Académique Documents

Professionnel Documents

Culture Documents

Biogas Energy and Sanitation Provision in South Africa

Transféré par

Amr HassanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Biogas Energy and Sanitation Provision in South Africa

Transféré par

Amr HassanDroits d'auteur :

Formats disponibles

Biogas energy and sanitation provision in South Africa http://www.esi-africa.com/last/ESI_1_2003/031_26.

htm

Home Editorial Calendar $,£, Euro Rates Magazine Archive Subscribe to ESI Africa

Distribution Events eNews About Us Contact Us

Biogas energy and sanitation provision in South Africa

By Greg Austin, Director, Biogas Technology Africa

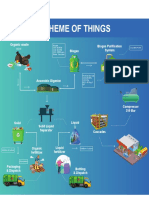

Biogas is a low cost form of energy derived from renewable resources: animal dung and human waste. In

developing countries such as China, India and Nepal, biogas has been used widely as a source of energy and

as liquid fertiliser for soil enhancement, since the 1950s. A biogas digester, in which the biogas is produced, also

provides an ideal on-site wet sanitation system.

In this article we look at how biogas is manufactured, consider the advantages of this form of appropriate

technology, and examine the potential of the technology as an alternative energy supply for rural households and

institutions such as schools. We also look at two biogas projects that have been piloted in the Ndwedwe District

of KwaZulu-Natal, one at household level and the other at school level.

Biogas digesters and their functioning

Biodigesters are airtight containers in which water, animal wastes and/or faeces are acted upon by anaerobic

bacteria. The three most common and successful designs are the fixed dome, the floating drum and the plastic

covered ditch types. Biogas is formed by bacterial action on the plant or animal matter: the organic material is

hydrolysed, from which organic acids are produced, leading to methane gas production. Biogas should not be

confused with other forms of combustible gases produced from biomass e.g. producer gas or wood gas.

Biogas consists of methane (CH4) 55-65% and carbon dioxide (CO2)

35-45%, with the balance being made up of nitrogen (N2), hydrogen (H2)

and hydrogen sulphide (H2S). The second product is a digested effluent

with between 60 and 80% reduction of the biological oxygen demand

(BOD) compared with the input material. Biogas is about 20 percent lighter

than air and has an ignition temperature in the range of 650 to 750º C. It is

an odourless and colourless gas that burns with a blue flame similar to that

of liquefied petroleum gas (LPG).

Factors affecting biogas production and the composition of biogas include the carbon/nitrogen ratio (optimum

level is around 25 to 1), the pH (6.5 – 7), while the loading rate, temperature and retention time in the digester all

also affect gas output. The optimum temperature is 36º C.

These factors are not mutually exclusive, but rather act in concert. Thus an increase in temperature will allow a

shorter retention time or an increased loading rate. Typically, though, one might expect a range in biogas

production of between 1,000 and 1,600 litres per 4,000 litres of digester volume per day. One thousand litres of

biogas will provide a cooking time of 2 hours, or 1.5 kWh electrical output.

Advantages of biogas technology

Biogas is an important form of renewable energy, which can be used

where organic waste is produced in appropriate quantities. It can make an

important contribution to the protection and improvement of natural

resources and environment. Slurry, a residue from the process, is a

high-grade fertilizer which can replace expensive mineral fertilizers, in

particular nitrogen. The technology also provides an efficient sanitary

system, that enhances effective waste product disposal.

The use of biogas also enables women, especially in rural areas, to save time for productive agriculture, leisure

and family care and welfare. It also improves the standard of living and can directly contribute to economic and

social development of a country.

Recent case studies in South Africa

Two pilot biogas digesters have been installed in the Ndwedwe District outside Durban. One is a residential

system with a volume of 9.5 m3 that was commissioned in November 2000. This digester takes input from a

toilet and dung from three cows that are kraaled overnight. The digester generates in the region of 3 m3 of

biogas each day, enough to cook for the family of eight. Of particular interest is the integration of the digester

1 van 3 30/01/2007 21:52

Biogas energy and sanitation provision in South Africa http://www.esi-africa.com/last/ESI_1_2003/031_26.htm

within the household, since all food and water wastes (viz. grey water) are directed through the biogas plant. It is

a common misperception that access to water is a constraint on the application of biogas technology at the

household level. Since each family uses water every day, this same water can easily be directed to the biogas

digester. The levelised cost of this system is equal to the cost of LPG, without taking externalities or biogas

benefits into account.

