Académique Documents

Professionnel Documents

Culture Documents

Jen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial Manual

Transféré par

আফজাল -উল ইসলাম নূরTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial Manual

Transféré par

আফজাল -উল ইসলাম নূরDroits d'auteur :

Formats disponibles

JEN. 2 PACK PU ENAMEL JEN.

2 PACK PU ENAMEL

DESCRIPTION: Jen. PU Enamel is an Acrylic PU coating which provides a durable finish for chemical and saline coastal OLD CONCRETE: Remove all salt deposits from the surface by water jet washing. Light sand blast the surface to remove all

environments. It has excellent color and gloss retention properties. When fully cured it forms an extremely tough and high loosely bound coatings and roughing up of firmly adhering coatings to ensure anchorage with recommended system. Ensure

abrasion resistance finish. It possesses high gloss and is suitable for both exterior and interior structure. The product has a all dust or other particles are fully removed by suction or air blast and the surface are fully cleaned and dry before application

proven record of aesthetic retention ability in various environments including high humidity and salinity for prolonged periods. of paint. In non critical area where blasting is not possible, water jet washing and hard wire brushing are minimum requisites.

The product is compatible with Epoxy and PU Undercoats.

CONDITION DURING APPLICATION:

USES: Recommended for use in new construction and maintenance services as an effective top coat over properly primed 1. Use the mixed paint within the stipulated pot life period.

surfaces. This is suitable for use in refineries, petrochemical, fertilizer, chemicals, cement industries, cargo tankers, railway

2. Do not apply at temperature below 10ºC or at relative humidity above 80% or when the surface is less than 5ºC above the dew point.

coach exterior, bus or coach bodies, industrial infrastructure, power plants and other industrial installations where color and

gloss retention is of prime importance. 3. Adequate ventilation is required in confined areas to ensure proper drying of the paint. Coating should not be exposed

to oil, chemicals or mechanical stress until cured.

PRODUCT DATA RESISTANCE GUIDE

4. The primer coat should be applied within the shortest possible delay i.e. a few hours after surface preparation to

Composition: 2 Pack, Cured with aliphatic Isocyanate Chemical Resistance: prevent the premature corrosion or contamination by impurities from the air (dust, salts, sulphur di oxide etc.).

Mixing Ratio = Base: Catalyst = 3:1 by volume for Glossy Finish Exposures Splash & Mild Fumes/ 5. Clean all equipment with Jen. Thinner T-8 immediately after use; otherwise equipment is likely to be damaged/clogged.

5:1 by volume for Matt finish Spillage Outdoor 6. Freshly mixed materials must not be added to material that has been mixed for some time.

Pot Life: 3 - 4 hours Resistance

APPLICATION METHODS:

VOC: 280 – 350 g/L Acids Good Very Good

Alkali Good Very Good Stir the base thoroughly and then mix with catalyst in equal proportions to uniform consistency. Allow the mixture to mature for

Flash Point: above 220C 30 minutes and stir again before application and occasionally during use.

Solvents Good Good

Recommended DFT (µm/ Coat): 40 - 50 microns

Salt Excellent Excellent Brush & Roller: Apply preferably without thinning. However up to 10 - 20% Thinner T-8 may be added if absolutely essential

Corresponding WFT (µm/ Coat): 80 - 100 microns depending on conditions.

Fresh Water Excellent Excellent

Theoretical Spreading Rate: 120 ± 10 sft/Ltr Airless Spray: Apply preferably without thinning. However, up to 5 - 10% Thinner T-8 may be added if absolutely essential, depending

Thinner: Jen. Thinner T-8 on conditions. Use any standard equipment having pump ratio 30: 1; Tip Size 0.43 - 0.48 mm; Tip pressure 110 - 160 Kg/cm2

Temperature Resistance:

Rate of Thinning: (Min – Max): 5% - 20% Continuous (Dry): 93ºC TYPICAL PAINTING SPECIFICATIONS:

Drying Time: It is related to air circulation, temperature, film thickness Intermittent : 120ºC

Surface 1st Coat 2nd Coat 3rd Coat 4th Coat

and number of coats and would be affected accordingly. Weatherability: Excellent with suitable undercoat Steel Zinc Anode 304 or Epilux Zinc Epilux 4 HB MIO Jen. PU Enamel Jen. PU Enamel

➢ Good ventilation (Free circulation of air)

