X not complete catalogue.. Are not

provided . Please provide review and approval. (Please refer to

document as required in attached typical P&ID which was prepared

requisition KMPP-06- for one of our current clients / SPPC can

MEC-RE-004 observe the quality & detailed information

included)

Vendor to provide

Structure Drawing Including Walkway And Ladder for Loading Structure supply is not part of Vendor SOW. Only typical Typical detailed structure drawing

67 typical dimension of structure and

accessibility. structure drawing for Loading Accessibility is required. enclosed

platform*

skid based on customer PID - formal PIDto

68 P&ID P&ID for metering skid and loading arm is Required (*) Not provided be drawn after contract award (pls refer to

point 66 above)

- Please provide GA for

69 General arrangement Drawing Required typical each metering skids Pls refer to point 66 above.

including dimension

Signed Vendor Drawing and Data requirements Form

70

( Appendix C of Requisition )

Required (*) not indicated pls refer to point 66 above.

List of any and all exceptions/deviations to specifications (Filled Exception list are defined on page number

71 Required (*) not indicated

Table of compliance - Appendix G of Requisition ) 2 of our Technical & Commercial proposal.

Detail Standard Spares list for 2 years are

please provide spare part

72 Priced list of 2 Years Operational Spare Parts Required spare part offered but no list provided

list

considered and to be confirmed after

order.

Detail Standard Startup & commissioning

please provide spare part

73 Commissioning and startup Spare Parts Required spare part offered but no list provided

list

spares list are considered and to be

confirmed after order.

MISCELLANEOUS

74 Experience and reputation Required X Provided

75 Sub-supplier's list Required X Country of Origin Provided

BIDDER-1- MULTITERM

1- supplier have to provide complete and separate data for each skid (Acknowledged)

2- Missing or non compliant data shall be rectified (Acknowledged)

NOTES & RECOMMANDATIONS 3- vendor to include pover unit in the updated offer,(Acknowledged, pls refer to revised Technical & Commercial Proposal dated July 16,

(*) Supplier shall provide/complete missing data 2018)

1- Loading arm shall be equipped with local control panel for flow control, valve control, pump control, earthing device detection…

2- Control Valve shall be in conformity with SPECIFICATION FOR CONTROL VALVES "KMPP-00-INT-SP-003"

Vous aimerez peut-être aussi

- Material Handling Equipment World Summary: Market Values & Financials by CountryD'EverandMaterial Handling Equipment World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsD'EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahPas encore d'évaluation

- Reference ListDocument4 pagesReference ListAliZenatiPas encore d'évaluation

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiPas encore d'évaluation

- LNG Loading Arm: Fluid Transfer DivisionDocument2 pagesLNG Loading Arm: Fluid Transfer Divisionarmando0212-1Pas encore d'évaluation

- AMIPURDocument28 pagesAMIPURHugo ArmandoPas encore d'évaluation

- DLA Cat EUROPE - Multiple Address - English - Low Res PDFDocument18 pagesDLA Cat EUROPE - Multiple Address - English - Low Res PDFAnonymous cVnKDdhPas encore d'évaluation

- AmiPur Survey Form AttachmentDocument2 pagesAmiPur Survey Form AttachmentSushant SharmaPas encore d'évaluation

- Liquip Gantry Plugs: Title: PurposeDocument5 pagesLiquip Gantry Plugs: Title: PurposePatricio AguilarPas encore d'évaluation

- Skid Size StandardDocument18 pagesSkid Size StandardrichardchiamPas encore d'évaluation

- (SB007A6E) Smith Meter® Loading SystemsDocument4 pages(SB007A6E) Smith Meter® Loading SystemsRoberto Carlos TeixeiraPas encore d'évaluation

- TW Unloading Arms Tender DocumentDocument37 pagesTW Unloading Arms Tender DocumentVeena S VPas encore d'évaluation

- MLA Data Sheet - LNG - RevaDocument6 pagesMLA Data Sheet - LNG - RevaLuis Gonzalez0% (1)

- Preliminary Quotation of Design, Supply, Delivery, Commissioning, Transportation, Testing, Inspection For LNG Truck Loading SkidDocument32 pagesPreliminary Quotation of Design, Supply, Delivery, Commissioning, Transportation, Testing, Inspection For LNG Truck Loading SkidAyesha KiranPas encore d'évaluation

- E2824 E2839Document2 pagesE2824 E2839jhonarext100% (1)

- La233r1.ca100v-000 R03Document1 pageLa233r1.ca100v-000 R03Ricardo TurinPas encore d'évaluation

