Académique Documents

Professionnel Documents

Culture Documents

Cemengal S.A. / Colombia Profinet Connection

Transféré par

reinelvillarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cemengal S.A. / Colombia Profinet Connection

Transféré par

reinelvillarDroits d'auteur :

Formats disponibles

IE0010.057.001-E.

CEMENGAL S.A. / COLOMBIA

PROFINET CONNECTION

f

e

d

c

b

a 13.05.14 BDU PBA Document N°

Rev Date REDIGE / Written by VERIFIE / Checked by Installation Type Incr. L Rev

DD/MM/YY (nom,visa / name,initials) (nom,visa / name,initials) IE0010 . 057 . 001 - E a

Page Nr: 1 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

1 INTRODUCTION ...................................................................................... 3

2 PROFINET DESCRIPTON ....................................................................... 3

2.1 INTRODUCTION ............................................................................................................ 3

2.2 PRESENTATION ........................................................................................................... 3

2.3 PRINCIPLE................................................................................................................... 4

3 COMMUNICATION BOARD AND LED´S ................................................ 5

4 DATA LAYOUT ........................................................................................ 6

4.1 PRINCIPLE................................................................................................................... 6

4.2 M AIN FEATURES OF THE KGR EDITOR ............................................................................ 7

4.3 DATA LAYOUT OF A WEIGHFEEDER ............................................................................. 12

4.3.1 ADDRESS ........................................................................................................... 12

4.3.2 POLL ................................................................................................................... 12

4.4 OUTPUTS ............................................................................................................... 12

4.4.1 OUTPUT VALUES .............................................................................................. 12

4.4.2 STATUS .............................................................................................................. 13

4.4.3 STATUS .............................................................................................................. 14

4.4.4 STATUS .............................................................................................................. 15

4.4.5 STATUS OF DIGITAL OUTPUTS ...................................................................... 16

4.4.6 STATUS OF DIGITAL INPUTS .......................................................................... 17

4.4.7 STATUS OF COMMUNICATION ....................................................................... 18

4.5 INPUTS ................................................................................................................... 19

4.5.1 INPUT VALUES .................................................................................................. 19

4.5.2 COMMANDS ....................................................................................................... 19

4.5.3 CONTROL OF COMMUNICATION .................................................................... 20

Page Nr: 2 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

1 Introduction

This document describes the used way in HE0050 to connect the SCM

equipments to Profinet.

2 PROFINET DESCRIPTON

2.1 Introduction

The purpose of this protocol is to establish a multipoint link for one or more SCM units

on a communication bus with a special interface card. This protocol allows SCM units

to be linked with programmable logic controllers or other higher level supervisors.

Until a communication protocol is standardized and becomes general, we have

implemented the PROFINET protocol, which is one of the most commonly used at

the present time.

This communication protocol is based on the OSI model and uses the following

layers:

7 (application layer) described in chapter25

2 (link layer) described in chapter 2.6

1 (physical layer) described in chapter 2.7

Communication with a PLC or other hierarchically superior equipment should

provide access to the following data and functions:

1. Reading the SCM status

2. Carrying out SCM commands (activation of functions)

3. Reading SCM parameter tables

4. Writing SCM parameter tables

5. Under defined conditions to read/write individual parameters

2.2 Presentation

The PROFINET protocol is a communication protocol developed by MODICON and

implemented by APRIL and other manufacturers to link together automatic devices.

In most cases, equipment manufacturers provide hardware and/or software

interfaces to handle the complete PROFINET protocol. This means that the user

has only to run the available services in the application layer according to the

provided instructions, the communication is than totally transparent.

In appendix we describe the different hardware and Software devices needed to link

SCM to Controllers from Siemens.

For the users, having to write the complete communication protocol (layers 1, 2

and 7) the complete specification of the protocol can be requested by:

Gould-MODICON

Gould PROFINET protocol, reference PI-MBUS-300 Rev D

Page Nr: 3 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

2.3 Principle

The PROFINET protocol is of I/O Controller – I/O Device

Each communication exchange includes 2 messages, that is:

• a request from the master and

• an answer from the slave.

