Académique Documents

Professionnel Documents

Culture Documents

181 FX-4076

Transféré par

Haytham A.Elaal M.Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

181 FX-4076

Transféré par

Haytham A.Elaal M.Droits d'auteur :

Formats disponibles

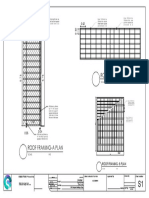

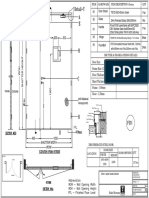

L & L L&L LOUVERS INC.

12355 DOHERTY STREET MODEL FX-4076

RIVERSIDE, CA. 92503 FIXED EXTRUDED ALUMINUM LOUVER

(951) 735-9300 FAX:(951)735-4628 4" Inverted 60° Blade

E-MAIL: info@louver1.com

Removable Insect Expansion Joint

or Bird Screen @ Interlocking Mullion

Opening Head

(ref.)

Screen Frame,

Extruded 6063-T5

Aluminum, .050"

LOUVER Wall Thickness

1/8" Clr. (3mm)

BLADES

1-3/4" (44mm)

Opening

Frame Face

Jamb Channel Frame,

(ref.) Extruded 6063-T5

Caulking Slot Aluminum, .081"

1/8"Clr. 3/16" (5mm) Wall Thickness

(3mm) (EXTERIOR)

Opening Dimension

4" (100mm) O.C.

Louver Blades

Frame Depth

TYPICAL HORIZONTAL SECTION 4" (100mm) Removable Bird

Screen 1/2" Mesh,

.063" Aluminum Wire

Mitred and

Opening Dimension

*Opening Width Reinforced

Corners

Fixed Inverted V

Louver Blade

Extruded 6063-T5

Blade Face

1" (25mm)

Aluminum, .100"

60 Wall Thickness

(EXTERIOR)

*Opening Height

1/8" Clr. (3mm)

3/16" (5mm)

Screen Mounting

Screws, #8 x1/2"

Hex Washer Head

TEKS 2 Plated

@ 24" O.C.

Opening Sill

(ref.)

*Actual net louver size will be

1/4" under Opening Dimensions.

FRONT ELEVATION TYPICAL VERTICAL SECTION

PROJECT:

LOCATION:

ARCHITECT:

CONTRACTOR:

CUSTOMER: DATE:

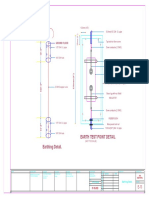

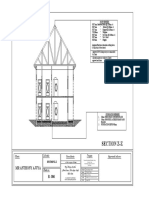

L & L L&L LOUVERS INC. TYPICAL LOUVER

12355 DOHERTY STREET INSTALLATION METHODS

RIVERSIDE, CA. 92503 (EXTRUDED ALUMINUM LOUVERS )

(951) 735-9300 FAX:(951)735-4628

E-MAIL: info@louver1.com

FIGURE B FIGURE D FIGURE E FIGURE F

1/4-20 BOLT

AND NUT

(BY OTHERS)

LOUVER

FRAME

FIGURE I FIGURE J

FIGURE C EXPOSED MULLION HIDDEN MULLION

FIGURE G

JOINT DETAIL JOINT DETAIL

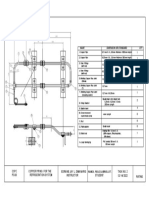

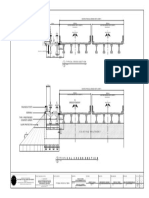

1. UPON RECEIPT, CHECK SHIPPING CONTAINERS FOR ANY DAMAGE 6. STRAP ANCHORS MAY BE USED IF THEY WERE INSTALLED WHILE MASONARY

THAT MAY HAVE OCCURRED DURING TRANSIT. NOTE ANY WAS BEING POURED OR WHILE BLOCKS WERE BEING LAID

DAMAGES ON THE DELIVERY RECEIPT. IF CONCEALED DAMAGE

HAS OCCURRED. YOU MUST NOTIFY THE FREIGHT CARRIER WITHIN 7. EXPANSION ANCHORS OR LEAD SHIELDS AND BOLTS MADE FOR MASONARY

(15) DAYS SO THAT CLAIMS CAN BE FIELD. WAY BE USED. FASTENING CAN BE ACHIEVED THROUGH THE LOUVER

FRAME OR BY USING ANGLES LOCATED BEHIND THE LOUVER (SEE FIGURES

B AND C).