- IFC Inflow UK-Loading Arms & SkidsDocument16 pagesIFC Inflow UK-Loading Arms & SkidslpczyfansPas encore d'évaluation

- VV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFDocument253 pagesVV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFLê Phước PhúPas encore d'évaluation

- 01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringDocument4 pages01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringZahidRafiquePas encore d'évaluation

- FMC - Ethanol Blending IntegrationDocument15 pagesFMC - Ethanol Blending Integrationmohd_zaieriPas encore d'évaluation

- E2814Document2 pagesE2814Abdul RehmanPas encore d'évaluation

- Tender SpecificationDocument62 pagesTender SpecificationblessingPas encore d'évaluation

- Specification Sheet MLA PDFDocument2 pagesSpecification Sheet MLA PDFRobin Abu FaqihPas encore d'évaluation

- J06 PT PDT 5988 5989 PDFDocument10 pagesJ06 PT PDT 5988 5989 PDFnashittPas encore d'évaluation

- Emco Wheaton Loading Arm Installation Operation and Maintenance ManualDocument21 pagesEmco Wheaton Loading Arm Installation Operation and Maintenance ManualGusukuma JGPas encore d'évaluation

- WSL Brochure Dec.2008Document20 pagesWSL Brochure Dec.2008Aníbal Mellano100% (1)

- SWS Process Flow DiagramDocument1 pageSWS Process Flow DiagramNKPas encore d'évaluation

- Brochure Uk ProductsDocument2 pagesBrochure Uk ProductsJavier TrujillanoPas encore d'évaluation

- 02 Samss 012Document10 pages02 Samss 012bmkalePas encore d'évaluation

- Reduce Bicine Corrosion PDFDocument7 pagesReduce Bicine Corrosion PDFmahesh070Pas encore d'évaluation

- Typical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)Document1 pageTypical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)AliZenatiPas encore d'évaluation

- TE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.BDocument13 pagesTE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.Brizwan.zamanPas encore d'évaluation

- JDP Introduction - Rev 3 - 04 Dec 2019Document24 pagesJDP Introduction - Rev 3 - 04 Dec 2019TeatimerobPas encore d'évaluation

- EPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionDocument140 pagesEPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionkrcomeyPas encore d'évaluation

- S-000-5360-005 Rev B Specification For Marking and Color Coding PDFDocument15 pagesS-000-5360-005 Rev B Specification For Marking and Color Coding PDFMidhun K ChandrabosePas encore d'évaluation

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387Pas encore d'évaluation

- Presentasi - Cortec CGIDocument38 pagesPresentasi - Cortec CGImoch ardiansyahPas encore d'évaluation

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- Anti FoamDocument7 pagesAnti FoamMohammad MohseniPas encore d'évaluation

- Pipe Mill Assessment Report 13-08-14-RevADocument10 pagesPipe Mill Assessment Report 13-08-14-RevAAldeline SungahidPas encore d'évaluation

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPDocument17 pagesDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandPas encore d'évaluation

- Technical Specification PDFDocument101 pagesTechnical Specification PDFAsma KhanPas encore d'évaluation

- HEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant OperationDocument8 pagesHEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant Operationrizwan chPas encore d'évaluation

- Saes L 140 PDFDocument13 pagesSaes L 140 PDFsamsurendran_mech4020Pas encore d'évaluation

- Attachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0Document173 pagesAttachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0AliZenatiPas encore d'évaluation

- Internship Report On Process of PPLDocument23 pagesInternship Report On Process of PPLShannPas encore d'évaluation

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFDocument19 pages50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFChemkhiPas encore d'évaluation

- 12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksDocument12 pages12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksIonut FloricaPas encore d'évaluation

- 05.0 Mta-Approval Sheet FormatDocument1 page05.0 Mta-Approval Sheet FormatAswin KurupPas encore d'évaluation

- PNGRB Erdmp RegulationsDocument61 pagesPNGRB Erdmp Regulationsb080480mePas encore d'évaluation

- An Exergy Analysis of Small-Scale Liquefied Natural Gas (LNG)Document15 pagesAn Exergy Analysis of Small-Scale Liquefied Natural Gas (LNG)feraldoPas encore d'évaluation

- Saes A 102Document21 pagesSaes A 102Ziyad ShaathPas encore d'évaluation

- Functional Specification: Eni S.p.ADocument24 pagesFunctional Specification: Eni S.p.AKthiri WaelPas encore d'évaluation

- RT17 Samss 518Document25 pagesRT17 Samss 518ahm3d16n0% (1)

