Académique Documents

Professionnel Documents

Culture Documents

Filterรุ่น NF1000

Transféré par

surasan_thDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Filterรุ่น NF1000

Transféré par

surasan_thDroits d'auteur :

Formats disponibles

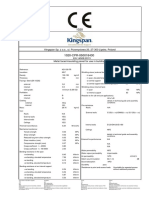

PARTIAL FLOW FILTER Sheet No.

Series NF 1000 DN 50-65 PN 16 1116 J

1. Type index:

1.1. Complete filter: (ordering example)

NF. 1000. 10VG. 10. B. P. -. FS. 3. -. -. AE

1 2 3 4 5 6 7 8 9 10 11 12

1 series:

NF = partial flow filter

2 nominal size: 1000

3 filter-material and filter-fineness:

25 VG= 20 µm(c), 16 VG = 15 µm(c), 10 VG = 10 µm(c),

6 VG = 7 µm(c), 3 VG = 5 µm(c) Interpor fleece (glass fibre)

10 WVG = 10 µm(c), 3 WVG = 5 µm(c) Watersorp-filter element

4 resistance of pressure difference for filter element:

10 = ∆p 10 bar

5 filter element design:

B = both sides open

6 sealing material:

P = Nitrile (NBR)

V = Viton (FPM)

7 filter element specification: (see catalog)

- = standard

VA = stainless steel

IS06 = see sheet-no. 31601

8 connection:

FS = SAE-flange connection 3000 PSI

9 no. of version:

connection

version A B C

connection connection connection

size size size

1 8 8 -

2 8 8 8

3 9 9 -

4 9 9 9

connection size: 8 = 2“

9 = 2 ½“

- = without connection

10 filter housing specification: (see catalog)

- = standard

IS06 = see sheet-no. 31605

11 internal valve:

- = without

S1 = with by-pass valve ∆p 3,5 bar

12 clogging indicator or clogging sensor :

- = without

OP = visual, see sheet-no. 1628

OE = visual-electrical, see sheet-no. 1628

AE = visual-electrical, see sheet-no. 1609

VS1 = electrical, see sheet-no. 1607

VS2 = electrical, see sheet-no. 1608

1.2. Filter element: (ordering example)

01NR. 1000. 10VG. 10. B. P. -

1 2 3 4 5 6 7

1 series:

M2, p1 = measure connection dirt side 01NR. = standard return line filter element according to DIN 24550, T4

M2, p2 = measure connection clean side 2 nominal size: 1000

E1 = aie bleeding dirt side 3 - 7 see type index-complete filter

E2 = drain dirt side

E3 = drain clean side 2. Accessories:

- measure- and bleeder connection, see sheet-no. 1650

- evacuation- and bleeder-connections, see sheet-no. 1651

- counter flange, see sheet-no. 1652

weight : approx. 23 kg

EDV 10/09 Changes of measures and design are subject to alteration!

Friedensstrasse 41, 68804 Altlussheim, Germany

phone +49 - (0)6205 - 2094-0 e-mail sales@internormen.com

fax +49 - (0)6205 - 2094-40 url www.internormen.com

3. Spare parts:

item qty. designation dimension article-no.

1 1 filter element 01NR. 1000

2 1 filter cover without by-pass valve 31065-3

1 filter cover with by-pass valve S1 31461-3

3 1 mini-measuring connection MA.3.St 308630

4 3 screw plug G½ 304678

5 1 O-ring (only with by-pass valve) 22 x 3 304387 (NBR) 304931 (FPM)

6 1 O-ring 170 x 6 304799 (NBR) 306529 (FPM)

7 2 O-ring 90 x 4 306941(NBR) 307031(FPM)

8 1 O-ring 22 x 3 304387(NBR) 304931(FPM)

9 1 clogging indicator, visual OP see sheet-no. 1628

10 1 clogging indicator, visual-electrical OE see sheet-no. 1628

11 1 clogging indicator, visual-electrical AE see sheet-no. 1609

12 1 clogging sensor, electronical VS1 see sheet-no. 1607

13 1 clogging sensor, electronical VS2 see sheet-no. 1608

14 2 O-ring 14 x 2 304342 (NBR) 304722 (FPM)

15 2 screw plug G 1/8 304791

16 1 screw plug G 1/8 305496

17 1 O-ring 183 x 4 337005 (NBR) 337006 (FPM)

item 15 execution only without clogging indicator or clogging sensor

4. Description:

The partial flow filter NF is foreseen for the fine filtration of hydraulic and lubrication circuits additionally to the main filter.

The big filtration area in comparison to the nominal size is the premise for a high dirt-retaining capacity even in case of small filter-

fineness.

Filter elements as fine as 5 µm (c) are available; finer filter elements on request.

To protect the filter elements and the filter housing equipment with by-pass valves is foreseen. Element change without tools is

possible. After release of the straining screw and removal of the cover the elements are accessible and could be changed. The filter

elements were delivered completely inclusive seals. Cleaning of the elements not possible therefore the user should have enough

spare elements on stock.

5. Technical data:

temperature range: - 10°C to + 80°C (for a short time + 100 °C)

operating medium: mineral oil, other media on request

max. operating pressure: 16 bar

test pressure: 23 bar

connection: SAE-flange connection 3000 PSI

housing material: aluminium forging alloy

sealing material: Nitrile (NBR) or Viton (FPM), other materials on request

installation-position: vertical

measure connection: G¼

evacuation -or bleeder connection: G½

volume tank: 11,4 l

Classified under the Pressure Equipment Directive 97/23/EC for mineral oil (fluid group 2), Article 3, Para. 3.