The second system is at a school with 1,000 learners. It is comprised of two 20 m3 digesters, each fed from an

eight-toilet block. Additional gas is generated through the addition of cow dung through separate inlet chambers.

This system produces around 16 m3 of biogas each day. The gas has dual end uses: cooking in the domestic

science classroom by means of modified gas stoves, and running a modified 5 HP diesel engine which in turn

drives a 2 kW AC generator. The biogas is sufficient to cook on four gas plates for eight hours per day, or to run

the generator for eight hours each day. The diesel engine operates as a duel-fuel system, since the biogas

replaces about 85% of the diesel that would otherwise be normally used. The unit energy costs over a 15-year

lifecycle are lower than solar electrification, and can be markedly cheaper than grid power should the grid have

to be extended to a particular end-use point. A biogas plant also does not suffer from the security risks faced by

a solar installation.

Biogas technology’s potential in SA

At the household level, extrapolating the data for rural KwaZulu-Natal to the rest of South Africa indicates

conservatively that over 400,000 households could make use of the technology. This is based purely on those

families with two or more cows, and without electricity.

Minister of education Kader Asmal told parliament in 2001 that 45% of schools in South Africa have no

electricity, 27% lack clean water, 66% have inadequate sanitation, and 12% have no sanitation at all. These

statistics have bearing on the over 16,000 rural schools in South Africa currently without power, many thousands

of which will not get grid power in the foreseeable future.

Low-cost housing developments also provide an opportunity. It is easy to visualise a peri-urban, or rural, housing

development where sewer lines are fed directly to a biogas plant. By adding a purpose-built effluent purification

plant (which derives its power from the biogas itself) to the digester’s output means that clear water can be

recycled to the toilets. In this way about 90% of the total black water is continuously recycled. Development of

such a system is already at an advanced stage.

Other opportunities exist in the cattle and livestock industry, a market that is being increasingly tapped in Europe,

USA and Australia. In South Africa, there is a potential energy output from dairy farms and beef cattle feedlots in

the order of 3.9 GWh per year. A biogas energy plant also solves the dung disposal problem faced by these

farms and feedlots.

There are rural and peri-urban orphanages and clinics that do not have any sanitation in place. For the former

the biogas provides the opportunity for a self-feeding scheme; for the latter, the energy can be used for

sterilisation.

Developing the technology

Of all the national biogas programs instituted to date, Nepal’s probably has

had the best results. It is therefore instructive to look at some of the

reasons behind their successes. A well-proven and reliable fixed dome

biogas plant design, and biogas appliances, have been introduced

following several years of research and development of the technology.

This was accompanied by a national survey to assess the potential of and

demand for biogas in the country. Nationally, an ongoing program of

promotion and awareness activities were carried out at different levels.

Financial and cost benefit analyses of the technology have been performed, resulting in continuous subsidies

being provided through various banks. As with other technologies affordability remains the biggest barrier to

wider biogas dissemination in rural areas, and it is felt that once a successful programme is under way that

subsidies should give way to a purely market-driven industry.

Technical capacities were also properly examined, with resultant widespread local mason training. In addition,

biogas plant construction is followed by quality control visits in order to ensure a high standard. Excellent user

support has been gained by good organisational networking through, for example, biogas and slurry

co-ordination committees. A slurry extension programme has been introduced, and an association of all biogas

construction companies has been formed for the promotion and extension of biogas. These companies now

number 39.

Finally, and most importantly, the technology has generated

employment in rural areas, since all the construction companies use

locally sourced labour. The industry has created 2,000 permanent

mason jobs (with 500 entering it each year) and around 500

working in the biogas appliance industry.

