Académique Documents

Professionnel Documents

Culture Documents

Introduction To CCPP by BAB

Transféré par

Bilawal AhmedDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction To CCPP by BAB

Transféré par

Bilawal AhmedDroits d'auteur :

Formats disponibles

Introduction to Combined Cycle Power Plant

Introduction to Combined Cycle Power Plant

3.1 Introduction

The Combined Cycle Power Plant is based on cogeneration systems. In the

combined cycle power plants instead of getting work and heat we further process to get

only work which is converted to high grade energy called electricity.

3.2 Cogeneration

Cogeneration is the term used for the combined generation of work and heat. Any

heat engine must reject a lot of heat to the environment, but this energy has no exergy

(i.e. utility) in the ideal heat engine. Practical engines however reject useful heat in the

exhaust gasses and in the cooling circuit, that could be directly used or the engine

modified to provide more useful heat at a small expense in work output.

Cogeneration is provided by using a heat engine (a steam turbine, a gas turbine or

a reciprocating engine) to generate work and, at the same time, heat is captured in a

boiler. The great advantage of cogeneration is the energy saving and the main drawback

is that the ratio of work-to-heat generation is rather stiff, none can be easily accumulated,

and the actual need of work and heat may vary a lot with time (that was one of the main

advantages of central production: the levelling of the averaged demand). To stiffness of a

cogeneration plant is relaxed by the possibility to send excess work-power to the

electrical grid, a convenience that has been enforce by public authorities on account of

the social benefit that saving in primary energy resources (fossil fuels) cogeneration

brings.

Efficiencies of cogeneration plants are high, but care must be paid not to mix

work and heat values because we knows that work is usually two or three times more

expensive than heat, i.e. the output should be consistently measured in exergy, so that the,

instead of W+Q, the output value is W+Q(1-T0/T), where T is the temperature at which

heat is delivered.

Department of Mechanical Engineering, MUET Jamshoro

1

Introduction to Combined Cycle Power Plant

3.2.1 Gas turbine cogeneration

The useful heat-to-work ratio is around 2. It does not require changes in the power

plant, it is a versatile cogeneration system, and its use is expanding in most industries:

textile, chemical, food. Because the exhaust gasses are relatively hot (some 700 K), it is

suitable for high temperature applications.

3.2.2 Vapour turbine cogeneration

The useful heat-to-work ratio is around 7 (suitable for the iron industry, but still

low for the ceramic and glass industry). It directly provides useful vapour, either by

extracting some of it at an intermediate stage in the turbine, or by not expanding to the

low pressures of ambient temperatures but to higher than atmospheric pressures (it is

called a back-pressure turbine), to render the whole turbine outlet vapour useful.

3.3 History of Cogeneration

In 1882 Pearl Street Station was the first commercial power plant in the world

which was made by Thomas Edison who had performed the first modern use of energy

recycling. The plant was so designed that produces both thermal energy and electricity.

With energy recycling, the power plant of Edison had achieved an approximate 50% of

energy efficiency.

Now a day, the European Union generates 11% of its entire electricity by using

cogeneration systems. With this, Europe is able to save for their annual energy source.

Apparently, a huge savings difference still exists between the member states within

Europe because of the variations of energy use. The savings range between 2%-60%. The

region of Europe consists of three countries that are included in the world’s list of most

intensive cogeneration economies. These countries include Finland, Netherlands, and

Denmark.

Outside the United States, the use of energy recycling is more universal just like

in Denmark, which is probable the most active energy recycler in the world as the

country obtains about 55% of its energy efficiency from waste heat recovery and

Department of Mechanical Engineering, MUET Jamshoro

2

Introduction to Combined Cycle Power Plant

cogeneration. Other huge countries like India, Russia, and Germany also obtain their

energy efficiency from decentralized sources like cogeneration.

On the other hand, there are also other European countries that make great efforts

to increasing their energy efficiency. One of these countries is Germany in which they

reported to have more than 50% of the total electricity demand in the country that is

provided by cogeneration. The United Kingdom is also supporting actively the

combination of power and heat. Their goal is to achieve reduction of 60% in carbon

dioxide before the year 2050 comes.

3.4 Combined Cycle Power Plant

A combined cycle is a characteristic of a power producing engine that employs

more than one thermodynamic cycles. Heat engines that are used for producing power are

able to utilize only a portion of the energy from the fuel that is being used (usually less

than 50%). The remaining heat energy after combustion is being wasted. By the

combination of two or more "cycles" such as the “Brayton cycle” and “Rankine cycle”

results in improving overall efficiency.

The Combined-cycle power plants (CCPP) are those which have both gas and

steam turbine supplying power to the network as shown (Figure 3-1). The idea of

combined cycle has grown to improve the efficiency of simple Brayton-cycle by using

heat recovery boilers to capture heat form the exhaust gases of gas-turbine and used to

produce steam to operate Rankine-cycle.

Department of Mechanical Engineering, MUET Jamshoro

3

Introduction to Combined Cycle Power Plant

Figure 3-1 Schematic flow diagram of 300MW Combined Cycle Power Plant

(Reproduced from Google Images Website)

3.5 Working Mechanism of Combined Cycle Power Plant

As the combined cycle power plant is an integration of steam turbine power plant

and gas/combustion turbine power plant in which the exhaust gases from the gas turbine

are reused for the steam turbine power plant because the gas turbine is relatively high-

temperature machine operated at about 2000 to 3000°F, 1100 to 1650°C whereas the

steam turbine is a relatively low-temperature machine operated at about 1000 to 1200°F,

540 to 650°C Source [Page310 M.M.EI Wakil]. The heat energy in the exhaust gases of a

gas turbine is enough to produce superheated steam from pure water but it also use

supplementary firing lets the plant respond to fluctuations of electrical load i.e on full

load where the exhaust temperature from gas turbine is not enough to operate steam

turbine.