Flexibility: Excellent Rich Primer Epilux 4 MIO (Optional)

➢ Typical paint film thickness

Touch : 1 hours Epilux 610 Primer or Epilux 4 Epilux 4 HB MIO Jen. PU Enamel -

Abrasion Resistance: Excellent

Handle : 6 - 8 hours Zinc Phosphate Primer Epilux 4 MIO Jen. PU Enamel Jen. PU Enamel (Optional)

Hard : Overnight Protectomastic Epilux 4 HB MIO Jen. PU Enamel -

Epilux 4 MIO Jen. PU Enamel Jen. PU Enamel (Optional)

Curing Time: 7 days

Concrete and plastic Epilux 4 clear Lacquer or Jen. PU Enamel Jen. PU Enamel -

Overcoating Interval: Min: Overnight Max: 5 days surfaces Protectomastic

Color: Assorted Shades Galvanized iron Degrease and abrade the surface. Apply a coat of wash primer followed by any of the above system

Finish: Matt/ Semi Glossy/ Glossy & Aluminium excluding primer coat.

Shelf Life: Up to 12 months as long as the sealed containers STORAGE: Store under cover in a well-ventilated area away from the source of heat or ignition. Keep the containers closed

are kept covered in a dry place at room temperature when not in use.

SURFACE PREPARATION HANDLING: As with any chemical, ingestion, inhalation and prolonged or repeated skin contact should be avoided by good

Steel: Remove grease, oil and other contaminants preferably by using Rust Bluster or Jen. T-8 solvent. Blast clean to a occupational work practice. Eye protection should be provided if there are possibilities of splash entering the eyes.

minimum of SA 2½ Swedish Standard SIS 05 5900 with a surface profile not exceeding 30-40 microns. If blasting is not HEALTH & SAFETY: Use with good ventilation and avoid inhalation of spray mists and fumes. While spraying, users should

possible, make full use of mechanical tools along with manual chipping and wire brushing to remove loose rust and scale to St. comply with Spray Painting Regulations. This product is flammable. All sources of ignition must be eliminated in, or near the

2 Swedish standard SIS 05 5900. Excessive burnishing of steel should be avoided. Thoroughly dust down all surfaces. Best working area. Fight fire with foam, CO2, dry chemical powder.

result can be achieved if the manually cleaned surface is primed with Protectomastic- self priming surface tolerant coating. The

CAUTION! Keep away from heat and open flame. Avoid prolonged contact with skin and breathing of vapor or spray mist. Do

surface should be clean and dry before application of appropriate primer coat.

not inhale. Close container after each use. KEEP OUT OF REACH OF CHILDREN.

Concrete:

DISCLAIMER: The information given herein is to the best of our knowledge. However, no guarantee of results is implied

NEW CONCRETE: Ensure that concrete is cured for a minimum of three months. The surface is to be made rough and free

since conditions of use are beyond Berger’s control. Berger Paints shall not be liable for any consequential loss or damage

from laitance and other contaminants by sand sweeping.

arising out of such uses.

76 BERGER INDUSTRIAL MANUAL BERGER INDUSTRIAL MANUAL

77

Vous aimerez peut-être aussi

- Test Report (Primer Coating)Document1 pageTest Report (Primer Coating)Kish Shan S SubediPas encore d'évaluation

- Sikaproof Membrane: Safety Data SheetDocument6 pagesSikaproof Membrane: Safety Data SheetSamuel CastilloPas encore d'évaluation

- PUF - Voracor CD 1786 Polyol With CD345 TDS PDFDocument2 pagesPUF - Voracor CD 1786 Polyol With CD345 TDS PDFRajendra Kumar SharmaPas encore d'évaluation

- MasterSeal 380 TDSDocument2 pagesMasterSeal 380 TDSEngTamerPas encore d'évaluation

- Ti e Protegol 32-55 H Nov 07Document3 pagesTi e Protegol 32-55 H Nov 07A MahmoodPas encore d'évaluation

- Ti e Protegol 32-47 R Jan 08Document3 pagesTi e Protegol 32-47 R Jan 08A MahmoodPas encore d'évaluation

- SoniCell ASTM E85 Fire TestDocument10 pagesSoniCell ASTM E85 Fire TestAvs CrPas encore d'évaluation