From the South African perspective, we can learn from the Indian,

Chinese and Nepalese programs, with offers already having been

made of bilateral governmental assistance in setting up such a programme here. We have both the natural and

human resources to develop the technology, and perhaps the recent move by government in meeting targets for

renewables over the next 10 years will see us starting a national biogas dissemination programme in the not too

2 van 3 30/01/2007 21:52

Biogas energy and sanitation provision in South Africa http://www.esi-africa.com/last/ESI_1_2003/031_26.htm

distant future.

Based on a presentation at the CARENSA-SPARKNET-LAMNET joint workshop 2002.

Résumé

Le biogaz est une forme d’énergie à faible coût, dérivée de source d’énergie renouvelable :

les excréments animaux et humains. Dans les pays en voie de développement comme la

Chine, l’Inde et le Népal, le biogaz a largement été utilisé comme une source d’énergie et en

tant que fertilisant liquide pour les champs depuis les années 50.

Le biogaz consiste de 55 à 65% de méthane (CH4) et de 35% à 45% de dioxyde de carbone

(CO2), le reste est composé de nitrogène (N2), d’hydrogène (H2) et de sulphide

d’hydrogène (H2S). C’est un gaz sans odeur ni couleur qui brûle avec une flamme bleue

similaire à celle du gaz de pétrole liquéfié (GPL).

Deux digesteurs de biogaz au stade experimental ont été installés dans la région de

Ndwedwe, près de Durban. L’un d’eux est un système résidentiel d’un volume de 9,5m? qui

est alimenté par les toilettes et par les excréments de trois vaches gardées en enclos durant

la nuit. Ce digesteur produit environ 3m? de biogaz par jour, assez pour cuisiner pour une

famille de huit personnes. Il est particulièrement intéressant de considérer un digesteur au

sein même du ménage car tous les déchets alimentaires et les eaux usées partent vers

l’usine biogaz.

Le deuxième système se trouve dans une école de 1000 étudiants. Il comprend 2 digesteurs

de 20 m?, chacun est alimenté par un bloc sanitaire de 8 toilettes. En supplément, du gaz est

produit à partir d’excréments de vache alimentés dans la machine par un compartiment

séparé. Ce système produit environ 16m? de biogaz par jour. Le gaz est utilisé de deux

façons : pour les cours culinaires avec des fourneaux à gaz modifiés et pour faire marcher

un générateur à courant alterné de 2kW. Le biogaz est suffisant pour faire marcher le

générateur ou pour cuisiner sur quatre plaques chauffantes pendant huit heures par jour.

Sur une durée de vie de plus de 15 ans, le coût de cette machine productrice d’énergie est

moins élevé que le coût de l’électrification solaire et certainement beaucoup moins cher que

le réseau électrique s’il devait être étendu à un utilisateur isolé.

Le potentiel du biogaz est très important. En Afrique du Sud par exemple, quand les données

du KwaZulu-Natal rural sont extrapolées par rapport au reste du pays, elles indiquent de

manière conventionnelle que 400 000 ménages pourraient utiliser cette technologie. De plus,

plus de 16 000 écoles rurales en Afrique du Sud n’ont pas d’électricité et beaucoup

manquent d’eau courante ainsi que de sanitaires adéquates.

© 2003 Copyright Spintelligent (Pty) Ltd

For more information on this article, please mail: jonathan@spintelligent.com

Include your contact details and quote the article reference: ESI12003_031 page 26_1 in

the subject line.

3 van 3 30/01/2007 21:52

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- 1 Biodigester DesignDocument9 pages1 Biodigester DesignJhe Inibam100% (2)

- The Treatment of Brewery Wastewater For Reuse State of The ArtDocument13 pagesThe Treatment of Brewery Wastewater For Reuse State of The ArtWaheed Miran100% (1)

- ChemicalEngineering Che December-2023Document44 pagesChemicalEngineering Che December-2023Antonio Mungioli100% (1)

- Bio Digest orDocument31 pagesBio Digest orAxl EmmanuellePas encore d'évaluation

- Solid Waste Management NepalDocument12 pagesSolid Waste Management NepalAnish GhimirePas encore d'évaluation