The PROFINET / SCM interface is of slave type, which means that the SCM will only

respond to an explicit request from the master

The PROFINET protocol is multipoints.

This means that a master (and one only) and several slaves can be interconnected to

a communication network, as long as feasible with the hardware link. Each message

will include a destination address for the master´s request and a source address for the

slave's answer.

Page Nr: 4 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

3 COMMUNICATION BOARD AND LED´S

Page Nr: 5 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4 Data layout

4.1 Principle

The mapping of the data of each slave can be freely edited in the file

xxx.kgr for the weighfeeder machine. These operations are handled

with HASLER Tools distributed on CD ROM.

The mapping of the data, the IN/OUT block size are :

Input block size (64 Bytes)

Output block size (16 Bytes)

Page Nr: 6 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.2 Main features of the kgr editor

A) Main frame

Address of the communication protocol

1) The node address corresponds to the basic MB slave address. When the kgr-file is

downloaded to the SCM, this address is set to: SCM address + Node address.

For this, one kgr file can be downloaded to several SCM.

WF D1 Address: 1

IP ADRESS to be set by the MBDP SLAVE ADDRESS: 1+1=2

client

WF2 = 3 , WF3=4

Register size (Word) Example: MB address of the first SCM =27

Node address: 28

Page Nr: 7 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

B) Register properties for the Bitmap status

The register Nb can be edited.

The function for the register Nb can be edited.

C) Register properties for the edition of the bitmap status

An ASR, PSR (Parameter for the process) or ASW (Alarm process) can be affected at

each bit. The chart with all available ASR, ASW is distributed with the HASLERs Tools.

The ASR, ASW data are arranged inside according to the type of machine (Loss in weigh

feeder, Beltweighfeeder).

Page Nr: 8 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

D) Register properties for the edition of single parameters

Single parameters (Flowrate, setpoint,) can be mapped according to the following screen.

The register type can be also edited.

E) Register properties for a command edition

Each start-stop, clear alarm can be affected at each bit

Page Nr: 9 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

F) Reading an output status

The status of each output of the SCM (Total 16) can be read through a word.

Each bit is affected by a configured output of the SCM.

Example: Loss in weigh feeder with 2 agitators.

Bit 0 : Screw run

Bit 1 : Free

Bit 2 : Refill valve

Bit 3 : Hard alarm

Bit 4 : Feeder run

Bit 5 : Agitator I Run

Bit 6 : Agitator 2 Run

Bit 7 : Local / Remote

This outputs are configured with the SDU (output menu). The attributes of bit number is

according to the FE0040 number of the output.

Page Nr: 10 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

G) Reading or writing an input

Reading

The status of each input of the SCM (total 24) can be read through a word.

Each bit is affected to one individual word. Each word is set to a configured input of the

SCM.

Writing

It is also possible to modifiy the value of each input. For this, we have to switch off the

internal control of all inputs. We do not recommend to work in this mode.

It means for your application, we cannot check the “feedback run” and “thermal status” of

the machine.

Page Nr: 11 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

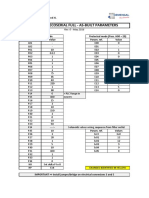

4.3 Data layout of a weighfeeder

IE0010_WBF1_Reva.kgr

4.3.1 ADDRESS

IP : 172.30.84.0

NetWork maskIP: 255.255.0.0

Default Gateway: 172.30.80.201

4.3.2 POLL

20 WORDS FOR READING / OUTPUT VALUES from 40001

4 WORDS FOR WRITING / INPUT VALUES from 41025

4.4 OUTPUTS

4.4.1 OUTPUT VALUES

FONCTION REGISTER FORMAT

ADRESS

Setpoint 40001-40002 IEEE FLOAT Feedback setpoint ( t/h)

Massflow 40003-40004 IEEE FLOAT Flowrate ( t/h)

Totalizer 40005-40006 IEEE FLOAT Dailay totalizer ( kg)