2. PRIOR TO INSTALLING CHECK THE OPENING FOR SQUARNESS AND

ANY OBSTRUCTIONS THAT MAY INTERFERE WITH THE MOUNTING OR

8. A FLANGED FRAME LOUVER CAN BE INSTALLED WITH FASTENERS THROUGH

OPERATION OF THE LOUVER. VERIFY THAT THE LOUVER IS UNDER-

THE FLANGE INTO THE WALL (SEE FIGURE D).

SIZED APPROXIMATELY 1/4" SO THAT THE LOUVER IS NOT FORCED

INTO THE OPENING. 9. FASTENERS THROUGH THE LOUVER FRAME INTO THE SUBFRAME CAN BE

USED IT BLADE SPACING AND ACCESSIBILITY PERMIT (SEE FIGURE E).

3. THE LOUVER MUST BE INSTALLED SQUARE AND FREE FROM RACKING

TO ENSURE PROPER PERFORMANCE. THIS SHOULD BE CHECKED 10. CLIPS, CONTINUOUS ANGLES, OR PLATES MAY BE INSTALLED BEHIND THE

PRIOR TO FASTENING THE FRAME TO THE OPENING. LOUVER AND FASTEND TO SUBFRAME (SEE FIGURE F).

4. WHEN JOINING MULTIPLE SECTION LOUVER ASSEMBLIES. LARGER 11. INSTALLATION INTO WOOD FRAMING IS THE SAME AS METAL FRAMING,

ASSEMBLY MAY REQUIRE ADDITIONAL BRACING ON THE INTERIOR FOR EXCEPT THAT WOOD SCREWS WOULD NORMALLY BE USED.

TYPICAL MULLION JOINT DETAILS.

12. PROTECTION AGAINST WATER INFILTRATION CAN BE ACHIEVED BY ADDING A

5. SECURE LOUVER INTO OPENING USING THE APPROPRIATE TYPE OF DRIP CAP AT THE HEAD AND RECESSING THE LOUVER AS A MINIMUM (SEE

FASTENER FOR WHICH THE WALL OPENING IS MADE OF SPACE FIGURE G). ADDITIONAL PROTECTION CAN BE ACHIEVED BY ADDING A

GUTTERRRRR STYLE DRIP CAP AT THE HEAD, A WATER TIGHT DRIP PAN, AND

FASTENERS A MAXIMUM OF 24 INCHES ON CENTER.

AN OPTIMAL DRAIN

13. ALL HARDWARE SUCH AS CLIPS, ANGLES, AND ADDITIONAL BRACING ARE

SUPPLIED BY OTHERS UNLESS OTHERWISE NOTED.

PROJECT:

LOCATION:

ARCHITECT:

CONTRACTOR:

CUSTOMER: DATE:

Vous aimerez peut-être aussi

- Section-05 RJT RJTWDocument2 pagesSection-05 RJT RJTWSandro gomez castroPas encore d'évaluation

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIAPas encore d'évaluation

- A703 -SKY LIGHT & HANDRAIL DETAILSDocument1 pageA703 -SKY LIGHT & HANDRAIL DETAILSØwięs MØhãmmedPas encore d'évaluation

- Standing Seam Awning Product SheetDocument1 pageStanding Seam Awning Product SheetMoezart JsPas encore d'évaluation

- Drawing4 AOTpdfDocument1 pageDrawing4 AOTpdfSUBHAJIT DHARAPas encore d'évaluation

- Drawing4 AOTDocument1 pageDrawing4 AOTSUBHAJIT DHARAPas encore d'évaluation

- SD220511 01Document1 pageSD220511 01Minh TranPas encore d'évaluation

- Zenith - Barrier ChannelsDocument2 pagesZenith - Barrier ChannelsJustine PechayPas encore d'évaluation