Department of Mechanical Engineering, MUET Jamshoro

4

Introduction to Combined Cycle Power Plant

3.6 Steam Turbine Power Plant

Steam turbine power plants operate on a Rankine-cycle. The steam is produced by

a boiler, where pure water passes through a series of tubes to capture heat from the

firebox and then boils under high pressure to become superheated steam. The heat in the

firebox is normally provided by burning fossil fuel (e.g. coal, fuel oil or natural gas).

However, the heat can also be provided by biomass, solar energy or nuclear fuel. The

superheated steam leaving the boiler then enters the steam turbine throttle, where it

powers the turbine and connected with generator to generate the electricity. After the

steam expands through the turbine, it exhaust the back end of the turbine, where it is

cooled to condensed back to water in the surface condenser. This condensate water is

then returned to the boiler through high-pressure feed pumps for reuse. Heat from the

condensing steam is normally rejected from the condenser to a body of water, such as a

river or cooling tower.

Figure 3-2 Schematic flow diagram of a Rankine-cycle (Reproduced from

www.CombinedCyclePowerPlants.com)

Department of Mechanical Engineering, MUET Jamshoro

5

Introduction to Combined Cycle Power Plant

3.7 Gas Turbine Power Plant

Gas turbine plants operate on the Brayton-cycle. They use a compressor to

compress the inlet air upsteam of a combustion chamber. Then the fuel is introduced in

the combustion chamber and ignited to produce a high temperature, high-pressure gas

that is allowed to enter and expand through the turbine section. The power produced by

the turbine section is utilized by the generator and compressor. Combustion turbines are

also able to burn a wide range of liquid and gaseous fuels from crude oil to natural gas.

Figure 3-3 Schematic flow diagram of a Simple-Cycle Gas Turbine (Reproduced from

www.CombinedCyclePowerPlants.com)

Integrated Parts of Combined Cycle Power Plant

Normally, combined-cycle station consists of the following major components.

• Gas Turbine

• Steam Turbine

• Heat Recovery Steam Generators (HRSG)

• Condensers

• Steam and feed water makeup system

Department of Mechanical Engineering, MUET Jamshoro

6

Introduction to Combined Cycle Power Plant

3.8 Turbines

The turbines are also known as prime movers and it is a one of the steady flow

device which can operate for long time continuously. It consist of numbers of stages of

blades or vans they may be stationary or moving mounted on a shaft known as periphery,

the function of a turbine is to convert the fluid kinetic energy into a mechanical energy.

Turbines are simple but powerful machines that based on Newton’s third law of motion

which states that for every action there is an equal and opposite reaction.

The turbines are available in size from 32 to 173,000bhp and there speed varies from

3600 to 60,000rpm.

3.9 Combustion Turbine

The combustion turbine consist of three sections compressor, combustion

chamber (combustor), and turbine, in an air compressor the combustion air pressure is

increased and then fuel-air mixture inside the combustion chamber produces high

pressure and high energy after combustion, and then combusted gases drives the power

turbine section by extracting energy from the combustion gases. The gas turbines were

most often used by jet aircraft for propulsion but now a day it is also used as a stationary

device in most of thermal power plants.

3.9.1 Compressor

The various types of compressors are used in gas turbine to decreases the volume

and increases the pressure ratio of air by mechanical means. As the pressure ratio is

increased the air rate firstly decreases to a minimum value (which decreases temperature)

and then starts increasing. With increase of turbine inlet temperature the air rate is

decreased and compressor work increased and the net turbine output is decreased.

1) Centrifugal Compressor

It consists of stationary casing and rotating impeller. Impeller is provided with

blades. When the impellor rotates the air enters axially and leaves radially. When the

impellor rotates the pressure in the region at the compressor inlet falls and, therefore the

Department of Mechanical Engineering, MUET Jamshoro

7

Introduction to Combined Cycle Power Plant

air enter through the eye. The air then flows radially outward through the impellor blades.

After that the air flows through converged passages of diffuser blades and finally the air

flows to compressor outlet or exist. The centrifugal compressors are preferred when the

pressure ratio not more than 4:1 is required

2) Axial Flow Compressor

The Axial Compressor consists of a stator which encloses the rotor. Both stator and

rotor are fitted with rings of blades (RB-Rotor Blades, SB-Stator Blade). In this

compressor air flows in an axial direction from inlet to outlet. Air entering at one end and

flows through alternatively arranged rings or blades and get compressed successively.

The axial flow compressors are preferred when the pressure ration more than 6:1 is

required. In the gas turbine power plant of high output and efficiency generally pressure

ratio more than 10:1, therefore to attain such high pressure multi-stage centrifugal

compressor does not prove to be useful as an equivalent axial flow compressor.

3.9.2 Combustion Chamber

In the combustion chamber, combustion of fuel takes place. The combustion chamber

should provide thorough mixing of fuel and air as well as combustion products and air so

that complete combustion and uniform temperature distribution in the combustion gases

may be achieved. Combustion should take place at high efficiency, because the losses

incurred in the combustion process have direct effect on thermal efficiency of the gas

turbine cycle. The combustion chamber should provide sufficient volume and length for

complete combustion of the fuel. The temperature developed inside the combustion

chamber should be at low; this may be achieved by adding satisfactory amount of air to

maintain stable combustion conditions and then introducing secondary air into the

product of combustion for cooling. The sum of primary and secondary air supplied is

total air needed for combustion. Air fuel ratio in the gas turbine is nearly 60:1

Department of Mechanical Engineering, MUET Jamshoro

8

Introduction to Combined Cycle Power Plant

Figure 3-4 Schematic flow diagram of a Gas Turbine (Reproduced from Google Images

Website)

Figure 3-5 Schematic flow diagram of a Centrifugal Compressor (Reproduced from

Google Images Website)

Department of Mechanical Engineering, MUET Jamshoro

9

Introduction to Combined Cycle Power Plant

Figure 3-5 Schematic flow diagram of a Axial Flow Compressor with Stator and Rotor

Blades (Reproduced from Google Images Website)

3.9.3 The single-shaft combustion turbine

The single-shaft turbine has the air compressor, gas-producer turbine, and the

power turbine on the same shaft. They are usually selected when a constant speed drive is

required, as in generator drives, and when the starting torque requires are low. A single-

shaft engine can be used to drive centrifugal compressor, but the starting system and the

compressors match point must be considered.