Permanent Totalizer 40007-40008 IEEE FLOAT Permanent totalizer( kg)

Free 40009-40010 IEEE FLOAT -

Belt load 40011-40012 IEEE FLOAT Load on the belt ( kg/m)

Belt speed 40013-40014 IEEE FLOAT Beltspeed ( m/s)

DriveCommand 40015-40016 IEEE FLOAT Feeder command ( %)

Free 40017-40018 IEEE FLOAT -

Free 40019-40020 IEEE FLOAT -

Free 40021-40022 IEEE FLOAT -

Page Nr: 12 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.2 STATUS

FUNCTION REGISTER FORMAT

ADDRESS

- 40023 BIT MAP STATUS

STATUS BIT DEFINITION

HASLER’S REGISTER FUNCTION (ACTIVE=1)

VALUE OFFSET

PSW 0 0 (LSB) FEEDER RUNNING

PSW 1 1 GRAVIMETRIC MODE

PSW 8 2 FEEDER INTERLOCKED

PSW 10 3 GENERAL ALARM

PSW 11 4 NEW ALARM

PSW 15 5 FEEDER AVAILABLE

PSW 23 6 HAND MODE ACTVATED

PSW 25 7 FEEDER STOPPED ON

ALARM

PSW 47 8 LOCAL/ REMOTE MODE

(LOCAL:1)

PSW 144 9 STATIC TARING IN

PROGRESS

PSW 148 10 NOT USE

PSW 149 11 NOT USE

PSW 161 12 NOT USE

PSW 151 13 BELT TARING IN

PROGRESS

PSW 152 14 BELT TARING RESULT

WITHIN LIMITS

XXXX 15 (MSB) ------

Page Nr: 13 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.3 STATUS

FUNCTION REGISTER FORMAT

ADDRESS

- 40024 BIT MAP STATUS

STATUS BIT DEFINITION

HASLER’S REGISTER FUNCTION

VALUE OFFSET

ASW 0 0 (LSB) ALARM:CPU FAULT

ASW 8 1 ALARM:BATTERY LOW

ASW 26 2 ALARM:SETPOINT TOO

LOW

ASW 27 3 ALARM:SETPOINT TOO

HIGH

ASW 28 4 ALARM:HAND MODE

SWITCH ON

ASW 29 5 ALARM:FLOWRATE OUT

OF RANGE

ASW 11 6 ALARM:MASSFLOW LOW

ASW 10 7 ALARM:MASSFLOW HIGH

ASW 64 8 ALARM: LOAD OF

MATERIAL TOO HIGH

ASW 65 9 ALARM: LOAD OF

MATERIAL TOO LOW

ASW 66 10 ALARM: WEIGHING

SYSTEM ERROR

ASW 80 11 ALARM: BELTDRIFT

ASW 81 12 ALARM: BELTSLIP

ASW 84 13 ALARM: BELT INDEX

FAULT

ASW 86 14 ALARM: TACHO FAULT

ASW 90 15 (MSB) ALARM: BELT TARE OUT

OF RANGE

Page Nr: 14 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.4 STATUS

FUNCTION REGISTER FORMAT

ADDRESS

- 40025 BIT MAP STATUS

STATUS BIT DEFINITION

HASLER’S REGISTER FUNCTION

VALUE OFFSET

ASW 91 0 (LSB) ALARM: COEF

CORRECTION OUT OF

RANGE

ASW 200 1 ALARM: FEEDBACK RUN

BELT MOTOR NOT

RESPONDING

XXX 2 ------

XXX 3 ------

XXX 4 ------

XXX 5 ------

XXX 6 ------

XXX 7 ------

XXX 8 ------

XXX 9 ------

XXX 10 ------

XXX 11 ------

XXX 12 ------

XXX 13 ------

XXX 14 ------

XXX 15 (MSB) ------

Page Nr: 15 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.5 STATUS OF DIGITAL OUTPUTS