- Truss DEtailDocument1 pageTruss DEtailjerick calingasanPas encore d'évaluation

- Second Floor Reflected Ceiling Plan: Schedule of Ceiling FinishesDocument1 pageSecond Floor Reflected Ceiling Plan: Schedule of Ceiling FinishesMJian VergaraPas encore d'évaluation

- MISCELLANEOUSDocument1 pageMISCELLANEOUSDerf Jayson AdantePas encore d'évaluation

- # Exhaust Stack Detail: (17.8 M/S) Outlet VelocityDocument1 page# Exhaust Stack Detail: (17.8 M/S) Outlet VelocityKen SuPas encore d'évaluation

- Besada BT05 Sheet3 SectionandplotdetailsDocument1 pageBesada BT05 Sheet3 SectionandplotdetailsBesada BryanPas encore d'évaluation

- Elevation: SectionDocument1 pageElevation: SectioncimpstazPas encore d'évaluation

- S1 PDFDocument1 pageS1 PDFHassan AlaskaPas encore d'évaluation

- Centria-Super Rib-Tech Data SheetDocument2 pagesCentria-Super Rib-Tech Data SheetwipiriPas encore d'évaluation

- Tractor Flail MowerDocument1 pageTractor Flail MowerRaheem m.aPas encore d'évaluation

- Construction of Gate-Layout3Document1 pageConstruction of Gate-Layout3michael jan de celisPas encore d'évaluation

- Hand SketchDocument3 pagesHand SketchNevena StojkovicPas encore d'évaluation

- Gabion Basket Isometric: AB ION CE LLDocument1 pageGabion Basket Isometric: AB ION CE LLruspapiPas encore d'évaluation

- Electrical Drawing of School Building E-13Document1 pageElectrical Drawing of School Building E-13shafiq_05Pas encore d'évaluation

- SC 500/1000 Series: Capable of Lateral MovementDocument2 pagesSC 500/1000 Series: Capable of Lateral Movementami oreverPas encore d'évaluation

- C200-Roadworks Notes and Details-C210Document1 pageC200-Roadworks Notes and Details-C210Don WangPas encore d'évaluation

- Structural Steel in Housing Connection Examples - OS20 PDFDocument6 pagesStructural Steel in Housing Connection Examples - OS20 PDFMuriungi RicharsPas encore d'évaluation

- Standard Fire Hosereel Cabinet FeaturesDocument2 pagesStandard Fire Hosereel Cabinet FeaturesJimmy TanPas encore d'évaluation

- American-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps SpecsDocument24 pagesAmerican-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps Specsjuan davidPas encore d'évaluation

- 9 Pieces of Trusses With 1.5M Gap: Typ. Con. Gutter Details Parapet Roof DetailsDocument1 page9 Pieces of Trusses With 1.5M Gap: Typ. Con. Gutter Details Parapet Roof DetailsJericho Jon IlocoPas encore d'évaluation

- 9 Pieces of Trusses With 1.5M Gap: Typ. Con. Gutter Details Parapet Roof DetailsDocument1 page9 Pieces of Trusses With 1.5M Gap: Typ. Con. Gutter Details Parapet Roof DetailsJericho Jon IlocoPas encore d'évaluation

- Stoody 105Document1 pageStoody 105JUAN DAVID ESPITIAPas encore d'évaluation

- PLAN at FUENTE STATION - DRAINAGE-PLAN AT FUENTE 02Document1 pagePLAN at FUENTE STATION - DRAINAGE-PLAN AT FUENTE 02Dyeri FloresPas encore d'évaluation

- Type 2.1Document1 pageType 2.1daveglai24Pas encore d'évaluation

- Ramos Copper Piping For The Refrigeration System Layout2Document1 pageRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosPas encore d'évaluation

- BelGAS P627 R627 F627Document24 pagesBelGAS P627 R627 F627Prihartono Danan WingusPas encore d'évaluation

- UntitledDocument1 pageUntitledemmanuelPas encore d'évaluation

- Silicon Chip Magazine 2009-10 Oct PDFDocument108 pagesSilicon Chip Magazine 2009-10 Oct PDFLucilia Dos Santos100% (1)

- Crude Oil 200 BBL - Ga - RCDocument1 pageCrude Oil 200 BBL - Ga - RCApichart ChoksawadPas encore d'évaluation