3.9.4 The split-shaft or dual-shaft turbine

The split-shaft or dual-shaft turbine has the section required for air compression

on one shaft and the section producing output power on a separate shaft. In a split-shaft

turbine the portion that includes the compressor, combustion chamber, and the first

turbine section is the hot gas producer. The second turbine section is the power turbine.

The split-shaft engines allow for variable speed at full load. It can be started with a high

torque load connected to the power output shaft, and the power turbine can be more

optimally configured to match load requirement.

Department of Mechanical Engineering, MUET Jamshoro

10

Introduction to Combined Cycle Power Plant

3.10 Steam Turbine

The steam turbine is that which is operated on steam they are usually impulse type

turbine in which superheated steam from the Heat Recovery Steam Generator (HRSG)

after passing through a row of fixed nozzles impinges on vans or buckets which are

mounted on a periphery with a little or no steam pressure. The vans or blades are

designed in crescent-shaped that extract kinetic energy of fluid i.e. steam and convert it

into mechanical energy.

3.11 Construction of a steam turbine

Turbine manufacturers’ standards prescribe casing materials for various limits of

steam pressure and temperature as given below in table. The choice between built-up or

solid rotors depends on turbine speed or inlet steam temperature. Water must drain from

pockets within the turbine casing to prevent damage caused by condensate accumulation.

Carbon rings prevent leakage of steam between pressure stage of the turbine, outward

steam leakage, and inward air leakage at the turbine glands. The erosive and corrosive

effect of moisture entering with the supply steam must be considered. Heat loss is

controlled by applying thermal insulation.

3.12 Impulse Type Turbine

In the impulse turbine the steam exerts force on the blade due to the velocity of

steam. In this type of turbine the steam is first passed from nozzle so that its velocity

should increase with the drop in pressure and then steam impinges or strikes on the

turbine blades (which are curved like buckets) which are mounted in the form of ring on

shaft.

The action of the jet of steam, impinges on the blades, is said to be an impulse and the

rotation of the rotor is due to the impulse force

Department of Mechanical Engineering, MUET Jamshoro

11

Introduction to Combined Cycle Power Plant

Figure 3-6 Schematic flow diagram of an Impulse Turbine (Reproduced from

explainthatstuff/turbine Website)

3.13 Reaction Type Turbine

In a reaction turbine, the blades sit in a much larger volume of fluid and turn

around as the fluid flows past them. A reaction turbine doesn't change the direction of the

fluid flow as drastically as an impulse turbine: it simply spins as the fluid pushes through

and past its blades.

Figure 3-7 Schematic flow diagram of a Reaction Turbine (Reproduced from Google

image Website)

Department of Mechanical Engineering, MUET Jamshoro

12

Introduction to Combined Cycle Power Plant

3.3.1 Pressure and Velocity of steam in a Reaction and Impulse Turbine

In the reaction turbine the pressure is reduced in the fixed blades as well as in

moving blades and the velocity of steam is increased in the fixed blades, and is reduced

while passing through the moving blades. While in impulse type turbine the steam is first

passed through nozzle in which velocity of steam is increased at the loss of pressure and

then steam with very high velocity impinges on blade at constant pressure where its

velocity decreases.

Figure 3-8 Schematic flow diagram of Pressure and velocity diagram of a Reaction and

Impulse Turbine (Reproduced from Google Images Website)

3.7.2.4 Axial Flow Turbines

The axial flow turbines are those in which the working fluid is injected axial to

the peripheral blades of one or more staged turbine wheel.

Department of Mechanical Engineering, MUET Jamshoro

13

Introduction to Combined Cycle Power Plant

3.7.2.5 Radial Flow Turbines

The Radial in flow turbines are those in which steam enters through center or eye

of the impeller and exits from the periphery.

3.7.2.6 Condensing Turbine

A steam turbine with an exhaust steam pressure below atmospheric pressure, such

that steam is directly and completely condensed.

3.7.2.7 Non-Condensing (back pressure) Turbines

A steam turbine designed to operate with an exhaust steam pressure at any level

that may be required by a downstream process, where all condensing takes place.

3.7.2.8 Modern Steam Turbines

The scientist and engineers, working in research centers all over the world,

concentrated their attention to produce more power and to improve efficiencies of these

turbines. They have listed numbers a numbers of methods for this purpose, but the

following are important from thesis point of view.

3.7.2.8.1 Reheating of Steam

As we know the efficiency of Rankine cycle can be improved by increasing the

pressure and temperature of the steam entering into the turbine, A little consideration will

shows, that the increase in the initial pressure will increase the expansion ratio, and the

steam will become quite wet at the end of expansion, It is further explained that, as the

quality of the steam decreases, the concentration of water droplets increases. The turbine

blades move rapidly through the steam and tend to collect the water droplets. This is

because the denser water droplets do not move with quite the same velocity as the steam,

and therefore collected at the blade, when these large drops impact with the turbine

blades causes erosion of the blades and increases internal losses. This will ultimately

reduce the blade efficiency of the turbine.

Department of Mechanical Engineering, MUET Jamshoro

14

Introduction to Combined Cycle Power Plant

Thus the above difficulty may be removed by reheating of the steam. In this

system the steam is removed from the turbine when it becomes wet. It is then reheated at

a constant pressure by the flue gases, until it becomes superheated steam. It should be

noted that steam with qualities of less than around 85% to 90% to remain in the turbine is

not allowed. The figure( ) shows bellow the reheating system of steam for steam turbine

in which the steam is first expand in the turbine T-1 from 3-4 and then reheated from 4-5

so that quality may improve and then after it is expanded in the turbine T-2 from 5-6 .