FUNCTION REGISTER FORMAT

ADRESS

- 40026 INTEGER PASS THRU

STATUS BIT DEFINITION

DIGITAL INTEGER FUNCTION

OUTPUT VALUE

1 20 START BELT DRIVE

2 21 -----

3 22 -----

3 -----

4 2

5 24 -----

5 -----

6 2

7 26 -----

7 -----

8 2

9 28 -----

10 29 -----

11 210 -----

12 211 -----

13 212 -----

14 213 -----

15 214 -----

16 215 -----

... .... -----

24 223 -----

Page Nr: 16 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.6 STATUS OF DIGITAL INPUTS

FUNCTION REGISTER FORMAT

ADDRESS

- 40027 INTEGER PASS THRU

STATUS BIT DEFINITION

DIGITAL INTEGER FUNCTION

OUTPUT VALUE

1 20 -----

2 21 -----

3 22 -----

3 FRENQUENCY INVERTER

4 2

AVAILABLE

5 24 -----

6 25 BELTDRIFT

7 26 HAND MODE ACTVATED

8 27 -----

9 28 -----

10 29 -----

11 210 -----

12 211 -----

13 212 -----

13 -----

14 2

15 214 -----

15 -----

16 2

Page Nr: 17 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.4.7 STATUS OF COMMUNICATION

FUNCTION REGISTER FORMAT

ADRESS

HeartBeat 40028 INTEGER PASS Communication crtl: The

THRU SCM writes a value to

the above register and

the supervisor checks

that the value has

changed

Page Nr: 18 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.5 INPUTS

4.5.1 INPUT VALUES

FUNCTION REGISTER FORMAT

ADDRESS

Setpoint 41025-41026 IEEE FLOAT

4.5.2 COMMANDS

FUNCTION REGISTER FORMAT

ADDRESS

- 41028 COMMANDS

STATUS BIT DEFINITION

HASLER’S REGISTER FUNCTION

VALUE OFFSET

CSTC 0 (LSB) Start feeder ACTIVE HIGH

CSPC 1 Stop feeder ACTIVE HIGH

CALA 2 Alarm acknowledge RISING EDGE

CALC 3 Alarm clear RISING EDGE

CTOC 4 Clear totalizer RISING EDGE

CVOM 5 Set Vol. Mode RISING EDGE

CMAM 6 Set Mass Mode RISING EDGE

CTAR 7 Belt tare RISING EDGE

CTR2 8 Static taring RISING EDGE

CCPM 9 Main ctrl point RISING EDGE

selection

(Remote mode)

CCPA 10 Aux ctrl point RISING EDGE

selection

(Local mode)

XXX 11 ------

XXX 12 ------

XXX 13 ------

XXX 14 ------

XXX 15 (MSB) ------

Page Nr: 19 / 20 13.05.15 Rev.a /BDU

IE0010.057.001-E.a

4.5.3 CONTROL OF COMMUNICATION

FUNCTION REGISTER FORMAT

ADDRESS

HostHeartBeat 41027 INTEGER PASS Communication crtl: The

THRU Host writes a value to

the above register and

the SCM checks that the

value has changed. If

not, a message is

displayed on the SDU

Page Nr: 20 / 20 13.05.15 Rev.a /BDU

Vous aimerez peut-être aussi

- Truckcom TE ManualDocument44 pagesTruckcom TE ManualNgo Ngoc Tu100% (9)

- Meag 66499-14Document43 pagesMeag 66499-14DMPas encore d'évaluation

- Terra AC Modbus Documentation - 20210903Document25 pagesTerra AC Modbus Documentation - 20210903HenrikPas encore d'évaluation

- Your Soul Is A River by Nikita Gill PDFDocument6 pagesYour Soul Is A River by Nikita Gill PDFAnnePas encore d'évaluation

- Enterprise Resource Planning: Concepts and PracticeDocument16 pagesEnterprise Resource Planning: Concepts and PracticePaul Macovei0% (1)

- NOJA-508-02 Modbus Protocol ImplementationDocument18 pagesNOJA-508-02 Modbus Protocol Implementationpatricio2015100% (1)

- Selectra CommuniationDocument30 pagesSelectra CommuniationSyarif Udin100% (1)