Classified under ATEX Directive 94/9/EC according to specific application (see questionnaire sheet-no. 34279-4).

6. Symbols:

filter without indicator with electrical with visual-electrical with visual-electrical with visual with visual-electrical with electronical with electronical

and without indicator indicator indicator indicator indicator clogging sensor clogging sensor

internal valve AE 30 and AE 40 AE 50 and AE 62 AE 70 and AE 80 OP OE VS1 VS1

filter with

by-pass valve

7. Pressure drop flow curves: Precise flow rates see ‘INT-Expert-System Filter’, respectively ∆p-curves; depending

on filter fineness and viscosity.

8. Test methods: Filter elements are tested according to the following ISO standards:

ISO 2941 Verification of collapse/burst resistance

ISO 2942 Verification of fabrication integrity

ISO 2943 Verification of material compatibility with fluids

ISO 3723 Method for end load test

ISO 3724 Verification of flow fatigue characteristics

ISO 3968 Evaluation of pressure drop versus flow characteristics

ISO 16889 Multi-pass method for evaluating filtration performance

E 1116 J

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Bridge NotesDocument32 pagesBridge NotesJaydee100% (1)

- Unit 2 Electrical InstrumentDocument45 pagesUnit 2 Electrical InstrumentBoopathy C P100% (1)

- Lesson 13 Algebraic CurvesDocument21 pagesLesson 13 Algebraic CurvesNiño Jhim AndrewPas encore d'évaluation

- Solutions Manual To Introduction To Continuum Mechanics: Second EditionDocument247 pagesSolutions Manual To Introduction To Continuum Mechanics: Second EditionRaj Pratyush80% (5)

- QOSDocument40 pagesQOSravindraPas encore d'évaluation

- C 14Document26 pagesC 14pfylPas encore d'évaluation

- Runway DesignDocument44 pagesRunway DesignAnonymous 0pzPb3q100% (1)

- Lecture4 Static and Dynamic Fluid PDFDocument13 pagesLecture4 Static and Dynamic Fluid PDFRudi BerlianPas encore d'évaluation

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Document1 pageA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboPas encore d'évaluation

- Chapter 4 - Drains and SwalesDocument23 pagesChapter 4 - Drains and SwalesFadhlullah Abu Bakar100% (1)

- MAG8000 Manual PDFDocument137 pagesMAG8000 Manual PDFHanks EpphPas encore d'évaluation

- The Core-Periphery Model With Three Regions and MoreDocument25 pagesThe Core-Periphery Model With Three Regions and MoreJomit C PPas encore d'évaluation

- Pushin Fitting PDFDocument4 pagesPushin Fitting PDFvishal.nithamPas encore d'évaluation

- Peda Office Complex: Study ByDocument12 pagesPeda Office Complex: Study ByRiya RajPas encore d'évaluation

- MH1811 Tutorial 1 Diff Eqns 1 2018Document2 pagesMH1811 Tutorial 1 Diff Eqns 1 2018Monisha DasarathanPas encore d'évaluation

- Incubator ReportDocument26 pagesIncubator ReportxiastellaPas encore d'évaluation

- Autoeng Advising Document Fall 2013 Entry or EarlierDocument11 pagesAutoeng Advising Document Fall 2013 Entry or Earlieranonimus19Pas encore d'évaluation

- Catalog PlasfabDocument8 pagesCatalog PlasfabDeep ZaveriPas encore d'évaluation

- Diseño Cercha Metalica Tipo I VerificadoDocument36 pagesDiseño Cercha Metalica Tipo I VerificadoJosé Mario Blacutt AléPas encore d'évaluation

- Homework 07 ProblemsDocument6 pagesHomework 07 ProblemsBrianna ChapaPas encore d'évaluation

- Airspeed Indicator - Wikipedia, The Free EncyclopediaDocument6 pagesAirspeed Indicator - Wikipedia, The Free EncyclopediaAnand TRPas encore d'évaluation

- What Is An Electrical Switch?Document6 pagesWhat Is An Electrical Switch?Aeylla ZeorainePas encore d'évaluation

- NFC 33-209Document2 pagesNFC 33-209shivam dwivedi0% (1)

- LogiComm Pattern ControlDocument2 pagesLogiComm Pattern ControlNordson Adhesive Dispensing SystemsPas encore d'évaluation

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- Structural Analysis and Design of Commercial Building: Supervised byDocument43 pagesStructural Analysis and Design of Commercial Building: Supervised bySudip ShresthaPas encore d'évaluation

- MSQE Program: With Tracks in Economics, Finance, and MarketingDocument20 pagesMSQE Program: With Tracks in Economics, Finance, and MarketingSimone MarrettaPas encore d'évaluation

- Radiation Dose Limits: Appendix BDocument6 pagesRadiation Dose Limits: Appendix BVaradha RajanPas encore d'évaluation

- Year 6 - EclipsesDocument7 pagesYear 6 - EclipsesHani BakarPas encore d'évaluation

- Midterm Exam Fall 2012Document5 pagesMidterm Exam Fall 2012Asanka RodrigoPas encore d'évaluation