Figure 3-8 Schematic flow diagram of Reheating of steam (Reproduced from Google

Images Website)

3.7.2.8.2 Multi-stage Turbines

Multi-stage steam turbines are those in which expansion of steam takes place into

numbers of stages. The stages may be categories according to fixed and moving blades

and also according to the pressure ranges. As we have already discussed in a two-stage

impulse turbine in which steam after leaving the moving blades is made to flow though a

fixed ring and it impinges on the fixed to the secondary moving rings and then steam is

passed from secondary moving rings to the condenser, it is known as two-stage turbine.

But some time we make the steam to pass through a number of stages in order to get

more work. Such turbine is known as multi-stage turbine. As shown in figure() the steam

Department of Mechanical Engineering, MUET Jamshoro

15

Introduction to Combined Cycle Power Plant

turbine with three stages according to the pressure ranges High Pressure, Medium

Pressure or Intermediate Pressure and Low Pressure Turbine.

Figure 3-8 Schematic flow diagram of Multistage Steam Turbine (Reproduced from

Google Images Website)

3.7.2.8.3 Bleeding

The process of draining steam from the turbine, at certain points during its

expansion and using this steam for heating the feed water and then supplying it to the

boiler is known as bleeding. A feed water heater is a simple form of heat exchanger

consists of tubes through which feed water flows. These tubes are surrounded by a

casing, containing the heating steam. The steam condenses and transfers its latent heat to

the feed water. By the bleeding we can avoid wet steam at the end of expansion because

we are draining steam from turbine at about dry saturated vapors point

3.7.2.8.4 Pass-out or Extraction Turbine

A pass-out or extraction turbine is of the type used in center stations, in which

steam is extracted at different stages and used in heating the feed water for the boiler or

processing work such as paper making, textile, dying etc

It consist of high pressure (H.P) and low pressure (L.P) stage in which high

pressure steam from boiler enters the H.P stage of the turbine where it expands and

pressure is reduced to such a value as required for processing work. A part of this low

Department of Mechanical Engineering, MUET Jamshoro

16

Introduction to Combined Cycle Power Plant

pressure steam leaving the H.P stage is supplied for processing work while remaining

steam expands further in the L.P stage of turbine. The exhaust steam from the processing

plant and low pressure turbine is considered in a condenser and pumped back to the

boiler.

3.7.2.8.5 Back Pressure Turbine

In this the exhaust from the steam turbine is generally supersaturate which is not

suitable for process work due to following reasons. In this type of turbine the control of

temperature is impossible and the rate of heat transfer from the supersaturated steam is

lower than that of saturated steam Thus, the exhaust supersaturated steam is passed

through a de-superheater to make the steam saturated, and then further processed for

condensation.

3.7.3 Heat Recovery Steam Generator (HRSG)

Heat Recovery Steam Generators, or "HRSG" - are, also called as boilers, a

HRSG is used to recover energy from the hot exhaust gases in power generation. It is a

bank of tubes that is mounted in the exhaust stack. Exhaust gases as much as 800 °F to

1200 °F heat these tubes source [www.cogenration.com]. Water is pumped and circulated

through the tubes and can be held under high pressure to temperatures of 370°F or higher

which can be boiled to produce steam. HRSG's are found in may combined cycle power

plants. HRSGs consist of three major components: the Evaporator, Superheater, and

Economizer. The different components are put together to meet the operating

requirements of the unit.

Some HRSGs include supplemental because the exhaust from a gas turbine

contains large amounts of excess air. This exhaust has oxygen content close to fresh air,

and will be utilized as preheated combustion air for supplementary fuel firing.

Supplementary fuel firing permits increasing steaming of the waste heat boiler. Hence

increases the output of the steam turbine. Generally, Supplementary fuel firing or duct

firing provides electrical output at lower capital cost. It is therefore often utilized for

Department of Mechanical Engineering, MUET Jamshoro

17

Introduction to Combined Cycle Power Plant

peaking operations. Supplementary burners also permit generation when the gas turbine

is out of service.

Emissions controls may also be located in the HRSG. Some may contain a

Selective Catalytic Reduction system to reduce nitrogen oxides (a large contributor to the

formation of smog and acid rain) and/or a catalyst to remove carbon monoxide. NOx

catalyst performs best in temperatures between 650 °F (340 °C) and 750 °F (400 °C)

source [encyclopedia]. This usually means that the evaporator section of the HRSG will

have to be split and the SCR placed in between the two sections. Some low temperature

NOx catalysts have recently come to market that allows for the SCR to be placed

between the Evaporator and Economizer sections (350 °F - 500 °F (175 °C - 260 °C)).

3.7.3.1 Evaporator Section

The most important component would, of course, be the Evaporator Section. So

an evaporator section may consist of one or more coils. In these coils, the effluent

(water), passing through the tubes is heated to the saturation point for the pressure it is

flowing.

3.7.3.2 Superheater Section

The Superheater Section of the HRSG is used to dry the saturated vapor being

separated in the steam drum. In some units it may only be heated to little above the

saturation point where in other units it may be superheated to a significant temperature

for additional energy storage. The Superheater Section is normally located in the hotter

gas stream, in front of the evaporator.

3.7.3.3 Superheat Control

It is desirable that there should be a close control over the final temperature of

steam over a reasonably wide range of load. The various methods employed to achieve

this are as given.

Department of Mechanical Engineering, MUET Jamshoro

18

Introduction to Combined Cycle Power Plant

1) Desuperheater

To control the temperature of steam a desuperheater (attemperator) is used. In the

desuperheater some quantity of cold water is injected into or around the pipe carrying the

steam. This causes the evaporation of water injected and thus the temperature of steam is

lowered.

2) Tilting Burners

Tilting burners in the furnace are used to regulate the temperature of gases

leaving the furnace.