- Decentralization With Profibus DP DPV1 2ed-07-2003 eDocument254 pagesDecentralization With Profibus DP DPV1 2ed-07-2003 eLinh-son LeTien100% (2)

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxD'EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxÉvaluation : 4 sur 5 étoiles4/5 (1)

- VOCALOID4 Editor ManualDocument178 pagesVOCALOID4 Editor ManualAlekid ThunderPas encore d'évaluation

- 1SFC132085M0201 PSTX AB ProfiBusDocument27 pages1SFC132085M0201 PSTX AB ProfiBusfpg.servicosPas encore d'évaluation

- 452 840 840C 880 PLC 135WB 135WB2 Package 7 Code CarriersDocument110 pages452 840 840C 880 PLC 135WB 135WB2 Package 7 Code CarriersООО ЛантисPas encore d'évaluation

- Application Note On Upgradation of C-Dot Dss To Support V5.2 InterfaceDocument72 pagesApplication Note On Upgradation of C-Dot Dss To Support V5.2 InterfaceMahesh Kumar NigamPas encore d'évaluation

- DCON Utility Pro User Manual: Version 2.0.1, February 2019Document49 pagesDCON Utility Pro User Manual: Version 2.0.1, February 2019harves100% (1)

- PM130 ModbusDocument29 pagesPM130 ModbusStanleyPas encore d'évaluation

- 1SFC132367M0201 PSE Internal Modbus RTUDocument22 pages1SFC132367M0201 PSE Internal Modbus RTUAhmed OsmanPas encore d'évaluation

- BA - KOSTAL Interface Description MODBUS - PIKO CIDocument38 pagesBA - KOSTAL Interface Description MODBUS - PIKO CIJuan Carlos Martinez ChavesPas encore d'évaluation

- NOJA-519-07 DNP3 Protocol Implementation PDFDocument40 pagesNOJA-519-07 DNP3 Protocol Implementation PDFDale Johnson100% (2)

- Compass OverviewDocument44 pagesCompass OverviewjersonPas encore d'évaluation

- Sunny Webbox Plant Monitoring User ManualDocument30 pagesSunny Webbox Plant Monitoring User ManualpvpavanPas encore d'évaluation

- Recipe Function: Sample Screen ManualDocument14 pagesRecipe Function: Sample Screen ManualRafael GagoPas encore d'évaluation

- SERRATRON PROC - 001a - XSMDocument17 pagesSERRATRON PROC - 001a - XSMFelipe Ribeiro MatiasPas encore d'évaluation

- Fiber Media Converter - 93X - User Manual V1.5Document16 pagesFiber Media Converter - 93X - User Manual V1.5olaadesamPas encore d'évaluation

- Modbus Application Protocol V1 1b3Document50 pagesModbus Application Protocol V1 1b3cjalanisPas encore d'évaluation

- NOJA-565-14 SCADA Interface Description - 0Document67 pagesNOJA-565-14 SCADA Interface Description - 0astorzeroPas encore d'évaluation

- LM500Document88 pagesLM500Coste GuillaumePas encore d'évaluation

- NOJA-519-10 DNP3 Protocol ImplementationDocument41 pagesNOJA-519-10 DNP3 Protocol Implementationbrykyma100% (2)

- 443 840 840C 850 880 Computer Link Descr of Message FramesDocument140 pages443 840 840C 850 880 Computer Link Descr of Message FramesООО ЛантисPas encore d'évaluation

- An-15007 2016-05-03 Using Redundancy Protocols v1.0 With G6 Devices v1.0Document44 pagesAn-15007 2016-05-03 Using Redundancy Protocols v1.0 With G6 Devices v1.0victor mauricio colonia rangelPas encore d'évaluation

- SPI-Telecom Operation Procedure PDFDocument133 pagesSPI-Telecom Operation Procedure PDFsithulibraPas encore d'évaluation

- Manual ProtoCessorDocument33 pagesManual ProtoCessorjohaquin lovePas encore d'évaluation