- Syaukani Muhammad AliDocument6 pagesSyaukani Muhammad AlidotcomPas encore d'évaluation

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayPas encore d'évaluation

- Saudi Aramco Engineering Index : A B C D E F G H J L M E Q WDocument3 pagesSaudi Aramco Engineering Index : A B C D E F G H J L M E Q Wkhuram916Pas encore d'évaluation

- DME As Alternative Gas Turbine FuelDocument3 pagesDME As Alternative Gas Turbine FuelJacob RobinsonPas encore d'évaluation

- PHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow DiagramsDocument54 pagesPHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow Diagramsmashari budiPas encore d'évaluation

- Process Gas Compressors: Comprehensive Api 618 Compressor PortfolioDocument20 pagesProcess Gas Compressors: Comprehensive Api 618 Compressor PortfolioaliakbarPas encore d'évaluation

- MD-200 Anticorrosive Hybrid Spray Polyurea Product DescriptionDocument3 pagesMD-200 Anticorrosive Hybrid Spray Polyurea Product DescriptionAliZenatiPas encore d'évaluation

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiPas encore d'évaluation

- IOM-Air CannonDocument16 pagesIOM-Air CannonAliZenatiPas encore d'évaluation

- SBF Tank and Impeller RecommendationDocument4 pagesSBF Tank and Impeller RecommendationAliZenatiPas encore d'évaluation

- Goulds Data Sheets & Performance CurvesDocument7 pagesGoulds Data Sheets & Performance CurvesAliZenatiPas encore d'évaluation

- Spua 351Document3 pagesSpua 351AliZenatiPas encore d'évaluation

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiPas encore d'évaluation

- DATA SHEET FOR PIG RECEIVER - Rev.1Document4 pagesDATA SHEET FOR PIG RECEIVER - Rev.1AliZenati100% (1)

- DATA SHEET FOR MOGAS STORAGE TANK - Rev.0Document6 pagesDATA SHEET FOR MOGAS STORAGE TANK - Rev.0AliZenati100% (1)

- TDS For Spray PolyueraDocument2 pagesTDS For Spray PolyueraAliZenatiPas encore d'évaluation

- Attachment G - Environmental Design Criteria - E352921-00000-200-210-0001 - Rev BDocument13 pagesAttachment G - Environmental Design Criteria - E352921-00000-200-210-0001 - Rev BAliZenatiPas encore d'évaluation

- Sonatrach: Project SpecificationDocument13 pagesSonatrach: Project SpecificationAliZenatiPas encore d'évaluation

- Attachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0Document173 pagesAttachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0AliZenatiPas encore d'évaluation

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Document13 pagesPRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiPas encore d'évaluation

- S 0100 1520 201 - 1 PDFDocument15 pagesS 0100 1520 201 - 1 PDFAliZenati100% (1)

- Attachment N - El Aouj - Execution Schedule - Draft H35921-00000-610-076-002Document4 pagesAttachment N - El Aouj - Execution Schedule - Draft H35921-00000-610-076-002AliZenatiPas encore d'évaluation

- Attachment P - WBS - 100769-0000-TX-WBS-0001 - Rev.CDocument4 pagesAttachment P - WBS - 100769-0000-TX-WBS-0001 - Rev.CAliZenatiPas encore d'évaluation

- Sonatrach: Project SpecificationDocument12 pagesSonatrach: Project SpecificationAliZenati100% (1)

- P4D Paep TM Eppm 0673Document1 pageP4D Paep TM Eppm 0673AliZenatiPas encore d'évaluation

- 2503-01483-MR-042 - Check Valves Rev.a (JTF) PDFDocument1 page2503-01483-MR-042 - Check Valves Rev.a (JTF) PDFAliZenatiPas encore d'évaluation

- Sonatrach: Project SpecificationDocument23 pagesSonatrach: Project SpecificationAliZenatiPas encore d'évaluation

- S-0100-1520-104 - 1 - Manuf Data Record PDFDocument13 pagesS-0100-1520-104 - 1 - Manuf Data Record PDFAliZenati100% (1)

- Typical Loading Arm and Metering Skid Assembly G.A Drawing-1 (For Ref. Only)Document1 pageTypical Loading Arm and Metering Skid Assembly G.A Drawing-1 (For Ref. Only)AliZenatiPas encore d'évaluation

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocument12 pages2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiPas encore d'évaluation

- Typical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)Document1 pageTypical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)AliZenatiPas encore d'évaluation

- Pages de MR-084 BondstrandDocument2 pagesPages de MR-084 BondstrandAliZenatiPas encore d'évaluation