3) Damper

Dampers are provided to control the direction of hot combustion gases in order to

control to vary the quantity of gas passing through superheater.

3.7.3.4 Economizer Section

The Economizer Section, sometimes called a preheater or preheat coil, is used to

preheat the feed water being introduced to the system to replace the steam (vapor) being

removed from the system via the superheater or steam outlet and the water loss through

blow down. It is normally located in the colder gas downstream of the evaporator. Since

the evaporator inlet and outlet temperatures are both close to the saturation temperature

for the system pressure, the amount of heat that may be removed from the flue gas is

limited due to the approach to the evaporator, whereas the economizer inlet temperature

is low, allowing the flue gas temperature to be taken lower.

3.7.3.5 Feed Water Treatment

It is desirable that the water to be used in the boiler should be free from various

impurities. The impure water is chemically treated in different ways depending upon the

nature and concentration of impurities, these water treatment processes are carried under

the supervision of a chemical engineer. The different types of water treatment process are

enlisted bellow which may be carried to remove the various impurities.

Department of Mechanical Engineering, MUET Jamshoro

19

Introduction to Combined Cycle Power Plant

1. Mechanical Treatment

2. Thermal Treatment

3. Chemical Treatment

4. Demineralization

5. Blow down

Figure 3-7 Schematic flow diagram of a Heat Recovery Seam Generator (Reproduced

from Google image Website)

3.7.4 Condenser

The condenser is one of the important equipment of a Power Plant. The purpose

of condenser is to condense the exhaust steam from the steam turbine to recover the high-

quality feed water for reuse in the cycle. If the circulating cooling-water temperature in

the condenser is low enough it creates low back pressure (vacuum) for the turbine to

exhaust. This pressure is equal to the saturation pressure that corresponds to the

condensing steam temperature. As we know that, the turbine work per unit pressure drop

is much greater at the low-pressure than the high-pressure at the end of turbine, so by

lowering the back pressure by only a few Psi will increase the work output.

Department of Mechanical Engineering, MUET Jamshoro

20

Introduction to Combined Cycle Power Plant

Thus thermodynamically it is important to use cooling-water temperatures that are

the lowest available. Condensing power plant is much more efficient than a non-

condensing power plant. There are primarily two types of condensers

Figure 3-7 Schematic flow diagram of a Heat Recovery Seam Generator (Reproduced

from Google image Website)

Surface Condensers

Direct-Contact Condensers

3.7.5 Surface Condensers

Surface condensers are the most common types used in power plants. It is much

like heat exchanger which consists of series of tubes and a shell. In which the steam from

exhaust of the steam turbine is allowed to pass through series of tubes where it exchange

its heat with the cold water circulating around the tubes in the shell and get hot, the

Department of Mechanical Engineering, MUET Jamshoro

21

Introduction to Combined Cycle Power Plant

mechanism of transferring heat depending upon temperature difference between steam in

the tubes and water circulating around the tubes.

The tubes are rolled into the tube sheet at both ends to prevent leakage of the

circulating water into the steam. An expansion joint allows for the different rates of

expansion between the tubes and shell. The tube sheets are usually made of Muntz metal,

which is similar to brass.

A problem of steam distribution, other than vertical penetration, is end-to-end or

horizontal distribution that arises with present day long tubes units. Tube lengths of 30 to

50ft (~9 to 15m) are in common use. Multi-pressure condensers (below) may have 70 to

90ft (~ 21 to 27m) source [page 225 M.M. EI-Wakil] tubes. Long tubes result in larger

changes in temperature changes and hence greater changes in condensing ability. Thus,

the tubes would be too close at the cold end, where condensing is good, and too open at

the hot end.

Another distribution problem is the result of the undesired unequal steam flow

from the turbine exhaust duct to the condenser tubes. Thus special attention must be paid

to the design of the connection between turbine and condenser called exhaust neck, such

as adding a well-tapered steam dome above the tube bundle to minimize the problem. An

expansion joint is usually provided between the turbine exhaust and the condenser steam

inlet. This permits the condenser to be rigidly mounted on the floor and also to bolt the

condenser directly to the turbine exhaust duct and support it on springs that allow a

certain vertical movement and reduce the strain on the turbine casing.

3.7.5.1 Number of Passes and Divisions

The condensers are designed one, two, or four cooling-water passes. The numbers

of passes determines the size and effectiveness of a condenser. Four passes condenser are

seldom used in utility installations.

Department of Mechanical Engineering, MUET Jamshoro

22

Introduction to Combined Cycle Power Plant

3.7.5.2 Single-Pass tube Condenser

A single-pass tube is that in which cooling water passes through all tubes at once,

from one end to the other end. In this condenser, with the same total number and size of

tubes, i.e. (the same heat transfer area and with the same water velocity), flow of water

requires twice as much water flow but results in half the water temperature rise and thus

lower condenser pressure. Thus such a single-pass condenser is good for plant thermal

efficiency and reduces thermal pollution, but requires more than twice the water and

hence four times the pumping power.

3.7.5.3 Two-Pass Tube condenser

In a two-pass condenser the water enters half the tubes at one end of a divided

inlet water box, passes through these tubes to an undivided water box at the other end,

reverses direction, and passes through the other half of the tubes back to the other side of

the divided water box.

3.7.5.4 Division of Water Box

Water boxes are often divided beyond the divisions required by the number of

passes. A divided water box single-pass condenser allows condenser to operate while

other half is being cleaned or repaired. In case of divided two-pass condenser, the water

boxes are divided into four quarters. Divided water boxes have duplicate inlet and outlet

connections, each with its own circulating water circuit. Valves in the division plates

permit back washing by reversing water flow for cleaning purpose.