- Modbus Application Protocol V1 1bDocument51 pagesModbus Application Protocol V1 1bAlexander E. GuzmanPas encore d'évaluation

- Modbus Application Protocol V1 1aDocument51 pagesModbus Application Protocol V1 1aKamal BajajPas encore d'évaluation

- Devicenet: Commissioning Examples Scalable PLC For Individual AutomationDocument28 pagesDevicenet: Commissioning Examples Scalable PLC For Individual AutomationJuan Pablo Galvan CamachoPas encore d'évaluation

- Alarm Function (Level/Sort) : Sample Screen ManualDocument14 pagesAlarm Function (Level/Sort) : Sample Screen ManualRafael GagoPas encore d'évaluation

- Fuji FRENICeco PDP ManualDocument36 pagesFuji FRENICeco PDP ManualHamadi Ben SassiPas encore d'évaluation

- Commissioning Example Scalable PLC For Individual AutomationDocument8 pagesCommissioning Example Scalable PLC For Individual AutomationJuan Pablo Galvan CamachoPas encore d'évaluation

- STM32F10xxx I2C Optimized ExamplesDocument16 pagesSTM32F10xxx I2C Optimized ExamplescansuPas encore d'évaluation

- Modbus Remote Communication Protocol For REC 523: Technical DescriptionDocument124 pagesModbus Remote Communication Protocol For REC 523: Technical DescriptionBata ZivanovicPas encore d'évaluation

- Web Master® WIND Modbus Instruction ManualDocument22 pagesWeb Master® WIND Modbus Instruction ManualWalchem MarketingPas encore d'évaluation

- Hardware Module Description: Kongsberg Maritime Part No.330924Document42 pagesHardware Module Description: Kongsberg Maritime Part No.330924edi2805Pas encore d'évaluation

- NY8B062D v1.8Document115 pagesNY8B062D v1.8webebe9888Pas encore d'évaluation

- S0100846 T7433 - DCDA System, Keppel FELS B289 Keppel Fels B289Document28 pagesS0100846 T7433 - DCDA System, Keppel FELS B289 Keppel Fels B289John LockPas encore d'évaluation

- Simatic Net: S7-Cps For Industrial EthernetDocument36 pagesSimatic Net: S7-Cps For Industrial EthernetTrust MarongedzePas encore d'évaluation

- CC2520 Software Examples User's Guide: SWRU137B 1Document28 pagesCC2520 Software Examples User's Guide: SWRU137B 1John MacPas encore d'évaluation

- PGH FC FB Fuer s7cp 76Document191 pagesPGH FC FB Fuer s7cp 76Surit ApiwanPas encore d'évaluation

- Simatic Net: S7-Cps For Industrial EthernetDocument34 pagesSimatic Net: S7-Cps For Industrial EthernetObby AryasuciPas encore d'évaluation

- Manual Fairbanks FB 2250Document26 pagesManual Fairbanks FB 2250CCASTELLARPas encore d'évaluation

- CP 443-1Document28 pagesCP 443-1Jacob KalloorPas encore d'évaluation

- AN-1160 Application Note: Cortex-M3-Based Serial Download ProtocolDocument8 pagesAN-1160 Application Note: Cortex-M3-Based Serial Download ProtocolMárcio FerreiraPas encore d'évaluation

- Appendix B To The A955 V5.01 User ManualDocument21 pagesAppendix B To The A955 V5.01 User ManualSaptono GunawanPas encore d'évaluation

- Modbus RTU - One JobDocument24 pagesModbus RTU - One JobIsmail ShahidPas encore d'évaluation

- CP 443-1 PDFDocument28 pagesCP 443-1 PDFmlcsdrPas encore d'évaluation

- CODESYS SoftMotion & IndraDrive - EtherCAT CoEDocument33 pagesCODESYS SoftMotion & IndraDrive - EtherCAT CoEAjay SahuPas encore d'évaluation

- DPM b100 Modbus Map UserDocument4 pagesDPM b100 Modbus Map UsermkarimiloloPas encore d'évaluation