- Paint Calculation: Factor To Consider AreDocument1 pagePaint Calculation: Factor To Consider AreKalyanasundaram ThirugnanasambandamPas encore d'évaluation

- PC-7320 (Polypoxy) - TDSDocument2 pagesPC-7320 (Polypoxy) - TDSedwin cPas encore d'évaluation

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتPas encore d'évaluation

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.Pas encore d'évaluation

- Appendix 3 - Technical Data For Jotun Coat System 1aDocument12 pagesAppendix 3 - Technical Data For Jotun Coat System 1aMohd Azizul AzamPas encore d'évaluation

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoPas encore d'évaluation

- Paint Data Sheet - National Synthetic Enamel Gloss IDocument3 pagesPaint Data Sheet - National Synthetic Enamel Gloss Iaakh0% (1)

- NYPC Leveling Test BladeDocument1 pageNYPC Leveling Test BladecaronieblesPas encore d'évaluation

- Hardtop AX: Technical Data Sheet Application GuideDocument7 pagesHardtop AX: Technical Data Sheet Application GuideTrịnh Minh KhoaPas encore d'évaluation

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFSohail Tisekar100% (1)

- Nitocote PE135 : Constructive SolutionsDocument2 pagesNitocote PE135 : Constructive SolutionsMPS KALIBARUPas encore d'évaluation

- Paint ApplicationDocument4 pagesPaint ApplicationSteven FlynnPas encore d'évaluation

- Non-Destructive Testing of ConcreteDocument29 pagesNon-Destructive Testing of ConcreteNagha RamasamyPas encore d'évaluation

- (PDS) Nitoproof RS (Green Label)Document3 pages(PDS) Nitoproof RS (Green Label)Hendra WahyuPas encore d'évaluation

- Uvasorb® HA-88FDDocument2 pagesUvasorb® HA-88FDXuân Giang NguyễnPas encore d'évaluation

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- Atactic Polypropylene (APP) Modified Bituminous Sheet Materials Using A Combination of Polyester and Glass Fiber ReinforcementsDocument3 pagesAtactic Polypropylene (APP) Modified Bituminous Sheet Materials Using A Combination of Polyester and Glass Fiber ReinforcementsKevin JosuePas encore d'évaluation

- Epoxy Bonding AgentDocument2 pagesEpoxy Bonding AgentbarunPas encore d'évaluation

- Methodology (Anti Termite Treatment Pre Con)Document3 pagesMethodology (Anti Termite Treatment Pre Con)Rohit MallaiyaPas encore d'évaluation

- Product Data Sheet: Hempafloor Durable 300Document2 pagesProduct Data Sheet: Hempafloor Durable 300Fadi MagdyPas encore d'évaluation

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocument2 pagesAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerPas encore d'évaluation

- FM Approval Requirements For DI PipeDocument25 pagesFM Approval Requirements For DI Pipemmkamran1017Pas encore d'évaluation

- Cover BlockDocument6 pagesCover BlockRandhvir KharatmolPas encore d'évaluation

- Jotun Pioner Topcoat Application Guide - AcrylicDocument6 pagesJotun Pioner Topcoat Application Guide - AcrylicChaerul AnwarPas encore d'évaluation

- Brushbond TI Flexicoat PDFDocument3 pagesBrushbond TI Flexicoat PDFbalab2311Pas encore d'évaluation

- Astm D4445 10Document5 pagesAstm D4445 10Cristian Castillo0% (1)

- Stiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestDocument11 pagesStiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestCristian DíazPas encore d'évaluation

- DR Fixit FastflexDocument3 pagesDR Fixit FastflexsubhaschandraPas encore d'évaluation

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadPas encore d'évaluation

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoPas encore d'évaluation

- Jotun Penguard Midcoat MIO Application GuideDocument8 pagesJotun Penguard Midcoat MIO Application GuideSANKARAN.KPas encore d'évaluation

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqPas encore d'évaluation

- Apcosil - PC 2568Document3 pagesApcosil - PC 2568Naren SudarsanPas encore d'évaluation

- Pioneer Pro Water Tite 102 Technical Spec SheetDocument2 pagesPioneer Pro Water Tite 102 Technical Spec SheetGerald Ordoñez Delos ReyesPas encore d'évaluation

- Al Jazeera Rawa15Document1 pageAl Jazeera Rawa15hemajsuryaPas encore d'évaluation