- Microproject Part-A: Analysis of Waste Management in IndustryDocument16 pagesMicroproject Part-A: Analysis of Waste Management in Industrybhagyashrimunde86Pas encore d'évaluation

- Capstone DocsDocument2 pagesCapstone DocsIoan TodorPas encore d'évaluation

- Olive Mill Wastewater Treatment and Valorization Technologies-ConvertiDocument29 pagesOlive Mill Wastewater Treatment and Valorization Technologies-ConvertiYoussef KamounPas encore d'évaluation

- Bai Tap Unit 11 Travelling in The Future Tieng Anh 7Document6 pagesBai Tap Unit 11 Travelling in The Future Tieng Anh 7Hương Giang ĐồngPas encore d'évaluation

- CBG Flow Chart & MachineryDocument4 pagesCBG Flow Chart & MachineryNikhil sakharePas encore d'évaluation

- 3-EC. Renewable Energy ResourcesDocument13 pages3-EC. Renewable Energy Resourcessathish0% (1)

- DOSIWAM System Developed by Dr.S.V.Mapuskar.Document50 pagesDOSIWAM System Developed by Dr.S.V.Mapuskar.svmapuskar4914100% (3)

- Lecture 3 - Biochemical Conversion of BiofuelsDocument43 pagesLecture 3 - Biochemical Conversion of BiofuelsIhsan MohamedPas encore d'évaluation

- Automated Waste SegregatorDocument3 pagesAutomated Waste SegregatorEditor IJTSRDPas encore d'évaluation

- Biogas Technology Suppliers Directory 2017: Company Comments Country WEBDocument5 pagesBiogas Technology Suppliers Directory 2017: Company Comments Country WEBGeorge SheytanovPas encore d'évaluation

- Đề Kiểm Tra Chất Lượng Học Kì Ii-Đề Đề Xuất Part A. ListeningDocument7 pagesĐề Kiểm Tra Chất Lượng Học Kì Ii-Đề Đề Xuất Part A. ListeningBii HeePas encore d'évaluation

- En Installation&Piping Manual 2.6 PRINTDocument23 pagesEn Installation&Piping Manual 2.6 PRINTSuril PanneerselvamPas encore d'évaluation

- Perhitungan Anaerobik Digester, Floating Dome, Fixed DomeDocument51 pagesPerhitungan Anaerobik Digester, Floating Dome, Fixed DomesehonoPas encore d'évaluation

- KEF LATAC 2023 - 16th MarchDocument76 pagesKEF LATAC 2023 - 16th MarchMunguntsetseg GanboldPas encore d'évaluation

- Biogas From BiomassDocument32 pagesBiogas From Biomassahmad fauziPas encore d'évaluation

- 1 s2.0 S0048969720311049 MainDocument8 pages1 s2.0 S0048969720311049 MainfsaadatinavazPas encore d'évaluation

- Solid Waste ManagementDocument15 pagesSolid Waste ManagementmaaahiiPas encore d'évaluation

- AnkurScientific BiomasstoEnergyDocument43 pagesAnkurScientific BiomasstoEnergyMarceloPas encore d'évaluation

- Gas Flowmeters PDFDocument1 pageGas Flowmeters PDFManufacturer VerifyPas encore d'évaluation

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocument23 pagesMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPPas encore d'évaluation

- Community Based Biogas Consultation SrilankaDocument30 pagesCommunity Based Biogas Consultation SrilankaPradeep EhanPas encore d'évaluation

- Md. Fazley Rabbi - Growing Rural Economy Through Solar PowerDocument9 pagesMd. Fazley Rabbi - Growing Rural Economy Through Solar PowerAsia Clean Energy ForumPas encore d'évaluation

- Takele UmaDocument50 pagesTakele UmazigaPas encore d'évaluation

- Phenomenal Bombardment of Antibiotic in Poultry: Contemplating The Environmental RepercussionsDocument15 pagesPhenomenal Bombardment of Antibiotic in Poultry: Contemplating The Environmental RepercussionsCrislyn Akilit BayawaPas encore d'évaluation