- CISCO PACKET TRACER LABS: Best practice of configuring or troubleshooting NetworkD'EverandCISCO PACKET TRACER LABS: Best practice of configuring or troubleshooting NetworkPas encore d'évaluation

- C Programming for the Pc the Mac and the Arduino Microcontroller SystemD'EverandC Programming for the Pc the Mac and the Arduino Microcontroller SystemPas encore d'évaluation

- Evidence My Dream VacationDocument6 pagesEvidence My Dream VacationreinelvillarPas encore d'évaluation

- Manual Usuario FTV SE InglesDocument573 pagesManual Usuario FTV SE InglesJorge Luis Martinez GarciaPas encore d'évaluation

- Evidence - Vacations Around - The WorldDocument4 pagesEvidence - Vacations Around - The WorldreinelvillarPas encore d'évaluation

- Evidence Vacations Around The WorldDocument4 pagesEvidence Vacations Around The WorldMadeleine Elles MaciasPas encore d'évaluation

- LCD and TV Repair GuideDocument195 pagesLCD and TV Repair GuideUlisesMartin79% (14)

- Learning Activity 1 / Actividad de Aprendizaje 1 Evidence: Describing My Kitchen / Evidencia: Describiendo Mi CocinaDocument3 pagesLearning Activity 1 / Actividad de Aprendizaje 1 Evidence: Describing My Kitchen / Evidencia: Describiendo Mi CocinareinelvillarPas encore d'évaluation

- DSE701 MKII Installation Instructions PDFDocument2 pagesDSE701 MKII Installation Instructions PDFAung MhPas encore d'évaluation

- DSE701 MKII Installation Instructions PDFDocument2 pagesDSE701 MKII Installation Instructions PDFAung MhPas encore d'évaluation

- LG CM8440 PDFDocument79 pagesLG CM8440 PDFALEJANDROPas encore d'évaluation

- DSE701 MKII Installation Instructions PDFDocument2 pagesDSE701 MKII Installation Instructions PDFAung MhPas encore d'évaluation

- DSE701 MKII Installation Instructions PDFDocument2 pagesDSE701 MKII Installation Instructions PDFAung MhPas encore d'évaluation

- 4024 EPG (Electrically Powered Governor) : Product Manual 82042 (Revision B, 3/2008)Document34 pages4024 EPG (Electrically Powered Governor) : Product Manual 82042 (Revision B, 3/2008)reinelvillarPas encore d'évaluation

- IE0010-Lista de Piezas de RecambioDocument2 pagesIE0010-Lista de Piezas de RecambioreinelvillarPas encore d'évaluation

- DSE701 MKII Installation Instructions PDFDocument2 pagesDSE701 MKII Installation Instructions PDFAung MhPas encore d'évaluation

- Diagrama Deep Sea 5220Document1 pageDiagrama Deep Sea 5220MH..2023Pas encore d'évaluation

- General Specifications For The Installation and The Wiring of The Hasler Electrical EquipmentsDocument5 pagesGeneral Specifications For The Installation and The Wiring of The Hasler Electrical EquipmentsreinelvillarPas encore d'évaluation

- Cavotec Flexible Power and Control Cables CatalogueDocument34 pagesCavotec Flexible Power and Control Cables CatalogueRelief_EngineerPas encore d'évaluation

- Static Calibration Procedure: 1. Do The Zero Correction in The MenuDocument7 pagesStatic Calibration Procedure: 1. Do The Zero Correction in The Menureinelvillar100% (1)

- Diagrama Deep Sea 5220Document1 pageDiagrama Deep Sea 5220MH..2023Pas encore d'évaluation

- 416-BF01-REDECAM-ECOSERIAL ParametersDocument1 page416-BF01-REDECAM-ECOSERIAL Parametersreinelvillar0% (1)

- Redes Electricas 1ra Ed. - Leopoldo Silva Bijit PDFDocument470 pagesRedes Electricas 1ra Ed. - Leopoldo Silva Bijit PDFEdwin Santiago Villegas Auques100% (2)