Department of Mechanical Engineering, MUET Jamshoro

23

Introduction to Combined Cycle Power Plant

Figure 3-7 Schematic flow diagram of Single-Pass tube Condenser and Two-Pass Tube

condenser (Reproduced from Google image Website)

3.7.6 Single and Multi-Pressure Condensers

As the large power plants usually have two or ore low-pressure turbine sections in

tandem. The condenser may be divided into corresponding sections or shells, situated

Department of Mechanical Engineering, MUET Jamshoro

24

Introduction to Combined Cycle Power Plant

below the low-pressure turbine sections. If the turbine exhaust pressure in all sections is

the same, i.e. when the exhaust ducts are not isolated from each other, we would have a

single-pressure condenser. If the exhaust ducts are isolated from each other, these

individual condenser shell pressures will increase because the circulating water

temperature will increase as it flows from shell to shell called multi-pressure condenser.

A multi-pressure condenser results in efficiency improvement because the

average turbine back pressure is less compared with that of a single-pressure condenser

(which is determined by the highest circulating-water temperature). Multi-pressure

condensers are more commonly used in nuclear power plants. They are usually single-

pass unit arranged with their tubes parallel to the turbine shaft.

3.7.7 Feed Water Heater

The main purpose of feed water heater is to improve cycle efficiency by heating

the condensate and feed water before returning it to the steam generator. The heating

could be as high as 400 to 500°F (200 to 260°C) in a fossil-fueled power plant but it is

lower in a water-cooled nuclear-reactor power plant. There are two basic types of feed

water heaters

The closed, surface or shell and tube type.

The pen, direct-contact or deaerating type.

3.8 Fuel and Fuel System for Combined Cycle Power Plant

The ability to burn almost any combustible fluid is the key advantage of the gas

turbine. Natural gas (CH4) is most preferable fuel than other fuels because it is readily

available, has good combustion characteristics, and is relatively easy to handle. Other

fuel gas include liquefied petroleum gases, which are considered wet at normal gas

turbine operation condition and most a wide range of refinery waste and coal-derived

gases, which have relatively high friction of hydrogen. Both of these features lead to

problem in fuel handling and preparation, as well as in gas turbine operation.

Department of Mechanical Engineering, MUET Jamshoro

25

Introduction to Combined Cycle Power Plant

Distillate oil is the most common liquid fuel and used where natural gas is not

available, it is the primarily used as backup and alternative start-up fuel where as the

crude oil and residual are also available in abundant in oil-producing country and can also

be used but it required treatment for sodium salts and vanadium contamination.

A typical fuel gas control system is a two stage system that uses pressure control

in combination with flow control to achieve turndown ration from 60:1 to 100:1.

The Steam turbine which is only operated with the steam formed by heat recovery

steam generator, the heat recovery steam generator may be waste HRSG or it may require

supplementary heating to avoid fluctuation in the quality of steam formed.

The supplementary fuel may be natural gas, fuel oil, or coal. Integrated solar

combined cycle power stations are currently under construction at Hassi R'mel, Algeria

and Ain Beni Mathar, Morocco.

3.9 Lubrication System for Combustion Turbine

The gas turbine requires an affective lubricating system to overcome the friction

in the rotating parts and to serve the purpose of cooling these elements for that filtered

and cooled lubrication is provided to the gear reducer, gas turbine bearings, and to the

other driven equipments. The lubrication system is carried out by a motor-driven, start-

up/coast-down oil pump, a primary oil pump mounted on and driven by the gear reducer,

filters, an oil reservoir, an oil cooler, and automatic control.

The start-up/coast-down oil pump circulates oil until the gas turbine reaches a

speed at which the primary pump can takeover, Oil filters serves the full flow of the

pumps, The oil reservoir is mounted in the base of the gas turbine and with that cooling

and heating system is also provided to get required viscosity of lubricating oil due to

climate change.

Department of Mechanical Engineering, MUET Jamshoro

26

Introduction to Combined Cycle Power Plant

3.10 Starting System for Combustion Turbine

Starting system can be pneumatic, hydraulic, or electric motor starter. All systems

uses a one way clutch to couple the starter motor to the gas engine so that as the engine

accelerates above the start speed, the starter can shut down.

3.11 Starting System for Steam Turbine

Unlike the combustion turbine, steam turbine do not require auxiliary starting

system, Steam turbines are stared through controlled opening of the main steam valve,

which is controlled by governing system. Larger turbines with multiple stages and/or

split-shaft arrangements are stared in gradual manner to allow for controlled expansion

and thermal stressing. Many of these turbines are provided with electrically power

turning gears that slowly rotate the shaft during initial stage of start-up.

Department of Mechanical Engineering, MUET Jamshoro

27

Vous aimerez peut-être aussi

- Combined Cycle, Combined Cycle With Heat Recovery..Document4 pagesCombined Cycle, Combined Cycle With Heat Recovery..abdul100% (1)

- Lecture 11: Combined Cycle, With Heat RecoveryDocument5 pagesLecture 11: Combined Cycle, With Heat RecoveryIjazzzAliPas encore d'évaluation

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningD'EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningÉvaluation : 5 sur 5 étoiles5/5 (2)

- Natural Gas EquipmentDocument26 pagesNatural Gas Equipmenthanisshi100% (1)

- Combined Cycle Power PlantDocument29 pagesCombined Cycle Power Plantrajib0403050cuetPas encore d'évaluation

- CCGT ExplainedDocument22 pagesCCGT ExplainedAli Bari100% (1)

- Case Study On Cogeneration in Sugar Mill 2023Document11 pagesCase Study On Cogeneration in Sugar Mill 2023Pranav TikarPas encore d'évaluation

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationD'EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationPas encore d'évaluation

- Assignment No 4: Power PlantDocument5 pagesAssignment No 4: Power PlantusamaPas encore d'évaluation

- Scientific American Supplement, No. 633, February 18, 1888D'EverandScientific American Supplement, No. 633, February 18, 1888Pas encore d'évaluation

- Summer Training ReportDocument32 pagesSummer Training ReportKuldeep ChauhanPas encore d'évaluation

- Combined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoDocument12 pagesCombined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoRobinsyahPas encore d'évaluation