- Property: +3.500 LEVEL +1187.30Document1 pageProperty: +3.500 LEVEL +1187.30Iveel PurevdorjPas encore d'évaluation

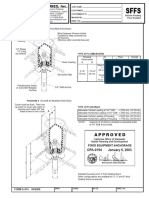

- SFFSDocument1 pageSFFSFede AccorintiPas encore d'évaluation

- Schedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanDocument1 pageSchedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanLeonard Delos ReyesPas encore d'évaluation

- Ground Floor Reflected Ceiling Plan: Legend: LegendDocument1 pageGround Floor Reflected Ceiling Plan: Legend: LegendMPas encore d'évaluation

- Details Sample 4 Roof Eve PDFDocument1 pageDetails Sample 4 Roof Eve PDFNg TzewayPas encore d'évaluation

- Clinic Livinus Section A-1Document1 pageClinic Livinus Section A-1Fernando RafaelPas encore d'évaluation

- PL300 1Document1 pagePL300 1Fatima GuinidPas encore d'évaluation

- Model C & CA Globe and Angle Main Valves Technical SpecsDocument4 pagesModel C & CA Globe and Angle Main Valves Technical SpecsAnderson SiqueiraPas encore d'évaluation

- Col & Beam & StairsDocument1 pageCol & Beam & StairsMohammad AlkahteebPas encore d'évaluation

- DFDFDSFDocument11 pagesDFDFDSFBayu SubiyantoPas encore d'évaluation

- Aakar Facade Solution-1Document1 pageAakar Facade Solution-1Nazeer AhamedPas encore d'évaluation

- Sl-Ab-Op-11m-Sa-Ga Drawing PDFDocument1 pageSl-Ab-Op-11m-Sa-Ga Drawing PDFAkash BogaPas encore d'évaluation

- Schedule and details of footingsDocument1 pageSchedule and details of footingsVerna Balang MartinezPas encore d'évaluation

- Clinic Project 01 - 014610Document1 pageClinic Project 01 - 014610Joyce JerePas encore d'évaluation

- Bay Sect VillanuevaDocument2 pagesBay Sect VillanuevaRafaela VillanuevaPas encore d'évaluation

- Section Z-Z: MR Anthony AjuyaDocument1 pageSection Z-Z: MR Anthony AjuyaMeshach SamuelPas encore d'évaluation

- Victorio PG 4Document1 pageVictorio PG 4Mark Nico Meneses GallogoPas encore d'évaluation

- Typical Cross Section: Existing Parallel Bridge Width (Verify)Document1 pageTypical Cross Section: Existing Parallel Bridge Width (Verify)Erika Faye GutierrezPas encore d'évaluation

- Poooooooooooooooooole Data SheetDocument1 pagePoooooooooooooooooole Data Sheetfathy.shehabPas encore d'évaluation

- Model EA 403 Louver SpecificationsDocument2 pagesModel EA 403 Louver SpecificationsAya EzzPas encore d'évaluation

- 21-010 Hernandez Barn - R22 - 07-05-2022Document3 pages21-010 Hernandez Barn - R22 - 07-05-2022sambhavi vermaPas encore d'évaluation

- Scheme 1Document1 pageScheme 1Jasmer Lloyd Diaz EspadaPas encore d'évaluation

- MEP-DD-L11-A2-EL-0004 A2-MEP A2-11th Floor LV Installation Details R0Document1 pageMEP-DD-L11-A2-EL-0004 A2-MEP A2-11th Floor LV Installation Details R0my.work.ksabPas encore d'évaluation

- An Introduction to Metal-Working (Illustrated)D'EverandAn Introduction to Metal-Working (Illustrated)Évaluation : 2.5 sur 5 étoiles2.5/5 (2)

- ATP IndexDocument2 352 pagesATP IndexRicardo zafra100% (1)

- Surface Vehicle Standard: (R) Hydraulic Hose FittingsDocument34 pagesSurface Vehicle Standard: (R) Hydraulic Hose FittingsLUCIANO SOTOPas encore d'évaluation

- Acc Grip Housing: Code Itemname Unit M.O.P MRPDocument118 pagesAcc Grip Housing: Code Itemname Unit M.O.P MRPphenomenal hunkPas encore d'évaluation