- Manual para Tarjeta Reguladora de Voltaje AVR MX321Document6 pagesManual para Tarjeta Reguladora de Voltaje AVR MX321Rodrigo ObregonPas encore d'évaluation

- Spring Boot 033Document10 pagesSpring Boot 033Raj AryanPas encore d'évaluation

- DM GTU Study Material Presentations Unit-6 21052021124430PMDocument33 pagesDM GTU Study Material Presentations Unit-6 21052021124430PMSarvaiya SanjayPas encore d'évaluation

- PythonDocument1 pagePythonvinodjamesPas encore d'évaluation

- FYND OMS Overview 23Document33 pagesFYND OMS Overview 23rahulPas encore d'évaluation

- Implementating Air Traffic Fow Management and Airport-Collaborative Decision MakingDocument75 pagesImplementating Air Traffic Fow Management and Airport-Collaborative Decision MakingPRAKPas encore d'évaluation

- AMC-KM CA 000246 RevF EN-mobile PDFDocument220 pagesAMC-KM CA 000246 RevF EN-mobile PDFray rayPas encore d'évaluation

- CPU AffinityDocument4 pagesCPU Affinityvivek_ibmPas encore d'évaluation

- Data Structures Through C++Document2 pagesData Structures Through C++Mighty ITPas encore d'évaluation

- Database Client Installation Guide Oracle SolarisDocument63 pagesDatabase Client Installation Guide Oracle Solarispush55Pas encore d'évaluation

- Scheme of Study BS (IT) 2019-23Document21 pagesScheme of Study BS (IT) 2019-23Rashid MehmoodPas encore d'évaluation

- Huawei Singlesdb v100r006c00 Hss9860 Feature Descriptionhlr and Epc Hss FeDocument191 pagesHuawei Singlesdb v100r006c00 Hss9860 Feature Descriptionhlr and Epc Hss FeMahamane Ali SalatouPas encore d'évaluation

- Kia J2534 Reprogramming SystemDocument1 pageKia J2534 Reprogramming SystemCristhian HuilcapazPas encore d'évaluation

- Project Task List TemplateDocument4 pagesProject Task List TemplateSantiago FonsecaPas encore d'évaluation

- Awsome Day Online Conference Hands On Lab Handout q420 FinalDocument2 pagesAwsome Day Online Conference Hands On Lab Handout q420 Finalsunilbhardwajblb2392Pas encore d'évaluation

- Shark 250 Meter Modbus Manual E169711Document354 pagesShark 250 Meter Modbus Manual E169711Jorge RojasPas encore d'évaluation

- Software Description For Front Loaded Bill ValidatorDocument6 pagesSoftware Description For Front Loaded Bill ValidatorzhekasxgPas encore d'évaluation

- LS07 Chassis Service ManualDocument33 pagesLS07 Chassis Service ManualnaughtybigboyPas encore d'évaluation

- Activate by Using Multiple Activation KeyDocument3 pagesActivate by Using Multiple Activation KeyMonokino GmzPas encore d'évaluation

- DAE Brochure - 2022Document52 pagesDAE Brochure - 2022Wsi Andrea ChlebikovaPas encore d'évaluation

- PQView Expanding Into Grid Operations PDFDocument60 pagesPQView Expanding Into Grid Operations PDFbdsrlPas encore d'évaluation

- A Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationDocument6 pagesA Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationAhmadMoaazPas encore d'évaluation

- Infoblox API Documentation 5Document1 064 pagesInfoblox API Documentation 5Helios De CreisquerPas encore d'évaluation

- Installing The Dark GDK With Visual Studio 2008Document9 pagesInstalling The Dark GDK With Visual Studio 2008chuckschultz22Pas encore d'évaluation

- Attacks Against Bluetooth Low Energy FindersDocument5 pagesAttacks Against Bluetooth Low Energy FindersMoath NajiPas encore d'évaluation

- Manual Kenwood DNX9960Document124 pagesManual Kenwood DNX9960Belkys Paez100% (1)

- Sap Basis T CodesDocument3 pagesSap Basis T CodesVenkatesh Vykuntam100% (1)