- EEC 122 CompleteDocument34 pagesEEC 122 CompleteAdeniji OlusegunPas encore d'évaluation

- Prospect of Combined Cycle Power Plant Over Conventional Single Cycle Power Plants in Bangladesh - A Case StudyDocument5 pagesProspect of Combined Cycle Power Plant Over Conventional Single Cycle Power Plants in Bangladesh - A Case StudyTaskinJamalPas encore d'évaluation

- Combined - Cycle Power PlantDocument9 pagesCombined - Cycle Power PlantRavi Kumar GuptaPas encore d'évaluation

- TRIGENERATIONDocument21 pagesTRIGENERATIONShreyas Saumitra100% (1)

- Cogeneration - Combined Heat and Power (CHP)Document23 pagesCogeneration - Combined Heat and Power (CHP)Reyes SanchezPas encore d'évaluation

- Steam Power PlantDocument10 pagesSteam Power PlantJoel DalePas encore d'évaluation

- Cogeneration or Combined Heat and Power (CHP) Is The Use of A Power (CCHP) Refers To The Simultaneous Generation of Electricity and Useful Heating and CoolingDocument14 pagesCogeneration or Combined Heat and Power (CHP) Is The Use of A Power (CCHP) Refers To The Simultaneous Generation of Electricity and Useful Heating and CoolingakmohideenPas encore d'évaluation

- UNIT IV V Two MarksDocument2 pagesUNIT IV V Two MarksMohammed ashiq SPas encore d'évaluation

- Brayton CycleDocument15 pagesBrayton CycleWahyudin BetaPas encore d'évaluation

- Exploiting Waste Heat in Small and Medium-Sized Combined Heat and Power Plants Using Steam InjectionDocument11 pagesExploiting Waste Heat in Small and Medium-Sized Combined Heat and Power Plants Using Steam InjectionAnonymous VfmEOJ6wE1Pas encore d'évaluation

- Cogeneration CycleDocument30 pagesCogeneration Cyclekaladher5311937Pas encore d'évaluation

- ThesisDocument123 pagesThesisTahir AzizPas encore d'évaluation

- Gas Turbine ApplicationDocument15 pagesGas Turbine ApplicationsecahegazyPas encore d'évaluation

- Cogeneration Heat Power CHPDocument10 pagesCogeneration Heat Power CHPMKOZERDEMPas encore d'évaluation

- Topic: - Power Cogeneration Plant: Term Paper OF Project ManagementDocument13 pagesTopic: - Power Cogeneration Plant: Term Paper OF Project ManagementankuaaaPas encore d'évaluation

- CHAPTER III IV and VDocument84 pagesCHAPTER III IV and VJohn Louie Pimentel0% (1)

- CogenerationDocument53 pagesCogenerationSri Ch.V.Krishna Reddy Assistant Professor (Sr,)Pas encore d'évaluation

- Combined CycleDocument8 pagesCombined CycleAnonymous mNQq7oj100% (1)

- Experiment No.:-3 TITLE: Study of Co-Generation Power Plant AIM: Study of Co-Generation Power Plant TheoryDocument10 pagesExperiment No.:-3 TITLE: Study of Co-Generation Power Plant AIM: Study of Co-Generation Power Plant Theory9527530909100% (1)

- An Overview of Combined Cycle Power Plant - EEPDocument12 pagesAn Overview of Combined Cycle Power Plant - EEPrereilham100% (1)

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyPas encore d'évaluation

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (1)

- Energy Conversion TechnologiesDocument38 pagesEnergy Conversion TechnologiesKannan MuthuPas encore d'évaluation

- Combined Cycle Power Plant - Summary StudyDocument3 pagesCombined Cycle Power Plant - Summary StudydndudcPas encore d'évaluation

- Combine Gas Cycle TurbineDocument20 pagesCombine Gas Cycle Turbinekts700175% (4)

- Heat Engines Mechanical Energy Make ElectricityDocument5 pagesHeat Engines Mechanical Energy Make ElectricityAbdelrhman AboodaPas encore d'évaluation

- Gas Turbines Applications ReportDocument9 pagesGas Turbines Applications ReportKareem Ibrahim Mohamed NasrPas encore d'évaluation

- Ppe Unit 01 Combined Power Plants and Comparison V+Document11 pagesPpe Unit 01 Combined Power Plants and Comparison V+sshridhar2008Pas encore d'évaluation

- Power Plant EngineeringDocument25 pagesPower Plant EngineeringlitonPas encore d'évaluation

- Thermodynamic Evaluation of The Performance of A Combined Cycle Power PlantDocument11 pagesThermodynamic Evaluation of The Performance of A Combined Cycle Power PlanthansleyPas encore d'évaluation

- Combined Gas and Steam Power PlantDocument8 pagesCombined Gas and Steam Power Planttushar1128100% (1)

- Power Plant Project ReportDocument66 pagesPower Plant Project ReportPoojit PopliPas encore d'évaluation

- Combined Cycle Power PlantDocument2 pagesCombined Cycle Power Plantiman562Pas encore d'évaluation

- Combined Cycle PowerplantDocument34 pagesCombined Cycle PowerplantDarrel CamachoPas encore d'évaluation

- Expt. 02 Stusy of A Gas Turbine Power PlantDocument5 pagesExpt. 02 Stusy of A Gas Turbine Power PlantSajeeb SarkerPas encore d'évaluation

- Heat Engine Thermal Energy Combustion Fuel Second Law of Thermodynamics District Heating Cogeneration Heat-Only Boiler Stations DesalinationDocument1 pageHeat Engine Thermal Energy Combustion Fuel Second Law of Thermodynamics District Heating Cogeneration Heat-Only Boiler Stations DesalinationMayur MandrekarPas encore d'évaluation

- CogenerationDocument11 pagesCogenerationeddy hernandezPas encore d'évaluation

- Training Report CCPPDocument38 pagesTraining Report CCPPTaresh MittalPas encore d'évaluation