- Fusion4 Portal: Global Experience. Locally AppliedDocument8 pagesFusion4 Portal: Global Experience. Locally AppliedAliZenatiPas encore d'évaluation

- Pages de Scope of SupplyDocument5 pagesPages de Scope of SupplyAliZenatiPas encore d'évaluation

- 13.0 Temperature TransmitterDocument2 pages13.0 Temperature TransmitterAliZenatiPas encore d'évaluation

- Event MCQDocument9 pagesEvent MCQpralay ganguly50% (2)

- Memorandum of AgreementDocument6 pagesMemorandum of AgreementJomar JaymePas encore d'évaluation

- Valery 1178Document22 pagesValery 1178valerybikobo588Pas encore d'évaluation

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDocument5 pagesRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavPas encore d'évaluation

- Good Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaDocument2 pagesGood Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaADBGADPas encore d'évaluation

- Oxford Handbooks Online: From Old To New Developmentalism in Latin AmericaDocument27 pagesOxford Handbooks Online: From Old To New Developmentalism in Latin AmericadiegoPas encore d'évaluation

- List of Newly and Migrated Programs For September 2022 - WebsiteDocument21 pagesList of Newly and Migrated Programs For September 2022 - WebsiteRMG REPAIRPas encore d'évaluation

- FAA PUBLICATIONS May Be Purchased or Downloaded For FreeDocument4 pagesFAA PUBLICATIONS May Be Purchased or Downloaded For FreeFlávio AlibertiPas encore d'évaluation

- Introduction and Instructions: ForewordDocument20 pagesIntroduction and Instructions: ForewordDanang WidoyokoPas encore d'évaluation

- Challan FormDocument2 pagesChallan FormSingh KaramvirPas encore d'évaluation

- HRM Ass1Document3 pagesHRM Ass1asdas asfasfasdPas encore d'évaluation

- Emergency Communication Procedures Communication Equipment Wake TurbulenceDocument38 pagesEmergency Communication Procedures Communication Equipment Wake TurbulenceRaluca StoicaPas encore d'évaluation

- Instrumentation and Control Important Questions and AnswersDocument72 pagesInstrumentation and Control Important Questions and AnswersAjay67% (6)

- HRM Final Ass Apple Human Resource Management AssesmentDocument8 pagesHRM Final Ass Apple Human Resource Management AssesmentAditya Nandi Vardhana100% (1)

- Work Order TemplateDocument2 pagesWork Order TemplateRed DragonPas encore d'évaluation

- Centurion Bank of PunjabDocument7 pagesCenturion Bank of Punjabbaggamraasi1234Pas encore d'évaluation

- Genesis and Development of The Network Arch Consept - NYDocument15 pagesGenesis and Development of The Network Arch Consept - NYVu Phi LongPas encore d'évaluation

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Document18 pagesABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatPas encore d'évaluation

- Sterling PumpeDocument20 pagesSterling PumpesrdzaPas encore d'évaluation

- Hydraulic Breakers in Mining ApplicationDocument28 pagesHydraulic Breakers in Mining ApplicationdrmassterPas encore d'évaluation

- Comprehensive Case 2 - QuestionDocument7 pagesComprehensive Case 2 - QuestionPraveen RoshenPas encore d'évaluation

- What Is Bitcoin MiningDocument4 pagesWhat Is Bitcoin MiningCarmen M Leal CurielPas encore d'évaluation

- MF 660Document7 pagesMF 660Sebastian Vasquez OsorioPas encore d'évaluation

- Tesco 750 ESIDocument2 pagesTesco 750 ESIjlmunozvPas encore d'évaluation

- Tesco Travel Policy BookletDocument64 pagesTesco Travel Policy Bookletuser001hPas encore d'évaluation

- Vehicle Detection and Identification Using YOLO in Image ProcessingDocument6 pagesVehicle Detection and Identification Using YOLO in Image ProcessingIJRASETPublicationsPas encore d'évaluation

- How To Configure VFD - General - Guides & How-Tos - CoreELEC ForumsDocument13 pagesHow To Configure VFD - General - Guides & How-Tos - CoreELEC ForumsJemerald MagtanongPas encore d'évaluation

- Raspberry Pi Installing Noobs OSDocument3 pagesRaspberry Pi Installing Noobs OSEXORCEPas encore d'évaluation

- Modeling Cover Letter No ExperienceDocument7 pagesModeling Cover Letter No Experienceimpalayhf100% (1)

- La Naval Drug Co Vs CA G R No 103200Document2 pagesLa Naval Drug Co Vs CA G R No 103200UE LawPas encore d'évaluation