- Prem Satin EnamelDocument1 pagePrem Satin EnamelShashank AgarwalPas encore d'évaluation

- Carbomastic 801 PDFDocument2 pagesCarbomastic 801 PDFkayPas encore d'évaluation

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraPas encore d'évaluation

- Concrete Specifications Rev ADocument15 pagesConcrete Specifications Rev ABdteam T2Pas encore d'évaluation

- QCD AnnexDocument122 pagesQCD AnnexNirupan Kumar100% (1)

- Fosroc Polyurea WH 200Document4 pagesFosroc Polyurea WH 200Arun KumarPas encore d'évaluation

- BricksDocument15 pagesBricksKeysang WangmoPas encore d'évaluation

- January - 2021 - FinalDocument13 pagesJanuary - 2021 - FinalMohammed FasilPas encore d'évaluation

- ASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible PaintsDocument2 pagesASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible Paintshenry rojasPas encore d'évaluation

- Epoxy ChalkingDocument2 pagesEpoxy Chalkingiran1362100% (1)

- PU Clear LacquerDocument1 pagePU Clear LacquerA.F.M Salman AkterPas encore d'évaluation

- TDS - Jen Eplx 89 HB PDFDocument1 pageTDS - Jen Eplx 89 HB PDFআফজাল -উল ইসলাম নূরPas encore d'évaluation

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- NP ArocoatDocument4 pagesNP ArocoatJohn HaPas encore d'évaluation

- DS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Document2 pagesDS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Ranjan Kumar SahuPas encore d'évaluation

- Bergerthane PU Glossy Finish: Product Data Resistance GuideDocument2 pagesBergerthane PU Glossy Finish: Product Data Resistance Guidesangram keshari pattanaikPas encore d'évaluation

- FINISH COAT-Bergerthane PU CoatingDocument2 pagesFINISH COAT-Bergerthane PU CoatingMANIMARAN QCPas encore d'évaluation

- Part 1 General 1.01 SummaryDocument5 pagesPart 1 General 1.01 Summaryআফজাল -উল ইসলাম নূরPas encore d'évaluation

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- TDS - Jen Eplx 89 HB PDFDocument1 pageTDS - Jen Eplx 89 HB PDFআফজাল -উল ইসলাম নূরPas encore d'évaluation

- Hatim PDFDocument2 pagesHatim PDFআফজাল -উল ইসলাম নূর100% (1)

- Turbine Start Up Curve in Cold Start Up: Automatic Speed IncreaseDocument2 pagesTurbine Start Up Curve in Cold Start Up: Automatic Speed Increasekumarmm1234Pas encore d'évaluation

- Arvedi Brief Presentation Modernisation ProgrammeDocument30 pagesArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitPas encore d'évaluation

- List of BIS StandardsDocument9 pagesList of BIS StandardsKumar100% (1)

- NPCP Chapter 2 PDFDocument12 pagesNPCP Chapter 2 PDFbenPas encore d'évaluation

- Wiring Diagram SectionDocument76 pagesWiring Diagram Sectiondavydenkoanton5Pas encore d'évaluation

- 1301A01422 Zaranda 3500Document2 pages1301A01422 Zaranda 3500Edgar FloresPas encore d'évaluation

- Catalysis: Submitted By: Ahsan Misbah Ul Hadi Submitted ToDocument10 pagesCatalysis: Submitted By: Ahsan Misbah Ul Hadi Submitted ToAsim AliPas encore d'évaluation

- Refrigeration and Cooling ManualDocument15 pagesRefrigeration and Cooling ManualGrundfosEgyptPas encore d'évaluation

- Binder 1Document6 pagesBinder 1Andy SoxxPas encore d'évaluation

- 6-Absorption Stripping Pt1Document18 pages6-Absorption Stripping Pt1Naufal FasaPas encore d'évaluation

- Research (Edible Cutlery)Document9 pagesResearch (Edible Cutlery)Reylsea MayPas encore d'évaluation

- PP H2222 36Document2 pagesPP H2222 36keyur1109Pas encore d'évaluation

- EMT 272 Semiconductor Fundamentals Semiconductor Physics: PN JunctionDocument39 pagesEMT 272 Semiconductor Fundamentals Semiconductor Physics: PN Junctionayuni2602Pas encore d'évaluation

- Student Safety Sheets: EthanolDocument1 pageStudent Safety Sheets: EthanolNina FairuzPas encore d'évaluation