- Classification: by Heat SourceDocument1 pageClassification: by Heat SourcetrusselPas encore d'évaluation

- Thermal Power Plant Project ReportDocument63 pagesThermal Power Plant Project Reportasutoshjena28171% (24)

- ASME GT2011 45736final LibreDocument8 pagesASME GT2011 45736final LibreGaluh MuhendraPas encore d'évaluation

- Brayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsDocument15 pagesBrayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsmechturboPas encore d'évaluation

- RINNER Motor 57 SeriesDocument2 pagesRINNER Motor 57 Serieschar_lynPas encore d'évaluation

- Gep22 4Document4 pagesGep22 4RktBatam100% (1)

- Split Tee Hot Tap Fitting Spec SheetDocument4 pagesSplit Tee Hot Tap Fitting Spec SheetCarlos ShuntaPas encore d'évaluation

- Operators Manual 500 SeriesDocument36 pagesOperators Manual 500 SeriesAutochthon GazettePas encore d'évaluation

- Marine Engines ABATO WeichaiDocument14 pagesMarine Engines ABATO Weichaiarf89Pas encore d'évaluation

- Steam Power PlantDocument24 pagesSteam Power PlantNandan Kumar100% (1)

- Spares Part HIMSEN UsedDocument4 pagesSpares Part HIMSEN UsedPaulo MandingaPas encore d'évaluation

- Advancement in Cement TechnologyDocument12 pagesAdvancement in Cement Technologyreubenmth100% (1)

- Calculate Jockey Pump Capacity in Fire Fighting SystemDocument1 pageCalculate Jockey Pump Capacity in Fire Fighting SystemkarpakkiPas encore d'évaluation

- 2008 Escape Hybrid Mariner Hybrid: Emergency Response GuideDocument12 pages2008 Escape Hybrid Mariner Hybrid: Emergency Response GuideWil ParedesPas encore d'évaluation

- Transmisión Automática Parte 2Document39 pagesTransmisión Automática Parte 2romeo_mec100% (1)

- Cummins Service ProtocolDocument1 pageCummins Service ProtocolartemPas encore d'évaluation

- Pie ChartDocument6 pagesPie ChartNguyen LePas encore d'évaluation

- TM 5-4320-218-35PDocument110 pagesTM 5-4320-218-35PAdvocatePas encore d'évaluation

- Evinrude E25dgte 2018 085Document1 pageEvinrude E25dgte 2018 085Cristian FilipPas encore d'évaluation

- Machinery Operating Manual TransferDocument249 pagesMachinery Operating Manual TransferEmin Alim100% (3)

- Oil Grades and Capacities PDFDocument1 pageOil Grades and Capacities PDFAlin ŞovăialăPas encore d'évaluation

- Technical Specification of 1MW Diesel Generator Power Plant Set From ChinaDocument21 pagesTechnical Specification of 1MW Diesel Generator Power Plant Set From ChinaAndrew Jeyakumar100% (1)

- PDFDocument101 pagesPDFParaZzzitPas encore d'évaluation

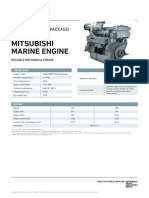

- Mitsubishi Marine Engine - S6R2-T2MPTK3LM (Package)Document2 pagesMitsubishi Marine Engine - S6R2-T2MPTK3LM (Package)david alvianPas encore d'évaluation

- Operation & Maintenance Manual: P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocument226 pagesOperation & Maintenance Manual: P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIjulio cesar navaPas encore d'évaluation

- Manual Allis Chalmers tl14Document7 pagesManual Allis Chalmers tl14Johan QuesadaPas encore d'évaluation

- Technical Data: Fiberglass Tubulars Selected Chemical Resistance ChartDocument2 pagesTechnical Data: Fiberglass Tubulars Selected Chemical Resistance ChartMargarit IonelaPas encore d'évaluation

- Telecommunication Systems in Visakhapatnam Steel PlantDocument45 pagesTelecommunication Systems in Visakhapatnam Steel PlantNeeluCuteStarPas encore d'évaluation

- Dynamic Ultra Plus: SAE 15W-40Document2 pagesDynamic Ultra Plus: SAE 15W-40Wahyudhi Eko PrasetyoPas encore d'évaluation

- Yamaha - Service Manual - F300aDocument572 pagesYamaha - Service Manual - F300aJorge Lopes100% (1)

- Cam Belt (M40)Document11 pagesCam Belt (M40)Metin OmerPas encore d'évaluation

- UNIT-I (Engine Construction) .Ppt2Document47 pagesUNIT-I (Engine Construction) .Ppt2dhavalPas encore d'évaluation

- Mus (PPT 1)Document14 pagesMus (PPT 1)Sagar GawdePas encore d'évaluation

- Material Balance Estimation For OilDocument4 pagesMaterial Balance Estimation For OilPraveen Ran SubhePas encore d'évaluation

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherD'EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedD'EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- The Importance of Being Earnest: Classic Tales EditionD'EverandThe Importance of Being Earnest: Classic Tales EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (44)

- The Inimitable Jeeves [Classic Tales Edition]D'EverandThe Inimitable Jeeves [Classic Tales Edition]Évaluation : 5 sur 5 étoiles5/5 (3)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolD'EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolÉvaluation : 4 sur 5 étoiles4/5 (14)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoD'EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoÉvaluation : 3.5 sur 5 étoiles3.5/5 (1428)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyD'EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- The Comedians in Cars Getting Coffee BookD'EverandThe Comedians in Cars Getting Coffee BookÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Take My Advice: Letters to the Next Generation from People Who Know a Thing or TwoD'EverandTake My Advice: Letters to the Next Generation from People Who Know a Thing or TwoJames L. HarmonÉvaluation : 4 sur 5 étoiles4/5 (5)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticD'EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticÉvaluation : 3.5 sur 5 étoiles3.5/5 (10)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)