- Is 4996 1984Document31 pagesIs 4996 1984Upali KarunarathnePas encore d'évaluation

- PM IS 1364 Part 1 April 2020Document9 pagesPM IS 1364 Part 1 April 2020jyoti prakash singhPas encore d'évaluation

- Design of an above ground sulphuric acid storage tankDocument143 pagesDesign of an above ground sulphuric acid storage tankAngel Alvarez100% (6)

- IRC5-IRC5 Product Reference Manual 3HAC021313-001 - Part2 - Reva - en PDFDocument144 pagesIRC5-IRC5 Product Reference Manual 3HAC021313-001 - Part2 - Reva - en PDFjdcpe17Pas encore d'évaluation

- Quiz 4 POSDDocument1 pageQuiz 4 POSDJewelPas encore d'évaluation

- Disco1 Comb MPL 090508 Add DelDocument6 pagesDisco1 Comb MPL 090508 Add DelBalachandar SathananthanPas encore d'évaluation

- SECTION 16400 Electrical Overhead Transmission: GeneralDocument15 pagesSECTION 16400 Electrical Overhead Transmission: Generalgerrzen64Pas encore d'évaluation

- 8.4 Spherical Roller BearingsDocument68 pages8.4 Spherical Roller Bearingsrrobles011Pas encore d'évaluation

- Build An Adjustable Sawhorse Under $60 In 3 HoursDocument15 pagesBuild An Adjustable Sawhorse Under $60 In 3 HoursMad Cow100% (1)

- Hex Cap Screw Certificate of ComplianceDocument1 pageHex Cap Screw Certificate of ComplianceAlexander Ortiz CarrionPas encore d'évaluation

- Bridge Bearings and Expansion JointsDocument20 pagesBridge Bearings and Expansion Jointstset123456100% (2)

- Report KamcoDocument17 pagesReport Kamcoshamins123Pas encore d'évaluation

- Capacities and SpecificationsDocument14 pagesCapacities and SpecificationsAndrey LuquePas encore d'évaluation

- Section J - Overview 2 Modification Code J2 - Truck-Bus Body Fitting 13Document18 pagesSection J - Overview 2 Modification Code J2 - Truck-Bus Body Fitting 13Mina RemonPas encore d'évaluation

- Liquid Erection Manual Bolted Tank Api 12BDocument56 pagesLiquid Erection Manual Bolted Tank Api 12BLukarsa2013100% (2)

- 17-3 Metal Doors & WindowsDocument10 pages17-3 Metal Doors & WindowsZuberYousufPas encore d'évaluation

- Investigation of High-Strength Bolt-Tightening Verification TechniquesDocument51 pagesInvestigation of High-Strength Bolt-Tightening Verification TechniquesTrung Trần BảoPas encore d'évaluation

- Dismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor UnitDocument18 pagesDismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor UnitGaby CrisPas encore d'évaluation

- 02 FebDocument764 pages02 FebRobert Keith Macdonald100% (1)

- Connection Design TableDocument9 pagesConnection Design TableMongkol JirawacharadetPas encore d'évaluation

- Comefri - TLZ-THLZ Fan Catalogue 04-08Document46 pagesComefri - TLZ-THLZ Fan Catalogue 04-08João Guilherme Raimundo GarciaPas encore d'évaluation

- L1 - ScheduleDocument163 pagesL1 - ScheduleVVRAOPas encore d'évaluation

- bp2036 Piezoelectric Charge Accelerometer Types 4371Document2 pagesbp2036 Piezoelectric Charge Accelerometer Types 4371ategPas encore d'évaluation

- MANUAL EMPILHADEIRA MR 14, 16, 16HD, 16N, 20, 20HD e 25Document348 pagesMANUAL EMPILHADEIRA MR 14, 16, 16HD, 16N, 20, 20HD e 25Thiago Oliveira100% (3)

- Mil S 901DDocument83 pagesMil S 901DParamaet TamPas encore d'évaluation

- Is 319 2007 PDFDocument14 pagesIs 319 2007 PDFsingaravelan narayanasamyPas encore d'évaluation

- Rota Disc OPERATORS MANUALDocument53 pagesRota Disc OPERATORS MANUALCoco BangoPas encore d'évaluation