- Supercharging and TurbochargingDocument23 pagesSupercharging and TurbochargingTrain Placement CellPas encore d'évaluation

- ANODIZING The Finish of ChoiceDocument4 pagesANODIZING The Finish of ChoiceAhmed HelalPas encore d'évaluation

- Advanced Polymer Panel TDS PDFDocument2 pagesAdvanced Polymer Panel TDS PDFsaint222Pas encore d'évaluation

- Batch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingDocument3 pagesBatch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingVipin Singh KandholPas encore d'évaluation

- Kinetic Molecular Theory and States of MatterDocument25 pagesKinetic Molecular Theory and States of MatterjunnaPas encore d'évaluation

- Summer Internship At: Haldia Petrochemicals LTDDocument11 pagesSummer Internship At: Haldia Petrochemicals LTDJyoti PrakashPas encore d'évaluation

- TriNano Ultra Precision CMM (White Paper)Document6 pagesTriNano Ultra Precision CMM (White Paper)TriNanoPas encore d'évaluation

- Air Mite CatalogDocument56 pagesAir Mite Catalogtemoc128Pas encore d'évaluation

- New Company ProfileDocument14 pagesNew Company Profileanamika tripathiPas encore d'évaluation

- 24 - 25 PF Furnace'12Document5 pages24 - 25 PF Furnace'12DSGPas encore d'évaluation

- Fabric Inspection Under 4Document5 pagesFabric Inspection Under 4texcons677150% (2)

- Storage Tank DetailDocument22 pagesStorage Tank DetailRamu NallathambiPas encore d'évaluation

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganPas encore d'évaluation

- Filtros de Sistema de Purificacion de Agua PDFDocument20 pagesFiltros de Sistema de Purificacion de Agua PDFMarcos ArruePas encore d'évaluation

- EN36 Case Hardening Steel: Shipping PolicyDocument2 pagesEN36 Case Hardening Steel: Shipping PolicyMohit YadavPas encore d'évaluation

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiD'EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiÉvaluation : 4 sur 5 étoiles4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeD'EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeÉvaluation : 5 sur 5 étoiles5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsD'EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsPas encore d'évaluation

- House Rules: How to Decorate for Every Home, Style, and BudgetD'EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetPas encore d'évaluation

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiD'Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiÉvaluation : 5 sur 5 étoiles5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsD'EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersD'EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestD'EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestÉvaluation : 5 sur 5 étoiles5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!D'EverandCrochet Impkins: Over a million possible combinations! Yes, really!Évaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.D'EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Évaluation : 2 sur 5 étoiles2/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsD'EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsD'EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsPas encore d'évaluation

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsD'EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsÉvaluation : 5 sur 5 étoiles5/5 (3)

- The Beading Bible: A Comprehensive Guide to Beading TechniquesD'EverandThe Beading Bible: A Comprehensive Guide to Beading TechniquesPas encore d'évaluation

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)D'EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Pas encore d'évaluation

- Harter's Picture Archive for Collage and IllustrationD'EverandHarter's Picture Archive for Collage and IllustrationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastD'EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastÉvaluation : 5 sur 5 étoiles5/5 (1)

- How to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerD'EverandHow to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerÉvaluation : 5 sur 5 étoiles5/5 (2)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsD'EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsÉvaluation : 4 sur 5 étoiles4/5 (5)

- Crochet Lace: Techniques, Patterns, and ProjectsD'EverandCrochet Lace: Techniques, Patterns, and ProjectsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Japanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreD'EverandJapanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreÉvaluation : 4 sur 5 étoiles4/5 (4)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeD'EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeÉvaluation : 5 sur 5 étoiles5/5 (1)

- Artisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingD'EverandArtisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingÉvaluation : 5 sur 5 étoiles5/5 (4)

- Celtic Line Drawing - Simplified InstructionsD'EverandCeltic Line Drawing - Simplified InstructionsÉvaluation : 5 sur 5 étoiles5/5 (4)

- Paper Cutting: Contemporary Artists, Timeless CraftD'EverandPaper Cutting: Contemporary Artists, Timeless CraftÉvaluation : 5 sur 5 étoiles5/5 (1)

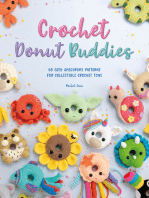

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysD'EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)